Hey there! Have you ever wondered if you can use router bits in a CNC machine? Well, you’re in luck because today we’re going to dive into this topic and see what we can find out. So, let’s get started with the basics!

If you’re not familiar with CNC machines, they’re like super precise robots that can carve, cut, and shape materials with incredible accuracy. On the other hand, router bits are tools specifically designed for routers, which are handheld power tools used to hollow out an area in a material. Now, it’s time to answer the burning question: can you use router bits in a CNC machine?

The answer is yes, you can use router bits in a CNC machine! In fact, many CNC machines are equipped with a router spindle that allows you to use various types of router bits. This versatility opens up a whole world of possibilities for your CNC projects. So, whether you want to carve intricate designs, create precision joinery, or make decorative edges, router bits can be a valuable addition to your arsenal of CNC tools. Exciting, right? Let’s explore this topic further and discover the ins and outs of using router bits in a CNC machine.

Can You Use Router Bits in a CNC?

Router bits are commonly used in woodworking to shape and cut materials. On the other hand, CNC (Computer Numerical Control) machines are a modern innovation that automate various tasks in manufacturing and fabrication. But can you use router bits in a CNC? In this article, we will explore the compatibility of router bits and CNC machines, the advantages and drawbacks of doing so, and provide some tips for using router bits in a CNC effectively.

Understanding Router Bits and CNC Machines

Before delving into whether router bits can be used in CNC machines, it is essential to understand what each of these components entails.

A router bit is a cutting tool that attaches to a handheld router or a router table. It is typically made of high-speed steel or carbide and comes in a variety of shapes and sizes. Router bits are primarily used to form decorative edges, create profiles, and make intricate cuts in wood, plastic, or other soft materials.

CNC machines, on the other hand, are automated machines that read programmed instructions to precisely control tool movements. These machines use computer-aided design (CAD) software to generate the required tool paths and commands, making them ideal for precise and repetitive tasks. CNC machines can be used for cutting, drilling, carving, engraving, and more in a range of materials such as wood, metal, and plastics.

The Compatibility of Router Bits and CNC Machines

Using router bits in a CNC machine is indeed possible and can offer several advantages. The key factor for compatibility is the shank size of the router bit, which must match the collet size of the CNC machine’s spindle. Typically, the most commonly used shank sizes for router bits are 1/4 inch and 1/2 inch. By ensuring compatibility in terms of shank size, you can safely and effectively use router bits in a CNC machine.

It is important to note that not all router bits are suitable for use in a CNC machine. Straight bits, spiral bits, flush trim bits, and V-groove bits are among those commonly used in CNC applications. However, complex profile bits or raised panel bits, which require multiple passes and can strain the machine, might not be the best choice.

Another consideration is the speed at which a CNC machine operates. While routers typically run at high speeds, CNC machines may operate at lower speeds to account for the precision and control needed. Therefore, it is crucial to adjust the cutting speed of the CNC machine to ensure efficient and safe operation with the router bit.

Tips for Using Router Bits in a CNC

To ensure optimal performance and longevity when using router bits in a CNC machine, consider the following tips:

- Choose high-quality router bits specifically designed for CNC applications. These bits are often made with superior materials and craftsmanship, ensuring clean cuts and reduced wear and tear.

- Set the cutting speed of the CNC machine to an appropriate level for the specific router bit being used. Lower speeds are often preferable to prevent overheating and extend the lifespan of the bit.

- Securely fasten the router bit in the collet of the CNC machine, ensuring it is properly tightened to prevent slippage or accidents during operation.

- Perform regular maintenance on both the router bit and the CNC machine. This includes cleaning the bit after each use, checking for any signs of wear or damage, and lubricating moving parts of the CNC machine as recommended by the manufacturer.

- Experiment with different feed rates and cutting depths to find the optimal settings for the specific material and router bit being used. This will help achieve the desired results without straining the machine or the bit.

The Benefits of Using Router Bits in a CNC

Utilizing router bits in a CNC machine can offer several advantages:

- Versatility: By using router bits, CNC machines can perform a wide range of cuts and shapes, allowing for greater versatility in woodworking and fabrication projects.

- Precision: The automated nature of CNC machines ensures precise and accurate cuts, resulting in consistent and high-quality workmanship.

- Time efficiency: CNC machines can execute tasks faster compared to manual woodworking techniques, making them an efficient choice for production-based projects.

- Ease of use: With the right setup and programming, CNC machines with router bits can be relatively easy to operate, even for beginners.

Conclusion

Using router bits in a CNC machine is indeed possible and can be a valuable tool for woodworking and fabrication projects. By ensuring compatibility in terms of shank size and selecting appropriate router bits for CNC applications, you can achieve precise and high-quality results. Remember to follow the recommended tips and maintenance practices to optimize performance and prolong the lifespan of both the router bit and the CNC machine. Incorporating router bits into a CNC workflow can enhance versatility, precision, efficiency, and ease of use, making it a worthwhile consideration for both professionals and hobbyists in the industry.

Additional Information

The Advantages of CNC Machines

CNC machines offer numerous advantages over traditional manual methods of fabrication and manufacturing. Let’s explore some of these benefits:

- Precision: CNC machines are capable of incredibly precise and accurate cuts, ensuring consistency and high-quality workmanship.

- Efficiency: With their automated nature, CNC machines can complete tasks much faster than traditional manual methods, resulting in improved productivity.

- Repeatability: Once programmed, CNC machines can reproduce the same design or cut multiple times with consistent results, making them ideal for mass production.

- Complexity: CNC machines can execute intricate and complex designs that would be challenging or impossible to achieve manually.

- Reduced human error: As CNC machines are controlled by computer programs, the potential for human error is significantly reduced, leading to higher accuracy and fewer mistakes.

Choosing the Right Router Bit for Your CNC Machine

When selecting router bits for use in a CNC machine, consider the following factors:

- Material: Choose router bits specifically designed for the material you will be working with, such as wood or plastic.

- Bit Diameter: Consider the size of the cut or profile you intend to make and choose a router bit with an appropriate diameter.

- Type of Cut: Different router bits are designed for specific types of cuts, such as straight cuts, chamfer cuts, or dado cuts. Select the appropriate bit for your desired outcome.

- Quality: Invest in high-quality router bits to ensure clean cuts, longevity, and reduced wear and tear on the bit and the CNC machine.

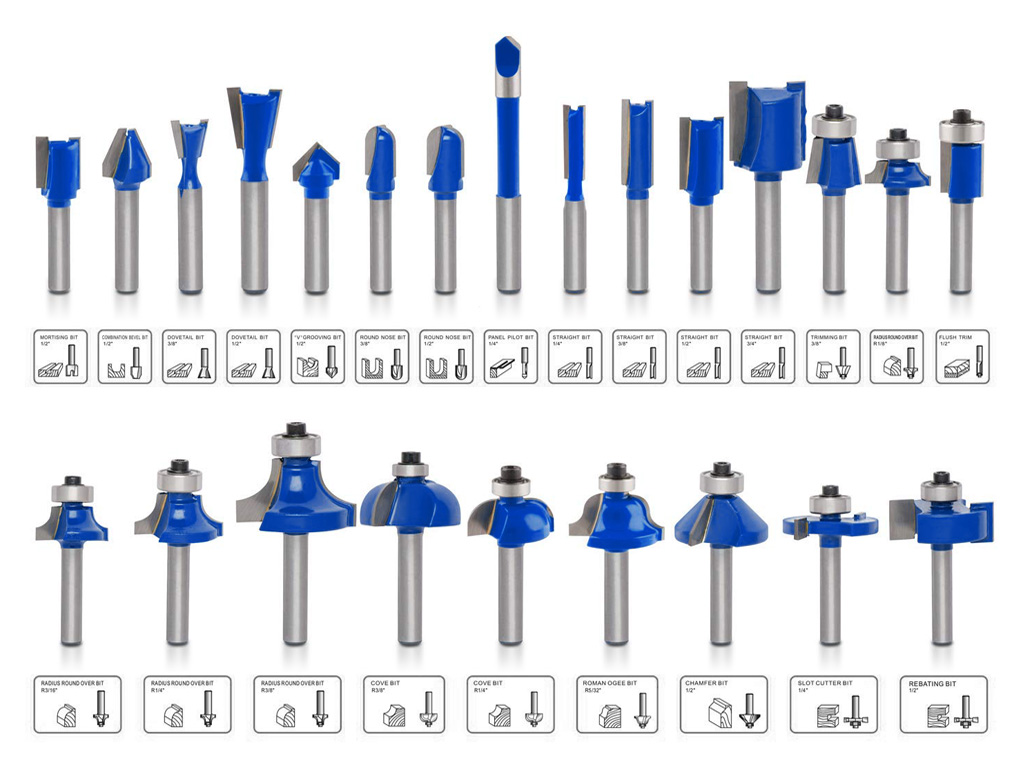

Common Router Bit Shapes for CNC Applications

Here are some common router bit shapes used in CNC applications:

- Straight Bits: Ideal for making straight cuts, dados, and slots.

- Spiral Bits: Designed for efficient chip evacuation and produce clean cuts in materials like wood and plastic.

- V-Groove Bits: Used to create decorative V-shaped grooves or channels.

- Flush Trim Bits: Perfect for trimming the edges of one material to match the contours of another.

- Round Nose Bits: Create rounded profiles, decorative grooves, or holes with rounded bottoms.

- Chamfer Bits: Used to create beveled edges or chamfers on materials.

- Rabbeting Bits: Designed to cut rabbets of various depths and widths.

Ensuring Safety when Using Router Bits with CNC Machines

Safety should always be a top priority when working with router bits in a CNC machine. Here are some safety guidelines to follow:

- Wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and hearing protection.

- Ensure the CNC machine is properly set up and secured to prevent movement or instability during operation.

- Securely fasten the router bit in the collet, making sure it is tightened properly to avoid any accidents or slippage.

- Always read and follow the manufacturer’s instructions and recommendations for operating the CNC machine and the router bits.

- Regularly inspect the router bit for any signs of wear or damage and replace if necessary.

Incorporating router bits into your CNC workflow can open up a world of possibilities for woodworking and fabrication projects. By understanding the compatibility, benefits, and safety measures, you can utilize router bits effectively and achieve outstanding results with your CNC machine.

Key Takeaways: Can You Use Router Bits in a CNC?

Yes, you can use router bits in a CNC (Computer Numerical Control) machine.

Router bits are designed for hand-held routers, but with the right adapter, they can be used in a CNC as well.

Using router bits in a CNC allows for versatile cutting and shaping of materials like wood, plastic, and metal.

It’s important to use the appropriate speed, feed rate, and tool path settings when using router bits in a CNC to ensure optimal results.

By using router bits in a CNC, you can achieve precise and accurate cuts for various woodworking and fabrication projects.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer some common queries related to using router bits in a CNC machine.

1. What is a router bit and can it be used in a CNC machine?

A router bit is a cutting tool used with a handheld router or a CNC machine to create different types of cuts on various materials. While router bits are primarily designed for use with handheld routers, they can also be used in a CNC machine with some considerations.

When using router bits in a CNC machine, it’s important to ensure compatibility with the machine’s collet size and shank diameter. Additionally, you need to consider the type of material being cut, the feed rate, and the bit’s speed rating to ensure optimal performance and safety.

2. What are the advantages of using router bits in a CNC machine?

Using router bits in a CNC machine offers several advantages. Firstly, router bits come in a wide variety of shapes and sizes, allowing for versatility in cutting different profiles or creating intricate designs. Additionally, they are typically made from high-quality materials, such as carbide, which ensures durability and long-lasting performance.

Router bits also provide precision and accuracy in cuts, resulting in clean and professional-looking finishes. With a CNC machine, you can program the toolpath and execute complex cuts with ease, allowing for efficient and consistent production. Overall, using router bits in a CNC machine expands the capabilities and possibilities of your projects.

3. Are there any limitations when using router bits in a CNC machine?

While using router bits in a CNC machine offers many benefits, there are some limitations to consider. One limitation is the maximum cutting depth that a router bit can achieve in a single pass. Depending on the bit’s size and the material being cut, you may need to make multiple passes to reach the desired depth.

Another limitation is the availability of specialized bits for certain CNC operations. Some operations, such as engraving or 3D carving, may require specific bits that are designed for those tasks. It’s important to have a diverse collection of router bits to fully utilize a CNC machine’s capabilities. Lastly, it’s important to consider the speed and feed rates when using router bits in a CNC machine, as improper settings can lead to issues such as burning or chipping of the material being cut.

4. How do you choose the right router bit for a CNC machine?

Choosing the right router bit for a CNC machine depends on various factors such as the type of material being cut, the desired cut profile, and the required cutting depth. It’s important to consider the bit’s flutes, diameter, and shank size to ensure compatibility and optimal performance.

For softer materials like wood, a straight or spiral upcut bit is often suitable. On the other hand, for harder materials like acrylic or aluminum, a compression bit or an end mill may be more appropriate. Consulting the router bit manufacturer’s guidelines or seeking advice from experienced CNC users can help in selecting the right router bit for your specific application.

5. How can I maintain and prolong the lifespan of router bits used in a CNC machine?

To maintain and prolong the lifespan of router bits used in a CNC machine, proper care and maintenance are essential. Firstly, it’s important to keep the bits clean and free from debris after each use. This can be done by using compressed air, a brush, or a designated cleaning solution.

Additionally, using the appropriate feed rates and speeds, as recommended by the router bit manufacturer, can help prevent premature wear. It’s also important to check the bit’s condition regularly for any signs of damage or dullness, and replace them as needed. Proper storage in a designated case or container, where the bits are protected from moisture and physical damage, is also recommended.

Summary

Can you use router bits in a CNC? The answer is yes, but there are a few things to consider. CNC machines are designed for precision and accuracy, so using router bits meant for woodworking may not always work well. You may need to use specialized CNC router bits to get the best results.

It’s important to match the router bit to the material you’re working with. Different bits are designed for different materials like wood, plastic, or metal. Using the wrong bit can cause damage or produce subpar results. Always make sure to understand the bit’s specifications before using it in your CNC machine.

So, while you can use router bits in a CNC, it’s crucial to choose the right ones for the job. Remember to consider the material, check the compatibility with your machine, and aim for quality and precision to achieve the best outcomes in your CNC projects.