Can you use router bits in a milling machine? If you’re curious about this topic, you’ve come to the right place! In this article, we’ll explore the possibility of using router bits, typically used in woodworking, with a milling machine. So, let’s dive in and uncover the answer!

When it comes to tools, versatility is key, and many of us wonder if we can repurpose our existing tools for other tasks. In the case of using router bits in a milling machine, the answer isn’t a simple yes or no. It depends on various factors, such as the type of milling machine, the material you’re working with, and the specific router bit you plan to use.

Milling machines are designed specifically for shaping and cutting metal, while router bits are primarily used in woodworking. While there may be some crossover, it’s crucial to consider the compatibility between the tool and the task at hand. In the following sections, we’ll delve deeper into the details and provide you with the information you need. So, let’s get started!

Can You Use Router Bits in a Milling Machine?

When it comes to machining operations, the choice of tools is crucial for achieving accurate and precise results. Many people wonder if it’s possible to use router bits in a milling machine, as both tools share some similarities. In this article, we will explore the compatibility of router bits with milling machines and delve into the advantages and considerations of using them in this context.

The Compatibility of Router Bits with Milling Machines: Explained

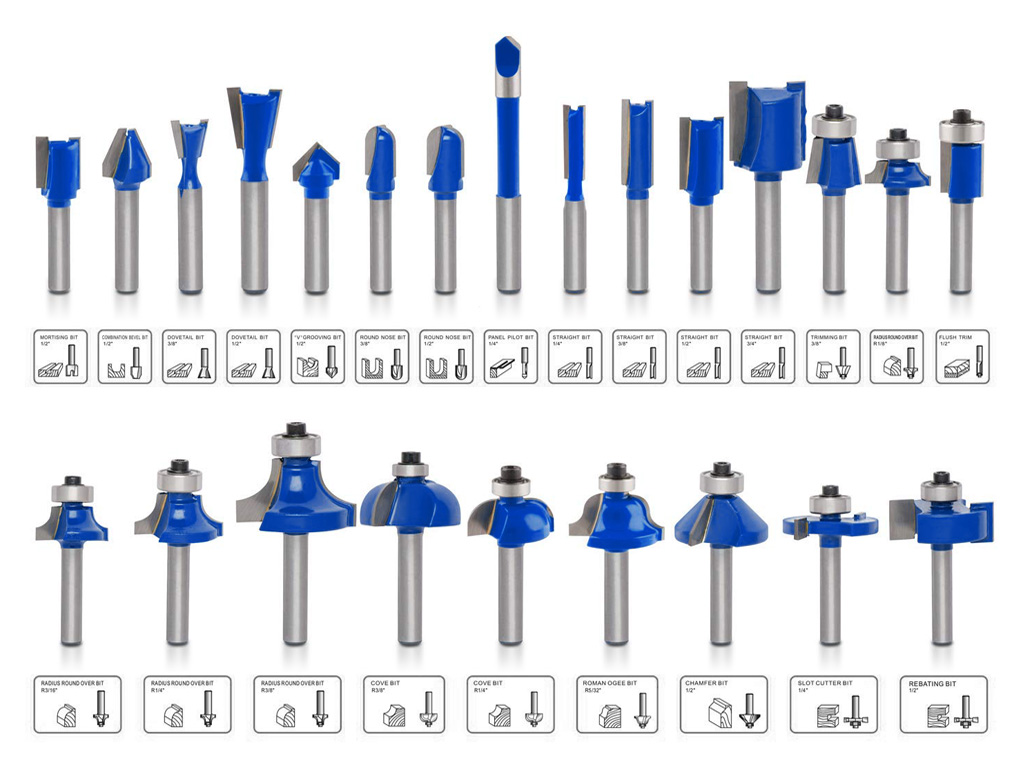

Router bits and milling machine cutters may look similar, but they are specifically designed for different applications. Router bits are primarily used for woodworking, while milling machine cutters are designed for metalworking. However, it is possible to use certain router bits in a milling machine, depending on the material being machined and the specific task at hand.

Before attempting to use router bits in a milling machine, it is important to consider the following factors:

1. Material:

The first consideration is the material you will be machining. Router bits are typically designed to cut softer materials such as wood, plastic, and some non-ferrous metals. While they might be suitable for softer metals like aluminum, they may not be suitable for harder materials like steel. It’s crucial to select the appropriate router bits that are compatible with the material you intend to machine.

It’s also essential to factor in the speed and feed rates at which the milling machine operates. The cutting parameters need to be adjusted accordingly to ensure optimal tool performance and prevent premature wear or breakage.

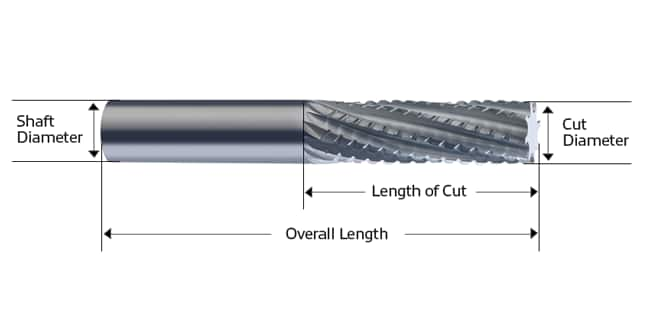

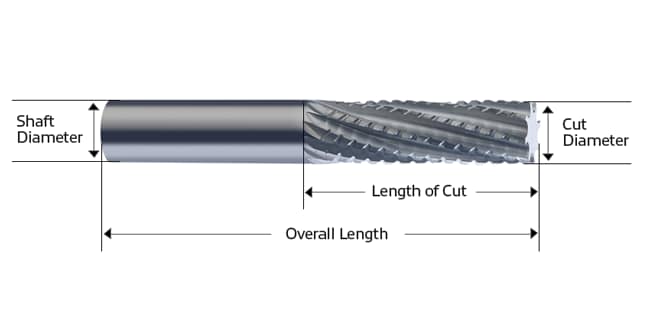

2. Shank Size and Compatibility:

Another important aspect to consider is the shank size of the router bits and the compatibility with the milling machine’s collet or chuck. Most router bits have a ^1⁄4 inch or ^1⁄2 inch shank diameter, while milling machines usually have various collet sizes to accommodate different cutter shank diameters. It is crucial to ensure that the router bits you plan to use have a shank diameter that is compatible with the milling machine.

Using adapters or collet reducers to fit router bits with different shank sizes into a milling machine can compromise the stability and accuracy of the tool setup. It is recommended to use router bits specifically designed for milling machines or choose milling machine cutters that are suitable for your specific machining needs.

3. Cutting Edge Design:

The design of the cutting edge on router bits is optimized for the specific tasks encountered in woodworking. They often feature more aggressive cutting angles and larger chip clearance. While these aspects may be advantageous for woodworking applications, they may not be ideal for metalworking tasks on a milling machine.

When using router bits in a milling machine, it is important to select bits that have a cutting edge design suitable for metal cutting. Look for router bits specifically designed for metalworking or milling machine cutters that offer the desired cutting edge geometry for your project.

4. Horsepower and Rigidity:

One of the key differences between routers and milling machines is the horsepower and rigidity. Milling machines are built to handle heavy-duty cutting operations and are typically equipped with more powerful motors compared to routers. The added horsepower is necessary to cut through tougher materials and maintain stability during the machining process.

Before attempting to use router bits in a milling machine, it’s important to ensure that the machine has sufficient horsepower and rigidity to handle the cutting forces generated by the router bits. Inadequate rigidity or insufficient horsepower can lead to poor results, tool breakage, and potential damage to the milling machine.

Can You Use Router Bits in a Milling Machine?

- Router bits can be used in a milling machine with the right setup.

- Both router bits and milling cutters have different designs and purposes.

- Router bits are typically used for woodworking, while milling cutters are used for metalworking.

- Using router bits in a milling machine may require adapters or modifications.

- It is important to ensure proper safety measures and compatibility when using router bits in a milling machine.

Frequently Asked Questions

Are you wondering if router bits can be used in a milling machine? Find answers to your questions below!

Can I use router bits in a milling machine?

Yes, you can use router bits in a milling machine. While they are originally designed to be used with a handheld router, they can also be used with a milling machine. The milling machine provides a stable and precise platform for using router bits.

However, it is important to note that not all router bits are suitable for use in a milling machine. You need to choose router bits specifically designed for milling machines to ensure optimal performance and safety. These bits are made with stronger materials and have a shank diameter that matches the milling machine’s collet.

What are the advantages of using router bits in a milling machine?

Using router bits in a milling machine offers several advantages. Firstly, it expands the range of operations you can perform with a milling machine. Router bits allow you to create intricate shapes, profiles, and patterns in various materials, including wood, plastic, and metal.

Secondly, using router bits in a milling machine allows for greater precision and control. The stability of the milling machine eliminates the risks of hand vibrations that can affect the accuracy of the cuts. This is especially beneficial when dealing with complex projects that require high precision.

Can I use any type of router bit in a milling machine?

No, you cannot use any type of router bit in a milling machine. It is important to use router bits specifically designed for milling machines. These bits are made with materials that can withstand the higher speeds and forces involved in milling machine operations.

Milling machine router bits also have a shank diameter that matches the collet of the milling machine, ensuring a secure and precise fit. Using router bits designed for handheld routers in a milling machine can compromise the performance and safety of both the bit and the machine.

What materials can I work with when using router bits in a milling machine?

Router bits used in a milling machine are versatile and can work with various materials. Common materials that can be worked on include wood, plastic, and metal. Depending on the router bit chosen and the milling machine’s capabilities, you can shape and carve intricate designs in these materials.

It is important to consider the material’s hardness and properties when choosing the appropriate router bit. For example, you may need a different type of router bit for cutting through hardwood compared to cutting through soft plastic.

Are there any safety precautions I need to take when using router bits in a milling machine?

When using router bits in a milling machine, it is essential to prioritize safety. Make sure to read and follow the manufacturer’s instructions for both the router bit and the milling machine. Wear appropriate safety equipment, such as safety glasses, hearing protection, and appropriate clothing.

Also, avoid rushing or forcing the router bit through the material. Too much pressure can lead to accidents or damage to the bit or the machine. Take your time and let the router bit do the work, ensuring smooth and controlled movements throughout the milling process.

Summary

Router bits cannot be used in a milling machine because they are designed for different tasks.

Milling machines have specific tools called end mills that are used for cutting metals precisely.

Router bits are meant for cutting wood and are not as precise as end mills.

Using router bits in a milling machine can result in poor cuts and damage to the machine.

So, it’s important to use the right tools for the right job to get the best results.