Are you curious about whether a circular saw needs a brake? Well, let’s dive right into it! A circular saw is a powerful tool that can make quick and precise cuts, but safety should always be a top priority. So, does it need a brake to ensure your safety?

You might be thinking, “Why would a saw need a brake?” It’s actually a great question. A brake is a safety feature that quickly stops the blade from spinning once you release the trigger. It can prevent accidents and injuries by reducing the risk of the blade coming into contact with anything unintentionally.

So, do all circular saws have brakes? The answer is no. While some models come equipped with a built-in brake, others may not. However, it’s important to note that having a brake can greatly enhance safety and peace of mind when using a circular saw. Now let’s explore the reasons why you might want to consider investing in a circular saw with a built-in brake.

Circular saws are designed with safety features to protect users, but a brake isn’t a standard requirement for all models. While some circular saws do come with a brake, others may not. A brake is an added safety feature that quickly stops the blade’s rotation when the trigger is released. It can help prevent accidents and reduce the risk of injuries. When choosing a circular saw, consider your safety needs and prioritize models with a built-in brake.

Does a Circular Saw Need a Brake?

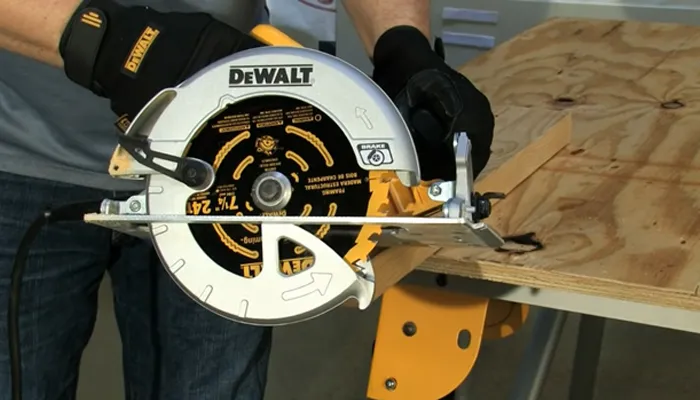

Introduction: Circular saws are powerful tools that are commonly used in woodworking and construction projects. One question that often arises when it comes to circular saws is whether or not they need a brake. In this article, we will delve into the importance of a brake in a circular saw, how it affects safety, and the benefits it provides to users.

Why a Brake is Crucial for Circular Saws

When operating a circular saw, safety should always be a top priority. A brake plays a crucial role in ensuring the safety of the user. The main function of a brake is to stop the blade from spinning immediately after the trigger is released. This allows the user to make quick adjustments or changes to their work without having to wait for the blade to come to a complete stop on its own. Additionally, a brake reduces the risk of accidental injuries by quickly stopping the blade if it comes into contact with something it shouldn’t.

Furthermore, a brake increases productivity and efficiency. With a brake, users can make repetitive cuts without wasting time waiting for the blade to stop spinning. This is especially important in time-sensitive projects where every second matters. Additionally, the quick stopping ability provided by the brake allows for smoother and more precise cuts, resulting in a higher quality finished product. Overall, a circular saw with a brake offers improved safety, increased productivity, and enhanced cutting accuracy.

The Benefits of a Circular Saw With a Brake

1. Increased Safety: The brake reduces the risk of accidents by quickly stopping the blade, preventing potential injuries to the user or damage to the workpiece. This is especially important for beginners or those who may be less experienced with handling power tools.

2. Time Efficiency: A circular saw with a brake allows for faster and more efficient work. The immediate stopping of the blade eliminates wait times, leading to increased productivity. This is particularly beneficial in projects that require repetitive cuts or time-sensitive deadlines.

3. Improved Cutting Precision: The brake ensures that the blade stops quickly and accurately, resulting in clean and precise cuts. This is essential for achieving professional-level results and can save time and effort spent on fixing mistakes caused by a spinning blade.

The Difference Between Circular Saws With and Without a Brake

While circular saws without a brake do exist, they lack the safety and efficiency features provided by their braked counterparts. A circular saw without a brake may take longer to stop spinning after the trigger is released, posing a higher risk of accidental injuries. Additionally, without a brake, users may experience reduced productivity as they have to wait for the blade to come to a complete stop before making any adjustments or changes to their work.

Circular saws with a brake, on the other hand, provide a higher level of safety by allowing for immediate stopping of the blade. They also offer increased efficiency by eliminating wait times and enabling faster and more precise cuts. Ultimately, the decision to invest in a circular saw with a brake depends on the user’s specific needs and the importance they place on safety and productivity.

Tips for Using a Circular Saw with a Brake

1. Familiarize yourself with the brake system before operating the saw. Read the user manual and understand how to engage and disengage the brake effectively.

2. Always wear appropriate safety gear, such as safety goggles and ear protection, when operating a circular saw with a brake. This will protect you from any potential hazards and improve your overall safety.

3. Regularly inspect the brake system for any signs of wear or damage. If you notice any issues, have it serviced or repaired by a professional before using the saw.

4. Remember to release the trigger and allow the blade to come to a complete stop before making any adjustments to your work or placing the saw down. This will prevent accidental injuries and damage to your workpiece.

5. Keep the saw clean and free from debris, as buildup can affect the performance of the brake system. Regularly remove sawdust and other particles to ensure optimal function.

In conclusion, a circular saw with a brake offers significant advantages in terms of safety, efficiency, and precision. The brake system allows for immediate stopping of the blade, reducing the risk of accidents and enabling faster work. When using a circular saw with a brake, always prioritize safety, familiarize yourself with the brake system, and perform regular maintenance to ensure optimal performance.

Key Takeaways: Does a Circular Saw Need a Brake?

- A circular saw does not necessarily need a brake, but having one is highly recommended for safety reasons.

- A brake helps stop the blade quickly after you release the trigger, reducing the risk of accidents.

- A saw with a brake can save you time and make your woodworking projects more efficient.

- Brakes can be either electric or mechanical, with electric brakes being more common in modern circular saws.

- When choosing a circular saw, consider one with a brake for added safety and convenience.

Frequently Asked Questions

Welcome to our FAQ section answering your queries about circular saw brakes. Read on to find out more!

1. How does a brake function in a circular saw?

A brake in a circular saw is a safety feature designed to stop the blade quickly after the trigger is released. It works by reversing the flow of electricity in the motor, which creates an opposing magnetic field. This magnetic field rapidly decelerates the spinning blade, bringing it to a stop in a matter of seconds.

The brake is essential because it reduces the risk of accidents and injuries. By stopping the blade quickly, it minimizes the chance of a user inadvertently coming into contact with the still-rotating blade, helping to prevent serious harm.

2. Are all circular saws equipped with brakes?

No, not all circular saws have brakes. While many modern circular saws are designed with this important safety feature, some older models or budget-friendly options may not include a brake. It’s crucial to check the specifications of a circular saw to determine whether it has a brake before making a purchase.

However, it is highly recommended to invest in a circular saw that has a brake. The added safety provided by a brake far outweighs the potential risks associated with using a saw without this feature.

3. How does a circular saw without a brake differ from one with a brake?

A circular saw without a brake will take longer to stop spinning after the trigger is released. This means it will continue to rotate for several seconds before coming to a complete stop. In contrast, a circular saw with a brake will stop the blade within a few seconds of releasing the trigger, significantly reducing downtime between cuts.

Using a circular saw without a brake requires extra caution and mindfulness. It is crucial to allow the blade to come to a complete stop before setting the tool down or moving it to a different location to minimize the risk of accidents.

4. Can a circular saw without a brake be retrofitted with one?

In most cases, it is not possible to retrofit a circular saw without a brake with this safety feature. Braking mechanisms are typically integrated into a saw’s design during the manufacturing process and cannot be added on afterward. If you require the safety benefits of a brake, it is recommended to purchase a new saw that already includes this feature.

Remember that safety should always be a top priority when using power tools, so investing in a circular saw with a built-in brake is the best option to minimize risks.

5. Are circular saw brakes required by law?

The requirements for circular saw brakes differ by country and jurisdiction. However, it is worth noting that many countries, including the United States, have regulations in place that govern the safety standards for power tools. These regulations often require circular saws to have a brake as a standard safety feature.

Regardless of legal requirements, it is always recommended to use a circular saw with a brake due to the added safety benefits it provides. It’s better to be proactive in ensuring your safety and the safety of those around you.

Summary

Circular saws are powerful tools that can be dangerous if not handled properly. While some models come with a brake feature that stops the blade quickly, not all circular saws have this feature.

It is important to consider safety when using a circular saw. Always follow the manufacturer’s instructions and wear protective gear, such as safety goggles and gloves. If your saw does not have a brake, be sure to wait for the blade to come to a complete stop before setting it down or moving it. Remember, safety should always be the top priority when working with any type of power tool.