Do lathes need guards? Let’s dive into this question together and explore the importance of guarding these powerful machines. You might be wondering why we’re talking about lathes and guards—well, it’s because safety is a top priority in any workshop!

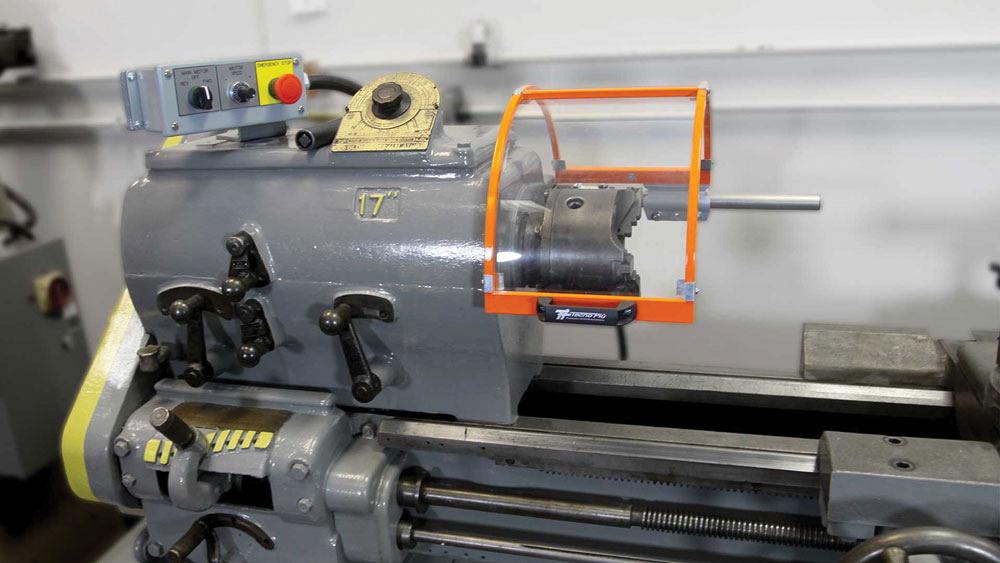

So, why does a lathe need a guard? Guards play a crucial role in protecting us from potential hazards while operating lathes. They act as a shield, keeping us safe from flying chips, rotating parts, and accidental contact. But how exactly do they work, and what types of guards are there? Let’s find out!

In this article, we’ll explore the different types of guards you can find on lathes and the safety benefits they provide. We’ll discuss chuck guards, splash guards, and more, all aimed at ensuring a secure and enjoyable lathe experience. So, grab your safety goggles, and let’s get started on this journey of discovery!

Do Lathes Need Guards? – Ensuring Safety in the Workshop

Welcome to our comprehensive guide on the importance of guards for lathes. In this article, we will explore the various aspects of lathe safety and discuss whether or not lathes need guards for optimal protection. Whether you’re an experienced machinist or just starting out, understanding the significance of proper guarding is crucial for maintaining a safe working environment. Let’s delve into the topic and shed light on the importance of guards in the world of lathes.

Understanding the Function of Lathe Guards

When it comes to woodworking and metalworking, lathes play a significant role in shaping and creating various objects. However, it is important to recognize the potential hazards associated with operating these machines. Lathe guards serve as a protective barrier, preventing operators from coming into direct contact with the spinning workpiece or rotating parts of the lathe. They are designed to safeguard machinists from flying debris, accidental contact with the rotating parts, and the risks of entanglement or entrapment.

The Benefits of Having Guards on Lathes

There are several notable benefits to having guards on lathes:

- Enhanced Safety: Guards serve as a physical barrier between the operator and the rotating components, minimizing the risk of accidents and injuries. By containing debris and preventing contact with moving parts, guards significantly reduce the chances of potential harm.

- Compliance with Safety Standards: Many safety regulatory bodies require the use of guards on lathes to meet safety standards. Ensuring compliance is not only a legal obligation but also an ethical responsibility.

- Protection against Debris: Guards create a shield that prevents wood chips, metal shards, and other debris from being projected towards the operator. This reduces the risk of eye injuries, lacerations, and other potential harm caused by flying objects.

When Guards Might Not Be Necessary

While the benefits of guards on lathes are undeniable, there are situations where their use may not be necessary. For instance, when working with smaller workpieces or certain turning operations, guards could impede visibility and hinder efficiency. However, it is important to note that these situations are exceptions, and the use of guards should be prioritized in most lathe operations.

The Importance of Proper Placement and Maintenance of Lathe Guards

Ensuring that lathe guards are properly placed and well-maintained is essential for their efficacy. Improperly installed or damaged guards can be ineffective and compromise operator safety. Here are a few key considerations:

Proper Placement:

The guards should be positioned in a way that adequately covers the rotating parts and work area. They should not obstruct visibility or hinder the operator’s ability to perform tasks. It’s crucial to follow the manufacturer’s guidelines for installation and placement to ensure maximum protection.

Regular Maintenance:

Guards should be regularly inspected to ensure they are secure and free from damage. Any signs of wear, cracks, or breakage should be addressed immediately. Proper maintenance also involves keeping the guards clean and clear of debris to maintain visibility and functionality.

Training and Education:

Alongside the use of guards, proper training and education play a vital role in promoting lathe safety. Operators should receive comprehensive training on the proper use of lathes, including the importance of guards, safe work practices, and emergency procedures. Ongoing education and regular refresher courses are valuable for maintaining a strong safety culture.

Common Myths About Lathe Guards

As with any safety measure, there can be misconceptions or myths surrounding the use of guards on lathes. Let’s debunk some of the common myths:

Myth 1: Guards Impede Productivity

While it’s true that guards can sometimes affect visibility or require adjustments, they are designed to enhance safety rather than hinder productivity. With proper training and practice, operators can work efficiently and effectively while adhering to safety protocols.

Myth 2: Experienced Operators Don’t Need Guards

No matter how experienced an operator is, accidents and incidents can still occur. Guards provide an extra layer of protection and help mitigate the risks involved in lathe operations. Every machinist, regardless of their skill level, should prioritize safety by using guards.

Myth 3: Guards Are Only Necessary for High-Speed Lathes

While high-speed lathes may pose additional risks due to the increased velocity of the rotating parts, guards are essential for all types of lathes. Even at lower speeds, accidents can happen. It is important to prioritize safety at all times, regardless of the speed of the lathe.

Conclusion

In conclusion, the use of guards on lathes is crucial for maintaining a safe working environment in workshops. They provide essential protection against accidents, injuries, and flying debris. While there may be certain exceptions where guards are not necessary, it is important to prioritize safety by using guards in most lathe operations. Proper placement, regular maintenance, and comprehensive training are key factors in ensuring the effectiveness and efficacy of guards. Remember, when it comes to lathe safety, prevention is always better than cure, and guards play a vital role in preventing potential harm.

Key Takeaways – Do Lathes Need Guards?

- Lathes are powerful machines used to shape wood, metal, and other materials.

- Guards on lathes are crucial for safety, preventing accidents and injuries.

- Guards protect operators from flying debris and rotating parts.

- Without guards, the risk of finger and hand injuries increases significantly.

- OSHA regulations require lathes to have guards in place for operator protection.

Frequently Asked Questions

Here are some common questions related to the use of guards on lathes:

1. Why are guards important when using a lathe?

Guards play a crucial role in ensuring safety when using a lathe. They act as protective barriers, preventing accidental contact with the rotating parts of the machine. The moving components of a lathe, such as the chuck, spindle, and cutting tools, can cause serious injuries if not properly guarded. By installing guards, the risk of accidents, such as entanglement or flying debris, is significantly reduced.

Moreover, guards also serve as a deterrent, discouraging operators from placing their hands or other objects near the rotating parts. They act as a visual reminder of the potential dangers involved, promoting responsible and cautious behavior while operating the lathe.

2. Can’t I just remove the guards for better visibility and control?

While it might seem tempting to remove guards for better visibility and control while using a lathe, it is highly discouraged. Guards are not installed without reason; they are designed to protect the operator from potential hazards. Removing them can expose operators to a higher risk of accidents, including severe injuries.

Modern lathes are typically equipped with transparent or adjustable guards that provide adequate visibility while still offering protection. It is essential to understand that the benefits of improved visibility do not outweigh the risks associated with operating the lathe without proper guards. Always ensure that the guards are correctly installed and in good working condition before using the lathe.

3. Are guards required by law when working with lathes?

Yes, in most jurisdictions, guards are legally mandated when operating lathes. Occupational safety regulations prioritize protecting workers from potential hazards, and the use of guards is a fundamental requirement. By implementing guard regulations, authorities aim to minimize the risk of work-related injuries and ensure a safe working environment.

It is essential to familiarize yourself with the specific regulations governing your area to ensure compliance. Ignoring or neglecting the use of guards can result in penalties, fines, or even legal consequences. Prioritizing safety by using guards not only safeguards your well-being but also demonstrates your commitment to maintaining a safe workplace.

4. Do guards hinder productivity when using a lathe?

Contrary to popular belief, guards do not have to hinder productivity when using a lathe. Modern lathe designs incorporate guards that strike a balance between safety and efficiency. These guards are designed to allow easy access to the working area while still providing protection from potential hazards.

Furthermore, safeguarding machinery is part of responsible operational practices. When operators feel safe and secure, they can focus better on their tasks, leading to increased efficiency. By preventing accidents and injuries, guards contribute to uninterrupted workflow and minimize costly downtime caused by avoidable mishaps.

5. Can guards be retrofitted onto older lathe models?

Yes, guards can often be retrofitted onto older lathe models. There are companies that specialize in creating customized guards for various machinery, including lathes. Retrofitting guards onto older machines ensures compliance with safety standards and minimizes risks.

When considering retrofitting guards, it is crucial to consult with professionals who can assess the specific machine and recommend suitable options. They will ensure that the retrofitted guards are appropriately designed, installed, and function as intended, offering optimal protection for operators.

Summary

Lathes are powerful machines used to shape and cut materials like wood and metal. It is important to have guards on lathes to keep operators safe. Guards help prevent accidents and injuries by blocking access to dangerous moving parts. They act as a barrier between the operator and the rotating chuck or blade, reducing the risk of accidents like finger or hand injuries. Without guards, operators could accidentally come into contact with the spinning parts, leading to serious harm. So, it is crucial to always use guards when operating a lathe.

Additionally, guards also help contain any debris or chips that may be generated during the machining process. This not only protects the operator but also prevents damage to the surrounding area or other equipment. By keeping the workspace clean and free from flying debris, guards contribute to a safer and more efficient working environment. Therefore, it is not only recommended but necessary to have guards on lathes to ensure the well-being of operators and maintain a safe workplace.