Do power tools need to be double insulated? Well, if you’re curious about the inner workings of these handy devices, you’ve come to the right place! Whether you’re a budding DIY enthusiast or just want to understand the safety features of power tools, we’ve got you covered. So, let’s dive in and explore the world of double insulation and its importance in power tool design.

Imagine you’re using a power tool. You feel the energy buzzing through your hands as you work on your latest masterpiece. But have you ever wondered about electrical safety? That’s where double insulation comes into play. You see, power tools are designed to protect both the user and the tool from electrical shocks. Double insulation is like an extra layer of armor, safeguarding you while you work.

Now, you might be wondering how double insulation works and why it’s necessary. Think of it this way: when you use power tools, there’s a possibility of electrical current leaking from inside the tool to the outer casing. Double insulation prevents this leakage by incorporating two layers of insulating material. This clever design keeps the electrical current contained within the tool, reducing the risk of electric shock and ensuring your safety.

So, the next time you reach for that power drill or circular saw, remember the importance of double insulation. It’s not just about protecting your tools; it’s about protecting yourself too. With double insulation, you can confidently work on your DIY projects, knowing that you have an extra layer of safety between you and potential electrical hazards. Stay safe and have fun creating!

When it comes to power tools, double insulation is not always necessary, but it offers an extra layer of protection. Double-insulated power tools are designed with 2 layers of insulation to prevent electric shocks. This is especially important for tools used in wet or humid environments. However, not all power tools require double insulation. It depends on the tool’s design and intended use. Always follow the manufacturer’s instructions to ensure safe usage of your power tools.

Do Power Tools Need to Be Double Insulated?

Power tools are a staple in many industries and DIY projects, making tasks easier, faster, and more efficient. One important consideration when using power tools is safety. This leads to the question: do power tools need to be double insulated? In this article, we will delve into the concept of double insulation, its purpose, requirements, and benefits, as well as provide tips for using power tools safely.

What is Double Insulation?

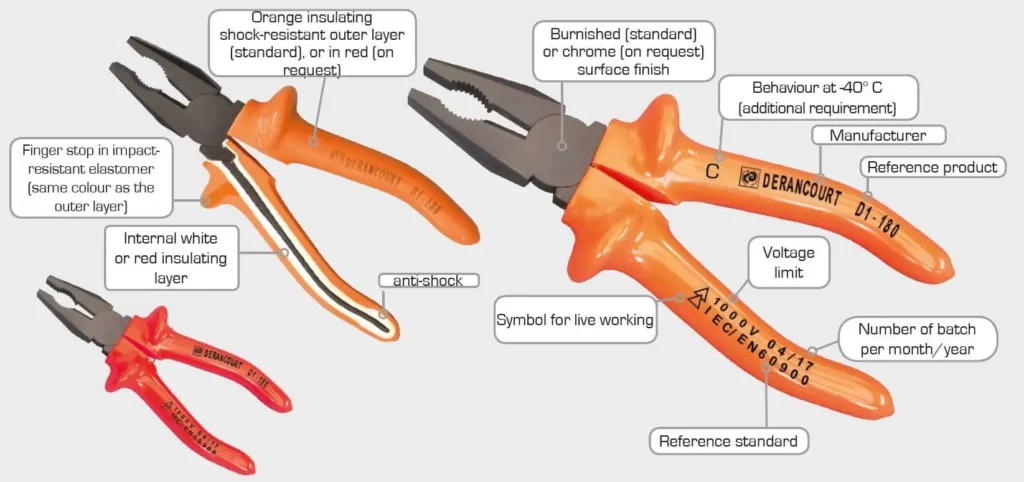

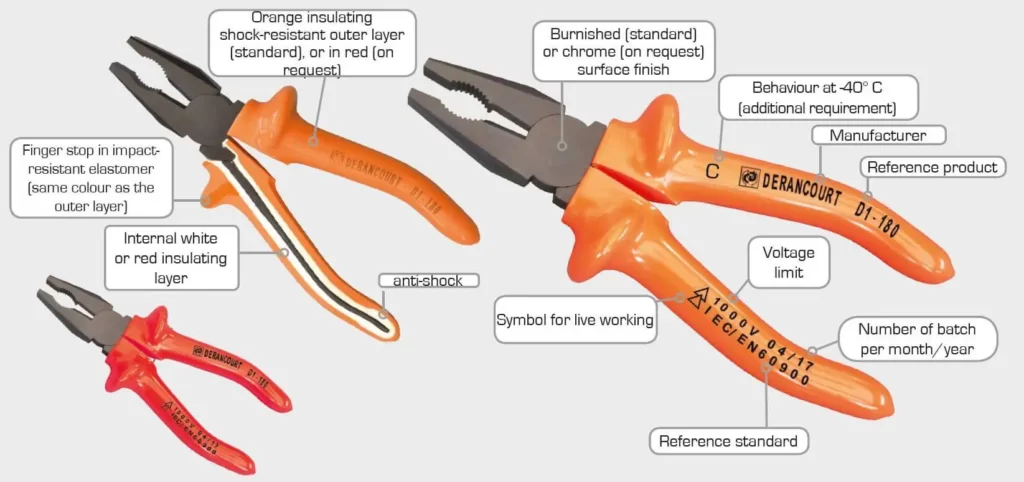

Double insulation is a safety feature found in many power tools. It is designed to provide protection against electric shock by providing an additional layer of insulation around the tool’s internal components. With double insulation, there is no need for the tool to be grounded. Instead, the extra layer of insulation acts as a barrier, preventing contact with any live parts of the tool.

This feature is denoted by the appearance of two square symbols on the tool – one inside the other. These symbols can usually be found on the tool’s housing or label. It is important to note that not all power tools have double insulation, as it is not a mandatory requirement. However, it is highly recommended, especially for tools that are used in wet or damp environments, or in situations where the risk of electric shock is higher.

Double insulation provides an added layer of protection against electric shock, making power tools safer to use. It eliminates the need for grounding, simplifies the tool’s design, and allows for greater mobility and flexibility when using the tool.

The Benefits of Double Insulation

There are several benefits to using power tools that are double insulated:

- Enhanced Safety: Double insulation provides an extra layer of protection against electric shock for the user. This is especially important when working with power tools in wet or damp environments, where the risk of electrical accidents is higher.

- Simpler Design: Double insulation eliminates the need for grounding, which simplifies the design of the tool and reduces the risk of electrical faults and malfunctions.

- Greater Mobility: Since double insulation eliminates the need for grounding, power tools can be used in a wider range of locations and situations, providing greater mobility and flexibility for the user.

- Reduced Maintenance: Double insulated power tools require less maintenance compared to grounded tools. There is no need to periodically check the grounding wire or connection for wear or damage.

By understanding the benefits of double insulation, users can make informed decisions when choosing power tools for their projects.

Tips for Using Power Tools Safely

While double insulation provides an added layer of safety, it is still important to follow proper safety precautions when using power tools. Here are some tips to ensure safe usage:

- Read the Manual: Before using any power tool, read and understand the manufacturer’s instructions and safety guidelines outlined in the product manual. This will help you familiarize yourself with the tool’s features, proper operation, and any specific safety precautions.

- Use Personal Protective Equipment (PPE): Always wear the appropriate PPE, such as safety goggles, gloves, and ear protection, when operating power tools. This will help protect you from potential hazards and injuries.

- Inspect the Tool: Before each use, inspect the power tool for any signs of damage, such as frayed cords, cracked housing, or loose parts. Do not use a tool that appears damaged or faulty.

- Maintain a Clean Workspace: Keep your work area clean and organized to minimize the risk of accidents. Remove any obstacles or debris that may interfere with the safe operation of the tool.

- Use Proper Technique: Follow the correct operating procedures for the specific power tool you are using. Improper handling or use of the tool can increase the risk of accidents or injuries.

- Disconnect Power: When not in use, turn off the power tool and unplug it from the power source. This will prevent accidental start-ups and ensure the safety of those around you.

By following these tips, users can minimize the risk of accidents and injuries when using power tools.

Common Power Tools That Require Double Insulation

When it comes to power tools, not all of them require double insulation. While it is a recommended safety feature, some tools are exempt from this requirement due to factors such as their design, intended use, or availability of alternative safety measures. Here are some common power tools that typically require double insulation:

Electric Drills

Electric drills are versatile tools used for drilling holes or driving screws. Since they are commonly used in various settings and may come into contact with wet or damp surfaces, double insulation is essential to ensure user safety.

[Insert image of electric drill with double insulation symbol]

Double insulated electric drills provide an extra layer of protection against electrical accidents, making them safer to use in a variety of environments.

Circular Saws

Circular saws are used for making straight cuts in various materials, including wood and metal. These power tools can generate a significant amount of dust and debris, increasing the risk of electrical faults. Double insulation helps safeguard against these potential hazards.

[Insert image of circular saw with double insulation symbol]

By using a double insulated circular saw, users can work confidently knowing they have an additional level of protection against electrical shock.

Jigsaws

Jigsaws are handy tools for making intricate cuts and curves in different materials. They are often used in woodworking and metalworking projects, where the risk of electrical accidents is present. Double insulation ensures that users can operate jigsaws safely.

[Insert image of jigsaw with double insulation symbol]

With a double insulated jigsaw, users can focus on their projects without worrying about the risk of electrical shock.

#Benefits of Double Insulation

The utilization of double insulation in power tools brings about various benefits. Some of these benefits include:

- Enhanced safety for users

- Simplified tool design

- Greater mobility and flexibility during use

- Reduced maintenance requirements

#Conclusion

When it comes to power tools, safety should always be a top priority. While not all power tools require double insulation, it is a recommended safety feature, especially for tools used in wet or damp environments. Double insulation provides an extra layer of protection against electric shock, eliminates the need for grounding, and simplifies the design of the tool. By understanding the importance of double insulation and following proper safety guidelines, users can ensure a safer and more efficient experience when using power tools.

Key Takeaways: Do Power Tools Need to Be Double Insulated?

- Power tools that are double insulated can provide additional safety.

- Double insulation helps prevent electric shocks.

- Tools marked with a double-square symbol or the words “double insulated” are safe to use without a ground wire.

- Single insulated tools may require a ground wire for safety.

- Always follow the manufacturer’s instructions and guidelines when using power tools.

Frequently Asked Questions

When it comes to power tools, double insulation is an important safety feature. Here are some frequently asked questions about whether power tools need to be double insulated.

1. What does it mean for a power tool to be double insulated?

Double insulation in power tools is a safety feature designed to protect the user from electric shock. It means that the tool has two layers of insulation, both the basic insulation and an additional layer of supplementary insulation. This eliminates the need for a grounding prong on the plug.

Electric current is carried through the internal electrical components of the tool and should not come into contact with the outer metal casing. With double insulation, even if there is a breakdown in the basic insulation, the supplementary insulation prevents the user from being exposed to the electric current, reducing the risk of electric shock.

2. Are all power tools required to be double insulated?

No, not all power tools are required to be double insulated. The need for double insulation depends on the design and construction of the tool. Some power tools have metal casings that can conduct electricity, and therefore, require double insulation for safety. However, other power tools, such as those with non-conductive casings, may not need to be double insulated.

It’s important to check the manufacturer’s specifications and labeling to determine if a power tool is double insulated. Look for symbols such as a square within a square or the letters “DI” (Double Insulated) on the tool or its packaging. This will indicate that the tool meets the necessary safety requirements.

3. What are the advantages of using double-insulated power tools?

One of the main advantages of using double-insulated power tools is increased safety. With the extra layer of insulation, the risk of electric shock is significantly reduced, providing peace of mind for the user. Double insulation also eliminates the need for a grounding prong on the plug, making it more convenient to use.

Additionally, double-insulated power tools can be used in areas where there are no grounded outlets. This is particularly beneficial in older buildings that may not have proper grounding, as it allows users to work safely without the need for additional precautions or modifications.

4. Can power tools without double insulation still be safe?

Yes, power tools without double insulation can still be safe if they are used properly and maintained in good condition. It’s important to follow all safety guidelines provided by the manufacturer, such as wearing appropriate protective gear, using the tool as intended, and avoiding water or wet conditions.

However, it’s worth noting that double insulation adds an extra layer of protection, reducing the risk of electric shock even if there is a fault in the tool. If you are unsure about the safety features of a power tool, it’s always best to consult the manufacturer or a knowledgeable professional.

5. Are there any alternatives to double insulation for power tool safety?

Yes, there are alternatives to double insulation for power tool safety. One common alternative is the use of a ground fault circuit interrupter (GFCI). A GFCI is an electrical device that can detect even small imbalances in the electrical current and quickly shut off the power, preventing electric shock.

GFCIs can be installed in the electrical outlets or in-line with the power cord of a power tool. They are particularly useful in situations where double insulation may not be feasible, such as with older power tools or when using power tools in wet environments. However, it’s important to note that GFCIs should never be used as a substitute for proper insulation and grounding when required.

Summary

Power tools can be made with double insulation to protect users from electric shocks. Double insulation means the tool has an extra layer of protection, like a plastic casing, so you don’t accidentally touch any live wires. It’s important to check if a power tool is double insulated before buying it to ensure your safety. However, even if a tool is not double insulated, it can still be safe as long as you use it properly, keep it dry, and avoid touching any exposed wires. Always follow the manufacturer’s instructions for using and maintaining your power tools.

In conclusion, while double insulation is a great safety feature, it’s not always necessary. As long as you take the proper precautions and use your power tools responsibly, you can still use them safely without double insulation. Remember to prioritize your safety and follow the guidelines provided by the manufacturer for the best results.