When it comes to working with plywood, one question that often arises is, “Does grain direction matter?” Well, let’s dive into this intriguing topic and find out! The grain direction of plywood can indeed impact its performance and appearance, making it crucial to understand its significance. So, if you’re curious to unravel the mystery behind grain direction in plywood, you’ve come to the right place!

Now, you might be wondering, “Why is grain direction important anyway?” Well, my friend, the direction in which the grain runs can affect the strength, stability, and overall aesthetic of plywood. It can impact how the material holds up under stress, how it warps or expands, and even how it looks when finished. So, whether you’re a woodworking enthusiast or just someone eager to expand their knowledge, understanding the intricacies of grain direction in plywood can be worthwhile and fascinating.

But fear not, fellow curious minds! In this article, we’ll explore the reasons why grain direction matters in plywood. We’ll uncover the differences between long grain and cross grain, discover how they affect the structural integrity, and learn which scenarios are best suited for each grain direction. So, grab a cup of coffee, put on your thinking cap, and let’s dive into the wonderful world of plywood grain direction!

Does Grain Direction Matter with Plywood?

Plywood is a versatile material that is commonly used in construction, furniture making, and various other applications. However, one question that often arises is whether the grain direction in plywood matters. In this article, we will explore the importance of grain direction in plywood and its impact on the strength, appearance, and performance of the material.

Understanding Grain Direction in Plywood

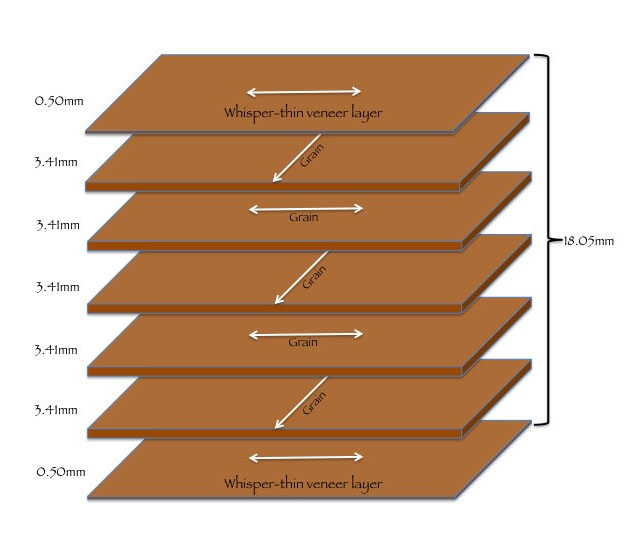

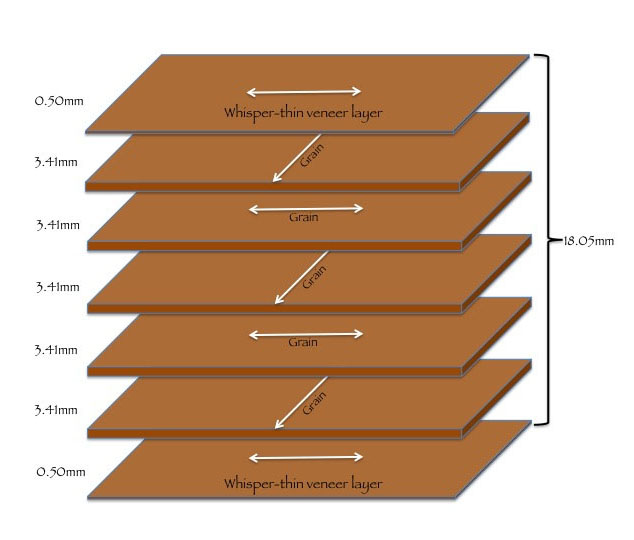

Grain direction refers to the orientation of the wood fibers in a piece of plywood. Plywood is made by gluing together multiple layers, or plies, of wood veneers. Each veneer typically has its own grain direction, and when they are stacked and glued, the orientation of these veneers determines the overall grain direction of the plywood.

The two main grain directions in plywood are “long grain” and “cross grain.” Long grain plywood has the veneer layers running parallel to the length of the sheet, while cross grain plywood has the veneer layers running perpendicular to the length of the sheet. The orientation of the grain can significantly impact the properties of the plywood.

The Strength Advantage of Long Grain Plywood

Long grain plywood offers certain advantages in terms of strength. When load is applied to a piece of plywood with long grain, the load is distributed along the length of the grain fibers. This results in a stronger and more stable material that is less likely to warp or split under stress.

Long grain plywood is commonly used for applications that require structural integrity, such as subfloors, roof decking, and wall sheathing. The lengthwise orientation of the grain provides added strength and stiffness, making it ideal for supporting heavy loads or spanning larger distances.

However, it is worth noting that the specific strength of plywood depends on various factors, including the type of wood used, the adhesive used in the manufacturing process, and the overall construction of the plywood panel.

The Benefits and Limitations of Cross Grain Plywood

While long grain plywood has its advantages, cross grain plywood also has its place in certain applications. Cross grain plywood is known for its increased dimensional stability, meaning it is less likely to expand or contract due to moisture changes. This can be beneficial in environments with high humidity or moisture fluctuations.

Additionally, cross grain plywood tends to be more flexible than long grain plywood. It can be more easily bent or curved to fit specific shapes and contours, making it suitable for applications that require curved surfaces or intricate designs. It is often used in furniture making, cabinetry, and decorative paneling.

However, the same properties that make cross grain plywood more flexible and dimensionally stable also make it less strong compared to long grain plywood. It may not be the best choice for applications that require high strength or load-bearing capabilities.

Choosing the Right Grain Direction for Your Project

When deciding on the grain direction for your plywood project, it is essential to consider the specific requirements and constraints of your application. If strength and load-bearing capacity are crucial, long grain plywood is generally the preferred choice.

On the other hand, if you are working on a project that involves curved surfaces, intricate designs, or requires dimensionally stable plywood, cross grain plywood may be the better option.

Ultimately, it is essential to understand the particular characteristics and trade-offs of each grain direction and make an informed decision based on the specific project requirements.

The Impact of Grain Direction on Plywood Quality

When it comes to plywood quality, grain direction is one of the factors that can significantly impact the overall performance and appearance of the material. Understanding this impact is crucial for ensuring you select the right plywood for your project.

Appearance and Aesthetics

Grain direction can have a significant impact on the appearance and aesthetics of plywood. Long grain plywood typically showcases the natural beauty and texture of the wood species used, as the continuous grain lines create a visually appealing pattern.

Alternatively, cross grain plywood may exhibit more uniformity in appearance, as the alternating grain direction can create a more consistent and homogeneous surface. This can be desirable for certain applications where a uniform and clean look is desired.

Ultimately, the choice between long grain and cross grain plywood for aesthetic purposes depends on the desired look and style of your project.

Preventing Delamination

Delamination is a phenomenon where the layers of plywood start to separate, compromising its structural integrity. The grain direction can play a role in preventing or minimizing delamination.

Long grain plywood tends to be more resistant to delamination due to the parallel alignment of the grain fibers. The continuous, uninterrupted grain lines provide strong bonding surfaces, reducing the risk of separation between the layers.

While cross grain plywood can still be structurally sound, the alternating grain direction poses a slightly higher risk of delamination. However, the quality of the plywood, including the adhesive used in its construction, plays a significant role in preventing delamination.

Impact on Strength and Durability

As mentioned earlier, the grain direction in plywood can influence its strength and durability. Long grain plywood, with its fibers running parallel to the length of the sheet, offers enhanced strength and stiffness properties, making it suitable for load-bearing and structural applications.

In contrast, cross grain plywood may exhibit lower strength and load-bearing capabilities due to the perpendicular orientation of the fibers. It may be prone to bending, warping, or sagging when subjected to heavy loads or prolonged stress.

However, it is crucial to note that plywood strength is also influenced by other factors, such as the wood species used, the number of veneer layers, and the manufacturing standards. Considering these factors alongside the grain direction is essential in selecting plywood that meets the required strength and durability standards for your project.

Tips for Working with Plywood Grain

Working with plywood grain can be challenging at times, but with the right techniques and considerations, you can achieve excellent results. Here are some tips to keep in mind:

1. Plan Your Cuts and Layout

Before cutting your plywood, carefully plan your layout to optimize the use of the grain direction. For projects that require strength or load-bearing capacity, position long grain plywood panels so that the grain runs parallel to the longest dimension of the project.

For applications that involve curved or shaped pieces, utilize cross grain plywood and plan your cuts to minimize wastage and achieve efficient use of the material.

2. Select the Right Blade

When cutting plywood, use a high-quality, sharp blade specifically designed for woodworking. A blade with fine teeth will produce cleaner and smoother cuts, reducing the chances of splintering or tear-out.

Ensure that the teeth of the blade are aligned in the same direction as the grain for cleaner cuts. For cross grain plywood, choose a blade with a higher tooth count to minimize tear-out and achieve smoother edges.

3. Properly Support the Material

When cutting plywood, make sure to adequately support the sheet to prevent tear-out and splintering. Use sawhorses or a workbench with sacrificial boards to provide a stable and supportive surface.

For cleaner cuts, use clamps or a straightedge guide to ensure smooth and straight lines. This will help maintain the integrity of the grain and reduce the risk of damage to the plywood surface.

Plywood Grain Direction – Long vs. Cross Grain: Which is Better?

When it comes to determining which grain direction is better, the answer ultimately depends on your specific project requirements. Both long grain and cross grain plywood have their advantages and limitations.

The Benefits of Long Grain Plywood

- Offers increased strength and load-bearing capacity

- Less likely to warp or split under stress

- Ideal for structural applications such as subfloors and roof decking

- Provides a visually appealing pattern due to continuous grain lines

The Benefits of Cross Grain Plywood

- Increased flexibility for curved or shaped projects

- Dimensionally stable, suitable for environments with moisture fluctuations

- Ideal for intricate designs, cabinetry, and decorative paneling

- Can exhibit a more uniform appearance

Ultimately, the decision between long grain and cross grain plywood should be based on the specific requirements of your project, considering factors such as strength, flexibility, appearance, and dimensional stability.

Conclusion

Grain direction does matter when it comes to plywood. The choice between long grain and cross grain plywood can significantly impact the strength, appearance, and performance of the material. While long grain plywood offers increased strength and load-bearing capacity, cross grain plywood provides flexibility and dimensional stability.

Understanding the specific characteristics and trade-offs of each grain direction is essential in choosing the right plywood for your project. Careful planning, proper cutting techniques, and consideration of your project requirements will help you achieve the best results when working with plywood grain.

Whether you opt for long grain or cross grain plywood, remember to choose high-quality plywood that meets the necessary standards for your application. With the right approach, plywood can be a reliable and versatile material for a wide range of projects.

Key Takeaways: Does Grain Direction Matter with Plywood?

1. Grain direction in plywood does matter and can affect its strength and stability.

2. Plywood has two grain directions: the face grain and the core grain.

3. The face grain runs perpendicular to the long edges of the plywood sheet.

4. The core grain runs parallel to the long edges of the plywood sheet.

5. Proper grain direction is important for specific applications, such as woodworking or structural projects.

Frequently Asked Questions

When it comes to plywood, understanding the grain direction is crucial for a successful project. Here are some frequently asked questions about the importance of grain direction in plywood.

1. Why is grain direction important in plywood?

Grain direction in plywood matters because it determines the strength, stability, and appearance of the final product. The orientation of the wood fibers affects how the plywood holds up to stress, how it resists warping, and how it looks when finished. Choosing the correct grain direction can make a significant difference in the overall quality and durability of your project.

For example, in structural applications like subflooring or roofing, the long grain direction (parallel to the supports) provides maximum strength and stability. On the other hand, in furniture or cabinetry where aesthetics matter, using plywood panels with the grain running perpendicular to the visible surfaces can give a more appealing appearance.

2. How can I determine the grain direction in plywood?

To determine the grain direction in plywood, you can start by looking at the surface texture. Typically, the grain direction follows the long edges of the plywood sheets. You can observe the pattern of the wood grain and see if the lines are continuous and parallel to the length or width of the sheet. The longer line direction indicates the grain direction.

Another method is bending the plywood slightly to see how it responds. Plywood tends to bend more easily along the grain direction. If you notice more flexibility along one direction than the other, that’s an indication of the grain direction. Additionally, you can examine the end grain of the plywood, which should reveal alternating thin layers (veneers) if you’re viewing the edge parallel to the grain direction.

3. Can I use plywood with grain running in any direction for all projects?

While using plywood with the grain running in any direction might be suitable for some projects, it’s not recommended for all. The grain direction plays a critical role in how the plywood performs under specific conditions, such as load-bearing, moisture exposure, or aesthetics. Therefore, it’s essential to consider the intended use and requirements of your project before deciding on the grain direction.

If you’re unsure of the ideal grain direction for your project, consulting with a woodworking professional or doing research specific to your application can provide valuable guidance. With their expertise, you can ensure that the grain direction in your plywood enhances the overall functionality and visual appeal of the finished product.

4. What are the consequences of using plywood with the wrong grain direction?

Using plywood with the wrong grain direction can lead to structural issues and compromised strength. Plywood is stronger along the grain than across it, so having the grain running the wrong way can result in weakened joints or connections. It can also increase the risk of warping or buckling, especially if the plywood is exposed to excessive moisture or changes in humidity.

In terms of aesthetics, the wrong grain direction can affect the appearance of the finished project. Plywood with visible grain lines that don’t align with the desired direction can create an uneven or undesirable pattern. This can be particularly noticeable when staining or painting the plywood surface, making it vital to choose the grain direction carefully to achieve the desired visual effect.

5. Can I change the direction of the grain in plywood?

Changing the direction of the grain in plywood is not possible because the grain direction is determined during the manufacturing process. However, you can select different plywood panels with the appropriate grain direction for your specific project. Manufacturers usually produce plywood sheets with the grain running either along the 8-foot length or the 4-foot width of the sheet.

If you need plywood with a different grain direction, you may need to cut and join multiple plywood pieces to achieve the desired orientation. This technique allows you to create larger panels with the grain running the preferred way. However, it’s important to consider the additional work involved and ensure proper reinforcement if you decide to join multiple plywood pieces.

Summary

So, does grain direction matter with plywood? The answer is yes. The direction of the grain affects the strength and stability of the plywood. When using plywood for projects, it’s important to consider the grain direction to ensure a successful outcome.