Can you use wood router bits on aluminum? If you’ve ever wondered about this, you’ve come to the right place. Today, we’re going to dive into the world of woodworking and see if those trusty wood router bits can tackle aluminum as well. So, grab your safety goggles and let’s explore this fascinating topic together!

Woodworking is a fantastic hobby that allows us to create beautiful and functional pieces from the warmth of wood. But sometimes, we may want to experiment with different materials like aluminum. But can our wood router bits handle the challenge? Let’s find out!

In this article, we’ll discuss whether wood router bits are suitable for working with aluminum, the potential risks involved, and any alternative options you may consider. So, if you’re ready to broaden your woodworking horizons, read on to discover the answers you’re looking for!

Wood router bits are not recommended for use on aluminum. While they may be able to cut through aluminum to some extent, they are designed specifically for wood and may not provide clean or efficient results on metal surfaces. It is best to use router bits specifically designed for aluminum or metalworking to ensure accuracy and prevent damage to both the material and the tool.

Can You Use Wood Router Bits on Aluminum?

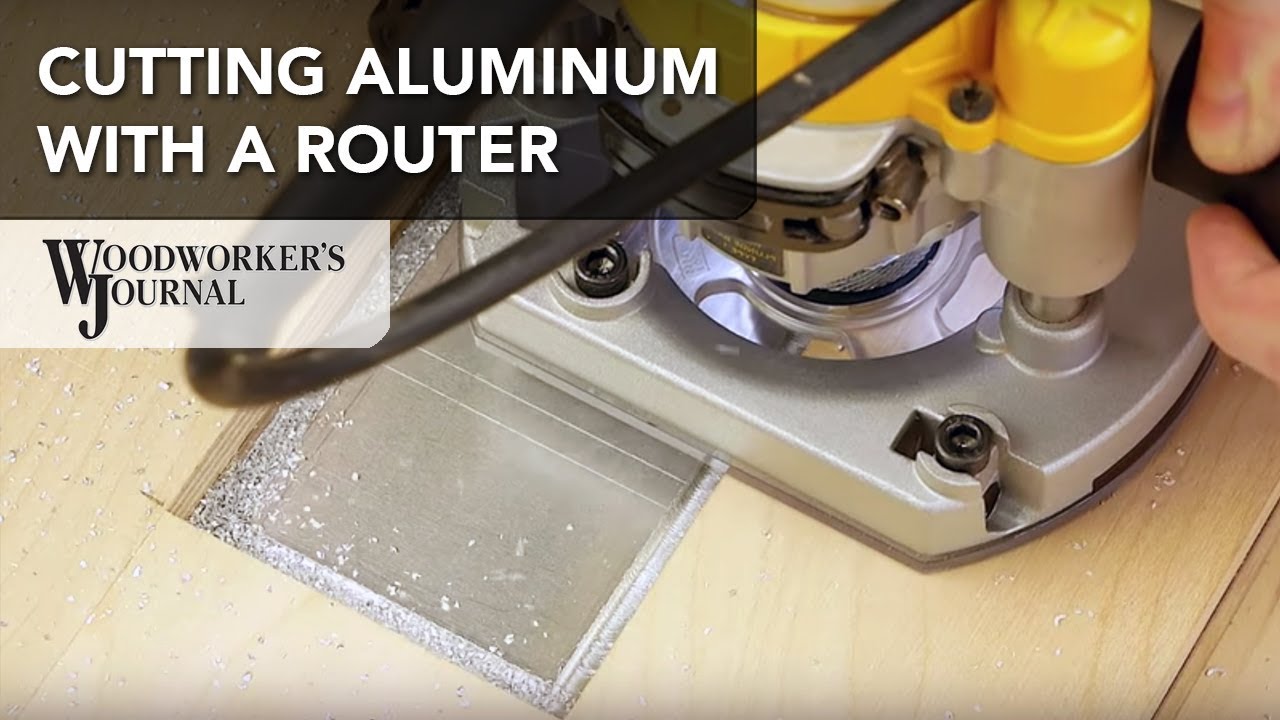

Wood routers are commonly used for shaping and cutting wood, but have you ever wondered if you can use wood router bits on aluminum? In this article, we will explore whether using wood router bits on aluminum is a viable option, discussing the benefits, challenges, and tips for achieving the best results.

Understanding the Compatibility: Wood Router Bits and Aluminum

Wood router bits are specifically designed for cutting and shaping wood. They are made of materials such as high-speed steel (HSS) or carbide, which are suitable for the hardness of wood. On the other hand, aluminum is a softer metal compared to wood and requires different cutting techniques.

While it may be possible to use wood router bits on aluminum, it is not recommended. Aluminum is a soft metal that can load up on the cutting edges of wood router bits, causing them to dull quickly and potentially damaging the bit. Additionally, the cutting angles designed for wood may not be optimized for efficient cutting of aluminum. Therefore, it is advisable to use router bits specifically designed for aluminum or other non-ferrous metals.

Benefits of Using Router Bits for Aluminum

Despite the challenges, there are some potential benefits to using router bits for aluminum:

- Cost-effective: If you already have wood router bits on hand, using them for light-duty aluminum projects can be a cost-effective solution.

- Convenience: Using wood router bits might be convenient if you don’t have access to specialized aluminum router bits.

While these benefits exist, it’s important to weigh them against the risks and limitations associated with using wood router bits on aluminum.

Challenges of Using Wood Router Bits on Aluminum

When using wood router bits on aluminum, you may encounter several challenges:

- Dulling of router bits: Aluminum is a relatively soft metal, causing it to load up and dull router bits quickly.

- Inefficient cutting: The cutting angles of wood router bits may not be optimized for cutting aluminum, resulting in inefficient and ineffective cutting.

- Reduced bit lifespan: Using wood router bits on aluminum can significantly reduce their lifespan, leading to frequent replacements and added costs in the long run.

- Poor finishes: Wood router bits may not provide the desired finishes on aluminum surfaces due to the difference in cutting geometries and speeds.

Considering these challenges, it is advisable to invest in router bits specifically designed for aluminum or other non-ferrous metals to achieve optimal results.

Tips for Using Wood Router Bits on Aluminum

If you still choose to use wood router bits on aluminum, here are some tips to improve your results:

- Choose the right bit material: Opt for router bits with carbide or titanium nitride (TiN) coatings for improved durability and performance.

- Run at lower speeds: Reduce the router speed and take light passes to prevent overheating and extend the lifespan of the router bits.

- Use lubrication: Applying a lubricant such as cutting oil or a lubricant stick can help reduce friction and prevent the aluminum chips from sticking to the router bit.

- Secure the workpiece: Ensure that the aluminum workpiece is securely clamped down to minimize vibrations and potential damage to the router bit.

- Consider using coolant: If you have access to a coolant system, using it while cutting aluminum can help dissipate heat and improve the overall cutting performance.

Using Wood Router Bits on Aluminum: The Verdict

While it is technically possible to use wood router bits on aluminum, it is not the recommended practice. The challenges, including rapid bit dulling, inefficient cutting, and limited finishes, make it more beneficial to invest in router bits specifically designed for cutting aluminum. By using the right tools for the job, you can achieve better results, prolong the lifespan of your router bits, and ensure safe and efficient cutting.

Conclusion

In this article, we explored the compatibility of wood router bits and aluminum. While using wood router bits on aluminum is possible, it is not recommended due to the challenges and limitations associated with the practice. We discussed the benefits, challenges, and tips for using wood router bits on aluminum, and concluded that investing in router bits designed for aluminum is the best approach for achieving optimal results. Remember to prioritize safety, efficiency, and the longevity of your tools when working with different materials.

“Can You Use Wood Router Bits on Aluminum?” – Key Takeaways

- Wood router bits are specifically designed for cutting and shaping wood materials.

- Using wood router bits on aluminum can cause damage to the bits and the material.

- Aluminum is a softer metal than wood and requires different cutting tools.

- Using the wrong tool can result in poor performance and potential safety hazards.

- It’s important to use the right router bits and tools for the specific material you’re working with.

Frequently Asked Questions

Welcome to our FAQ section where we will address some common queries related to using wood router bits on aluminum. If you’re wondering about the compatibility and effectiveness of using these bits, we’ve got you covered. Let’s dive into the questions:

1. Can I use wood router bits on aluminum?

While it is possible to use wood router bits on aluminum, it is not the ideal choice. Wood router bits are designed specifically for cutting and shaping wood, and they may not have the appropriate features to handle metal. The cutting angles, flutes, and materials used in wood router bits are optimized for wood, which has different properties than aluminum.

Using wood router bits on aluminum may result in poor performance, such as dulling the bit quickly or causing excessive chatter. It can also pose safety risks, as the bit may not cut smoothly or generate excessive heat. To achieve optimal results and ensure your safety, it is best to use router bits specifically designed for cutting aluminum.

2. What are the risks of using wood router bits on aluminum?

Using wood router bits on aluminum can pose several risks. The first risk is that the bit may quickly become dull due to the friction and heat generated while cutting metal. This can lead to an inefficient cutting process and poor results. Additionally, the cutting angles and flutes of wood router bits may not be suitable for efficiently cutting aluminum, resulting in rough edges and an overall unsatisfactory finish.

Furthermore, the lack of proper cooling mechanisms in wood router bits can cause excessive heat buildup when used on aluminum. This can not only damage the bit but can also create safety hazards. The heat can transfer to the material, causing warping and potential damage to your workpiece. To avoid these risks and achieve optimal results, it is recommended to use router bits specifically designed for cutting aluminum.

3. What type of router bits should I use for cutting aluminum?

For cutting aluminum, it is recommended to use router bits that are specifically designed for metalworking. These bits are typically made from carbide or high-speed steel, which are more durable and better suited for cutting metal than wood router bits. Look for router bits labeled as “aluminum cutting bits” or “metal cutting bits.”

Aluminum cutting bits often have special coatings, such as titanium nitride or other similar materials, to enhance the durability and longevity of the bit. They also feature appropriate cutting angles, flutes, and cooling mechanisms to ensure efficient and clean cuts. Using the right tool for the job will yield better results and help prolong the lifespan of your router bits.

4. Can I use a wood router with a plunge base for cutting aluminum?

While a wood router with a plunge base can technically be used for cutting aluminum, it is not the most suitable option. Plunge bases are primarily designed for making plunge cuts in wood, and they may not provide the necessary stability and control required for cutting metal.

When cutting aluminum, it is best to use a router specifically designed for metalworking. These routers often have features such as variable speed control, stronger motors, and more rigid bases, allowing for smoother and more precise cuts. Investing in a router specifically designed for cutting aluminum will ensure better results and a safer working experience.

5. How can I ensure clean and precise cuts when working with aluminum?

To achieve clean and precise cuts when working with aluminum, there are a few tips to keep in mind. Firstly, make sure to use the appropriate router bits specifically designed for cutting aluminum. These bits will have the necessary cutting angles and flutes to ensure clean and efficient cuts.

Additionally, using the appropriate cutting speed and feed rate is crucial. Aluminum requires slower cutting speeds compared to wood, as it conducts heat more effectively. Adjust your router’s speed accordingly to prevent overheating and achieve cleaner cuts. Lastly, proper clamping and securing of your workpiece will help minimize vibrations and ensure more accurate cuts. Taking these steps will help you achieve the desired results when working with aluminum.

Summary

So, can you use wood router bits on aluminum? Well, it’s not recommended.

Aluminum is a much softer material compared to wood, so wood router bits may not work effectively or produce clean cuts. It’s best to use router bits specifically designed for aluminum to achieve the desired results and ensure safety.