Can you use HSS drill bits for concrete? If you’re curious about whether these bits are suitable for the job, you’ve come to the right place! Whether you’re a DIY enthusiast or a budding handyman, this article will provide you with all the information you need.

Now, let me tell you a little secret. When it comes to drilling into concrete, you need a bit that’s as tough as nails. And that’s where High-Speed Steel (HSS) drill bits come into play. These bad boys are known for their durability and versatility, making them a popular choice for various drilling tasks. But can they handle concrete?

Well, my friend, you’re about to find out. In this article, we’ll dive into the world of HSS drill bits and explore whether they have what it takes to conquer concrete. So, grab your hard hat and let’s get drilling!

Can You Use HSS Drill Bits for Concrete?

When it comes to drilling holes in concrete, many people wonder if they can use High-Speed Steel (HSS) drill bits. HSS drill bits are commonly used for drilling into softer materials like wood and metal, but can they handle the tough job of drilling into concrete? In this article, we will explore whether or not HSS drill bits are suitable for concrete drilling and discuss alternative options if they are not.

Understanding HSS Drill Bits

High-Speed Steel (HSS) drill bits are made from a type of hardened steel that contains a combination of tungsten, chromium, and vanadium. This composition gives HSS drill bits their strength and durability, making them ideal for drilling through materials such as wood, aluminum, and plastic. However, concrete is a much harder material compared to these softer materials. Concrete contains aggregates such as gravel and sand, which can quickly dull the cutting edges of HSS drill bits. Additionally, the high heat generated during drilling can also cause the HSS drill bit to overheat and wear out quickly.

While HSS drill bits can technically be used for drilling into concrete, they are not the most efficient or recommended option. They are more likely to break or become dull, requiring frequent replacements. If you only have HSS drill bits on hand and absolutely need to drill into concrete, there are a few tips to keep in mind to improve your chances of success. First, using a slower drilling speed and applying steady pressure can help reduce heat buildup and prevent the bit from becoming dull too quickly. Second, periodically withdraw the bit from the hole to remove any debris and cool the bit down before continuing. Finally, using water or a lubricating oil while drilling can help keep the temperature down.

Alternative Drill Bits for Concrete

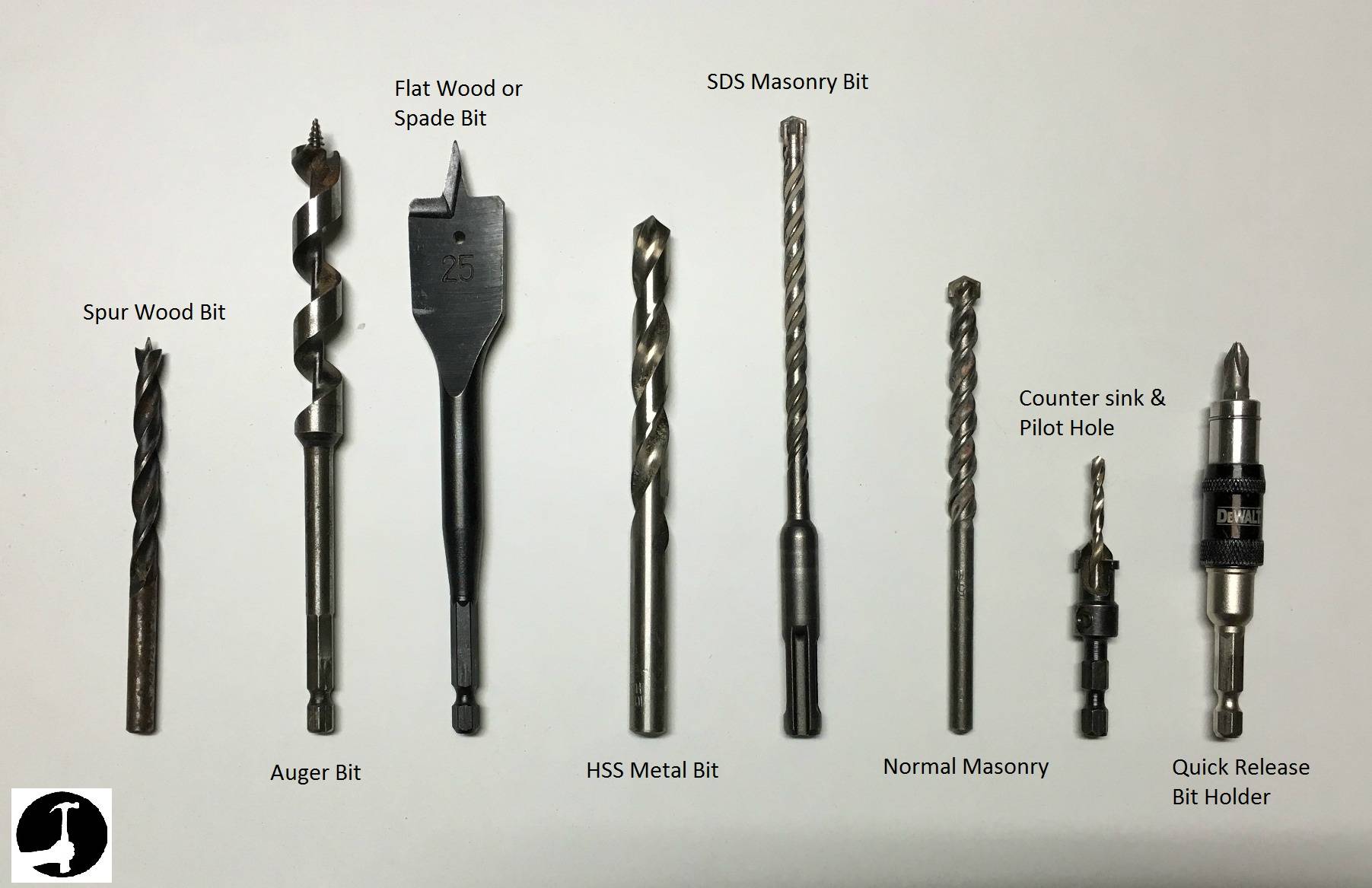

If you have a significant amount of concrete drilling to do, it is highly recommended to invest in drill bits specifically designed for concrete. There are two main types of drill bits that are widely used for concrete drilling – carbide-tipped masonry drill bits and diamond-tipped drill bits.

Carbide-tipped masonry drill bits are made from a combination of carbon and tungsten carbide. These bits are specifically designed to withstand the hardness of concrete and are more durable than HSS drill bits. They have a sharp, pointed tip that helps to penetrate the concrete surface and flutes that allow for easy removal of debris. Carbide-tipped masonry drill bits are available in various sizes to accommodate different hole diameters.

Diamond-tipped drill bits, as the name suggests, have a tip embedded with tiny industrial-grade diamonds. These bits are incredibly strong and can cut through even the toughest of materials, including reinforced concrete. Diamond-tipped drill bits are known for their exceptional durability and ability to withstand high heat. They are especially useful for drilling large and deep holes in concrete.

The Benefits of Using Dedicated Concrete Drill Bits

Using dedicated concrete drill bits offers several benefits over using HSS drill bits for drilling into concrete. Firstly, they are specifically designed for the task and can handle the hardness of concrete without quickly wearing down. This makes them more efficient and cost-effective in the long run, as they last longer and require fewer replacements. Secondly, dedicated concrete drill bits provide superior drilling speed and accuracy, ensuring cleaner and more precise holes. Lastly, these specialized drill bits often come with features such as anti-vibration design and improved heat dissipation, which further enhance their performance and lifespan.

Conclusion

While HSS drill bits can technically be used for drilling into concrete, they are not the most efficient or recommended option. Concrete is a hard material that can quickly dull the cutting edges of HSS drill bits and cause them to wear out prematurely. For more effective and durable results, it is best to invest in drill bits specifically designed for concrete, such as carbide-tipped masonry drill bits or diamond-tipped drill bits. These dedicated drill bits will make your concrete drilling tasks easier and more successful, ensuring clean and precise holes without the need for frequent bit replacements.

The Importance of Using Proper Safety Equipment

When it comes to any type of drilling, including drilling into concrete, it is crucial to prioritize safety. While using the right drill bits is essential, it is equally important to use proper safety equipment to protect yourself and others. Here are the key safety measures you should take when drilling into concrete:

1. Safety Glasses or Goggles

Always wear safety glasses or goggles to protect your eyes from flying debris and dust particles. Concrete drilling can produce high-speed fragments that can cause severe eye injuries. Make sure to choose safety glasses or goggles that provide adequate coverage and have impact-resistant lenses.

2. Respiratory Protection

Concrete drilling also produces a significant amount of dust, which can be harmful when inhaled. To prevent respiratory issues and lung damage, it is crucial to wear a properly fitted respiratory mask. Look for masks labeled as NIOSH-approved N95 or higher, as they are designed to filter out small particles, including concrete dust.

3. Hearing Protection

The loud noise generated during concrete drilling can cause hearing damage over time. To protect your hearing, wear earplugs or earmuffs while drilling. Ensure that the hearing protection device is appropriately rated for the noise level you are exposed to.

4. Protective Clothing

Concrete dust can irritate the skin, so it is advisable to wear long sleeves, long pants, and closed-toe shoes to minimize skin exposure. Additionally, consider wearing a dust mask or disposable coveralls for added protection.

5. Secure Work Area

Make sure to secure the work area and keep bystanders at a safe distance. Clear the area of potential tripping hazards and ensure that the drilling surface is stable and immovable. Using clamps or a vise to secure the material being drilled can also help prevent accidents.

6. Proper Technique and Handling

Follow proper drilling techniques and use the drill with caution. Maintain a firm grip on the drill and position yourself in a stable and balanced stance. Avoid applying excessive force or putting your body in awkward positions that may lead to muscle strain or injury.

Conclusion

When it comes to drilling into concrete, using the right drill bits is crucial, but ensuring your safety is equally important. Always wear the appropriate safety equipment, including safety glasses or goggles, respiratory protection, and hearing protection. Additionally, protect your skin by wearing suitable clothing. Take the necessary precautions, follow proper drilling techniques, and secure the work area to minimize the risk of accidents or injuries. By prioritizing safety, you can confidently tackle any concrete drilling project while protecting yourself and those around you.

Key Takeaways: Can You Use HSS Drill Bits for Concrete?

- HSS drill bits are not ideal for drilling into concrete due to their material composition.

- Concrete is a hard and abrasive material that requires specialized drill bits.

- Carbide-tipped masonry drill bits or diamond-tipped drill bits are better suited for drilling into concrete.

- Using HSS drill bits on concrete can result in dulling or breaking the bits.

- It is essential to use the right type of drill bit for the task at hand to ensure efficient and safe drilling.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we answer your queries about using HSS drill bits for concrete. Read on to find out everything you need to know!

1. Can HSS drill bits be used for concrete?

HSS (High-Speed Steel) drill bits are designed for drilling through materials like wood, plastic, and metal. While they can technically drill into concrete, it is not recommended. Concrete is a hard and abrasive material that can quickly wear down HSS drill bits, reducing their effectiveness and lifespan.

For drilling into concrete, it is best to use drill bits specifically designed for masonry, such as carbide-tipped or diamond-tipped bits. These are harder and more durable, allowing for efficient drilling without compromising the integrity of the bit.

2. What happens if I use HSS drill bits for concrete?

If you attempt to use HSS drill bits for drilling into concrete, you may experience several issues. Firstly, due to the hardness of concrete, the HSS bits can become dull and wear down quickly, making them less effective in drilling. This can result in slower drilling speeds and potential overheating of the bits.

Additionally, using HSS bits on concrete may also lead to chipping or breaking of the drill bits. Concrete is a tough material that can cause the bits to fracture or chip, rendering them unusable. To avoid these problems, it is best to use the appropriate drill bits designed specifically for concrete drilling.

3. Are there any alternatives to HSS drill bits for concrete?

Absolutely! When it comes to drilling into concrete, there are various alternatives to HSS drill bits that are better suited for the task. One popular option is carbide-tipped drill bits, which are designed to withstand the hardness of concrete. These bits have a carbide cutting edge that stays sharp for longer, allowing for efficient drilling.

Another alternative is diamond-tipped drill bits, which offer even greater durability and precision when drilling into concrete. The diamond cutting edge on these bits can easily cut through the tough surface of the concrete, providing excellent results. Both carbide-tipped and diamond-tipped bits are readily available and can be used with standard power drills.

4. Can I sharpen HSS drill bits after using them on concrete?

Typically, HSS drill bits can be sharpened to extend their lifespan and regain some of their cutting effectiveness. However, if you have used HSS drill bits on concrete, it’s unlikely that you’ll be able to restore their original sharpness. Concrete is a highly abrasive material that can quickly wear down the cutting edges of HSS bits, making them difficult to sharpen.

In this case, it is more practical to invest in purpose-built masonry drill bits, such as carbide-tipped or diamond-tipped bits, which are specifically designed for drilling into materials like concrete. These bits offer superior durability and performance compared to trying to salvage HSS drill bits that have been used on concrete.

5. Can HSS drill bits be used for other materials besides wood and metal?

Yes, HSS drill bits are versatile and can be used for a wide range of materials besides wood and metal. They are suitable for drilling through materials like plastic, fiberglass, and composites. HSS bits are designed to cut through these softer materials efficiently without dulling quickly.

However, it is essential to match the drill bit and speed to the specific material being drilled to ensure optimal results. For harder materials like concrete or masonry, it is best to use drill bits specifically designed for those purposes for optimal performance and longevity.

Ultimate Drill Bits 2021- It Really Works!

Summary

Using HSS drill bits for concrete is not recommended because they are not designed for it. Concrete is too hard and abrasive for HSS drill bits, which can cause them to break or become dull quickly. It is better to use masonry or carbide-tipped drill bits specifically made for concrete drilling.

Additionally, using the wrong drill bits may not only damage the drill bit but also make the drilling process slower and less effective. To ensure successful drilling in concrete, it is important to use the right tools for the job and follow proper drilling techniques.