Can you use a nail gun on metal? That’s a great question that many DIY enthusiasts and aspiring carpenters may have. Whether you’ve got a project in mind or you’re just curious, I’m here to give you the lowdown on this topic. So, buckle up and let’s dive in!

Nail guns are amazing tools that make carpentry projects a breeze. But when it comes to using them on metal, things can get a little tricky. So, can you use a nail gun on metal? The short answer is… it depends!

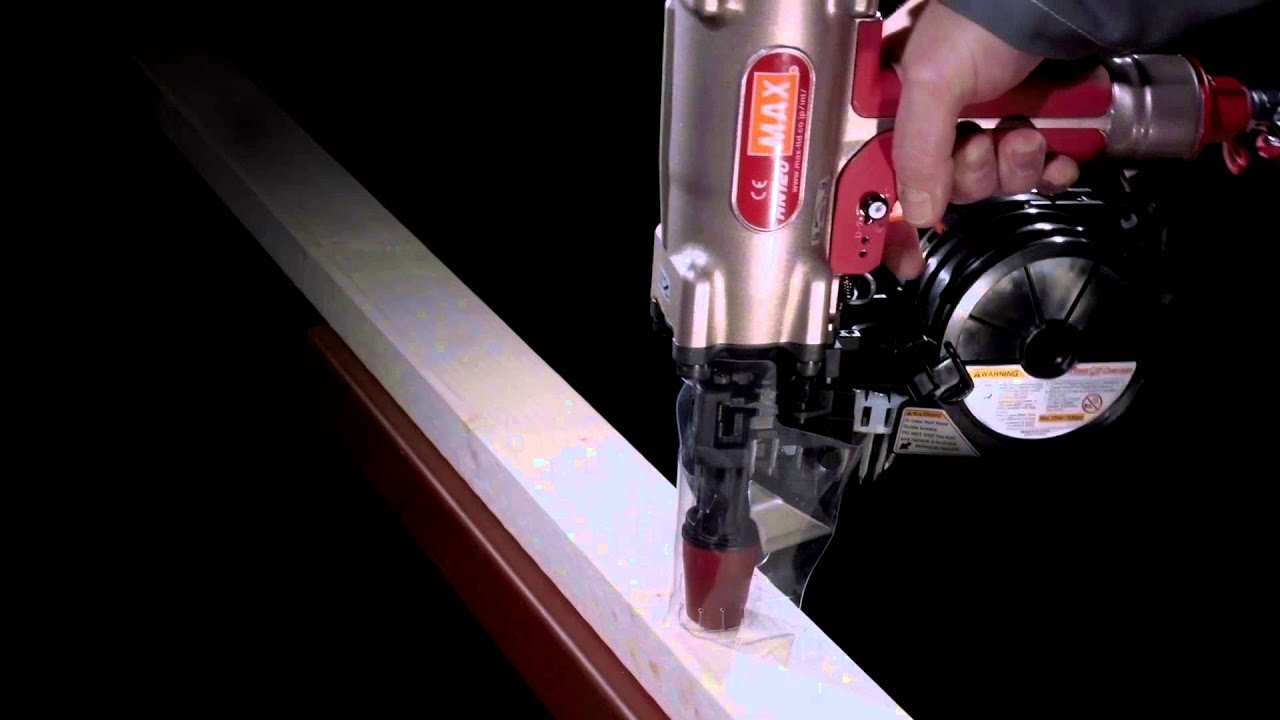

While nail guns are primarily designed for wood, there are specific types of nail guns that can handle metal. These nail guns, often called “metal roofing nailers,” are specifically built to penetrate and secure nails into metal materials. However, it’s important to note that not all nail guns are capable of handling metal, so you’ll need to choose the right tool for the job.

In this article, we’ll explore the different types of nail guns and their capabilities when it comes to metal. We’ll also discuss the safety precautions you need to take when using a nail gun on metal and offer some helpful tips to ensure a successful project. So, if you’re ready to learn more about using nail guns on metal, let’s get started!

- Choose the right nail gun with sufficient power.

- Select the appropriate type and length of nails.

- Wear safety gear, including gloves and goggles.

- Ensure the metal is properly secured.

- Adjust the nail gun settings for metal and test on a scrap piece first.

Remember to always prioritize safety and consult the manufacturer’s guidelines for your specific nail gun model.

Can You Use a Nail Gun on Metal? Exploring the Possibilities

When it comes to fastening materials together, nail guns are an essential tool in any handyman’s arsenal. But can you use a nail gun on metal? This question may arise when working on metal construction projects or making repairs involving metal. In this article, we will delve into the world of nail guns, exploring their compatibility with metal surfaces, safety considerations, and alternative methods for securing metal.

The Compatibility of Nail Guns with Metal

Traditionally, nail guns were designed for use on wood or other soft materials. However, as technology advanced, nail guns specifically optimized for metal fastening have emerged. These specialized nail guns, often referred to as metal connectors or metal framing nailers, are equipped with features like hardened steel nails and adjustable depth settings to ensure proper penetration and secure bonding with metal surfaces. Using a metal-compatible nail gun reduces the risk of structural failure or material damage that may occur when using a regular nail gun on metal.

It’s important to note that not all nail guns are suitable for metal. Therefore, if you plan to work extensively with metal or need to secure metal to other materials, investing in a metal-specific nail gun is highly recommended. These specialized nail guns are designed to provide the necessary power, precision, and durability to effectively penetrate and bond with metal surfaces.

Additionally, some nail guns offer compatibility with both wood and metal. These versatile models often feature interchangeable tips or specific modes for switching between the two materials. This flexibility can be advantageous if you frequently work with different materials, as it eliminates the need for multiple nail guns.

The Safety Considerations of Using Nail Guns on Metal

When using a nail gun on metal, it is crucial to prioritize safety. Metal surfaces can pose unique challenges compared to other materials, potentially increasing the risk of accidents or injuries. Here are some important safety considerations to keep in mind:

- Choose the appropriate nail gun: Select a nail gun specifically designed for metal fastening to ensure optimal performance and reduce the risk of accidents.

- Wear protective gear: Always wear safety goggles, gloves, and appropriate clothing to protect yourself from flying debris or potential metal splinters.

- Mind the settings: Adjust the depth settings and air pressure of your nail gun according to the thickness and hardness of the metal you are working with. This ensures proper penetration while minimizing the risk of damaging the material or causing it to warp.

- Secure the workpiece: Make sure the metal piece is securely held in place before driving nails. If possible, use clamps or vices to prevent movement or shifting during the nailing process.

- Position yourself correctly: Always stand in a stable position, ensuring a firm grip on the nail gun and maintaining a safe distance from the work area.

- Inspect the work area: Clear the work area of any potential hazards or obstacles that may interfere with safe operation.

- Practice proper maintenance: Regularly clean and lubricate your nail gun to ensure it operates smoothly and remains in good working condition.

Benefits of Using a Nail Gun on Metal

Speed and efficiency: One of the primary advantages of using a nail gun on metal is the significant time savings it offers. Nail guns allow for rapid and consistent nail placement, streamlining the construction or repair process.

Secure bonding: When used correctly, nail guns provide strong and secure bonding between metal surfaces, ensuring structural integrity.

Reduced effort: Hammering nails into metal can be physically demanding and time-consuming. By utilizing a nail gun, you can save energy and reduce the strain on your hands and arms.

Alternatives to Using a Nail Gun on Metal

While nail guns are a popular choice for fastening materials, there are alternative methods you can consider when working with metal:

- Screws: Using screws can provide a secure and long-lasting connection between metal surfaces. Screw gun attachments, similar to nail guns, can speed up the process and make it more efficient.

- Rivets: Rivets are a common choice for joining metal pieces together. They offer a reliable and permanent connection, particularly in industrial applications.

- Welding: Welding is a versatile method for securing metal. It provides a strong and durable bond, especially for structural applications.

Gaining Efficiency with the Right Nail Gun

Now that we’ve explored the possibility of using a nail gun on metal and the safety considerations involved, it’s essential to equip yourself with the right nail gun for the job. There are various nail gun options available, each suited for specific applications and materials.

Choosing a Metal-Compatible Nail Gun

When selecting a nail gun for metal fastening, consider the following factors:

- Type of metal: Determine the type of metal you will primarily be working with to ensure the nail gun is compatible with its thickness and hardness.

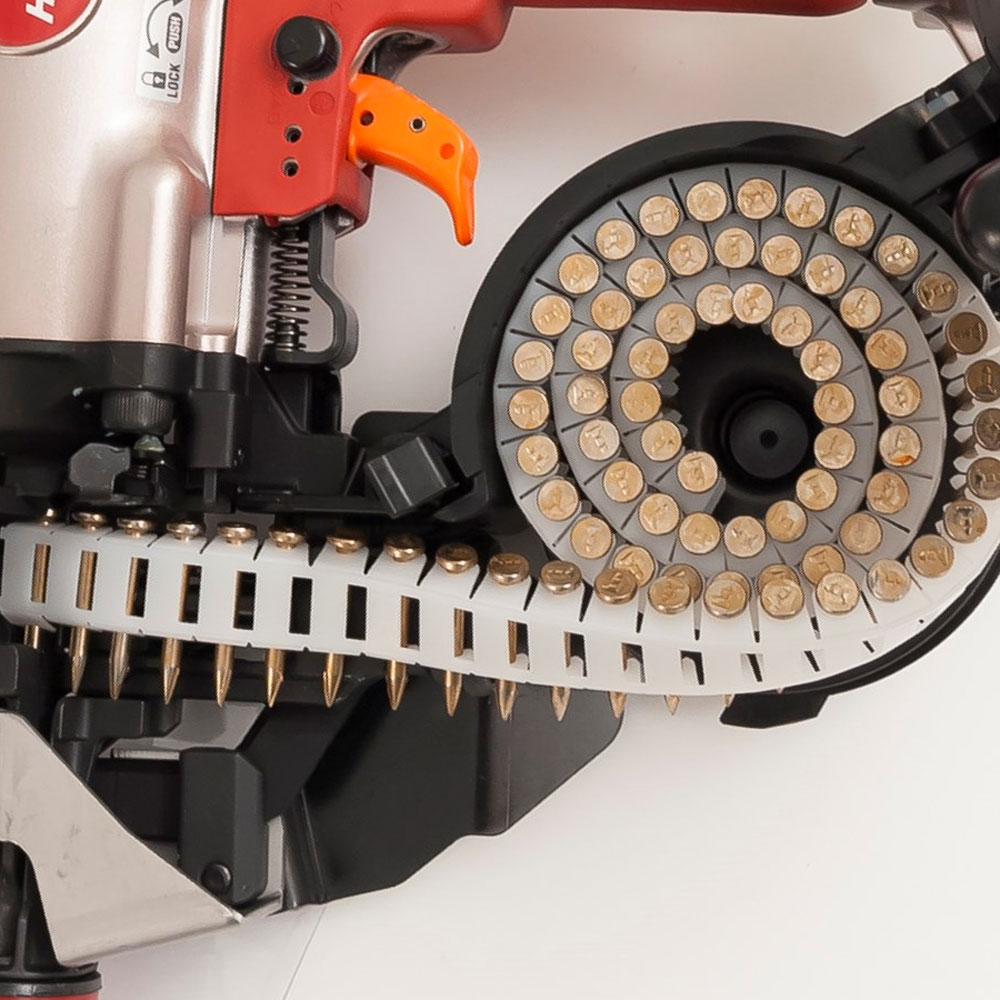

- Nail size: Consider the size of nails you will be using and ensure the nail gun can accommodate them.

- Power source: Choose between pneumatic nail guns, which use compressed air, or cordless nail guns, which run on batteries. Each has its advantages and limitations. Pneumatic nail guns are typically more powerful, while cordless options offer greater portability.

- Features and settings: Look for features like adjustable depth settings, magazine capacity, and quick-release mechanisms for efficient operation.

Tips for Safe and Efficient Metal Fastening

Here are some additional tips to ensure safe and efficient metal fastening with a nail gun:

- Prepare the work area: Clear the work area of any debris or objects that may interfere with the nailing process.

- Practice: Familiarize yourself with the nail gun and practice on scrap pieces of metal before tackling your actual project.

- Maintain proper grip and stance: Hold the nail gun firmly and position yourself securely to maintain control and accuracy.

- Use appropriate nails: Ensure you select the correct nail size and type for the metal you are working with, considering factors such as corrosion resistance and load capacity.

- Secure metal pieces: Use clamps or other means to hold the metal securely in place, preventing movement during nailing.

By following these tips and guidelines, you can safely and efficiently use a nail gun on metal, achieving strong and secure connections. However, always refer to the manufacturer’s instructions and guidelines when using any power tool, and prioritize safety throughout your projects.

Remember, whether you choose to use a nail gun or opt for alternative fastening methods, it’s essential to tailor your approach based on the specific requirements of your project. Consider the type of metal, the desired bond strength, and the overall construction or repair goals when determining the best method to use. With the right tools, knowledge, and safety precautions, you can confidently tackle any metal fastening task.

Key Takeaways: Can You Use a Nail Gun on Metal?

- Using a nail gun on metal is not recommended as it may damage the metal or cause injury.

- Nail guns are designed for use on wood and other soft materials.

- If you need to attach materials to metal, consider using screws, rivets, or a specialized metal fastening tool.

- Using the right tool for the job ensures safety and prevents damage to both the material and yourself.

- Always consult the manufacturer’s recommendations and safety guidelines before using any tools.

Frequently Asked Questions

Welcome to our FAQ section on using a nail gun on metal. Whether you’re a DIY enthusiast or a professional, this guide will answer some common questions you may have. Let’s dive in!

1. Can a nail gun be used on metal?

Yes, nail guns can be used on metal, but it depends on the type of nail gun and the metal you’re working with. Some nail guns are specifically designed for metal, such as those used in construction or metalworking industries. These nail guns have the power and specific features necessary for driving nails into metal surfaces.

However, it’s important to note that not all nail guns are suitable for metal. Nail guns designed for wood or general purposes may not have the necessary power or nail types to effectively penetrate metal surfaces. It’s crucial to choose the right nail gun for the job to ensure safety and efficiency.

2. What type of nail gun is best for metal?

When it comes to working with metal, pneumatic or air-powered nail guns are often the best choice. These nail guns use compressed air to drive nails into metal surfaces. They provide the power and precision required to penetrate metal without damaging it. Pneumatic nail guns also offer a wide range of nail sizes, allowing you to choose the appropriate one for your project.

For smaller metal projects, a cordless nail gun may also be suitable. These battery-powered nail guns provide portability and ease of use, though they may not have as much power as pneumatic options. Consider the size and requirements of your project to determine which type of nail gun is best for you.

3. Are there specific nails for metal?

Yes, there are specific nails available for metal. These nails, often referred to as “metal studs” or “metal framing nails,” are specially designed to penetrate and hold in metal surfaces. They are typically made of hardened steel, which allows them to withstand the hardness of metal without bending or breaking.

When working with metal, it’s essential to choose the proper nails that are compatible with your nail gun. Using the wrong type of nail could result in improper penetration, weak connections, or damage to the metal. Always consult the manufacturer’s guidelines or seek advice from a professional if you’re unsure about the correct nails to use.

4. What safety precautions should I take when using a nail gun on metal?

Working with a nail gun, especially on metal, requires proper safety precautions to prevent injuries. Here are some safety tips to keep in mind:

Firstly, always wear safety goggles to protect your eyes from flying debris. Additionally, wear gloves to shield your hands from sharp edges and potential injury. If working with larger metal pieces, consider using clamps or a vise to secure the material in place, ensuring stability during nailing.

Lastly, before using a nail gun on metal, ensure you have a suitable work area that is free from clutter and potential hazards. This will reduce the risk of accidents or damage to surrounding objects. Remember, safety should always be a top priority.

5. Can a nail gun be used on thin sheet metal?

Yes, a nail gun can be used on thin sheet metal, but it’s crucial to choose the appropriate nail size and type. Thin sheet metal requires nails that are specifically designed for this purpose, such as brads or finishing nails. These nails are smaller in size and have a thinner gauge, allowing them to penetrate thin metal without causing damage.

Before using a nail gun on thin sheet metal, it’s recommended to practice on a scrap piece to ensure the nail gun’s power and settings are suitable. Additionally, always exercise caution when working with thin materials, as they can be more prone to bending or warping. Take your time and work slowly and steadily for the best results.

Summary

Using a nail gun on metal can be dangerous and ineffective. The nails may not penetrate properly or could cause harm due to ricochets. It is best to use a specialized tool for metal applications.

Additionally, using a nail gun on metal could damage the gun itself, leading to costly repairs. It’s important to always read the manufacturer’s instructions and use the appropriate tools for each job. Safety should be the top priority when working with power tools.