Is plywood the star of your DIY projects? Have you ever wondered, “Does plywood go bad?” Well, I’ve got some good news for you, my curious friend! In this article, we’re going to explore the lifespan of plywood, its potential deterioration factors, and how you can keep your plywood in tip-top shape. So, let’s dive right in and discover the fascinating world of plywood longevity!

Plywood is like a superhero of construction materials, but even superheroes have their limits. That’s why it’s important to know whether plywood can go bad over time. Don’t worry, we’re here to shed some light on this question and ease your worries. Whether you’re building furniture, a treehouse, or even a spaceship (hey, dream big!), understanding plywood’s lifespan is key to ensuring the success and durability of your projects.

Now, we might not have the ability to predict the future, but we can certainly examine the factors that can impact plywood’s lifespan. From moisture and sunlight to improper storage and insect invasions, there are various culprits that can cause plywood to deteriorate. However, fear not! With some preventive measures, you can increase the longevity of your plywood and enjoy the fruits of your DIY labor for years to come. So, let’s embark on this plywood adventure together and uncover the secrets to keeping your plywood in pristine condition!

Does Plywood Go Bad? Exploring the Lifespan of Plywood

Plywood is a versatile building material that is commonly used in various construction projects. It is known for its strength, durability, and cost-effectiveness. However, like any other material, plywood is not immune to the effects of time, weather, and other external factors. In this article, we will delve into the question of whether plywood goes bad and explore the factors that can affect its lifespan.

Understanding Plywood and Its Composition

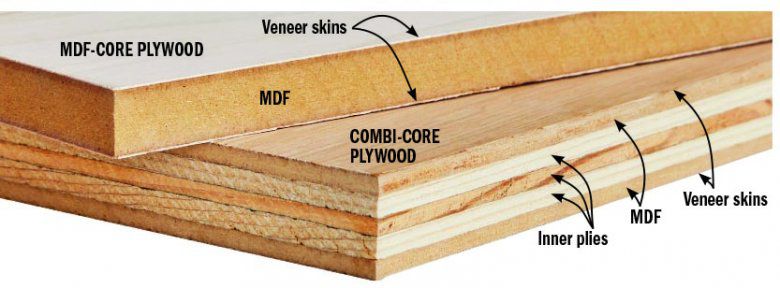

To understand whether plywood can go bad, it is essential to first comprehend its composition. Plywood is made by gluing multiple layers of thin veneers together, with each layer having its grain direction. This cross-lamination technique gives plywood its strength and stability. The adhesive used in the manufacturing process plays a crucial role in determining the lifespan of the material.

Plywood is commonly graded based on its quality and intended use. Different grades of plywood have different levels of resistance to weather, moisture, and other external elements. It is important to choose the appropriate grade of plywood for your project to ensure its longevity.

Factors Affecting the Lifespan of Plywood

Now that we understand the composition of plywood, let’s explore the factors that can impact its lifespan:

1. Moisture and Humidity: Plywood is susceptible to damage from moisture and high humidity levels. Extended exposure to these elements can lead to warping, swelling, and delamination of the layers. Proper sealing and finishing techniques can help protect plywood from moisture-related issues.

2. Sunlight and UV Radiation: Continuous exposure to sunlight and UV radiation can cause the surface of plywood to fade and develop cracks. If plywood is used outdoors or in areas with direct sunlight, it is important to apply appropriate sealants or coatings to protect it from UV damage.

3. Insects and Fungi: Plywood, especially untreated or low-grade plywood, is vulnerable to insect infestation and fungal growth. Termites and wood-boring beetles can compromise the structural integrity of plywood, while fungi such as mold and rot can cause decay. Proper treatment and regular inspection can help prevent these issues.

4. Mechanical Stress: Plywood can withstand a significant amount of mechanical stress, but excessive loads, impacts, or repetitive movements can lead to damage. It is important to consider the intended use and load-bearing capacity of plywood to ensure its longevity.

5. Improper Installation and Maintenance: Incorrect installation techniques and inadequate maintenance can significantly reduce the lifespan of plywood. Properly fastening plywood, providing sufficient ventilation, and addressing any issues promptly can help prolong its durability.

Benefits of Using Plywood

Plywood offers several advantages over other building materials, making it a popular choice in construction and woodworking projects. Here are some of the key benefits of using plywood:

1. Strength and Durability: Plywood’s cross-lamination technique gives it exceptional strength and durability, making it resistant to warping, cracking, and twisting. It can handle heavy loads and withstand various weather conditions.

2. Versatility: Plywood can be utilized in a wide range of applications, including furniture, flooring, cabinetry, and structural elements. It can be easily cut, shaped, and finished according to project requirements.

3. Cost-Effectiveness: Plywood is an economical option compared to solid wood or engineered materials. It offers similar strength and performance at a lower cost, making it suitable for budget-conscious projects.

4. Sustainability: Plywood is an environmentally friendly choice as it is made from sustainable sources of wood. Look for plywood that is certified by organizations such as the Forest Stewardship Council (FSC) to ensure responsible sourcing.

5. Aesthetics: Plywood comes in various grades and finishes, allowing for a diverse range of visual appearances. From smooth, sanded finishes to decorative veneers, plywood offers versatility in design and aesthetics.

Common Uses of Plywood

Plywood finds applications in a multitude of industries and projects. Here are some of the common uses of plywood:

1. Construction: Plywood is extensively used in construction projects for structural elements such as roofs, walls, and floors. It provides stability and strength while reducing costs compared to traditional materials.

2. Furniture: Plywood is a popular choice for manufacturing furniture due to its strength, durability, and ease of shaping. It is commonly used for items like tables, chairs, cabinets, and shelves.

3. Interior Design: Plywood can be used to create visually appealing accents and decorative features in interior design. From wall paneling to ceiling finishes, plywood offers versatility and aesthetic appeal.

4. Packaging and Transport: Plywood crates and pallets are widely used for packaging and transporting goods. Plywood’s strength and rigidity make it an ideal choice for protecting items during shipping and storage.

5. Marine Applications: Marine-grade plywood, which is specially treated to resist water and withstand harsh marine conditions, is widely used in boat construction, docks, and other maritime applications.

Tips for Extending the Lifespan of Plywood

To ensure the longevity of plywood, consider these tips:

1. Choose the right grade of plywood for your project. Higher-grade plywood offers better resistance to moisture, insects, and decay.

2. Apply appropriate sealants and coatings to protect plywood from moisture and UV damage.

3. Avoid exposing plywood to prolonged periods of direct sunlight or extreme weather conditions.

4. Regularly inspect plywood for signs of damage, such as warping, delamination, or insect infestation.

5. Properly install and fasten plywood, following manufacturer guidelines and using suitable hardware.

6. Maintain adequate ventilation to prevent the buildup of moisture and humidity.

7. Clean plywood regularly using mild detergent and a soft cloth to remove dirt, dust, and stains.

In conclusion, while plywood is a durable and versatile material, it is not immune to the effects of time and external factors. Factors such as moisture, sunlight, insects, and mechanical stress can affect the lifespan of plywood. However, by choosing the right grade, protecting it from these elements, and following proper installation and maintenance practices, you can extend the longevity of plywood and ensure its optimal performance in various applications.

Key Takeaways: Does Plywood Go Bad?

- Plywood can deteriorate over time due to moisture, pests, and exposure to sunlight.

- Proper storage and maintenance can prolong the lifespan of plywood.

- Inspect plywood for signs of decay, such as warping, mold, or rot.

- Using plywood within its recommended lifespan ensures structural integrity and safety.

- Replace damaged or deteriorated plywood to maintain the quality of your projects.

Frequently Asked Questions

Curious about the lifespan of plywood? We’ve got you covered! Check out these commonly asked questions about whether plywood can go bad.

1. What factors contribute to plywood going bad?

There are a few factors that can contribute to plywood deteriorating over time. Firstly, exposure to moisture and extreme changes in humidity can cause the plywood to warp, split, or delaminate. Additionally, if the plywood hasn’t been properly sealed or treated, it can be more susceptible to damage from pests or decay-causing organisms. Finally, prolonged exposure to sunlight and UV rays can also affect the integrity of the plywood.

While plywood is generally a durable material, it’s essential to consider these factors when determining the lifespan of your plywood projects and taking proper precautions to prevent any potential damage.

2. How long does plywood typically last?

The lifespan of plywood can vary depending on various factors, including the quality of the plywood, its intended use, and the conditions it’s exposed to. In ideal conditions, with proper sealing and maintenance, plywood can last for decades. However, if exposed to excessive moisture, extreme temperature changes, or other harsh conditions, the lifespan of the plywood may be significantly shorter. It’s important to consider the specific use and environment of the plywood to determine its expected lifespan.

To maximize the lifespan of plywood, it’s recommended to protect it from excessive moisture, use proper sealants or coatings, and store or install it in a controlled environment, away from direct sunlight and extreme temperature fluctuations.

3. How can I prevent plywood from going bad?

To prevent plywood from deteriorating, there are a few preventive measures you can take. Firstly, ensure the plywood is properly sealed on all sides and edges with appropriate sealants or coatings. This will protect it from moisture and limit the chances of warping or delamination. Secondly, avoid exposing the plywood to prolonged direct sunlight, as UV rays can degrade the material over time.

Additionally, store plywood in a cool, dry place when not in use, and keep it elevated off the ground to prevent moisture absorption. If using plywood in outdoor applications, consider treating it with preservatives, such as wood treatment solutions or paint, to protect it from decay-causing organisms.

4. Can plywood be salvaged if it starts to go bad?

If plywood starts to show signs of deterioration, it may still be salvageable depending on the extent of the damage. Minor issues, such as small cracks or surface damage, can often be repaired with wood filler or epoxy. However, if the plywood has significant delamination, warping, or decay, it may be beyond repair and will need to be replaced.

It’s important to regularly inspect your plywood projects for any signs of damage and address them promptly to prevent further deterioration. Taking quick action can increase the chances of salvaging the plywood and extending its lifespan.

5. Is there an expiration date on plywood?

Plywood does not have a specific expiration date. However, as with any building material, plywood will degrade over time, especially if not properly maintained or exposed to harsh conditions. While there’s no set expiration date, it’s recommended to consider the factors mentioned earlier, such as moisture exposure, temperature changes, and UV rays, to assess the overall condition and usability of the plywood.

Regular inspection, maintenance, and proper storage or installation can help maximize the lifespan of plywood and ensure its long-term usability.

5 Mistakes Buying Plywood – Don’t Waste Your Money!

Summary

Plywood can go bad if it gets wet or exposed to extreme weather conditions. Water can cause it to warp or rot over time. It’s important to store plywood properly and protect it from moisture to make it last longer.

To prevent plywood from going bad, keep it in a dry and well-ventilated area. Avoid exposing it to rain or high humidity. If you notice any signs of damage such as swelling, mold, or a musty smell, it’s best to replace the plywood. Taking care of plywood will ensure it stays strong and useful for your projects.