Welcome, young DIY enthusiasts! Today, we’re diving into the exciting world of woodworking. But before we get our hands dirty, let’s address a common question: “Do you need to pre-drill plywood?” It’s a valid inquiry, and we’ve got answers for you. So, grab your tool belt, put on your safety goggles, and let’s explore this together!

Now, when it comes to working with plywood, you might be wondering whether it’s necessary to pre-drill before driving screws or nails into it. Well, the short answer is, it depends! Plywood is a versatile material, and drilling may or may not be required, depending on the thickness and type of screw or nail you’re using. So, let’s dig deeper into the intricacies of this woodworking technique.

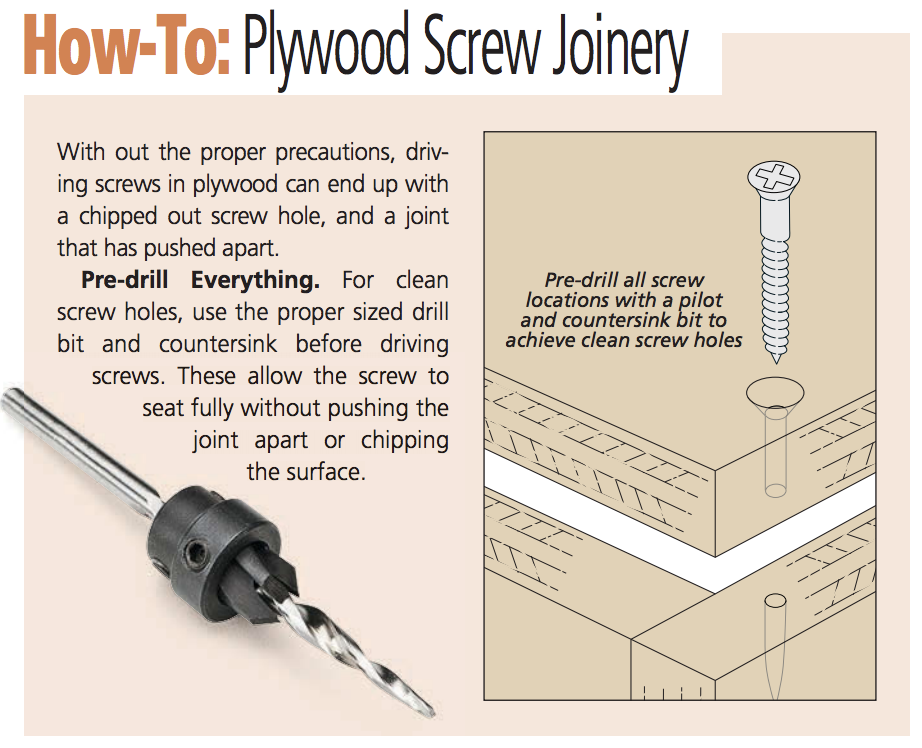

When dealing with thin or delicate plywood, pre-drilling can help prevent the wood from splitting or splintering. This is especially important when working with finer screws or nails. But fear not! Pre-drilling doesn’t have to be a tedious chore. With the right tools and a little know-how, you’ll be well-equipped to tackle any woodworking project that comes your way.

So, whether you’re an aspiring carpenter or simply looking to spruce up your living space, understanding when and how to pre-drill plywood can make all the difference. In the following paragraphs, we’ll explore the importance of pre-drilling, the tools you need, and step-by-step instructions to help you master this essential woodworking technique. So, let’s get started on this exciting journey into the world of plywood and pre-drilling!

Plywood is a versatile material commonly used in woodworking projects. When it comes to drilling, pre-drilling can prevent the plywood from splintering or splitting. It is recommended to pre-drill plywood to ensure cleaner holes and reduce the risk of damage. To pre-drill plywood, follow these steps:

- Choose the right drill bit for the size of the hole you need.

- Mark the location where you want to drill the hole.

- Secure the plywood with clamps or a vise to prevent it from moving.

- Apply gentle downward pressure and drill the hole slowly and steadily.

- Remove any wood chips or debris after drilling the hole.

Do You Need to Pre-Drill Plywood?

Introduction: When working with plywood, whether it’s for a home improvement project or a DIY endeavor, the question of whether to pre-drill holes often arises. Pre-drilling involves creating pilot holes before inserting screws or nails into the plywood, and it can have several advantages. In this article, we will delve into the topic of pre-drilling plywood, exploring its benefits, potential downsides, and providing expert tips for getting the best results.

The Importance of Pre-Drilling Plywood

Introduction: Pre-drilling plywood is an essential step that can help ensure the durability and longevity of your woodwork. By creating pilot holes, you can prevent the plywood from splitting, cracking, or warping, especially when dealing with thinner or more delicate plywood sheets. Let’s further explore the importance of pre-drilling and its benefits.

The Benefits of Pre-Drilling Plywood

Paragraph 1: The primary benefit of pre-drilling plywood is that it reduces the risk of splitting the wood. Plywood, especially when it’s near the edges or has a greater thickness, is prone to splitting when fasteners are driven directly into it. By pre-drilling pilot holes, you create a pathway for the screw or nail, allowing it to penetrate the plywood without exerting excessive force and causing damage.

Paragraph 2: Pre-drilling also helps to improve the overall aesthetics of your woodworking project. When screws or nails are directly driven into the plywood, they can leave unsightly bumps or indentations on the surface. By pre-drilling, you can ensure that the fasteners sit flush with the plywood, resulting in a smooth and professional-looking finish.

Paragraph 3: Additionally, pre-drilling makes it easier to drive screws or nails into the plywood. Pilot holes act as guides, directing the fasteners straight into the wood without the need for excessive force or awkward angles. This can help prevent the fasteners from stripping or breaking, saving you time and frustration during the installation process.

Potential Downsides and Considerations

Paragraph 1: While pre-drilling plywood offers numerous benefits, there are a few potential downsides to consider. One drawback is that pre-drilling can be time-consuming, especially when dealing with a large number of fasteners or intricate woodworking projects. It’s important to factor in the additional time required for pre-drilling when planning your project timeline.

Paragraph 2: Another consideration is that pre-drilling may weaken the plywood, especially if the pilot holes are too large or too close to the edges. These factors can compromise the integrity of the wood, potentially leading to instability or reduced load-bearing capacity. It’s crucial to choose the appropriate drill bit size and carefully position your pilot holes to maintain the plywood’s strength.

Paragraph 3: Lastly, pre-drilling may not be necessary for every plywood application. Thicker plywood sheets, such as those used in construction or heavy-duty projects, may be less susceptible to splitting and may not require pre-drilling. Assess the specific needs of your project and consult with experts or experienced woodworkers to determine if pre-drilling is necessary.

Tips for Pre-Drilling Plywood

Introduction: To ensure the best results when pre-drilling plywood, consider the following tips and guidelines to enhance your woodworking experience.

1. Choose the Right Drill Bit

Paragraph 1: When pre-drilling plywood, it’s crucial to select the appropriate drill bit size. The drill bit should be slightly smaller in diameter than the thickness of the screw or nail you plan to use. This will provide a snug fit, preventing the fastener from becoming loose or stripped.

Paragraph 2: Keep in mind that plywood can vary in thickness, so it’s essential to measure the specific sheet you’re working with before selecting the drill bit. Test the fit of the drill bit in a scrap piece of plywood to ensure it creates a pilot hole that is neither too tight nor too loose.

Paragraph 3: Additionally, consider using a drill bit with a tapered tip. This can help create a clean pilot hole while reducing the risk of splitting the plywood.

2. Mark and Measure Your Pilot Hole Locations

Paragraph 1: Before pre-drilling, lightly mark the desired locations of your pilot holes on the plywood surface. Use a measuring tape or ruler to ensure the accurate placement of the holes. Taking the time to measure and mark these locations will result in a neat and precise outcome.

Paragraph 2: Ensure that the pilot holes are evenly spaced, especially when dealing with multiple screws or nails. A well-planned layout will enhance the overall appearance of your woodwork and improve its structural integrity.

Paragraph 3: Take into account the thickness of the plywood and the specific equipment or accessories you will be attaching. This will help determine the appropriate spacing between the pilot holes and the optimal distance from the edges of the plywood to prevent splitting.

3. Drill Straight and Steady

Paragraph 1: When it’s time to pre-drill the plywood, make sure to drill straight and steady. Misaligned pilot holes can lead to skewed screws or nails, compromising the stability and appearance of your woodworking project.

Paragraph 2: Apply gentle pressure while drilling, allowing the drill bit to penetrate gradually and smoothly. Avoid excessive force, as it can cause the drill bit to wander or create oversized holes. Take your time and use a controlled motion to achieve accurate and clean pilot holes.

Paragraph 3: If you’re new to woodworking or unsure of your drilling skills, practice on a scrap piece of plywood before working on your actual project. This will help you develop a feel for the drilling process and ensure you can consistently create precise pilot holes.

Common Mistakes to Avoid When Pre-Drilling Plywood

Introduction: Although pre-drilling plywood is a straightforward process, there are a few common mistakes that beginners should be aware of and avoid. By learning from these mistakes, you can achieve better results and enhance your woodworking skills.

4. Using the Wrong Drill Bit Size

Paragraph 1: One common mistake is using the wrong drill bit size. Using a drill bit that is too large can result in oversized pilot holes, compromising the grip and stability of the fasteners. Conversely, using a drill bit that is too small can lead to difficulty when inserting the screws or nails.

Paragraph 2: To avoid this mistake, refer to the recommendations for the screw or nail sizes provided by the manufacturer. Select the corresponding drill bit size, or opt for one slightly smaller to allow for a snug fit.

Paragraph 3: Remember that it’s always better to start with a smaller drill bit size and gradually increase if necessary. This will help you avoid creating oversized holes and ensure a tight and secure connection.

5. Failing to Secure the Plywood Properly

Paragraph 1: Another common mistake is failing to secure the plywood properly while pre-drilling. Plywood sheets can easily shift or slip when drilling, resulting in misaligned pilot holes or damaged edges.

Paragraph 2: To avoid this, use clamps or additional support to hold the plywood firmly in place. This will minimize movement and provide stability during the pre-drilling process.

Paragraph 3: Additionally, consider using a piece of scrap wood as a backing when drilling through the plywood. The scrap wood will act as a sacrificial surface, preventing tear-out and ensuring clean and neat pilot holes.

6. Neglecting Safety Precautions

Paragraph 1: It’s important to prioritize safety when pre-drilling plywood. Neglecting safety precautions can lead to accidents or injuries, potentially harming yourself or damaging the woodwork.

Paragraph 2: Always wear proper safety gear, such as safety goggles and gloves, when operating power tools. These will protect your eyes from flying debris and your hands from potential mishaps.

Paragraph 3: Additionally, make sure the drill is securely plugged into a grounded outlet and that the cord is clear of any obstructions or hazards. Take breaks as needed to prevent fatigue, as this can impact your concentration and grip on the drill.

Summarizing Key Points: Pre-drilling plywood is an essential step for preventing splitting, enhancing aesthetics, and facilitating easier installation. However, it’s important to consider the specific needs of your project and the thickness of the plywood. Follow expert tips for choosing the right drill bit, marking and measuring pilot hole locations, and drilling straight and steady. Avoid common mistakes such as using the wrong drill bit size, failing to secure the plywood properly, and neglecting safety precautions. By pre-drilling plywood correctly, you can ensure the durability, stability, and overall quality of your woodworking projects.

Key Takeaways: Do You Need to Pre-Drill Plywood?

– Pre-drilling plywood can help prevent splitting and cracking.

– It is especially important to pre-drill near the edges to avoid splintering.

– Using the correct drill bit size is crucial for a proper pre-drilling process.

– Pre-drilling also ensures that screws go in smoothly and securely.

– Taking the time to pre-drill plywood can save you from costly mistakes and ensure a professional finish.

Frequently Asked Questions

Are you wondering whether pre-drilling plywood is necessary for your project? Check out these frequently asked questions to find the answers you need.

1. Why is pre-drilling plywood important?

Pre-drilling plywood is important for several reasons. Plywood is prone to splitting when screws or nails are driven directly into it. Pre-drilling helps to prevent this by creating a pilot hole, giving the fastener a clear path to follow. Additionally, pre-drilling reduces the chance of the plywood cracking or splintering, ensuring the integrity of your project.

By pre-drilling, you are also able to control the depth of the hole, ensuring that the fastener doesn’t penetrate too deep or go through the material entirely. This level of precision is crucial for a sturdy and professional-looking result.

2. Do I need to pre-drill for every screw or nail?

Pre-drilling is typically required for hardwood plywood, as it is denser and more prone to splitting. However, for softer plywood or thinner materials, you may not need to pre-drill for every screw or nail. Instead, you can experiment by driving a fastener without pre-drilling to see if the material splits or cracks.

If you notice any signs of splitting, it’s best to pre-drill for every fastener. It’s always better to be safe than sorry, and pre-drilling ensures the longevity and durability of your project.

3. What size drill bit should I use when pre-drilling plywood?

The size of drill bit you should use when pre-drilling plywood will depend on the size of the screw or nail you plan to use. As a general rule, the drill bit should be slightly smaller in diameter than the fastener. This allows the screw or nail to grip the wood firmly while still preventing splitting.

For example, if you are using a #8 screw, a 1/8-inch drill bit is commonly used for pre-drilling. If you are using a larger screw, you will need a corresponding larger drill bit. It’s always a good idea to test on a scrap piece of plywood first to ensure the drill bit size is appropriate.

4. Can I use a regular drill bit for pre-drilling plywood?

While you can technically use a regular drill bit for pre-drilling plywood, it is best to use a specialized drill bit designed for woodworking. These drill bits have a sharp point and a tapered shape, making it easier to create clean and precise pilot holes.

A regular drill bit may not provide the same level of control and may result in rough holes or increased risk of splitting. Investing in a set of woodworking drill bits will improve the quality of your pre-drilled holes and ensure better overall results.

5. Are there any alternatives to pre-drilling plywood?

If you prefer not to pre-drill plywood, you can consider using self-drilling screws or specialized screws designed for plywood. These screws have a built-in drill bit at the tip, allowing for easier installation without pre-drilling. However, it’s important to note that pre-drilling still provides better control and reduces the risk of splitting, so it is generally recommended for optimal results.

Another alternative is using a nail gun, which doesn’t require pre-drilling. However, nail guns may not provide the same level of precision and control as pre-drilling, and they are typically more suitable for larger construction projects rather than fine woodworking.

Remember, while alternatives to pre-drilling exist, they may not offer the same level of reliability and quality as pre-drilling plywood.

Choosing The Right Size Pre Drill Bit | Beginner

Summary

So, do you need to pre drill plywood? Well, it depends on a few things. If you’re working with thinner plywood or using larger screws, pre drilling can help prevent splitting. However, for smaller screws and thicker plywood, pre drilling may not be necessary. It’s always a good idea to start with a smaller pilot hole and gradually increase the size if needed. And remember, safety first! Always wear protective gear and consult an adult if you’re unsure.

To recap, pre drilling plywood can be helpful in certain situations, but it’s not always required. Consider the size of the screws and the thickness of the plywood when making your decision. And above all, make sure to take safety precautions and ask for guidance when needed. Keep on building and exploring!