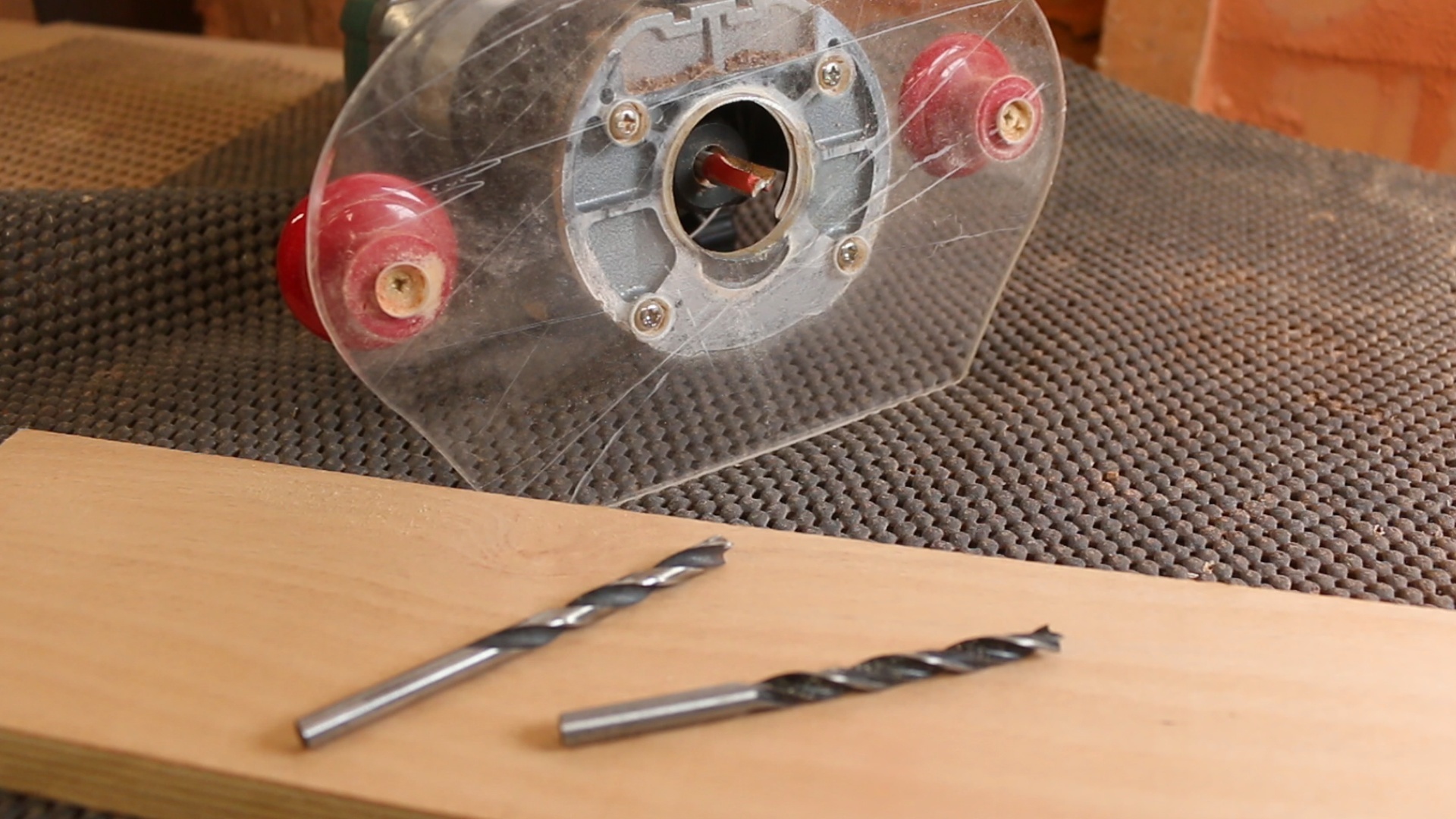

Have you ever wondered if you can use drill bits in a router? Well, you’re in the right place! In this article, we’re going to explore whether it’s possible to interchange these two tools and what you need to consider before giving it a try.

Let’s dive right in and address the burning question: can you use drill bits in a router? While both tools involve spinning bits, they serve different purposes. A drill is mainly used for creating holes, while a router is designed for shaping and cutting grooves in wood. So, using a drill bit in a router may not yield the desired results or could potentially damage your workpiece.

Before you go experimenting, let’s explore the reasons why using drill bits in a router may not be the best idea. Understanding the differences between these tools will help you make an informed decision and ensure you achieve the best possible results in your woodworking projects.

Can You Use Drill Bits in a Router?

Drilling and routing are two fundamental techniques in woodworking and DIY projects. While both involve cutting into materials, they require different tools and approaches. However, a common question among DIY enthusiasts is whether they can interchange drill bits and router bits. In this article, we will explore the compatibility and limitations of using drill bits in a router, providing insights into the tools’ functionality, differences, and safety considerations.

Understanding Drill Bits and Routers

Drill bits are cylindrical cutting tools designed to create holes in various materials, including wood, metal, and plastic. They typically consist of a shank which is inserted into a drill chuck, a spiral-shaped body called the flute that helps remove materials, and a pointed tip for precise drilling. Drill bits are available in various sizes and shapes, such as twist bits, spade bits, and Forstner bits, catering to different drilling needs.

On the other hand, routers are versatile power tools used for shaping, trimming, and hollowing out materials like wood. They employ specialized router bits to remove material as the spinning bit is guided along the workpiece. Router bits come in a wide range of shapes, including straight bits, flush trim bits, and dovetail bits, enabling intricate detail work and decorative edging.

While drill bits and router bits may seem similar at first glance, they serve different purposes and have key design differences. The primary distinction lies in the way they cut: drill bits cut along the axial direction, creating holes, while router bits cut laterally, allowing for more intricate shaping and profiling.

The Compatibility Factor: Drill Bits in a Router

Despite the similarities in appearance, it is not recommended to use drill bits in a router. These tools are designed for specific tasks and differ in crucial aspects that affect their functionality and safety.

One of the key differences between drill bits and router bits is the direction of the cutting action. Drill bits cut in a straight line along the axis of rotation, making them suitable for creating holes. Router bits, on the other hand, cut as they move horizontally across the material’s surface. Attempting to use a drill bit in a router may lead to inaccurate cuts, damage to the workpiece, and potential injury.

Another major consideration is the shank design. Drill bits typically have a straight shank that fits into a drill chuck, while router bits have a specialized shank that fits into the collet of a router. The different shank designs make it impractical and unsafe to use drill bits in a router, as they may not securely fasten and could potentially come loose during operation, causing accidents.

Safety is paramount when working with power tools, and using tools for unintended purposes can jeopardize both the user and the project’s outcome. It’s important to follow manufacturers’ recommendations and use the appropriate tools for each task to ensure accuracy, efficiency, and safety.

Benefits of Using Proper Router Bits

While it is not advisable to use drill bits in a router, there are numerous benefits to utilizing the correct router bits for your woodworking projects. Here are a few advantages of using proper router bits:

1. Versatility: Router bits come in a wide variety of shapes and sizes, allowing for a vast range of creative possibilities. From basic profiling to intricate joinery, the right router bit can transform the outcome of your project.

2. Precision: Router bits are designed to cut smoothly and accurately, ensuring clean edges and precise detailing. This level of precision is especially important when working on projects that require fine finishing or tight tolerances.

3. Efficiency: Using the appropriate router bit for each task can significantly improve efficiency. For example, using a flush trim bit can quickly and accurately trim laminate, while a round-over bit can create decorative edges in one pass.

4. Safety: Using the correct tools for their intended purpose prioritizes safety. Router bits are designed and manufactured to withstand the stresses and forces generated during routing operations, reducing the risk of accidents and injuries.

5. Professional Results: Properly selected and utilized router bits can elevate the quality of your woodworking projects, helping you achieve professional-looking results.

By investing in a range of router bits and learning how to use them effectively, you can unlock the true potential of your router and enhance your woodworking skills.

Common Router Bit Types

Router bits come in a vast array of shapes and sizes, each designed to perform specific woodworking tasks. Understanding the different types will help you select the right bit for your project. Here are some common router bit types:

1. Straight Bits: These bits have a flat bottom and straight sides, allowing for precise and clean cuts. They are ideal for rabbeting, dadoing, and grooving.

2. Flush Trim Bits: Flush trim bits have a bearing on the tip, guiding the bit along the edge of a template or workpiece. They are used to remove excess material and create a flush, even edge.

3. Cove Bits: Cove bits create concave profiles, often used for adding decorative edges to wood pieces or making curved recesses.

4. Round-Over Bits: Round-over bits create a rounded edge on a workpiece. They are commonly used for easing sharp edges and creating decorative curves.

5. Chamfer Bits: Chamfer bits are used to create beveled edges or angled cuts on the corners of a workpiece. They are often used for decorative purposes or to make angled joints.

6. Dovetail Bits: Dovetail bits are specifically designed for creating dovetail joints, commonly used in drawer and box construction.

7. Roman Ogee Bits: Roman ogee bits create a classic S-shaped profile, often used for decorative edging on furniture and moldings.

8. V-Groove Bits: V-groove bits create V-shaped grooves, commonly used for sign-making, lettering, and decorative purposes.

9. Raised Panel Bits: Raised panel bits are used for creating raised panels commonly found in cabinet doors, allowing for elegant and decorative profiles.

10. Spiral Bits: Spiral bits have a twisted design and are often used for plunge cutting and creating deep grooves.

Special Considerations for Router Bits

When working with router bits, there are some essential considerations to keep in mind to ensure optimal performance and safety:

1. Speed Control: Different router bits require varying speeds to achieve the best results. Adjust the router’s speed according to the bit’s diameter and the material being cut. Higher speeds are generally suitable for smaller bits and softer materials, while lower speeds are better for larger bits and harder materials.

2. Router Bit Maintenance: Routinely clean your router bits to remove built-up pitch and resin, as this can affect their performance. Additionally, sharpening dull bits or replacing damaged ones will help maintain clean and accurate cuts.

3. Safety Measures: Always wear appropriate safety equipment, such as safety goggles, a dust mask, and hearing protection, when operating a router. Additionally, follow all manufacturer guidelines and safety precautions for your specific router model.

4. Test Cuts: Before working on your final piece, it’s advisable to make test cuts on scraps of similar material to assess the router bit’s performance and achieve the desired outcome.

5. Router Table vs. Handheld Routing: Depending on the project and preference, you can perform routing tasks using a handheld router or a router table. Each method offers its own benefits and limitations, so choose the approach that best suits your needs.

By understanding the different router bit types and practicing safe routing techniques, you can expand your woodworking capabilities and achieve professional-quality results.

Using Router Bits Safely: Tips and Best Practices

Operating a router requires attention to detail, precision, and adherence to safety protocols. Here are some tips and best practices to ensure safe and successful router bit usage:

Selecting the Right Bit

When choosing a router bit for your project, consider the following factors:

1. Material Compatibility: Ensure that the router bit is designed for the specific material you will be working with. Using the wrong bit can result in poor performance and potential damage to the workpiece.

2. Bit Size: Select the appropriate bit size for the desired cutting depth and width. Using a bit that is too large or too small for the task can lead to imbalance, inaccurate cuts, and potential safety hazards.

3. Shank Size: Verify that the router bit’s shank matches the collet size of your router. Using a mismatched shank size can cause the bit to come loose during operation, leading to accidents.

Preparing the Workspace

Before beginning any routing operation, take the following precautions:

1. Secure the Workpiece: Ensure that the workpiece is securely clamped or fastened to a stable surface. This prevents unintended movement and helps maintain control over the routing process.

2. Clear the Area: Remove any obstacles or debris from the routing area, ensuring a clean and safe workspace. This prevents interference and potential accidents during operation.

3. Adequate Lighting: Ensure that the routing area is well-lit, allowing for clear visibility of the workpiece and router bit. This improves accuracy and minimizes the risk of mistakes or accidents.

Operating the Router Safely

When using a router, follow these safety guidelines:

1. Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, hearing protection, and a dust mask, to protect against flying debris and potential health hazards.

2. Maintain a Firm Grip: Hold the router with a firm grip, using both hands for stability and control. This enables precise movements and reduces the likelihood of slips or accidents.

3. Start at Low Speed: Begin routing at a low speed, gradually increasing it as you gain confidence and control over the tool. This prevents sudden movement or kickback and allows for smoother cuts.

4. Proper Feed Direction: Move the router against the rotation of the bit to ensure stability and controlled cutting. This technique helps prevent the router from jerking or slipping out of the hands.

5. Use Light Pressure: Apply consistent but gentle pressure when guiding the router along the workpiece. Excessive force can lead to erroneous cuts, material damage, and potential injury.

6. Allow the Bit to Cool: Routinely pause during extended routing sessions to allow the router bit to cool down. Overheating can affect the bit’s performance and lead to premature wear.

7. Disconnect Power: Always unplug the router when changing bits or performing maintenance tasks. This prevents accidental starts and keeps you safe from rotating blades.

By following these tips and implementing safe routing practices, you can maximize the capabilities of your router while minimizing the risk of accidents.

Overall, while it may be tempting to use drill bits in a router, it is not advisable due to fundamental differences in function, design, and safety considerations. Instead, invest in high-quality router bits, understand their specific applications, and utilize them properly to achieve professional-quality results. With the right tools, knowledge, and safety measures in place, you can take your woodworking projects to the next level and enjoy the rewarding experience of creating beautiful and functional pieces.

Can You Use Drill Bits in a Router?

Here are the key takeaways about using drill bits in a router:

- Using drill bits in a router is not recommended.

- Drill bits are designed for drilling holes, while routers are designed for shaping and trimming wood.

- Using drill bits in a router can lead to damage to the router or the workpiece.

- It’s important to use the right tool for the job to ensure safety and achieve the desired results.

- If you need to drill holes, it’s best to use a drill designed specifically for that purpose.

Frequently Asked Questions

Welcome to our FAQ section on using drill bits in a router. Below, we’ve answered some of the most common questions regarding this topic. Read on to find out more!

Can I use drill bits in a router?

No, it is not recommended to use regular drill bits in a router. Drill bits and router bits are designed for different purposes and have different operating mechanisms. Drill bits are primarily used for drilling holes, while router bits are designed to shape, cut, and hollow out areas in wood or other materials. Using drill bits in a router can lead to inefficient cutting, damaged bits, and potential hazards. It’s important to use the right tool for the right job to ensure optimal results and safety.

If you need to drill holes in various materials, it’s best to use a drill. However, if you plan on cutting, shaping, or hollowing out materials, a router with the appropriate router bits will be the better choice. Remember to always follow the manufacturer’s instructions and guidelines for each tool to ensure proper usage and safety.

Are drill bits and router bits interchangeable?

No, drill bits and router bits are not interchangeable. Drill bits have a pointed tip and are designed to create cylindrical holes by rotating clockwise. On the other hand, router bits have a flat bottom and are specifically designed for cutting, shaping, and hollowing out areas in materials. Router bits work by spinning counterclockwise, typically with the help of a motor-driven router. Attempting to use drill bits in a router or vice versa can damage the bits, compromise their performance, and even pose a safety risk.

It’s essential to use the appropriate tool and bit for each specific task. If you’re unsure about which tool or bit to use, consult the manufacturer’s instructions or seek guidance from a professional to ensure safe and effective use.

What are the differences between drill bits and router bits?

Drill bits and router bits differ in several ways. Firstly, the shape of the tip or cutting edge varies. Drill bits have a pointed, self-centering tip, while router bits have a flat bottom with various cutting edges such as straight, spiral, or profiled. Secondly, the rotational direction is different. Drill bits typically rotate clockwise, while router bits spin counterclockwise. Additionally, the materials they are designed to work on may vary. Drill bits are often used to drill holes in different materials, while router bits are primarily used for cutting, shaping, and hollowing out areas in wood, plastic, or other materials.

Furthermore, the construction and design, as well as the speed and power at which they operate, differ between drill bits and router bits. It’s crucial to select the appropriate bit for the task at hand to ensure efficiency, safety, and optimum results.

Can I modify a drill bit to work with a router?

Modifying a drill bit to work with a router is not recommended and can lead to hazardous situations. Drill bits and router bits have different designs and cutting mechanisms, making them unsuitable for interchangeability. Attempting to modify a drill bit for router use can compromise the integrity of the bit, potentially causing it to break, overheat, or become unstable during operation. This not only poses a safety risk but also compromises the quality and accuracy of the cutting or shaping work you intend to perform.

It’s always best to use the right tools for the job. If you need to use a router, invest in a set of quality router bits designed for your specific routing needs. This will ensure optimal performance, safety, and results.

How do I choose the right router bit for my project?

Choosing the right router bit for your project depends on the specific task you want to accomplish. There are various types of router bits available, each with its own cutting profile and purpose. For example, if you want to create a smooth, straight edge on a piece of wood, a straight bit is suitable. If you need to create decorative edges, a roman ogee or cove bit might be the right choice. It’s important to consider the material you’re working with, the desired outcome, and the level of detail you want to achieve.

Research and familiarize yourself with the different types of router bits available. Consider consulting woodworking guides or seeking advice from professionals who have experience with similar projects. Additionally, ensure you have the appropriate router and router bit compatibility. By selecting the right router bit for your project, you’ll be able to achieve the desired results efficiently and effectively.

Summary

So, can you use drill bits in a router? The answer is no. Drill bits are designed for drilling straight holes, while router bits are made for cutting intricate shapes and edges. Using a drill bit in a router can lead to safety hazards and poor results. It’s best to use the right tool for the right job.

Routers and drill machines may look similar, but they serve different purposes. While drill bits are perfect for making holes, router bits are specifically designed for shaping and finishing edges. So, always remember to use the correct tool for the job to ensure safety and achieve the best results.