When it comes to using a drill press, one question often comes up: do drill presses need to be bolted to the floor? Well, I’m here to shed some light on this common query! Let’s dive in and explore the ins and outs of securing a drill press.

Now, you might be wondering why anyone would even consider bolting down a drill press. After all, isn’t it heavy enough to stay in place? Well, here’s the thing: bolting a drill press to the floor can provide extra stability and prevent any unwanted movement during operation.

But hey, before we go into further detail, let me reassure you that there’s no right or wrong answer here. It really depends on the situation and your personal preferences. So, let’s explore the reasons why some people choose to bolt their drill presses down and why others opt not to.

Ensure stability and safety with your drill press by bolting it to the floor. While not always necessary, securing the drill press provides added stability, especially when working with larger workpieces or performing heavy drilling tasks. By bolting the drill press, you minimize vibrations and movement, allowing for more accurate and precise drilling. Additionally, it reduces the risk of the drill press tipping over during operation. Consider bolting your drill press to the floor for optimal performance and safety.

Do Drill Presses Need to be Bolted to the Floor?

Welcome to this comprehensive guide on drill presses and whether they need to be bolted to the floor. If you are an avid DIY enthusiast or a professional woodworker, you have probably wondered about the importance of securing your drill press. In this article, we will explore the benefits of bolting a drill press, considerations for portable drill presses, and alternative methods of stabilization. Whether you are a seasoned pro or just starting out, this information will help you make an informed decision for your workshop.

Benefits of Bolting a Drill Press

When it comes to heavy-duty drilling, a securely bolted drill press offers numerous advantages. Firstly, stability is crucial for precision work. Bolting a drill press to the floor ensures minimal vibration, making it easier to drill accurate holes with greater control. Additionally, a bolted drill press eliminates the risk of tipping over, especially when working with larger workpieces or applying significant force. This safety feature not only protects the operator but also prevents damage to the workpiece and the drill press itself.

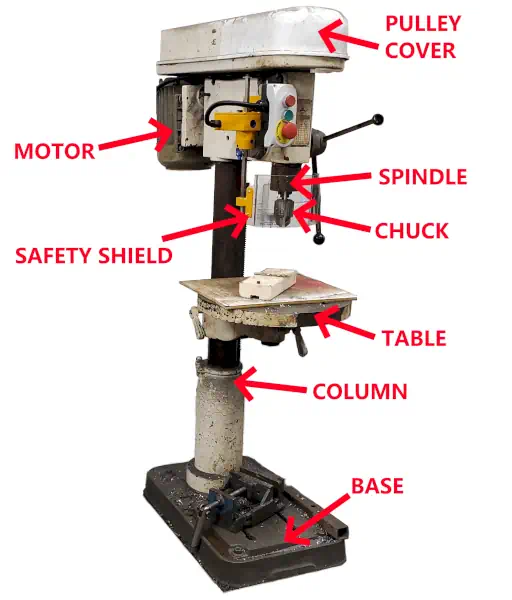

Bolting a drill press also enhances the overall durability of the machine. By reducing movement and preventing shifts during operation, it helps maintain the alignment of vital components, such as the chuck and the drill bit. This prolongs the lifespan of the drill press and ensures consistent performance, saving you money on repairs and replacements in the long run. Moreover, a secured drill press reduces the strain on the motor, minimizing the risk of overheating and increasing its efficiency.

In conclusion, bolting a drill press to the floor provides enhanced stability, safety, and longevity. It is a worthwhile investment for those who prioritize accuracy and reliability in their drilling projects.

Considerations for Portable Drill Presses

While bolting a drill press to the floor has its advantages, it may not be practical or necessary for all situations, particularly with portable drill presses. These versatile machines provide the flexibility to bring the drill press to the workpiece rather than vice versa, making them popular among contractors, renovators, and those with limited workshop space. However, there are still considerations to keep in mind when using portable drill presses.

One effective method of stabilizing a portable drill press is by using clamps or mounting it onto a sturdy workbench. This provides a secure base and reduces vibrations during operation. Another option is to add weight to the base of the drill press, either by using weights or securing it with sandbags. This can help minimize movement and enhance stability. However, it is important to ensure that the base remains balanced to prevent any wobbling or tipping.

It’s worth noting that while portable drill presses offer convenience, they may not provide the same level of stability and accuracy as their floor-mounted counterparts. Depending on the nature of your work and the precision required, you may need to weigh the benefits of portability against the advantages of a stationary drill press. Consider the types of projects you regularly undertake, the available space in your workshop, and your desired level of precision before making a decision.

Alternative Methods of Stabilization

If bolting a drill press or using a portable drill press with additional stabilizing measures are not viable options for you, there are alternative methods that can enhance stability. One such method is to use anti-vibration pads or mats placed under the base of the drill press. These pads absorb vibrations and reduce movement, creating a more stable working surface.

Another option is to invest in a freestanding drill press stand. These stands are designed to provide a stable base for your drill press without the need for drilling into the floor. They often feature adjustable height and clamping mechanisms to secure the drill press in place. While they may not offer the same level of stability as a floor-mounted drill press, they can be a suitable solution for those who require more stability than a portable drill press can provide.

When considering alternative methods, it is important to prioritize safety and stability. Always ensure that whatever method you choose provides an adequate level of support to prevent accidents or damage to the drill press or workpiece.

Drill Press Safety Tips

Now that we have discussed the importance of bolting drill presses and alternative methods of stabilization, it’s crucial to also highlight some essential safety tips when using a drill press. These guidelines will help you operate your drill press efficiently and minimize the risk of accidents or injuries.

1. Wear Protective Gear

Always wear appropriate personal protective equipment when using a drill press. This includes safety glasses to protect your eyes from flying debris, ear protection to minimize noise exposure, and gloves to provide a better grip and protect your hands. It is also wise to wear a dust mask when working with materials that generate dust or fine particles.

2. Secure Workpieces Properly

Ensure that the workpiece is securely clamped to the drill press table before starting. This prevents any movement or shifting and reduces the risk of accidents. Additionally, use a center punch to create a small indentation where you plan to drill. This helps guide the drill bit and prevents it from wandering, ensuring more accurate drilling.

3. Adjust the Depth Stop and Speed

Before drilling, set the depth stop to control the depth of the hole. This prevents drilling too deep and damaging the workpiece or drill bit. Also, choose the appropriate speed setting for the material being drilled. Higher speeds are suitable for metal, while lower speeds are suitable for wood and other softer materials. Refer to the manufacturer’s instructions for speed recommendations.

4. Avoid Loose Clothing and Jewelry

Remove any loose clothing, jewelry, or accessories that could get caught in the rotating parts of the drill press. These can pose a serious safety hazard and increase the risk of accidents.

5. Keep a Clean and Organized Workspace

Clear away any clutter and debris from your work area to maintain a clean and organized workspace. This reduces the risk of accidents caused by tripping or slipping. Additionally, ensure that the drill press and its surrounding area are well-lit for better visibility.

6. Familiarize Yourself with the Drill Press

Read the instruction manual carefully and familiarize yourself with the specific features and functions of your drill press. Understanding how to operate the various controls, such as the on/off switch, speed adjustment, and depth stop, ensures safe and efficient use.

7. Regular Maintenance and Inspection

Perform regular maintenance tasks, such as cleaning, lubricating, and replacing worn-out parts, to keep your drill press in optimal condition. Additionally, inspect the drill press for any damage or defects before each use. If you notice any issues, address them promptly to prevent further damage or accidents.

By following these safety tips, you can create a safer working environment and enjoy the benefits of using a drill press with peace of mind.

Key Takeaways: Do Drill Presses Need to Be Bolted to the Floor?

When it comes to drill presses, bolting them to the floor is generally recommended for stability and safety.

Bolting the drill press to the floor prevents it from moving or tipping over while in use.

Having a bolted drill press also reduces vibrations, resulting in a more accurate and precise drilling experience.

However, certain portable or benchtop drill presses may not require bolting to the floor as they are designed to be used on a workbench or tabletop.

Ultimately, it is important to consult the manufacturer’s instructions to determine if your specific drill press needs to be bolted to the floor.

Frequently Asked Questions

Drill presses are a versatile tool used for various woodworking and metalworking tasks. Many people wonder if they need to bolt their drill presses to the floor for stability and safety. Here are some common questions that people ask about this topic:

1. Can I use a drill press without bolting it to the floor?

Absolutely! A drill press can be used without being bolted to the floor. Most drill presses come with a sturdy base that provides stability during operation. With proper setup and adjustment, you can safely use your drill press on any sturdy workbench or surface. However, if you frequently work with large or heavy materials, bolting the drill press to the floor can provide extra stability.

Remember, bolting a drill press is not a requirement, but an option to enhance stability. It ultimately depends on the type of projects you work on and your personal preference.

2. What are the benefits of bolting a drill press to the floor?

Bolting a drill press to the floor offers several benefits. First, it provides maximum stability, especially when working with heavy materials or performing drilling operations that require high precision. It minimizes vibrations, ensuring the accuracy of your drilling.

Additionally, bolting a drill press to the floor reduces the risk of tipping or wobbling during operation. This can be especially important when drilling at high speeds or dealing with large workpieces. It also frees up valuable space on your workbench, allowing you to work more efficiently.

3. How do I bolt a drill press to the floor?

Bolting a drill press to the floor is a straightforward process. Start by choosing a suitable location where you plan to permanently place your drill press. Mark the drill holes on the base or stand of the drill press and make sure they align with the floor surface.

Next, use a suitable drill and drill bit to create holes on the marked spots. Insert appropriate anchor bolts into the holes and tighten them securely. Finally, place your drill press over the anchor bolts, ensuring it is level, and attach the drill press to the bolts using the provided nuts and washers.

4. Can I still move a drill press if it is bolted to the floor?

Yes, you can still move a drill press even if it is bolted to the floor. Most drill presses are designed to be easily detachable from the bolted base. Loosen the nuts that secure the drill press to the bolts, and you can lift the drill press off the floor-mounted base.

This feature allows you to move your drill press to different locations or store it when not in use. Just ensure that the floor-mounted base remains securely attached to the floor, so you can easily reattach the drill press when needed.

5. Are there alternative methods of enhancing stability without bolting a drill press?

Absolutely! If you prefer not to bolt your drill press to the floor, there are alternative methods to enhance stability. One option is to use a heavy-duty workbench or platform specifically designed for drill press use. These provide a solid and stable surface that minimizes vibrations.

Another option is to use clamps or bench vices to secure the drill press to your workbench. This will help prevent movement during operation. Additionally, placing your drill press on a non-slip mat can also provide some stability by reducing vibrations.

Summary

When it comes to drill presses, you don’t always have to bolt them to the floor. It largely depends on the size and power of the machine. Smaller or benchtop drill presses can usually be used without being bolted down. However, larger, more powerful drill presses are recommended to be bolted to the floor for stability and safety.

Bolting a drill press to the floor helps prevent it from moving or tipping over during operation, which can be dangerous. It also provides added stability, allowing you to work with more precision and accuracy. So, while it may not be necessary for all drill presses, bolting them down is a good idea if you have a larger, more powerful machine.