Are you wondering if you can use pocket screws with plywood? Well, you’ve come to the right place! In this article, we’ll explore the fascinating world of woodworking and dive into the specifics of using pocket screws with plywood. Get ready to discover the ins and outs of this popular woodworking technique!

Now, you might be asking yourself, “What are pocket screws?” Great question! Pocket screws are a type of fastener that allows you to join pieces of wood together with ease. They are often used in woodworking projects to create strong and secure connections. But can you use pocket screws with plywood? Let’s find out!

So, whether you’re a seasoned woodworker or just starting out, join us as we unravel the mysteries of pocket screws and plywood. By the end of this article, you’ll have all the knowledge you need to confidently tackle your next woodworking project. Let’s get started and explore the world of pocket screws and plywood together!

Are you wondering if pocket screws can be used with plywood? Absolutely! Pocket screws are a great option for joining plywood because they provide a strong and secure connection. The angled holes made by pocket screws create a tight bond, making plywood projects sturdy and durable. Whether you’re building furniture, cabinets, or other woodworking projects, pocket screws are an excellent choice for joining plywood panels. So go ahead and use pocket screws with plywood for your next project!

Can You Use Pocket Screws with Plywood?

Pocket screws are a popular choice for joinery in woodworking projects due to their simplicity and strength. However, when it comes to using pocket screws with plywood, there are some considerations to keep in mind. In this article, we will explore the compatibility of pocket screws with plywood and provide insights into best practices for achieving secure and durable connections. Whether you’re a woodworking enthusiast or a DIYer looking to tackle a project with plywood, this article will help you understand the feasibility of using pocket screws and offer valuable tips for successful outcomes.

1) Understanding Plywood and its Composition

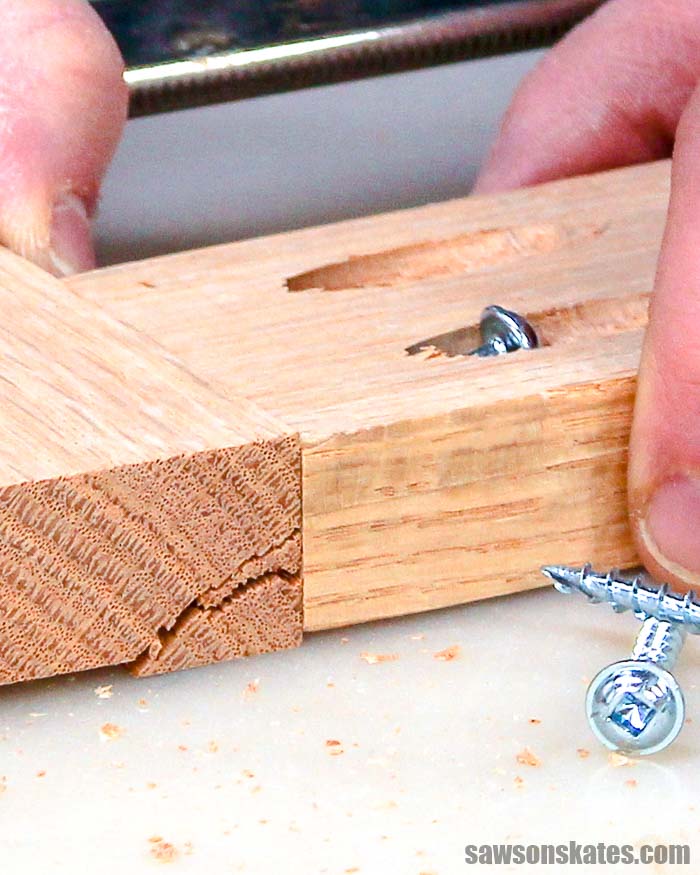

Plywood is a versatile material commonly used in various woodworking projects due to its strength, stability, and affordability. It consists of multiple layers of thin veneer sheets, called plies, glued together in a crisscross pattern. This construction gives plywood its exceptional strength and resistance to warping and cracking. However, the voids between the plies can present a challenge when using pocket screws.

When driving a pocket screw into plywood, the screw threads create a gap between the plies, potentially compromising the overall strength of the joint. Additionally, the screw might not provide a secure grip due to the varying density and thickness of the plies. Therefore, it is crucial to take certain precautions to ensure the effectiveness of pocket screws when working with plywood.

One way to address this issue is to use plywood specifically designed for pocket screws. These types of plywood have a denser core and are constructed with fewer, thicker plies to provide better holding power for screws. Alternatively, adding additional reinforcement to the joint, such as glue or dowels, can enhance the strength and stability of the connection.

2) Best Practices for Using Pocket Screws with Plywood

While plywood does present some challenges when using pocket screws, employing the right techniques and following best practices can lead to successful outcomes. Here are some tips to consider when working with pocket screws and plywood:

1. Use the appropriate pocket hole jig: Invest in a high-quality pocket hole jig specifically designed for plywood. These jigs will offer the necessary support and alignment to create accurate pocket holes in plywood without causing damage.

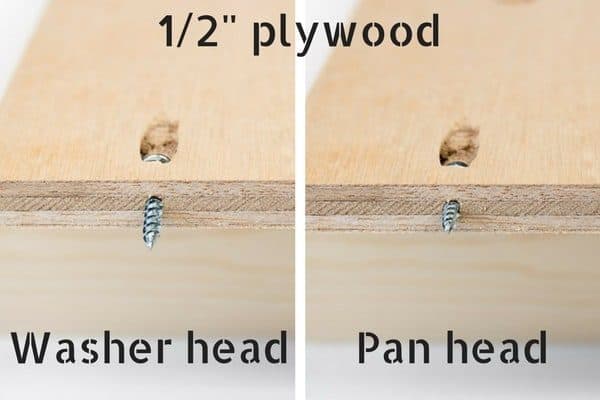

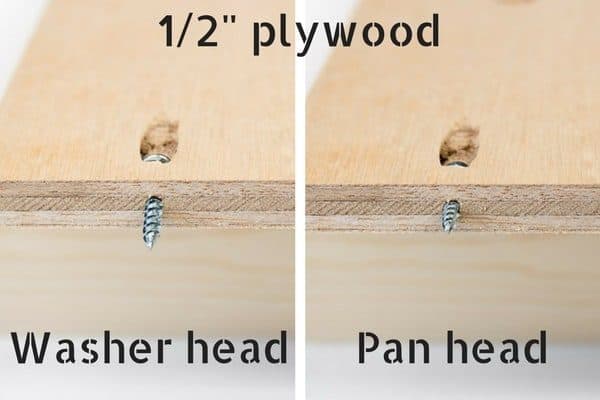

2. Choose the right screw size: When working with plywood, it is crucial to select the correct screw length to avoid splitting or protrusion through the material. The length of the screw should be slightly shorter than the combined thickness of the plywood layers to ensure a strong and secure connection.

3. Consider pilot holes and countersinking: To minimize the risk of splitting the plywood, it is advisable to pre-drill pilot holes before driving the pocket screws. Additionally, countersinking the screw heads will create a flush finish, preventing any obstructions when applying finishes or joining other components.

4. Use additional reinforcement: For critical joints or areas subjected to heavy loads, it is recommended to reinforce the connection by using glue, dowels, or other fasteners. This will provide added strength and prevent the joint from loosening over time.

5. Optimize placement and spacing: Properly spacing the pocket holes and positioning them away from the edges of the plywood will reduce the likelihood of splitting. It is essential to follow the manufacturer’s guidelines and consider the overall design and structural requirements of the project.

By following these best practices, you can overcome the challenges associated with using pocket screws with plywood and achieve strong, durable joints in your woodworking projects.

Troubleshooting Tips for Using Pocket Screws with Plywood

While pocket screws can be successfully used with plywood, it is essential to address any potential issues that may arise. Here are some troubleshooting tips to overcome common challenges:

1) Splitting Plywood

One of the main concerns when using pocket screws with plywood is the risk of splitting. To minimize splitting, consider the following:

– Choose a screw size that matches the thickness of the plywood. Avoid using screws that are too long, as they may penetrate through the material.

– Pre-drill pilot holes before inserting the screws. This will help create a path for the screw and reduce the likelihood of splitting.

– Use a sharp drill bit to ensure clean pilot holes without tearing the plywood layers.

2) Insufficient Holding Power

Due to the voids between the plies in plywood, achieving optimal holding power can be challenging. To increase holding power:

– Use plywood specifically designed for pocket screws, which has a denser core and fewer, thicker plies.

– Consider adding additional reinforcement to the joint, such as glue or dowels. This will enhance the overall strength and stability of the connection.

– Optimize the spacing and placement of pocket holes to distribute the load evenly and minimize stress on individual screws.

3) Uneven Surfaces

Plywood may have slight variations in thickness and surface level, which can affect the flushness of the pocket screw connection. To ensure a flush finish:

– Use a countersink bit to create a recess for the screw heads. This will allow the heads to sit flush with the surface, preventing any protrusions.

– Sand the plywood surface to achieve a smooth and level finish before joining the pieces with pocket screws. This will eliminate any high spots and ensure a tighter connection.

By addressing these troubleshooting tips, you can overcome common issues when using pocket screws with plywood and achieve secure, professional-looking joints in your woodworking projects.

Additional Considerations for Using Pocket Screws with Plywood

When working with plywood and pocket screws, it is important to keep these additional considerations in mind:

1. Plywood grade: Different plywood grades have varying quality and suitability for different applications. Choose a grade that is appropriate for your project to ensure the best results.

2. Edge banding: If aesthetics are important for your project, consider using edge banding to conceal the exposed edges of the plywood. This will give a more polished look and hide the pocket screw holes.

3. Finishing: Before applying any finishes to your plywood project, ensure that the pocket screw holes are adequately filled with wood putty or a similar material. This will create a seamless surface for the finish and prevent any imperfections.

By paying attention to these additional considerations, you can enhance the overall appearance and durability of your plywood projects when using pocket screws.

In conclusion, while using pocket screws with plywood does present some challenges, it is still possible to achieve secure and durable joints by following the best practices and troubleshooting tips mentioned in this article. By understanding the composition of plywood, selecting the right tools and materials, and employing appropriate techniques, you can successfully utilize pocket screws in your plywood woodworking projects. Happy building!

Key Takeaways: Can You Use Pocket Screws with Plywood?

1. Pocket screws can be used with plywood, as long as the plywood is thick enough to hold the screws securely.

2. It is important to choose the right type and length of pocket screws for plywood, ensuring a strong and secure joint.

3. Pre-drilling pilot holes can help prevent the plywood from splitting when using pocket screws.

4. Pocket screws provide a hidden and clean-looking joint, making them a popular choice for plywood projects.

5. It is recommended to use a pocket hole jig to accurately create the pocket holes for the screws in plywood.

Frequently Asked Questions

Welcome to our FAQ section where we address common questions about working with plywood and pocket screws. Here, we provide answers to help you understand the compatibility of pocket screws with plywood for your woodworking projects.

Question 1: Are pocket screws suitable for plywood joinery?

Yes, pocket screws are suitable for joinery in plywood projects. Unlike traditional screws, pocket screws are designed to create strong and secure connections in plywood by using angled holes and special self-tapping screws with coarse threads. This allows the screws to grip the softer plywood material firmly, providing excellent holding power.

When using pocket screws with plywood, it is important to choose the right screw length and diameter based on the thickness of the plywood. Additionally, using a pocket hole jig will help you create precise and consistent pocket holes for a professional finish.

Question 2: Why are pocket screws preferred for plywood joinery?

Pocket screws are preferred for plywood joinery due to their unique design. The angled pocket holes create strong connections between plywood pieces, preventing the wood from splitting or cracking. The self-tapping screws used with pocket holes are designed to pull the pieces together tightly, resulting in a secure and stable joint.

Moreover, pocket screws offer the advantage of a concealed joint since the screws are hidden within the pocket holes, enhancing the overall aesthetic appeal of the plywood project. This makes pocket screws an excellent choice for visible surfaces or furniture construction where a clean and seamless finish is desired.

Question 3: Can you use pocket screws with thin plywood?

Absolutely! Pocket screws can be used with thin plywood as well. However, when working with thin plywood, it is important to choose the appropriate screw length to ensure the screw does not extend beyond the thickness of the plywood, which could potentially cause damage to the material or create an unsightly appearance.

Using shorter screws and adjusting the pocket hole depth accordingly will allow you to create strong and secure joints without compromising the integrity of the thin plywood. It is recommended to experiment on scrap pieces of plywood to determine the proper length and depth settings for your specific project.

Question 4: Can pocket screws be used for plywood cabinet assembly?

Absolutely! Pocket screws are commonly used for plywood cabinet assembly. When constructing cabinets with plywood, pocket screws provide a fast and efficient method of joining the panels together. The angled pocket holes allow for secure and invisible connections, ensuring a clean and professional look.

Before assembling the cabinets, it is essential to accurately measure and mark the pocket hole locations to ensure proper alignment and a strong joint. By utilizing pocket screws, you can simplify the cabinet assembly process while ensuring a durable and sturdy construction.

Question 5: Are there any disadvantages of using pocket screws with plywood?

While pocket screws are highly versatile and suitable for plywood joinery, there are a few considerations to keep in mind. One potential disadvantage is the need for a pocket hole jig, which is an additional tool required for creating the angled holes. However, once you have the jig, it can be used for multiple projects.

Another aspect to consider is the cost of pocket screws. Compared to traditional screws, pocket screws are generally more expensive. However, the benefits they offer in terms of strength, aesthetics, and ease of use often outweigh the higher cost, especially for projects where the plywood joints will be visible or require additional strength.

Summary

So, can you use pocket screws with plywood? The answer is yes! Pocket screws are a great option for joining plywood pieces together. They provide a strong and secure connection that can withstand different forces. Just make sure to choose the right size and type of pocket screws for your plywood project. It’s also important to follow proper drilling techniques to prevent splitting and ensure a clean finish. With pocket screws, you can easily create sturdy and reliable plywood projects. Happy building!

In conclusion, using pocket screws with plywood is a practical and effective way to join pieces together. It offers strength and stability, making it suitable for various woodworking projects. By understanding the basics and following proper techniques, you can confidently use pocket screws with plywood and create amazing creations. So, grab your tools and get ready to build with confidence!