Do bandsaw blades stretch? That’s a question many woodworking enthusiasts like you may have pondered. Well, you’ve come to the right place for answers! In this article, we’re going to dive into the fascinating world of bandsaw blades and explore whether they have the ability to stretch or not. So, grab your tool belt, put on your safety goggles, and let’s get started on this exciting woodworking adventure!

Now, you might be wondering why we should even care if bandsaw blades stretch. After all, they’re just pieces of metal, right? Well, it turns out that bandsaw blades can experience some stretching over time, and this can affect their performance. Imagine if your trusty bandsaw blade suddenly became longer than it was initially designed to be. That wouldn’t be ideal, would it? So, it’s crucial to understand whether this phenomenon is real and how it can impact your woodworking projects.

Before we delve into the details of whether bandsaw blades stretch or not, let’s take a moment to appreciate the importance of these versatile tools. Bandsaws are a woodworker’s best friend when it comes to making precision cuts. With their continuous loop of teethed blades and their ability to cut through various materials with ease, bandsaws are a staple in workshops around the world. And that’s why it’s essential to understand everything about their blades, including the possibility of stretching. So, let’s embark on this journey together and uncover the truth behind bandsaw blade stretching!

Do Bandsaw Blades Stretch? The Truth Behind Blade Stretching

Are you a woodworking enthusiast who has recently delved into the world of bandsawing? If so, you may be curious about an age-old question: do bandsaw blades stretch? In this article, we will uncover the truth behind blade stretching and provide you with a comprehensive understanding of how it affects your woodworking projects. So, let’s dive right in and dispel the myths surrounding bandsaw blade stretching.

Bandsaw Blade Anatomy and Function

Before we can address the question of whether bandsaw blades stretch, it’s important to understand the anatomy and function of these cutting tools. Bandsaw blades are made up of a continuous loop of steel with teeth along one edge. They are welded or brazed together to form a closed loop, which is then affixed to the bandsaw machine. These blades are specifically designed for precision cutting in woodworking applications.

As the bandsaw machine is activated, the blade’s teeth engage with the material being cut, creating a shearing action. This powerful cutting motion is made possible by the tension applied to the blade, ensuring it remains taut and under pressure during the cutting process. While the tension keeps the bandsaw blade in place, it can affect its behavior and potentially lead to misconceptions about stretch.

Contrary to popular belief, bandsaw blades do not stretch in the traditional sense. Instead, they experience flex or deflection due to the tension applied to them. The blade’s behavior under tension, coupled with its flexibility, can create the illusion of stretching, especially when cutting dense or thick materials. However, this is an optical illusion rather than an actual stretching of the blade.

Factors Affecting Blade Behavior

Understanding the factors that influence a bandsaw blade’s behavior is vital in debunking the myth of stretching. Several key factors can contribute to the appearance of stretch or blade deflection when using a bandsaw machine:

1. Blade Tension:

Proper blade tension is essential for optimal cutting performance. Insufficient tension can lead to blade flutter or wavering, resulting in imprecise cuts. On the other hand, excessive tension can cause the blade to break or put unnecessary strain on the machine. Maintaining the correct tension is crucial to minimize any perceived stretching or blade flexion.

2. Blade Type:

The type of bandsaw blade being used can also impact its behavior. Different blade widths and tooth configurations are designed for specific cutting applications. Wider blades generally offer more stability and reduced deflection compared to narrower ones. Additionally, the tooth geometry, such as the number of teeth per inch (TPI) and tooth set, can affect the blade’s ability to cut smoothly and maintain its position.

3. Material being Cut:

The material being cut plays a significant role in how the bandsaw blade behaves. Dense and thick materials, such as hardwoods or metal, require greater force to cut through. This increased resistance can cause the blade to deflect or appear stretched, especially if the tension is not adequately set. On the other hand, softer materials like plywood or plastic may exhibit minimal blade deflection.

4. Feed Rate and Cutting Technique:

The speed at which the material is fed into the bandsaw, also known as the feed rate, can impact blade behavior as well. High feed rates or aggressive cutting techniques can exert more pressure on the blade, potentially causing it to deflect. Slower and controlled feed rates are generally recommended to minimize blade flexion and achieve cleaner cuts.

By understanding these factors and making the necessary adjustments, you can effectively manage blade deflection and achieve accurate and clean cuts with your bandsaw machine.

Busting Common Myths: Debunking Bandsaw Blade Stretching Misconceptions

Myth 1: Blades Stretch Over Time

One of the most prevailing misconceptions is that bandsaw blades stretch over time with prolonged use. However, as mentioned earlier, this is not the case. The appearance of stretching is typically due to other factors that influence blade behavior, such as tension, material being cut, or cutting technique. Regular tension adjustments and proper maintenance can help mitigate any perceived stretching issues.

Myth 2: Blade Stretching Causes Inaccurate Cuts

Another myth surrounding blade stretching is that it leads to inaccurate cuts. While blade deflection can impact cut quality, it is important to note that this is not solely caused by stretching. Factors like improper tension, incorrect feed rate, or worn-out blades can all contribute to inaccurate cuts. It is crucial to ensure proper blade setup, maintenance, and cutting techniques to achieve precise results.

Myth 3: Constant Blade Re-tensioning is Necessary

Some woodworkers believe that they need to re-tension their bandsaw blades frequently to counteract stretching. However, excessive blade re-tensioning can lead to unnecessary stress on the machine and potentially weaken the blade. If your blade consistently requires re-tensioning during the cutting process, it may be an indication of other underlying issues, such as improper blade setup or worn-out blade guides. Addressing these issues will help minimize the need for constant re-tensioning.

Bandsaw Blade Maintenance and Tips

Proper Blade Tensioning

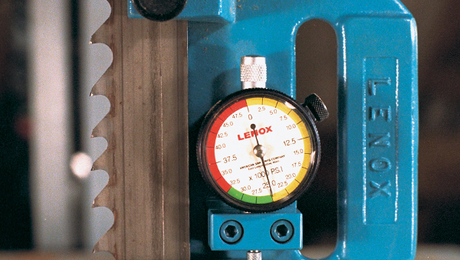

Ensuring the correct blade tension is crucial for optimal performance. Follow the manufacturer’s guidelines and use tension gauges to achieve the recommended tension for your specific bandsaw blade. Monitor the tension regularly and adjust as needed during prolonged cutting sessions.

Regular Blade Inspection

Inspect your bandsaw blade regularly for signs of wear, damaged teeth, or any abnormalities. Replace any worn-out or damaged blades promptly to maintain cutting accuracy and prevent accidents.

Blade Selection

Choose the appropriate blade for your specific cutting application. Consider the material being cut, desired cut quality, and the recommended blade specifications for your bandsaw machine. Using the right blade will help minimize deflection and ensure clean and accurate cuts.

Feed Rate and Cutting Technique

Practice controlled and steady feed rates when using the bandsaw. Avoid forcing the material through the blade, as this can cause excessive deflection and potential blade breakage. Develop good cutting techniques to achieve optimal results.

Blade Cooling and Lubrication

Keep your bandsaw blade cool and lubricated to prevent overheating and premature wear. Use appropriate cutting fluids or lubricants, depending on the material being cut, to prolong blade life and maintain cutting performance.

Frequent Blade Cleaning

Remove any sawdust, resin, or buildup from the blade to prevent blade drag and potential deflection. Clean the blade after each use and inspect it for any residue that may affect its performance.

Proper Storage

When not in use, store your bandsaw blades properly to prevent damage and maintain their cutting effectiveness. Coil the blades neatly or use blade storage solutions to avoid kinks, bends, or accidental cuts.

By following these maintenance tips and debunking the misconceptions surrounding bandsaw blade stretching, you can optimize your cutting experience and achieve precise and accurate results in your woodworking projects.

Conclusion

Bandsaw blades do not stretch in the traditional sense, despite common misconceptions. Their behavior is influenced by factors such as tension, material being cut, and cutting techniques. By understanding these factors, practicing proper maintenance, and selecting the right blades for your specific applications, you can minimize blade deflection and achieve accurate and clean cuts with your bandsaw machine. Remember to maintain the recommended blade tension, inspect your blades regularly, and establish good cutting techniques for optimal results. Happy woodworking!

Key Takeaways – Do Bandsaw Blades Stretch?

- Bandsaw blades can stretch over time due to continuous use and tension.

- Stretching of bandsaw blades can affect the accuracy of cuts and lead to poor performance.

- Regular maintenance and tension adjustment can help minimize the stretching of bandsaw blades.

- Using proper cutting techniques and avoiding excessive feed rate can also prevent blade stretching.

- Replacing worn-out or damaged bandsaw blades can enhance cutting efficiency and accuracy.

Frequently Asked Questions

Blades for bandsaws are an essential component for any woodworking project. However, there has been some confusion around whether bandsaw blades can stretch over time. In this section, we address some common questions related to the stretching of bandsaw blades.

1. What causes bandsaw blades to stretch?

Bandsaw blades do not inherently stretch. However, during the cutting process, the intense heat generated can cause the blade to expand temporarily. This expansion can be considered as “stretching” in a sense, but it is a reversible process. Once the blade cools down, it returns to its original size and shape.

It’s worth noting that poor tensioning or incorrect installation of the blade can result in premature wear and distortion, giving the appearance of stretching. Proper maintenance and regular adjustment of the blade tension can help prevent any such issues.

2. Can bandsaw blades permanently stretch?

No, bandsaw blades cannot permanently stretch. These blades are designed to withstand the stresses of cutting and are made from materials known for their durability. However, over time and with continued use, bandsaw blades can wear out, leading to a loss of tension and possibly affecting the performance of the cuts.

To prolong the life of your bandsaw blades, it is crucial to follow proper maintenance procedures, such as regularly cleaning and lubricating the blade, checking and adjusting the tension, and replacing worn-out blades as needed. By doing so, you can maintain the accuracy and efficiency of your bandsaw cuts.

3. How can I prevent my bandsaw blades from stretching?

While bandsaw blades do not stretch, improper tensioning can lead to premature wear and distortion, affecting the performance of the cuts. To prevent issues related to tensioning:

1. Always follow the manufacturer’s guidelines for tensioning the blade.

2. Regularly check the tension of the blade using a tension gauge.

3. Make sure the blade is properly installed, with the teeth facing in the correct direction.

4. Avoid excessive feed rates and feed pressure during cutting.

By following these guidelines, you can ensure that your bandsaw blades maintain the proper tension and perform optimally for a longer duration.

4. How often should I replace bandsaw blades?

The frequency of blade replacement depends on several factors, including the type of material being cut, the intensity of usage, and the condition of the blade. As a general rule, it is recommended to inspect your bandsaw blade regularly for signs of wear, such as dull teeth, cracks, or excessive vibration during cutting.

If you notice any of these signs or experience a decrease in the quality of your cuts, it may be time to replace the blade. Additionally, incorporating regular blade maintenance procedures, as mentioned earlier, can help prolong the lifespan of your bandsaw blades.

5. Can a stretched blade be restored to its original tension?

If the “stretching” of a blade is due to temporary expansion caused by heat during cutting, the blade will naturally contract as it cools down. This means it will return to its original size and shape without the need for any restoration. However, if the blade has been permanently distorted or its tension has been compromised due to poor maintenance or wear, it may not be possible to restore it to its original tension.

In such cases, it is usually best to replace the blade to ensure accurate cuts and optimal performance. This is why regular inspection and maintenance of bandsaw blades are crucial to prevent any issues that may lead to permanent stretching or distortion.

Summary

Bandsaw blades can stretch due to heat and tension, causing inaccurate cuts.

To prevent stretch, choose the right blade size, use proper tension, and avoid excessive heat.