Looking to find out if you can use different size blades on circular saws? Well, you’ve come to the right place! Whether you’re a DIY enthusiast or a professional woodworker, understanding the possibilities when it comes to circular saw blades is essential. So, let’s dive in and explore the exciting world of circular saw blades and their compatibility with different sizes.

Now, you might be wondering, “Can I use a different size blade on my circular saw?” The short answer is yes. Circular saws are designed to accommodate blades of various sizes, which can greatly impact the versatility and performance of your cutting tool. From smaller blades for precise cuts to larger ones for faster rip cuts, the options are endless.

But hang on a second, before you start swapping out blades like a pro, it’s important to remember a few key factors. While you technically can use different size blades, it’s crucial to ensure that the blade you choose is compatible with your specific circular saw model. Additionally, using the correct size blade ensures optimal safety and prevents any potential damage to your tool or workpiece.

So, get ready to uncover the possibilities of using different size blades on your circular saw and discover how it can enhance your cutting experience. Whether you’re tackling a woodworking project or simply honing your DIY skills, the world of circular saw blades is waiting for you to explore. Let’s dive in and find the perfect blade for your cutting needs!

When it comes to circular saws, it is important to use the correct blade size. Different size blades are specifically designed for different applications, and using the wrong blade size can compromise both the performance and safety of the saw. Always consult the manufacturer’s guidelines to determine the appropriate blade size for your specific circular saw model. Using the correct size blade will ensure optimal cutting performance and help prevent accidents.

Can You Use Different Size Blades on Circular Saws?

When it comes to using circular saws, one common question that often arises is whether you can use different size blades on these versatile power tools. Circular saws are commonly used for cutting various materials, including wood, metal, and plastic. The size of the blade plays a crucial role in determining the depth and accuracy of the cuts. In this article, we will explore the possibilities of using different size blades on circular saws and discuss the factors to consider to ensure safe and efficient cutting.

The Importance of Blade Size

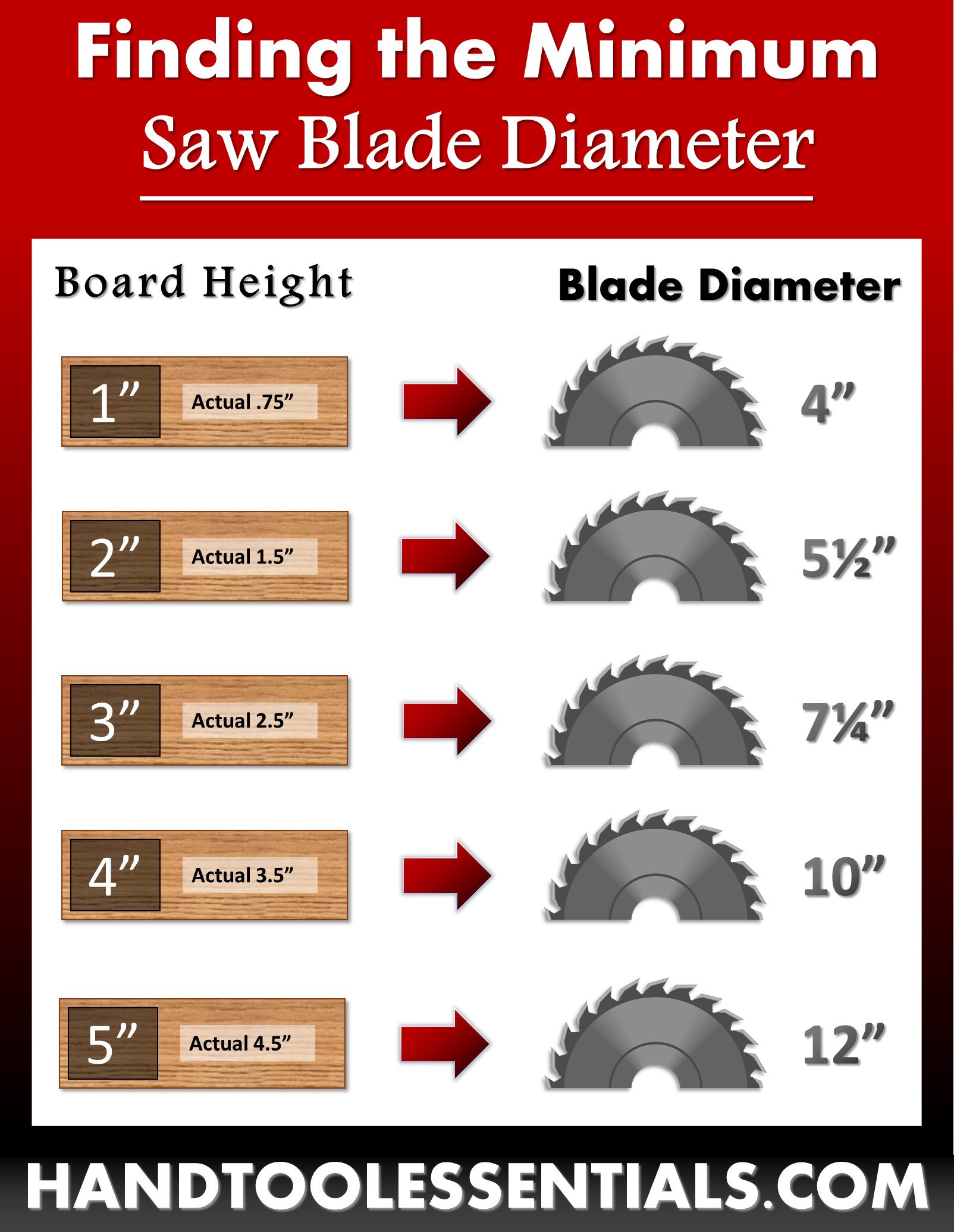

The size of the blade on a circular saw determines the depth of the cut it can make. Generally, circular saws come with blades ranging from 6 to 10 inches in diameter. The size of the blade you choose depends on the material you plan to cut and the depth of the cut you need to make. Blades with larger diameters are better suited for making deeper cuts, while smaller blades are ideal for more precise and intricate cuts.

It is important to note that the size of the blade also affects the power and performance of the circular saw. A larger blade requires more power to operate, so it is essential to ensure that your circular saw is compatible with the size of the blade you intend to use. Using a blade that is too large for your saw may result in decreased cutting performance and potential damage to the saw motor.

Selecting the Right Blade Size for Your Circular Saw

Before using a different size blade on your circular saw, it is crucial to check the manufacturer’s specifications and recommendations for blade sizes. These specifications can usually be found in the user manual or on the saw itself. Always follow the manufacturer’s guidelines to ensure safe and efficient operation. Additionally, consider the following factors when selecting a blade size:

- Material: Different materials require different blade sizes for optimal cutting. For example, if you primarily work with thick hardwood, a larger blade size may be more suitable. Conversely, if you often work with thin plywood or delicate materials, a smaller blade size may be preferable.

- Cutting Depth: Determine the maximum cutting depth you need for your projects. This will help you choose the right blade size that allows you to achieve the desired depth without straining the saw.

- Saw Power: Consider the power and capabilities of your circular saw. Ensure that it can handle the size of the blade you want to use without overloading the motor or compromising the saw’s performance.

By carefully considering these factors and following the manufacturer’s guidelines, you can select the appropriate blade size for your circular saw and achieve clean, precise cuts in various materials.

Benefits of Using Different Size Blades

Using different size blades on your circular saw can offer several benefits, depending on the specific project and materials you are working with. Here are a few advantages:

- Versatility: Having a range of blade sizes allows you to tackle a wider variety of cutting tasks and materials. You can switch between different blades to accommodate different cutting depths and achieve the desired results.

- Accuracy: Smaller blade sizes offer better control and precision, making them suitable for detailed and intricate cuts. On the other hand, larger blades can provide faster and more efficient cuts for larger or thicker materials.

- Efficiency: Using the appropriate size blade for a specific task can improve cutting efficiency and reduce the strain on your circular saw. This can lead to faster completion times and less wear and tear on the tool.

It’s important to note that while using different blade sizes can be beneficial, it is essential to prioritize safety and ensure that your circular saw is compatible with the chosen blade size.

Tips for Using Different Size Blades on Circular Saws

Here are a few tips to keep in mind when using different size blades on your circular saw:

- Read the Manual: Always refer to the manufacturer’s instructions and recommendations for blade sizes and usage.

- Use the Correct Blade: Ensure that the blade you choose is designed for the specific material you will be cutting.

- Securely Fasten the Blade: Properly secure the blade onto the saw’s arbor to prevent accidents or blade wobbling during operation.

- Adjust Cutting Depth: Set the cutting depth according to the thickness of the material and the size of the blade to achieve optimal results and prevent overloading the saw.

- Wear Safety Gear: Always wear appropriate personal protective equipment, including safety glasses and gloves, when operating a circular saw.

Following these tips will help ensure safe and efficient use of different size blades on your circular saw, allowing you to achieve professional-grade results in your woodworking or DIY projects.

Choosing the Right Blade Size: Key Considerations

When it comes to choosing the right blade size for your circular saw, there are several key considerations to keep in mind. By selecting the appropriate blade size, you can ensure precise cuts and optimal performance. Here are some factors to consider:

Material

Different materials require different blade sizes for efficient and effective cutting. Consider the type of material you most frequently work with and choose a blade size that is specifically designed for cutting that material. For example, if you often work with hardwood, a larger blade size may be necessary to handle the thickness and density of the wood.

Cutting Depth

The cutting depth required for your projects will also influence the blade size you choose. Measure the thickness of the material you plan to cut and ensure that the blade size allows for a clean and accurate cut. If you frequently work with materials of varying thicknesses, having a range of blade sizes will provide you with the flexibility to tackle different projects.

Saw Power

The power and capabilities of your circular saw should be taken into account when selecting a blade size. Ensure that your saw has the necessary power and torque to handle the size of the blade you choose. Using a blade that is too large for your saw may strain the motor and lead to subpar cutting results.

Manufacturer Recommendations

Always refer to the manufacturer’s recommendations for blade sizes and usage. The user manual or the saw itself will typically provide guidance on the compatible blade sizes for your specific model. Following these recommendations will help ensure safe and efficient operation of your circular saw.

By considering these key factors and taking the appropriate precautions, you can confidently select the right blade size for your circular saw and achieve exceptional results in your cutting projects.

Common Types of Circular Saw Blades

When it comes to circular saw blades, there is a vast array of options to choose from, each designed for specific cutting applications. Here are some common types of circular saw blades:

Rip-Cut Blades

Rip-cut blades are designed for cutting material parallel to the grain, such as when ripping boards to width. These blades typically have fewer teeth, which allows for faster cutting but may result in a rougher finish.

Crosscut Blades

Crosscut blades are used for making cuts perpendicular to the grain of the wood. These blades typically have more teeth and produce cleaner, smoother cuts. They are ideal for making precision cuts in trim work or for cutting plywood.

Combination Blades

Combination blades, as the name suggests, are designed to handle a variety of cutting tasks. They typically have a mix of rip-cut and crosscut teeth, allowing them to perform well in both types of cuts. Combination blades are commonly used for general-purpose cutting.

Finishing Blades

Finishing blades have a high tooth count and are designed specifically for achieving clean, smooth cuts in materials like plywood, hardwood, and laminate. These blades are ideal for woodworking projects where a polished finish is desired.

Dado Blades

Dado blades are unique because they consist of two or more blades that can be adjusted to cut grooves or dadoes of different widths. These blades are commonly used for joinery and creating precise dado cuts, rabbets, and grooves in wood.

Diamond Blades

Diamond blades are specifically designed for cutting hard materials such as concrete, stone, or tile. These blades feature diamond grit embedded in the cutting edge, allowing them to make clean and precise cuts in these tough materials.

Specialty Blades

Specialty blades are designed for specific cutting applications. They can include blades for cutting non-ferrous metals, plastics, laminates, and other materials. These blades often have unique tooth configurations and coatings to optimize cutting performance.

When selecting a circular saw blade, consider the type of material you will be cutting and choose a blade specifically designed for that application. Using the right blade will result in cleaner cuts, reduced splintering, and increased cutting efficiency.

Maintaining Your Circular Saw Blades

Proper maintenance of your circular saw blades is essential to ensure optimal cutting performance and prolong their lifespan. Here are a few tips for maintaining your circular saw blades:

Cleaning

After each use, clean the blade to remove any debris, pitch, or resin that may have accumulated. Use a cleaning solution specifically designed for saw blades, or simply soak the blade in warm soapy water. Gently scrub the blade with a soft brush or toothbrush to remove any stubborn buildup. Rinse the blade thoroughly and dry it before storing.

Sharpening

Over time, the teeth of the blade may become dull, resulting in less effective and inefficient cutting. Sharpening the blade will restore its cutting ability. You can sharpen the blade yourself using a file or a specialized blade-sharpening tool, or take it to a professional sharpening service. Follow the manufacturer’s guidelines when sharpening the blade.

Proper Storage

Store your circular saw blades in a clean and dry location to prevent corrosion and damage. Keep them in their original packaging or use protective blade covers or cases to prevent contact with other tools, which can cause chipping or dulling of the teeth.

Regular maintenance of your circular saw blades will ensure that they remain in excellent condition and perform optimally throughout their lifespan. This will not only save you money on replacement blades but also contribute to safer and more efficient cutting.

And that concludes our comprehensive guide on using different size blades on circular saws. By understanding the importance of blade sizes, selecting the right blade for your needs, and properly maintaining your circular saw blades, you can achieve superior cutting results in a variety of materials and projects. Remember to prioritize safety and always refer to the manufacturer’s guidelines for blade sizes and usage. Happy cutting!

Key Takeaways: Can You Use Different Size Blades on Circular Saws?

Using different size blades on circular saws can have advantages and disadvantages. Here are some key takeaways to consider:

- 1. Match the blade diameter to the saw’s specifications for optimal performance and safety.

- 2. Using a larger blade than recommended can cause kickback and damage the tool.

- 3. Smaller blades may result in limited cutting depth and slower cutting speed.

- 4. Different blade sizes are designed for specific applications, such as cutting wood or metal.

- 5. Always refer to the saw’s user manual for guidance on compatible blade sizes.

Frequently Asked Questions

Are you wondering if you can use different size blades on circular saws? We’ve got you covered! Check out these commonly asked questions to learn more about using different size blades on circular saws.

1. Can I use a blade with a larger diameter on my circular saw?

It’s important to use a blade with the correct diameter for your circular saw. Circular saws are designed to work with specific blade sizes to ensure optimal performance and safety. Using a blade with a larger diameter than recommended can cause the blade to bind or overload the motor, leading to potential damage or accidents. Always refer to the manufacturer’s instructions or consult a professional to determine the appropriate blade size for your circular saw.

Additionally, using a blade with a larger diameter may affect the accuracy and cutting depth of your saw. The larger blade can alter the balance and control of the saw, making it more difficult to handle. It’s best to use the recommended blade size for your circular saw to ensure smooth and precise cuts.

2. Can I use a blade with a smaller diameter on my circular saw?

Using a blade with a smaller diameter than recommended for your circular saw is generally not recommended. While it might be tempting to use a smaller blade for certain cuts, it can lead to safety hazards and compromised performance. The arbor size and depth of cut of your circular saw are specifically designed to accommodate blades of a certain diameter.

If you use a smaller blade, it may not reach the desired cutting depth, resulting in incomplete or ineffective cuts. Additionally, the smaller blade may not fit securely on the arbor, causing instability and potential accidents. Always follow the manufacturer’s guidelines and use the recommended blade size for your circular saw to ensure proper functionality and safety.

3. Can I interchange blades of the same diameter between different circular saws?

In most cases, you can interchange blades of the same diameter between different circular saws. As long as the arbor size and other specifications match, you should be able to use blades interchangeably. However, it’s essential to check the manufacturer’s recommendations for both the circular saw and the blade to ensure compatibility.

It’s also worth noting that different circular saw models may have varying power and speed capabilities. Before swapping blades, consider the material you’re cutting and the cutting speed required. Using a blade that exceeds the recommended speed for a particular circular saw can lead to overheating, premature wear, or even damage to the saw and the blade.

4. Can I use a different type of blade on my circular saw?

Circular saws are designed to work with specific types of blades, such as rip blades, crosscut blades, or combination blades. While it may be possible to use a different type of blade on your circular saw, it’s important to consider the intended use and cutting requirements.

For example, using a rip blade for crosscutting may result in rough or splintered cuts, while using a crosscut blade for ripping may cause excessive tear-out. It’s best to use the appropriate type of blade specifically designed for the task at hand to achieve the desired results. Consult the manufacturer’s instructions or seek professional advice to determine the best blade type for your circular saw.

5. Can using a different size blade void the warranty of my circular saw?

Using a different size blade than recommended by the manufacturer may potentially void the warranty of your circular saw. Manufacturers provide guidelines and specifications for blade size to ensure the safe and proper operation of their products. Modifying or deviating from these guidelines can result in unforeseen issues or accidents.

To protect your warranty and ensure the longevity of your circular saw, it’s best to use the recommended size and type of blade. If you have specific cutting requirements that require a different blade size, it’s advisable to consult the manufacturer or an authorized representative to determine if there are any compatible options available without voiding the warranty.

Summary

Using different size blades on circular saws can be risky and may lead to accidents. Circular saws are designed for specific blade sizes, and using the wrong size can affect the saw’s performance and safety.

It is crucial to choose the right blade size recommended by the manufacturer for your circular saw. Using the correct blade size ensures proper cutting depth and prevents the saw from binding or overheating. Always refer to the user manual or consult a professional if you are unsure about which blade size to use. Safety should always be the top priority when working with power tools like circular saws.