Have you ever wondered why it’s important to avoid drilling into the drill press table? Well, let me tell you!

You see, the drill press table is an essential part of the machine. It provides a stable and flat surface for your workpiece, giving you accuracy and control while drilling. So, drilling into the table can cause serious damage and compromise the functionality of the drill press.

But why is it such a big deal? Well, think of it like this: imagine using a chopping board with a big hole in the middle. It wouldn’t be very effective, right? The same principle applies to the drill press table. If you drill into it, you’re creating an uneven surface that can lead to wobbling, instability, and inaccurate drilling.

So, if you want to maintain the efficiency and precision of your drill press, remember this rule—do not drill into the drill press table! Trust me, your projects will turn out much better when you follow this simple yet crucial guideline.

1. Measure and mark your drilling area on the workpiece.

2. Place a sacrificial board or clamp a scrap piece to the table to protect it.

3. Adjust the drilling depth on the press.

4. Align the drilling bit with the marked spot on your workpiece.

5. Hold the workpiece securely and start drilling slowly.

6. Regularly check the depth to prevent drilling through the table.

7. Use a drill stop or tape to limit the drilling depth if needed.

Why You Should Never Drill into the Drill Press Table

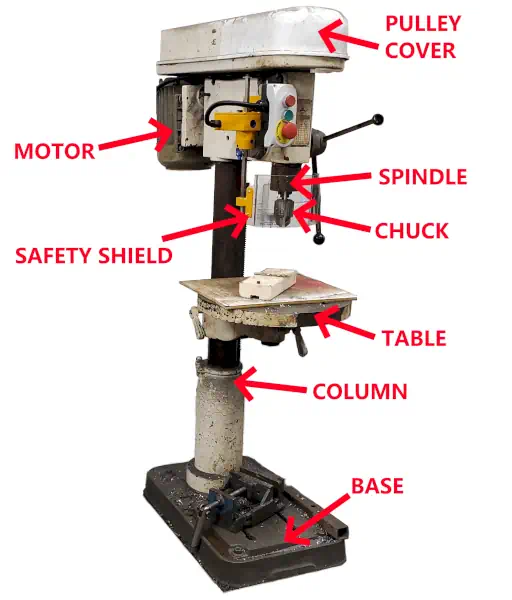

Introduction: The drill press is a powerful and versatile tool that is essential for any woodworking or metalworking project. However, it is important to understand that the drill press table is not meant to be drilled into. In this article, we will explore the reasons why you should avoid drilling into your drill press table and offer alternative solutions to ensure the longevity and functionality of your equipment.

Reasons to Avoid Drilling into the Drill Press Table

1. Maintain the Stability and Accuracy of the Drill Press:

Drilling into the drill press table can compromise the stability and accuracy of the tool. The table is designed to provide a flat and level surface for your workpiece, ensuring precise and consistent drilling. When you drill into the table, it can create uneven surfaces, resulting in inaccurate drilling depths and angles. This can lead to poor-quality work and decreased productivity.

Additionally, drilling into the table can cause it to become unstable, creating a safety hazard. The table’s stability is essential for preventing the drill bit from wandering or slipping during operation, which can result in damaged workpieces or injuries. By avoiding drilling into the drill press table, you can maintain its stability and accuracy, ensuring better results and a safer working environment.

2. Protect the Table Surface and Extend Its Lifespan:

The surface of the drill press table is often made of a durable material, such as cast iron or steel, which is designed to withstand the forces exerted during drilling operations. However, drilling into the table can cause significant damage to its surface, including scratches, dents, and holes. This not only compromises the flatness and levelness of the table but also reduces its lifespan.

By avoiding drilling into the table, you can protect its surface and extend its lifespan. This will save you money in the long run by avoiding the need for premature table replacements. To protect the table surface during drilling operations, consider using sacrificial materials, such as plywood or sacrificial drill press tables, which can be easily replaced when they become damaged.

3. Preserve the Versatility of the Drill Press:

The drill press is a versatile tool that can be used for a wide range of applications, including drilling, tapping, reaming, and more. However, drilling into the table can limit the versatility of the tool. The holes drilled into the table will restrict the positioning of workpieces, making it challenging to perform certain operations that require precise alignment.

To preserve the versatility of the drill press, it is important to avoid drilling into the table. Instead, utilize accessories such as drill press vises, clamps, and hold-downs to secure workpieces, allowing for greater freedom of movement and flexibility during operations. Additionally, adjustable fences and stops can be used to accurately position workpieces without the need for drilling into the table.

Alternative Solutions for Drilling on a Drill Press

1. Drill Press Vise:

A drill press vise is an essential accessory that securely holds workpieces in place during drilling operations. It features adjustable jaws that can be tightened around the workpiece, ensuring stability and accuracy. By using a drill press vise, you can perform drilling operations without the need to drill into the table, preserving its integrity and functionality.

2. Sacrificial Materials:

When drilling materials that may damage the drill press table surface, such as metal or materials with rough surfaces, it is advisable to use sacrificial materials. Place a sacrificial material, such as plywood or a sacrificial drill press table, on top of the existing table. This sacrificial material will act as a protective layer, preventing any damage to the table surface while allowing you to drill into the workpiece.

3. Adjustable Fences and Stops:

Adjustable fences and stops are useful accessories for accurately positioning workpieces during drilling operations. They can be adjusted to provide a guide for the workpiece, ensuring precise alignment without the need to drill into the table surface. By utilizing adjustable fences and stops, you can maintain the integrity of the drill press table while achieving accurate and consistent drilling results.

Conclusion

Drilling into the drill press table can have negative consequences for the stability, accuracy, and longevity of the tool. By avoiding this practice and utilizing alternative solutions such as drill press vises, sacrificial materials, and adjustable fences and stops, you can maintain the functionality and versatility of your drill press. Remember, it’s essential to prioritize the preservation of your equipment to ensure optimal performance and safety in your woodworking or metalworking projects.

Key Takeaways: Do Not Drill Into the Drill Press Table?

- Drilling into the drill press table can damage the table and affect its stability.

- It is important to use clamps or a vise to secure your workpiece before drilling.

- Always adjust the height and position of the drill press table to avoid drilling into it accidentally.

- Consider using a sacrificial board or a drill press table insert to protect the table surface.

- Regularly inspect the drill press table for any damage, cracks, or defects to ensure safe and accurate drilling.

Frequently Asked Questions

Welcome to our FAQ section where we address your concerns about drilling and the drill press table! Here, we provide answers to common questions related to the topic “do not drill into the drill press table?”. Read on to learn more:

1. Can I use my drill press table as a surface for drilling?

No, it is not recommended to use the drill press table as a surface for drilling. The drill press table is designed to support and guide the drill bit during operation, providing stability and accuracy. Drilling into the table can damage it, resulting in decreased performance and potential safety risks. It’s best to use the drill press table for its intended purpose, which is to support your workpiece and guide the drill bit.

2. What are the risks of drilling into the drill press table?

Drilling into the drill press table can cause various risks and issues. Firstly, the table’s surface may become uneven, affecting the accuracy of your drilling operations. The drilled holes can compromise the stability and structural integrity of the table, leading to wobbling or vibrations during use. Additionally, damage to the table can result in decreased lifespan and functionality. Lastly, drilling into the table may affect its warranty and void any manufacturer guarantees. It’s crucial to avoid drilling into the drill press table to maintain its performance and safety.

3. How can I prevent drilling into the drill press table?

There are a few precautions you can take to prevent accidentally drilling into the drill press table. First, always double-check the position of your workpiece and the drill bit before starting the drilling operation. Use a scrap piece of material underneath your workpiece to avoid direct contact with the table’s surface. Additionally, consider using a sacrificial insert or sacrificial board on top of the table to protect it from accidental drilling. These inserts can be replaced when damaged, saving your table from harm. By practicing these preventive measures, you can minimize the risk of drilling into the drill press table.

4. What should I do if I accidentally drill into the drill press table?

If you accidentally drill into the drill press table, stop the drilling operation immediately. Assess the extent of the damage and determine if it affects the functionality of the table. If the damage is minor, you can consider smoothing out the surface or using a filler to repair any holes. However, if the damage is severe, it is recommended to consult a professional or contact the manufacturer for guidance on possible repairs or replacements. Remember, prevention is better than a cure, so always exercise caution to avoid drilling into the drill press table in the first place.

5. Are there alternative options to drilling into the drill press table?

Absolutely! Instead of drilling directly into the drill press table, you can use clamps or vise grips to secure your workpiece firmly in place. This way, you can still drill into your workpiece without any risk of damaging the table. Additionally, you can consider using adjustable drill press fences or auxiliary tables that are specifically designed for drilling tasks. These accessories enhance stability and provide a dedicated surface for drilling, ensuring your drill press table remains intact. Exploring these alternative options will not only protect your drill press table but also improve your overall drilling experience.

Why I don’t use a drillpress table

Summary:

So, to wrap things up, it’s really not a good idea to drill into the drill press table. Why? Because it can damage the table, affect drilling accuracy, and even lead to serious injuries.

The drill press table is designed to support your work and provide a stable platform for drilling. It’s important to respect and care for the table to ensure it lasts longer and works effectively. So, always use a sacrificial board or clamp your workpiece to protect the table and prevent any mishaps. Stay safe and happy drilling!