Do power tools have built-in strain relief? If you’ve ever wondered about this, you’re in the right place. In this article, we’ll explore the world of power tools and their safety features. So, buckle up and let’s dive into the exciting world of power tools!

When it comes to power tools, safety should always be a top priority. That’s why many manufacturers have taken steps to incorporate strain relief into their designs. But what exactly is strain relief? Don’t worry, we’ll break it down for you in simple terms.

Strain relief is a feature that helps protect the power cord from being damaged or yanked out accidentally. It’s like a little guardian angel for your power tool, ensuring that the cord stays securely in place, even during those high-intensity jobs. Now that you know what strain relief is, let’s find out if power tools really have this important safety feature. So, let’s get started!

When it comes to power tools, built-in strain relief is an important feature to consider. It helps prevent damage to the tool’s power cord and ensures a longer lifespan. Most power tools nowadays have built-in strain relief to provide extra protection. This feature helps to reduce the strain on the cord where it meets the tool, preventing it from bending or breaking. So, when shopping for power tools, be sure to check if they have this handy feature!

Do Power Tools Have Built-In Strain Relief?

Power tools have become an essential part of any handyman or DIY enthusiast’s toolkit. From drills to saws, these tools make our lives easier by allowing us to complete tasks more efficiently. However, with the power and convenience these tools offer comes the concern for safety. One important safety feature to consider when using power tools is whether they have built-in strain relief. In this article, we will explore the concept of strain relief, its significance in power tools, and how it affects both the durability of the tool and the safety of the user.

The Importance of Strain Relief in Power Tools

Strain relief is a crucial feature in power tools as it protects the internal wiring and connections from excessive tension or stress. When power tools are used, the cords are often subjected to bending, pulling, and twisting, which can lead to damage over time. Strain relief is designed to alleviate this stress on the cord by providing a secure anchor point where the cord meets the tool. This anchor point helps distribute the stress more evenly, preventing premature wear and tear.

Furthermore, strain relief also safeguards the connections within the power tool. The constant movement and vibrations generated during tool operation can cause wires to become loose or disconnected, leading to electrical hazards or malfunctioning tools. By implementing proper strain relief, manufacturers ensure that the internal connections remain intact, minimizing the risk of electrical issues.

How Strain Relief Works

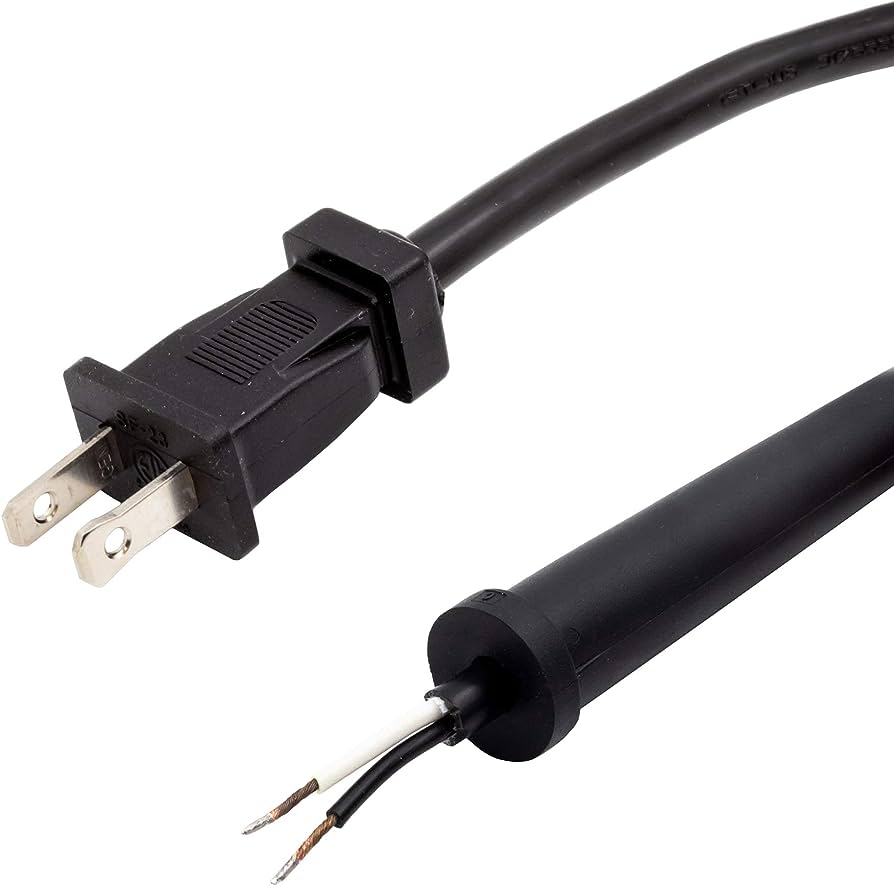

Strain relief works by incorporating flexible grommets or other mechanisms near the cord entry point of the power tool. These grommets are made from materials such as rubber or plastic, which can flex and absorb the stresses from the cord movement. The cord passes through the grommet, which provides a protective cushioning effect.

Additionally, strain relief may also involve features like a reinforced housing or a secure clamping system. This reinforces the connection between the cord and the tool, reducing the chances of accidental disconnections. Some power tools also employ retractable cords or adjustable cord lengths, which further minimize strain on the cord and increase convenience for the user.

In conclusion, strain relief is critical in power tools as it not only protects the cord and internal connections from damage but also ensures the safety of the user. Adequate strain relief mechanisms ensure that power tools can withstand the rigors of regular use and provide long-lasting performance. When considering purchasing a power tool, be sure to check if it has built-in strain relief, as it is an important factor in both the functionality and safety of the tool.

The Benefits of Power Tools with Built-In Strain Relief

Power tools equipped with built-in strain relief offer various benefits to both professionals and DIY enthusiasts. Let’s take a closer look at some of these advantages:

- Durability: Power tools with strain relief are designed to withstand the constant movement, bending, and pulling that occurs during use. This durability ensures that the tool can withstand the demands of various projects, resulting in a longer lifespan.

- Safety: By incorporating strain relief, power tool manufacturers prioritize safety. The strain relief mechanisms reduce the risk of electrical hazards caused by loose or damaged cords, preventing potential accidents and injuries.

- Reliability: With proper strain relief, power tool cords stay securely connected to the tool, minimizing the chances of accidental disconnections. This enhances the tool’s reliability, allowing users to work with confidence and peace of mind.

- User-Friendly: Power tools that incorporate strain relief often feature additional user-friendly design elements such as retractable cords or adjustable cord lengths. These features enhance convenience and make it easier to handle and store the tools.

Built-In Strain Relief vs. Aftermarket Solutions

While some power tools come with built-in strain relief, others may require the use of aftermarket solutions. Aftermarket strain relief options, such as cord grips or cable strain reliefs, can be added to existing tools to provide the same level of protection and durability. However, there are a few key considerations to keep in mind when choosing between built-in and aftermarket strain relief:

- Compatibility: Aftermarket strain relief solutions must be compatible with the specific power tool you are using. It is essential to ensure proper fit and functionality to guarantee optimal performance.

- Installation: Adding aftermarket strain relief may require some technical skills and knowledge. It is important to follow the manufacturer’s instructions carefully to ensure proper installation and avoid any potential issues.

- Warranty: Modifying a power tool with aftermarket strain relief could void the manufacturer’s warranty. It is crucial to review the warranty terms and conditions before making any modifications to the tool.

Conclusion

In conclusion, strain relief is an essential feature in power tools that protects the cords and internal connections from damage caused by excessive stress. Power tools equipped with built-in strain relief offer numerous advantages in terms of durability, safety, reliability, and user-friendliness. However, aftermarket strain relief solutions can also provide similar benefits for tools that do not come with built-in strain relief. Ultimately, the choice between built-in and aftermarket strain relief depends on the specific power tool and individual requirements. Regardless of the approach chosen, ensuring proper strain relief is critical for maintaining the longevity and safety of power tools.

Key Takeaways: Do Power Tools Have Built-in Strain Relief?

- Power tools typically have built-in strain relief features.

- Strain relief helps protect the power cord from damage and prevents accidental disconnections.

- It is important to look for power tools with strain relief to ensure safety and durability.

- Strain relief may come in the form of reinforced wire connections or specialized cording techniques.

- Proper usage and maintenance of power tools can also contribute to their overall longevity.

Frequently Asked Questions

<

1. How can I tell if a power tool has built-in strain relief?

A power tool with built-in strain relief is designed with features to protect the cord from excessive pulling or bending. Look for reinforced or thickened sections near the cord entry point and at the base of the handle. These areas help distribute stress and prevent damage to the cord.

Additionally, some power tools may have visible strain relief components, such as flexible rubber or plastic features that provide extra support and flexibility to the cord. These components act as a buffer against strain and prolong the lifespan of the tool’s cord.

2. What are the benefits of power tools with built-in strain relief?

Power tools with built-in strain relief offer several benefits. Firstly, they provide added safety by reducing the risk of cord damage or exposure. This helps prevent electric shocks or short circuits that can occur when the protective insulation of the cord is compromised.

Furthermore, power tools with built-in strain relief tend to have a longer lifespan. The strain relief components absorb and distribute stress, protecting the cord from excessive wear and tear. This means you can rely on your power tool for longer periods without worrying about cord damage or frequent replacements.

3. Can I add strain relief to a power tool that doesn’t have it?

While it is not recommended to modify power tools without proper expertise, there are some measures you can take to add extra strain relief if needed. One option is to secure the cord near the handle using cable ties or clamps to reduce strain at the entry point. Additionally, using a cord protector or wrap can help reinforce and protect the cord from excessive bending and pulling.

However, it is crucial to approach any modifications with caution and consult the manufacturer or a qualified professional if you are unsure. Altering a power tool without proper knowledge may void the warranty, compromise safety, or result in further damage.

4. Are all power tools designed with built-in strain relief?

No, not all power tools are designed with built-in strain relief. The presence of strain relief can vary depending on the make and model of the power tool. While many reputable power tool brands prioritize safety and include built-in strain relief, it is best to check the product specifications or consult the manufacturer to confirm the presence of this feature.

If a power tool does not have built-in strain relief, it is important to exercise caution when using it to avoid excessive pulling or bending of the cord, which can lead to damage or safety hazards.

5. How can I properly maintain the strain relief of my power tools?

To maintain the strain relief of your power tools, it is essential to follow a few simple guidelines. Firstly, regularly inspect the cord and strain relief components for any signs of damage, such as fraying, cracks, or loose connections. If any issues are found, it is crucial to address them promptly and seek professional assistance if needed.

Additionally, avoid excessive pulling or bending of the cord, as this can strain the insulation and strain relief components. Properly storing the power tools, keeping them away from extreme temperatures and moisture, can also help extend the lifespan of the strain relief and overall tool performance. Lastly, following the manufacturer’s recommended maintenance and usage guidelines can help ensure the longevity of your power tool’s strain relief.

Summary

Power tools do not always have built-in strain relief, which can put cords at risk of damage. Without strain relief, cords can bend or pull away from the tool, leading to potential hazards such as exposed wires or electrical shocks. It is important to check whether a power tool has this feature and to use strain relief devices when needed to ensure safety during use.

In addition to protecting cords from damage, strain relief also helps to extend the lifespan of power tools. By reducing stress on the electrical wiring, it minimizes the risk of short circuits and other electrical issues that can lead to costly repairs or replacements. Therefore, it is crucial to prioritize safety by choosing power tools with built-in strain relief or using external strain relief devices when necessary.