Are you wondering if you need a special blade to cut metal with a bandsaw? Well, you’ve come to the right place! In this article, we’ll explore the ins and outs of using a bandsaw for metal cutting and whether or not a special blade is required. So, grab your safety goggles and let’s dive in!

Picture this: you have a metal project in mind, but you’re not sure if your trusty bandsaw can handle the job. The good news is that bandsaws can indeed cut through metal, but the type of blade you use makes all the difference.

So, do you need a special blade? The answer is a resounding YES! Cutting metal requires a blade specifically designed for the task. These blades are made from materials like high-speed steel or carbide, and they have teeth specifically designed to handle the rigors of cutting metal.

In the next section, we’ll explore the different types of blades available and give you the lowdown on finding the perfect blade for your metal-cutting needs. So, stay tuned and get ready to unleash the power of your bandsaw on metal projects like a pro!

Do You Need a Special Blade to Cut Metal with a Bandsaw?

When it comes to cutting metal, many DIY enthusiasts and professionals turn to a bandsaw for its versatility and precision. However, not all bandsaw blades are created equal, and using the wrong blade for cutting metal can lead to less than optimal results. In this article, we will explore whether you need a special blade to cut metal with a bandsaw and discuss the different types of blades available for this purpose.

Understanding Bandsaw Blades

Before we delve into the specifics of cutting metal with a bandsaw, it’s crucial to understand the basics of bandsaw blades. Bandsaw blades consist of a continuous loop of metal with teeth along one edge. These teeth are responsible for cutting through various materials, including wood, plastic, and metal. The shape, size, and configuration of the teeth determine the blade’s suitability for specific cutting tasks.

Standard bandsaw blades are typically designed for cutting wood. They have larger, widely spaced teeth, suitable for removing wood chips efficiently. While these blades can cut through some metals, they are not the best choice for precise and clean metal cutting. Using a standard blade for cutting metal can result in premature dulling, poor cutting performance, and potentially dangerous situations.

Therefore, to achieve optimal results when cutting metal with a bandsaw, it is recommended to use a special blade specifically designed for metal cutting.

Types of Metal Cutting Bandsaw Blades

There are several types of bandsaw blades specifically designed for cutting metal, each with its own set of advantages and applications. Understanding these different blade types will help you choose the most appropriate one for your metal cutting needs.

1. Bimetal Blades

Bimetal blades are the most common type of bandsaw blade used for cutting metal. These blades consist of two layers, with a high-speed steel (HSS) tooth edge welded or electron beam-welded onto a high-tensile carbon steel backing. The HSS tooth edge provides excellent cutting performance and durability, while the carbon steel backing ensures flexibility.

Bimetal blades are suitable for cutting a wide range of metals, including steel, stainless steel, aluminum, and non-ferrous metals. They offer a good balance of cutting speed, durability, and versatility, making them a popular choice in many metal cutting operations.

2. Carbide-Tipped Blades

Carbide-tipped blades are known for their exceptional durability and long-lasting cutting performance. These blades are typically made by brazing small carbide tips onto a high-quality steel body. The carbide tips provide excellent hardness and wear resistance, allowing them to withstand the high temperatures and cutting forces involved in metal cutting.

Carbide-tipped blades are ideal for cutting hardened metals, such as tool steel or high-strength alloys. They are also suitable for cutting metal with abrasive surfaces, such as cast iron or exotic alloys. However, due to their high cost, carbide-tipped blades are often reserved for specialized metal cutting applications.

3. Coated Blades

Coated blades are regular blades that have been coated with a layer of special material to enhance their cutting performance and longevity. The most common coating used is titanium nitride (TiN), which reduces friction, increases hardness, and improves chip evacuation.

Coated blades are a cost-effective alternative to carbide-tipped blades, offering improved cutting performance and extended blade life. They are suitable for cutting a wide range of metals and can provide excellent results in many metal cutting applications if properly maintained.

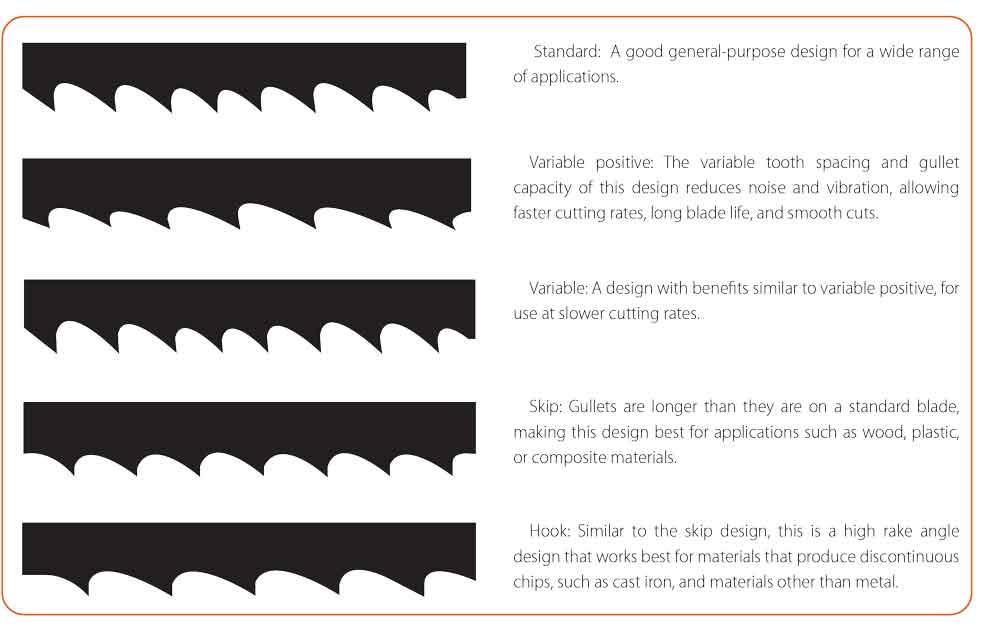

4. Variable-Tooth Blades

Variable-tooth blades, also known as skip-tooth blades, feature wide-spaced teeth followed by smaller, closer-spaced teeth. This tooth configuration helps reduce heat buildup during cutting and allows for efficient chip evacuation. Variable-tooth blades are often used for cutting thin sheets of metal, tubes, or pipes.

They are particularly effective in preventing blade binding and reducing the tendency for the blade to wander or drift during the cutting process. Variable-tooth blades are available in both bimetal and carbide-tipped versions, providing flexibility and options for different metal cutting requirements.

When choosing a bandsaw blade for metal cutting, consider factors such as the type and thickness of the metal, the desired cutting speed and finish, and the frequency of use. It’s also important to select the appropriate tooth pitch for the specific metal being cut, as this will affect cutting speed and performance.

Tips for Cutting Metal with a Bandsaw

Now that you understand the importance of using a special blade for cutting metal with a bandsaw, here are some additional tips to help you achieve the best results:

- Choose the appropriate blade type and tooth pitch for the metal being cut.

- Ensure the bandsaw is properly set up and in good working condition.

- Use the appropriate cutting speed and feed rate for the metal being cut.

- Apply cutting fluid or lubricant to the blade and workpiece to reduce friction and heat buildup.

- Secure the workpiece firmly to prevent vibrations and ensure accurate cuts.

- Wear appropriate safety gear, including gloves and eye protection, when operating a bandsaw.

Benefits of Using a Special Blade for Metal Cutting

Using a special blade specifically designed for cutting metal with a bandsaw offers several benefits compared to using a standard wood-cutting blade:

- Improved cutting performance and efficiency

- Longer blade life and reduced blade replacement costs

- Reduced risk of blade breakage or accidents

- Ability to achieve precise and clean cuts

- Minimized heat buildup and reduced material distortion

- Enhanced safety and reduced operator fatigue

Conclusion

If you want to cut metal with a bandsaw, using a special blade designed for metal cutting is highly recommended. Standard wood-cutting blades may work to some extent, but they are not optimized for metal cutting and can lead to subpar results. By selecting the appropriate blade type and following the recommended tips, you can achieve precise, clean, and efficient metal cuts with a bandsaw. Remember to prioritize safety and always wear the necessary protective gear when operating a bandsaw.

Key Takeaways: Do You Need a Special Blade to Cut Metal with a Bandsaw?

- Yes, you need a special blade called a metal-cutting blade to cut metal with a bandsaw.

- Metal-cutting blades are designed to withstand the heat and pressure generated when cutting metal.

- These blades have a strong and sharp edge that can handle the toughness of metal.

- It is important to choose the right blade based on the type and thickness of the metal you are cutting.

- Using the wrong blade can result in poor cuts, damage to the bandsaw, or even accidents.

Frequently Asked Questions

Metal cutting with a bandsaw may seem challenging, but with the right blade, it can be a breeze! Here are some common questions people have about using a bandsaw to cut metal.

1. What type of blade should I use to cut metal with a bandsaw?

To cut metal with a bandsaw, you will need a special blade called a metal-cutting blade. These blades are designed with a higher tooth count and a specific tooth shape to efficiently cut through metal. They are made from materials like high-speed steel or carbide, which are more durable and heat-resistant than regular bandsaw blades. Metal-cutting blades have teeth that are closer together, allowing for smoother cuts and reducing the chances of the blade snagging or breaking. So, yes, you need a special blade to cut metal with a bandsaw.

When selecting a metal-cutting blade for your bandsaw, consider the thickness and type of metal you’ll be cutting. Different blade styles and tooth pitches work better for specific metals. You can consult the bandsaw manufacturer’s guidelines or ask for recommendations at your local hardware store to ensure you choose the right blade for your needs.

2. Can I use a wood-cutting blade on a bandsaw to cut metal?

While it may be tempting to use a wood-cutting blade in a pinch, it is not recommended to cut metal with a bandsaw using a wood-cutting blade. Wood-cutting blades are designed with fewer teeth and a different tooth shape optimized for cutting through wood fibers. When used on metal, these blades can quickly become dull, overheat, and possibly break.

Using the wrong blade not only compromises the quality of your cuts but also poses a safety risk. Metal-cutting blades are specifically engineered to handle the forces and heat generated when cutting metal, ensuring better precision and reducing the risk of accidents. Therefore, it is essential to use a proper metal-cutting blade for the best results and to maintain safety while cutting metal with a bandsaw.

3. How do I choose the right metal-cutting blade for my bandsaw?

Choosing the right metal-cutting blade depends on several factors, including the type and thickness of metal you’ll be cutting. Different blade styles and tooth pitches work better for specific applications. For thin metals, a fine-toothed blade with more teeth per inch (TPI) will provide a smoother finish. Thicker metals require blades with fewer teeth per inch and a coarser tooth pitch to handle the material’s thickness.

Consider consulting the bandsaw manufacturer’s guidelines for recommendations or reach out to a knowledgeable professional at your local hardware store. They can help you select the appropriate metal-cutting blade based on your specific needs and the materials you’ll be working with. Taking the time to choose the right blade will ensure clean cuts, prolong blade life, and enhance your overall metal-cutting experience with a bandsaw.

4. How often should I replace the metal-cutting blade on my bandsaw?

The frequency of blade replacements depends on various factors, such as the type of metal being cut, the intensity of use, and the cutting conditions. As a general rule of thumb, you should inspect the blade regularly for signs of wear, such as excessive flexing or damage to the teeth. If you notice a decrease in cutting performance or the blade becomes dull, it’s time to replace it.

Proper maintenance, such as regular cleaning and lubrication, can help extend the blade’s lifespan. However, keep in mind that metal-cutting blades will wear out over time, especially if used frequently on tough metals. Be sure to have replacement blades on hand so that you can swap out the old blade for a fresh one when needed. This ensures optimal cutting performance and helps prevent damage to your bandsaw caused by a worn-out blade.

5. Are there any safety precautions I should take when cutting metal with a bandsaw?

Absolutely! When using a bandsaw to cut metal, it is crucial to prioritize safety. Here are a few key precautions to keep in mind:

– Wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and ear protection if needed.

– Make sure the bandsaw is properly set up and the metal you’re cutting is securely clamped or held in place.

– Take your time and cut at the appropriate speed for the type and thickness of metal being cut.

– Avoid cutting freehand whenever possible. Use jigs, guides, or a fence to maintain control and accuracy.

– Keep your hands and fingers away from the blade, using push sticks or other tools to feed the metal through the cut.

– Regularly inspect the blade for damage or dullness and replace it as needed.

– Clean and maintain your bandsaw regularly to ensure optimal performance and safety.

By following these safety guidelines, you can minimize the risk of accidents and injuries while cutting metal with a bandsaw.

Can You Cut Metal With a Wood Bandsaw? Yes But…. EthAnswers

Summary

Cutting metal with a bandsaw can be done without a special blade, but it may not be the best option. Using a blade designed specifically for metal cutting ensures cleaner and more efficient cuts. The right blade has fewer teeth and special features to handle the toughness of metal.

Additionally, it’s important to consider the type of metal you’re cutting and the thickness of the material. For thin metals, a fine-tooth blade works well, while thicker metals require a coarse-tooth blade. Using the correct blade reduces the risk of damage to your bandsaw and helps you achieve accurate and precise cuts.

In conclusion, while cutting metal with a regular bandsaw blade is possible, it’s advisable to use a specialized blade for optimal results. The right blade saves time, improves cutting quality, and extends the lifespan of your bandsaw. So, if you plan on cutting metal regularly, investing in a metal-cutting blade is definitely worth it.