So you’re curious about drill presses and whether they need a guard, huh? Well, you’ve come to the right place! Let’s dive right in and explore the importance of drill press guards and whether they are necessary for your safety.

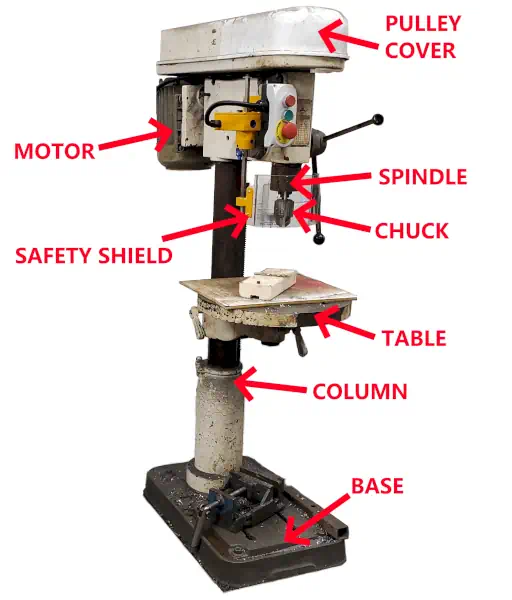

Now you might be wondering, “What exactly is a drill press guard?” Well, it’s a safety feature designed to protect you from potential hazards while using a drill press. It acts as a barrier between your hands and the spinning drill bit, reducing the risk of accidents and injuries.

But here’s the thing: even though a drill press guard is designed with your safety in mind, not all drill presses come with one. So the question arises: does a drill press really need a guard? Join me as we delve into the answer and uncover the truth behind this common query.

A drill press is an essential tool for woodworking and metalworking projects. While it is not required by law to have a guard on a drill press, it is highly recommended for safety purposes. A guard helps prevent accidental contact with the rotating drill bit and reduces the risk of injury. It acts as a protective barrier, shielding your hands and fingers from potential harm. Investing in a drill press guard is a wise decision to prioritize your safety while working with this powerful tool.

Does a Drill Press Need a Guard?

A drill press is a powerful tool that is commonly used in woodworking and metalworking projects. It provides precision and accuracy when drilling holes, making it an essential piece of equipment for professionals and hobbyists alike. However, safety is always a top priority when using any power tool, and one important aspect of drill press safety is the use of guards. In this article, we will explore the need for a guard on a drill press and the potential benefits it provides.

The Importance of Drill Press Guards

When operating a drill press, there is always a risk of accidents or injuries. The rotating drill bit can easily catch clothing, jewelry, or loose hair, leading to entanglement or severe injuries. Additionally, the high speed of the drill press can cause flying debris that can be hazardous to the operator and those nearby. This is where a drill press guard comes in.

A guard is a protective cover that is designed to enclose the drill bit during operation. It acts as a barrier between the operator and the rotating drill bit, preventing accidental contact. The guard is typically made of transparent material, allowing the operator to see the drilling process while maintaining a safe distance. It also helps to contain any flying debris, reducing the risk of injuries to the operator and other individuals in the vicinity.

Drill press guards are designed to meet safety standards and regulations set by organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). These standards ensure that the guard provides adequate protection and is constructed with durability and reliability in mind.

The Benefits of Using a Drill Press Guard

1. Enhanced Safety: The primary benefit of using a guard on a drill press is improved safety. It minimizes the risk of accidents and injuries by preventing contact with the rotating drill bit. This is especially important when working with long pieces of material or performing repetitive drilling tasks.

2. Dust and Debris Containment: A drill press guard helps contain the dust and debris generated during drilling. This not only keeps the work area clean but also reduces the risk of inhaling harmful particles. It is especially beneficial when working with materials such as wood or metal that can create fine particles when drilled.

3. Noise Reduction: The guard also acts as a noise barrier, reducing the noise level generated by the drill press. This is particularly useful in environments where noise control is necessary, such as workshops or shared spaces.

Types of Drill Press Guards

Drill press guards come in various types, each with its own design and features. Here are three common types of guards:

- Fixed Guard: A fixed guard is a permanent fixture attached to the drill press column or table. It provides continuous protection by fully enclosing the drill bit, but it may limit the visibility of the drilling process.

- Adjustable Guard: An adjustable guard allows for flexibility in positioning and provides protection while providing better visibility. It can be adjusted to accommodate different drill bit sizes and drilling depths.

- Removable Guard: A removable guard is designed to be easily attached or detached from the drill press. It offers convenience in situations where the guard is not always necessary, allowing for quick access to the drill bit.

Tips for Using a Drill Press Guard Safely

While a drill press guard is an important safety feature, it is crucial to use it correctly to ensure maximum protection. Here are some tips for using a drill press guard safely:

- Always ensure that the guard is properly fitted and secured before operating the drill press.

- Inspect the guard for any damage or defects before each use. If any issues are found, replace or repair the guard as necessary.

- Keep the work area clean and free from clutter to prevent any obstructions that may interfere with the guard’s functionality.

- Invest in a high-quality guard that meets safety standards to ensure optimal protection.

- Follow the manufacturer’s instructions for installing, adjusting, and maintaining the guard.

Additional Considerations

While a drill press guard is an excellent safety measure, it is important to note that it may not be required for all drilling operations. The need for a guard may vary based on the type of material being drilled, the size of the hole, and the level of experience of the operator. It is always recommended to assess the specific requirements of the task at hand and consult industry guidelines or safety experts when in doubt.

Conclusion

When it comes to drill press safety, a guard plays a crucial role in protecting the operator from potential accidents and injuries. It enhances safety, contains dust and debris, and reduces noise levels. By understanding the importance of a drill press guard and following proper safety practices, operators can significantly minimize the risks associated with drill press operations. Remember, safety should always be a top priority in any workshop or project involving power tools like drill presses.

Key Takeaways: Does a Drill Press Need a Guard?

- A drill press generally needs a guard for safety purposes.

- The guard helps protect your hands and fingers from accidentally coming into contact with the rotating drill bit.

- Some drill presses come with built-in guards, while others may require you to purchase and install one separately.

- Using a guard ensures that debris and wood chips are redirected away from you, minimizing the risk of injury.

- Always check the manufacturer’s instructions and guidelines to determine if a guard is necessary for your specific drill press model.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we will address common queries about drill presses and the need for a guard. Explore the questions below to learn more about drill press safety and the importance of using guards.

Q: How does a guard benefit me when using a drill press?

A: A guard on a drill press serves as a protective barrier between the user and the rotating drill bit. It helps prevent accidental contact with the bit, reducing the risk of injury. The guard acts as a shield, deflecting chips and debris away from the operator, ensuring safer operation. By providing a physical barrier, a guard can also prevent loose clothing or jewelry from getting caught in the moving parts, further reducing the risk of accidents.

In addition to personal safety, a guard can also contribute to the quality of your work. It helps maintain a consistent depth and angle of drilling by keeping the material aligned. By preventing the material from shifting, the guard ensures accurate and precise holes.

Q: Are guards necessary for all drilling operations?

A: Yes, using guards is highly recommended for all drilling operations on a drill press. Regardless of the material being drilled or the size of the hole, a guard provides an essential layer of protection. While some smaller drill press operations may seem less hazardous, accidents can happen unexpectedly. It’s better to be safe and use a guard at all times to minimize the risk of injury.

Even when working with materials that don’t produce large chips or shavings, such as plastic or metal, a guard is still essential. It helps protect against flying particles or flakes that can cause harm. Remember, safety should always be the top priority when operating any power tool, and a guard is an important safety feature to have in place.

Q: Can I remove the guard for better visibility during drilling?

A: While it may seem tempting to remove the guard for better visibility while drilling, it is strongly advised against doing so. The guard’s purpose is to protect you from potential hazards, and its removal significantly increases the risk of accidents and injuries. Any improvement in visibility is greatly outweighed by the potential danger.

If you find that the guard is obstructing your view, consider adjusting the position or angle of the workpiece. Use additional lighting or mirrors to enhance visibility without compromising safety. Always prioritize safety over convenience, as even a brief moment without a guard can result in a serious accident.

Q: What should I do if my drill press does not come with a guard?

A: If your drill press does not come with a guard, it is recommended to purchase and install one before using the machine. Guards designed specifically for drill presses are widely available and can be easily attached to the machine. Consult the manufacturer’s guidelines or seek professional advice to ensure you select the correct guard for your specific drill press model.

Using a drill press without a guard is not recommended and may compromise your safety. Investing in a guard is a small price to pay for the added protection it provides. Prioritize your well-being and follow proper safety protocols when operating a drill press, which includes using a guard at all times.

Q: Can I modify or remove the guard on my drill press?

A: It is strongly advised against modifying or removing the guard on your drill press. The guard is an integral part of the safety features designed to protect the user from potential hazards. Tampering with or removing the guard can increase the risk of accidents and injuries.

If you feel that the guard is hindering your work or needs adjustment, consult the manufacturer’s guidelines or seek professional assistance. It’s important to maintain the integrity of the guard and ensure it functions properly to provide optimal protection during drilling operations.

Summary

So, does a drill press need a guard? Well, the answer is yes! Having a guard on your drill press is essential for safety. Without a guard, you risk injury from flying debris or getting your fingers too close to the drill bit.

A guard acts as a protective barrier, preventing accidents and keeping you safe during operation. It should cover the spinning drill bit and have an opening that allows you to see and guide your workpiece. Remember, safety should always come first, so make sure to use a guard whenever you’re using a drill press!