Can you use wood router bits on aluminum? If you’re curious about this, you’ve come to the right place! In this article, we’ll explore the compatibility of wood router bits with aluminum and whether they can be used interchangeably. So, let’s delve into the world of woodworking and metalworking to find out the answer!

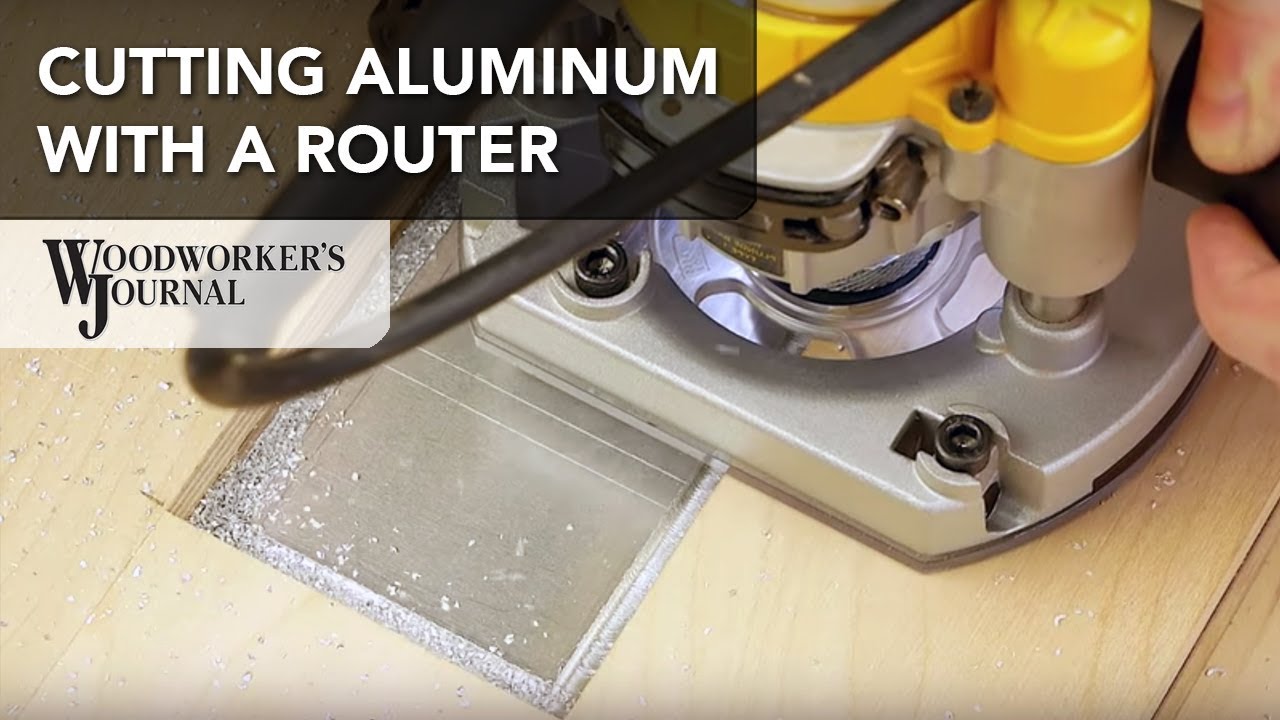

Wood routers are fantastic tools for shaping and cutting wood, but what about using them on aluminum? Many DIY enthusiasts wonder if they can save time and money by repurposing their wood router bits for metalworking projects. In the following paragraphs, we’ll uncover the facts and provide insights into the feasibility of using wood router bits on aluminum.

So, if you’re eager to know whether your wood router bits can tackle aluminum projects or if you need to invest in specific metalworking tools, keep reading! We’ll break down the considerations and provide you with the guidance you need to make informed decisions. Let’s get started on this exciting exploration together!

Wood router bits are designed specifically for woodworking projects and are not recommended for use on aluminum. Using wood router bits on aluminum can cause damage to the bits and may result in poor performance. Aluminum router bits, on the other hand, are specifically designed for cutting aluminum and will provide optimal results. It’s important to use the right tools for the job to ensure safety and efficiency.

Can You Use Wood Router Bits on Aluminum?

Wood router bits are commonly used for shaping and cutting wood, but can they be used on aluminum? This article will explore whether it is possible to use wood router bits on aluminum and discuss the potential risks, benefits, and tips for doing so.

Is It Possible to Use Wood Router Bits on Aluminum?

While wood router bits are designed specifically for cutting and shaping wood, they can also be used on aluminum with some precautions. However, it is important to note that using wood router bits on aluminum may result in less precise cuts and slower cutting speeds compared to using specialized metal cutting tools.

When using wood router bits on aluminum, it is crucial to choose the right type of bit and use proper techniques to minimize the risk of damage to the material and the tool itself. The hardness and density of aluminum are significantly different from wood, which means that wood router bits may not be as effective in cutting through aluminum as they are in cutting through wood.

Benefits of Using Wood Router Bits on Aluminum

Despite the challenges, there are some potential benefits to using wood router bits on aluminum. One advantage is cost-effectiveness, as wood router bits are generally less expensive than specialized metal cutting bits. If you already have wood router bits and need to make a few simple cuts on aluminum, using the existing tools can save you money.

Another benefit is versatility. Wood router bits come in a wide variety of shapes and sizes, allowing you to create intricate designs and profiles on aluminum. This versatility can be advantageous if you have unique projects that require both wood and aluminum cutting.

Furthermore, using wood router bits on aluminum can be a suitable option for hobbyists or DIY enthusiasts who may not require industrial-grade tooling for occasional small-scale projects. If you’re working on a small aluminum project and don’t have access to specialized metal cutting tools, using wood router bits can be a viable alternative.

Risks and Challenges of Using Wood Router Bits on Aluminum

Despite the potential benefits, there are significant risks and challenges associated with using wood router bits on aluminum. One primary risk is the potential for damage to the router bit and the material. Wood router bits are typically designed to handle the properties of wood, such as its lower density and lower heat generation.

Aluminum, on the other hand, is a much harder and denser material that can cause excessive strain on the wood router bit. This strain can lead to premature dulling, chipping, or even breaking of the router bit, which not only compromises the quality of the cut but can also pose safety hazards.

Additionally, using wood router bits on aluminum can result in less precise cuts. The ridges and edges of wood router bits may not provide the same level of accuracy as dedicated metal cutting tools. This can be problematic, especially if you require precise measurements and clean edges for your aluminum project.

Tips for Using Wood Router Bits on Aluminum

If you decide to use wood router bits on aluminum, here are some essential tips to follow:

- Choose router bits specifically designed for cutting aluminum or other metals. These bits will have a different cutting geometry and may feature specialized coatings to handle the higher heat and strain associated with metal cutting.

- Keep the cutting speed slow and steady to prevent excessive heat buildup that can damage the router bit and the aluminum.

- Use lubrication or cutting fluids to reduce friction and heat generation during the cutting process.

- Ensure your router is securely mounted and stable to minimize vibrations that can affect the precision of the cuts.

- Wear appropriate safety equipment, including goggles, gloves, and a dust mask, when working with aluminum and router bits to protect yourself from flying debris and metal particles.

- Regularly inspect the router bit for signs of wear or damage. Replace any worn or damaged bits immediately.

- Practice on scrap pieces of aluminum before working on your actual project to familiarize yourself with the behavior of the material and the limitations of the router bit.

Conclusion

While it is possible to use wood router bits on aluminum, it is important to be aware of the risks and challenges involved. Wood router bits may not provide the same level of precision or durability as specialized metal cutting tools. If your project requires high-quality cuts and precision, it is recommended to invest in dedicated aluminum cutting bits. However, if you’re working on smaller projects or have limited access to specialized tools, using wood router bits on aluminum can be a cost-effective alternative. Just remember to follow the recommended tips and precautions to ensure safety and minimize the risk of damage to the material and the tool.

Key Takeaways: Can You Use Wood Router Bits on Aluminum?

- Wood router bits are not specifically designed for cutting aluminum.

- Using wood router bits on aluminum may cause damage to the bits and result in poor cutting performance.

- Aluminum router bits have specialized geometry and cutting edges for efficient and clean cutting on aluminum.

- Using the correct tool for the material is important to achieve satisfactory results and ensure safety.

- It is recommended to use router bits specifically designed for cutting aluminum when working with the material.

Frequently Asked Questions

In this section, we will address some common questions related to using wood router bits on aluminum.

1. Can I use wood router bits on aluminum?

While wood router bits are specifically designed for woodworking projects, it is not recommended to use them on aluminum. The reason for this is that aluminum is a much softer material than wood, and wood router bits may not be able to handle the rigors of cutting through aluminum. Additionally, wood router bits have a different design and cutting angle compared to bits intended for working with metal. This means they may not be as efficient or effective when used on aluminum, leading to a poor-quality finish or even damage to the material.

If you need to work with aluminum, it is best to use router bits specifically designed for metalworking. These bits are typically made from materials such as carbide or high-speed steel and have a cutting design optimized for cutting through metal. Using the correct type of router bit ensures better performance, improved safety, and a higher-quality result.

2. What are the risks of using wood router bits on aluminum?

Using wood router bits on aluminum can present several risks. Since wood router bits are not designed to handle the harder and denser nature of aluminum, they may wear out quickly or become damaged during the cutting process. This can lead to a poor-quality finish or uneven cutting. Furthermore, the heat generated during the cutting process can cause the aluminum to warp or deform, resulting in an unsatisfactory result. Additionally, the cutting action of wood router bits may not be as precise on aluminum, leading to inaccurate cuts or even damage to the material.

Moreover, using wood router bits on aluminum can pose a safety risk. The bits may be more prone to breakage or dulling, which can lead to flying debris or accidents. It is always important to use the correct tools for the specific material you are working with to ensure safety, accuracy, and the best possible outcome.

3. Are there any specific router bits designed for cutting aluminum?

Yes, there are router bits specifically designed for cutting aluminum and other metals. These router bits are typically made from durable materials such as carbide or high-speed steel and have a cutting design optimized for metalworking. They are designed to handle the harder and denser nature of aluminum, ensuring better performance and longevity. Additionally, they have a suitable cutting angle and chip clearance to prevent clogging and ensure smooth cutting through metal. When working with aluminum, it is recommended to invest in router bits specifically designed for metalworking to achieve the best results.

4. What are the advantages of using router bits designed for aluminum?

There are several advantages to using router bits that are specifically designed for cutting aluminum. First and foremost, these bits are more durable and can withstand the rigors of cutting through metal. They are less likely to wear out quickly or become damaged, ensuring a longer lifespan and better performance. Additionally, router bits designed for aluminum have a cutting design and geometry optimized for metalworking, allowing for more accurate and efficient cutting. This leads to a higher-quality finish and reduces the risk of damaging the material. Furthermore, these bits often have coatings or surface treatments that enhance their performance and reduce friction and heat buildup during cutting, helping to prevent warping or deformations in the aluminum.

By using router bits specifically designed for aluminum, you can achieve better results, ensure safety, and prolong the lifespan of your tools.

5. Can I use wood router bits on softer metals like brass or copper?

While wood router bits are not designed for metalworking, they can sometimes be used on softer metals like brass or copper. These metals are relatively soft compared to aluminum and can be cut through more easily with wood router bits. However, it is still recommended to use router bits specifically designed for metalworking for the best results. Metalworking router bits are designed with the characteristics of different metals in mind, ensuring optimal cutting performance and longevity. They are less likely to wear out quickly or become damaged and can provide a higher-quality finish. Using the appropriate tools for the specific material you are working with always produces better results, both in terms of efficiency and safety.

Summary

Wood router bits are not recommended for use on aluminum because they are designed for different materials. Aluminum is a soft metal and requires specific tools to work with it effectively. The wrong bit can cause damage to the material or the router itself.

Using the right tools is important to ensure safety and achieve optimal results. If you need to work with aluminum, it is best to invest in router bits specifically made for metal. These bits have a different design and cutting edge angle that allows them to handle the properties of aluminum more effectively. This will help you achieve clean and precise cuts without compromising the integrity of the material. Always remember to prioritize safety and use the appropriate tools for the job at hand.