In the world of DIY projects and home improvement, power tools are like the superheroes of the toolbox. They can make our lives so much easier and help us tackle projects with efficiency and precision. But have you ever wondered if these powerful tools need to be grounded? Well, my curious friend, you’ve come to the right place to find out!

Now, before we dive into the nitty-gritty of power tool grounding, let’s take a step back and understand what grounding actually means. Imagine you’re walking barefoot on a carpet and suddenly touch a metal doorknob. Ouch! That unpleasant shock you feel is static electricity, and grounding helps to prevent such shocks and potential electrical hazards in power tools.

So, the burning question remains: Do power tools need to be grounded? And the answer is… it depends! Not all power tools require grounding, but some definitely do. Stick around as we unravel the mystery and dig deeper into the fascinating world of power tool safety!

Are Power Tools Grounded? Ensuring Safety and Efficiency

Power tools have become essential in various industries and DIY projects. They make our lives easier and help us complete tasks efficiently. However, safety should always be a top priority when using power tools. One important aspect of tool safety is grounding. In this article, we will explore the importance of grounding power tools, the potential hazards of not grounding them, and the best practices for ensuring electrical safety.

Understanding Grounding and Its Importance

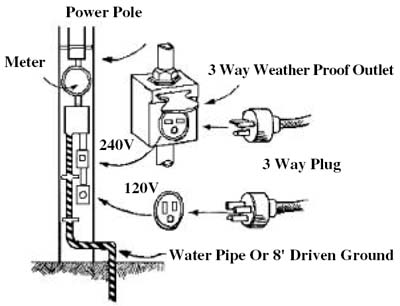

Grounding is the process of connecting an electrical device to the ground or a conductive surface, such as a metal rod driven into the earth. It is crucial for power tools because it provides a safe path for electric current in the event of a fault or malfunction. When a tool is properly grounded, any stray electricity or short circuits are directed to the ground, preventing electric shock, fires, and damage to the tool itself.

Grounding power tools also reduces the risk of electrostatic discharge, which can occur when working with materials that generate static electricity, like certain types of plastics. By grounding the tool, any static charges are dissipated harmlessly into the ground, preventing sparks that could ignite flammable substances.

The Hazards of Not Grounding Power Tools

Failing to ground power tools can have serious consequences. Without proper grounding, the tool’s metal housing or components can become energized, creating a potential shock hazard for the user. Additionally, in the event of a short circuit or fault, electrical current may flow through the user’s body instead of being safely redirected to the ground, potentially resulting in severe injury or even death.

Inadequate grounding can also increase the risk of electrical fires. Faulty power tools that are not properly grounded may cause sparks or overheating, leading to ignition of nearby flammable materials or electrical components. This can quickly escalate into a dangerous situation, causing property damage and endangering the safety of individuals in the vicinity.

Best Practices for Grounding Power Tools

To ensure the safe and efficient use of power tools, it is essential to follow a few guidelines for proper grounding:

1. Use Three-Prong Plugs: Most modern power tools come with three-prong plugs, which include a grounding pin. Always use power tools that have this type of plug and never attempt to remove or tamper with the grounding pin.

2. Check Power Cords: Inspect power cords before each use, ensuring they are in good condition with no exposed wires or frayed insulation. Damaged cords should be replaced immediately to avoid electrical hazards.

3. Use Ground Fault Circuit Interrupters (GFCIs): GFCIs are devices that can detect imbalances in electrical currents and quickly shut off power. They are highly recommended for power tool usage, particularly in damp or wet environments where the risk of electrical shocks is higher.

4. Regular Maintenance and Inspections: Periodically inspect power tools for any signs of damage or wear. Have them serviced and maintained by qualified professionals to ensure proper grounding and overall safety.

By following these best practices and prioritizing grounding, users can protect themselves and others from potential hazards associated with power tools. Remember, safety should never be compromised when using any type of equipment that involves electricity.

Benefits of Properly Grounding Power Tools

Grounding power tools provides various benefits that contribute to both safety and efficiency. Let’s delve into some of the advantages of the correct grounding techniques.

Electrical Safety

The primary benefit of grounding power tools is electrical safety. When a tool is grounded, any electrical faults or short circuits are directed safely to the ground instead of causing potential harm to users. This significantly reduces the risk of electric shocks and injuries, making the work environment much safer.

Fire Prevention

Grounding power tools helps prevent electrical fires. When a tool is properly grounded, the chances of sparks or overheating are minimized. These sparks or excessive heat can ignite nearby flammable materials, leading to fires that can spread rapidly throughout the workspace. By grounding the tools, the risk of electrical fires is significantly reduced.

Tool Longevity

Proper grounding also contributes to the longevity of power tools. When a tool is not grounded, there may be an increased risk of electrical damage to its internal components. This can lead to premature wear and tear, resulting in frequent breakdowns or the need for replacement. By ensuring proper grounding, power tools are protected against electrical surges and other potential damage, extending their lifespan.

In conclusion, grounding power tools is essential for ensuring safety, preventing electrical hazards, and maximizing tool efficiency. By adhering to best practices and prioritizing proper grounding techniques, users can mitigate the risks associated with power tool usage and create a safer working environment. Always remember to prioritize safety and consult professionals if you have any doubts about the grounding of your power tools. Stay safe and productive in your projects!

Key Takeaways: Do Power Tools Need to be Grounded?

- Power tools should be properly grounded to protect against electric shocks and fires.

- Grounding helps to redirect electrical current away from the tool to prevent accidents.

- Most power tools come with a three-prong plug that includes a grounding wire.

- Using power tools without proper grounding can be dangerous and increase the risk of electric shock.

- Always follow the manufacturer’s instructions and guidelines for grounding your power tools.

Frequently Asked Questions

When it comes to power tools, understanding if they need to be grounded is important for safety and performance. Here are some common questions related to the grounding of power tools.

1. How does grounding affect power tool safety?

Grounding plays a significant role in power tool safety. When a power tool is properly grounded, it provides a direct path for electrical current to flow back to the ground, reducing the risk of electrical shock. Without proper grounding, there is a higher chance of electric shock if there is a fault or malfunction in the tool. Grounding also helps prevent electrical fires by promptly dissipating excess electrical charges.

Remember, always check the manufacturer’s instructions or consult an electrician to determine if your power tool needs to be grounded.

2. Do all power tools require grounding?

No, not all power tools require grounding. Some power tools are designed to be double-insulated, which means they have built-in insulation that eliminates the need for grounding. Double-insulated tools are labeled with a symbol, usually consisting of the letters “SQ” inside a square. If a power tool has this symbol, it is not necessary to ground it.

However, it’s essential to follow the manufacturer’s instructions and check the labeling on the power tool to determine if it requires grounding or if it is double-insulated.

3. How can I tell if a power tool needs to be grounded?

To determine if a power tool needs to be grounded, there are a few indicators to look out for. Firstly, check the power cord. If the cord has three prongs (two flat prongs and one round prong), it is designed to be grounded. Additionally, the power tool may have a grounding screw or a symbol indicating that it needs to be grounded. Always refer to the manufacturer’s instructions and labeling to determine if grounding is necessary.

If there are no indicators or instructions available, it’s best to consult an electrician for guidance on grounding the power tool.

4. Can I use a power tool without grounding it?

If a power tool requires grounding according to the manufacturer’s instructions or labeling, it is crucial to follow those guidelines for safety reasons. Using a power tool without grounding it when it is required can increase the risk of electrical shock or fires due to potential electrical faults or malfunctions.

If you are unsure whether your power tool needs to be grounded, it is always recommended to err on the side of caution and consult the manufacturer or an electrician.

5. What are the best practices for grounding power tools?

When grounding a power tool, there are a few best practices to ensure safety. Firstly, always use a grounded outlet and never remove the grounding pin from the power cord. Additionally, regularly inspect the power cord for any damage or frayed wires, as this can compromise the grounding. If a power cord is damaged, it should be replaced before using the tool.

It’s also important to make sure the grounding system in your home or workspace is up to code and functioning properly. This can be confirmed by consulting a qualified electrician. Finally, if you are unsure about grounding a power tool or have any concerns, it is advisable to seek professional help to ensure proper grounding and safe operation of the tool.

Ground Wire Explained

Summary

So, do power tools need to be grounded? The answer is yes. Grounding power tools is important for safety. It helps protect you from electric shocks and prevents damage to the tools. Remember to always plug your power tools into grounded outlets or use grounded extension cords. Safety first!