Are you wondering if OSHA requires a guard on a drill press? Well, you’ve come to the right place! Let’s dive into this topic and find out what OSHA, the Occupational Safety and Health Administration, has to say about it.

When it comes to workplace safety, OSHA plays a crucial role in ensuring that workers are protected from hazards. Now, let’s tackle the burning question: does OSHA require a guard on a drill press?

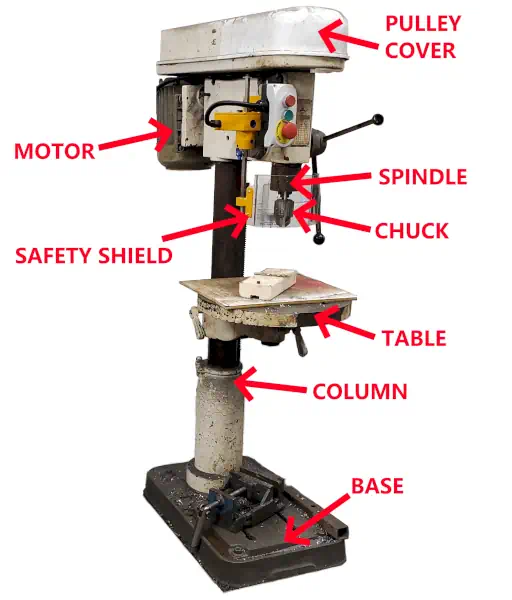

Drill presses are powerful tools that can pose serious risks if not used correctly. So, it’s essential to understand OSHA’s regulations regarding guard requirements for drill presses. Let’s explore this topic further!

In order to ensure workplace safety, it is crucial to understand OSHA requirements for drill presses. OSHA does indeed require a guard on drill presses to prevent operator injuries. These guards protect against rotating parts and flying debris, reducing the risk of accidents. By providing a barrier between the operator and the drill press, guards help maintain a safe working environment. Compliance with OSHA regulations is essential for all businesses to prioritize employee well-being.

Does OSHA Require a Guard on Drill Press?

In the realm of workplace safety, OSHA (Occupational Safety and Health Administration) plays a critical role in defining and enforcing regulations that safeguard employees. One commonly debated topic is whether OSHA requires a guard on drill presses. Let’s delve into this matter and explore what OSHA guidelines mandate, the potential benefits of drill press guards, and safety tips to enhance workplace safety.

Understanding OSHA Regulations for Drill Press Guards

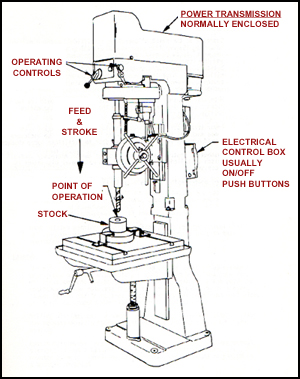

When it comes to drill press safety, OSHA does indeed provide guidelines regarding the use of guards. According to OSHA Standard 1910.212(a)(1), employers are required to provide safeguarding measures, such as machine guards, to protect workers from hazardous machine operations. This means that if a drill press poses a potential risk of injury to operators and those nearby, employers must install and maintain appropriate guards to mitigate this risk.

It’s important to note that the specifics of OSHA requirements for drill press guards may vary depending on factors like the type of drill press, the work being performed, and other employer-specific considerations. Employers should consult the OSHA website or seek guidance from OSHA representatives within their region to ensure compliance with the relevant regulations.

By adhering to OSHA guidelines and implementing necessary safeguards, employers can prevent accidents, reduce the risk of injuries, and maintain a safe working environment for their employees. Now, let’s explore the potential benefits of drill press guards.

The Benefits of Drill Press Guards

1. Injury Prevention: One of the primary benefits of drill press guards is their ability to prevent injuries. A properly installed guard acts as a physical barrier between the operator and the rotating drill bit, reducing the risk of accidental contact and subsequent injuries.

2. Dust and Debris Containment: In addition to protecting operators, drill press guards can also help contain dust and debris generated during drilling operations. This not only keeps the work area cleaner but also reduces the potential for respiratory issues or slip hazards caused by scattered debris.

3. Enhanced Work Efficiency: When operators feel safe and secure while using a drill press, they can focus on their tasks without the distraction of potential accidents or injuries. This, in turn, can lead to increased productivity and improved work efficiency.

How to Choose the Right Drill Press Guard

When selecting a drill press guard, it’s essential to consider the following factors:

- Compatibility: Ensure that the guard is compatible with your specific drill press model.

- Visibility: Opt for a guard that allows clear visibility of the drilling operation while still providing adequate protection.

- Durability: Choose a guard made from sturdy materials that can withstand regular use and potential impacts.

- Adjustability: Look for guards that offer adjustable features to accommodate different workpiece sizes and drilling depths.

- Easy Installation: Select a guard that is easy to install and remove for maintenance or tool changes.

Tips for Ensuring Drill Press Safety

In addition to utilizing an appropriate drill press guard, here are some general safety tips to promote a safe working environment:

- Provide comprehensive training to operators on the safe operation of drill presses.

- Maintain the drill press in good working condition by conducting regular inspections and maintenance.

- Wear personal protective equipment (PPE) such as safety glasses and gloves when operating a drill press.

- Keep the work area clean and free of clutter to prevent trips and falls.

- Follow proper procedures for securing workpieces and using clamps to prevent movement during drilling operations.

- Always use the appropriate drill bit for the material being drilled and adjust the drill press speed accordingly.

Conclusion

In conclusion, while OSHA does not explicitly require a guard on all drill presses, employers have a responsibility to assess potential hazards and implement appropriate safeguards to protect their workers. Utilizing a drill press guard can help prevent injuries, improve work efficiency, and maintain a safe working environment. Ensure your chosen guard is compatible, durable, and easy to install, and also follow general safety tips to enhance workplace safety. By prioritizing the well-being of employees and complying with OSHA guidelines, employers demonstrate their commitment to maintaining a safe and productive workplace.

Key Takeaways: Does OSHA Require a Guard on Drill Press?

- While OSHA does not specifically require a guard on drill press, it does require employers to ensure a safe working environment.

- A guard on a drill press helps prevent accidents and injuries by shielding workers from moving parts.

- Using a guard on a drill press can lower the risk of entanglement, amputations, or objects being ejected.

- Employers should conduct a hazard assessment to determine if a guard is necessary for the specific drill press and tasks being performed.

- Even if not required by OSHA, installing a guard on a drill press is a best practice to protect workers and promote a safe workplace.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we address common concerns about drill press safety and OSHA regulations. Discover everything you need to know about guards on drill press machines.

Why are guards necessary on a drill press?

Guards on a drill press serve a crucial role in ensuring operator safety. They act as a protective barrier between the user and the drill bit, reducing the risk of injury from accidental contact. Guards also help contain any flying debris or chips that may result from the drilling process, preventing them from hitting the operator or bystanders.

Additionally, guards on a drill press help prevent loose clothing, jewelry, or long hair from becoming entangled in the rotating drill bit. They play a vital role in minimizing the potential hazards associated with operating a drill press, protecting the operator from serious harm.

What are OSHA’s requirements regarding guards on drill presses?

OSHA, the Occupational Safety and Health Administration, mandates that employers must provide a safe working environment, including proper safeguards for hazardous equipment. While OSHA does not specifically outline the requirement of guards on drill presses in their regulations, they do expect employers to take appropriate measures to protect workers from potential hazards.

Although the specific design and type of guard may vary depending on the drill press model and its associated risks, OSHA emphasizes that guards should be in place to minimize the risk of injuries caused by contact with moving parts or ejected materials. Employers should follow industry best practices and manufacturer recommendations when it comes to installing and maintaining guards on drill presses to meet OSHA’s safety standards.

Can a drill press be operated without a guard?

No, a drill press should never be operated without a guard. Operating a drill press without a guard exposes the operator to significant risks of injury. Even experienced operators can accidentally come into contact with the rotating drill bit, resulting in severe cuts, lacerations, or even amputations. Without a guard, there is also a higher chance of materials being ejected, posing a danger to the operator and those nearby.

It’s important to prioritize safety and comply with OSHA regulations by always using the appropriate guards when operating a drill press. By adhering to these safety measures, you can help prevent accidents and maintain a safe working environment.

Are there any exceptions where guards may not be required on a drill press?

In certain cases, there may be exceptions where guards are not required on a drill press. However, these exceptions are limited and should be assessed and approved by safety professionals or regulatory authorities. Industries such as woodworking or metalworking may have specific applications or procedures that necessitate the removal of guards temporarily under controlled circumstances.

However, it is important to note that these exceptions should only be considered after conducting a thorough risk assessment, implementing alternative safety measures, and ensuring that all other OSHA requirements are met. It is crucial to consult with safety experts and follow all relevant safety guidelines and regulations to maintain a safe working environment.

What other safety precautions should be taken when operating a drill press?

In addition to using the appropriate guards, there are several other safety precautions that should be followed when operating a drill press. These include:

1. Wearing appropriate personal protective equipment (PPE) such as safety glasses and gloves to prevent injuries from flying debris.

2. Securing the workpiece firmly in place using clamps or a vise to ensure it won’t move during drilling.

3. Adjusting the drill press speed and feed rate according to the material being drilled to prevent overheating or accidents.

4. Using the proper drilling techniques and avoiding excessive force that could cause the bit to break or the workpiece to be ejected.

5. Regularly inspecting the drill press for any loose or damaged parts and ensuring it is properly maintained.

By following these safety precautions in addition to using guards, operators can minimize the risks associated with drill press operation and create a safer working environment.

Summary

To sum it up, OSHA does not explicitly require a guard on a drill press. However, they do mandate that employers provide a safe work environment. It is crucial for employers to assess the hazards associated with the drill press and take appropriate measures to protect workers.

In doing so, employers can install guards on drill presses to prevent accidents and injuries. By following OSHA guidelines and implementing safety measures, employers can ensure the well-being of their employees and promote a safe workplace.