When it comes to working with a lathe, there are often questions that arise, like “does the tailstock spin on a lathe?” If you’ve ever wondered about this, you’re in the right place! In this article, we’ll explore the intriguing world of lathes and reveal the answer to this burning question.

Now, you might be thinking, “Why is knowing if the tailstock spins important?” Well, my curious friend, the tailstock is a critical component of a lathe that helps support and stabilize the workpiece. So, let’s dive in and uncover the truth about whether or not it spins!

Before we unveil the answer, let’s take a moment to appreciate the artistry behind lathes. These powerful machines have been used for centuries to shape and transform various materials, allowing craftsmen and artisans to create intricate designs and precise objects. And the tailstock? It plays a vital role in ensuring accuracy and stability during the turning process. So, without further ado, let’s satisfy our curiosity and discover if the tailstock indeed spins on a lathe!

Does the Tailstock Spin on a Lathe?

Welcome to this comprehensive guide on the operation of a lathe’s tailstock. Whether you are a beginner or a seasoned woodworker, understanding the functionality and capabilities of the tailstock is crucial. In this article, we will delve into the topic of whether the tailstock spins on a lathe. We will explore how the tailstock functions, its purpose, and the various features that make it a valuable tool in the woodworking world.

Understanding the Tailstock on a Lathe

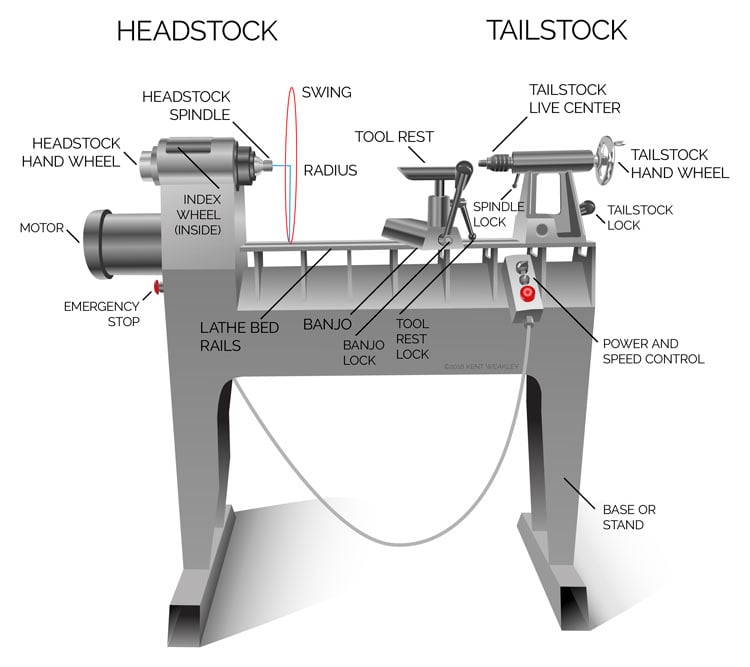

The tailstock is an essential component of a lathe machine. It is located opposite the headstock and plays a vital role in supporting long workpieces during turning operations. While the headstock rotates the workpiece, the tailstock remains stationary, providing stability and preventing vibrations. It consists of several parts such as the body, quill, ram, and spindle. Each component contributes to the tailstock’s functionality and versatility.

Components of a Tailstock

The body of the tailstock is typically made from cast iron or steel and is firmly attached to the bed of the lathe. It provides a sturdy base for the other components. The quill is a cylindrical part that slides along the body of the tailstock. It can be locked at different positions to accommodate workpieces of various lengths. The ram connects the quill to the handle, which allows for easy movement and adjustment. At the end of the quill is the spindle, which holds accessories such as drill chucks, live centers, or dead centers. This combination of components enables the tailstock to perform a wide range of operations.

Functionality of the Tailstock

The primary function of the tailstock is to provide support to long workpieces, preventing them from deflecting or vibrating during turning. It helps maintain accuracy and ensures a smooth and balanced rotation. The tailstock can be adjusted vertically along the bed to accommodate different workpiece lengths. By locking the quill at a specific position, the tailstock allows for precise positioning and drilling operations. Additionally, the tailstock spindle can hold various attachments, increasing the versatility of the lathe.

Benefits of Using the Tailstock

The tailstock offers numerous benefits to woodworkers, making it an indispensable component of a lathe. Firstly, it provides stability, allowing for smoother and more precise turning. This is particularly important when working with long or heavy pieces of wood. The tailstock’s ability to hold attachments such as drill chucks also enables drilling operations, expanding the range of possibilities. Furthermore, by supporting the workpiece, the tailstock reduces the risk of damage or accidents during the turning process. Overall, the tailstock enhances safety, accuracy, and versatility in woodworking projects.

Tailstock Vs. Faceplate: A Comparison

While the tailstock is an essential component in lathe operations, it is worth exploring its differences with another tool called the faceplate. The faceplate is a circular metal plate that attaches directly to the headstock of the lathe. It allows for the turning and shaping of irregularly shaped or asymmetrical workpieces. Let’s compare the tailstock and faceplate to understand their distinct features and when to use each.

Tailstock Vs. Faceplate: Stability

When it comes to stability, the tailstock is the clear winner. As mentioned earlier, the tailstock supports long workpieces, preventing any deflection or vibrations during turning. This stability ensures better accuracy and reduces the risk of accidents. On the other hand, the faceplate is primarily used for irregularly shaped workpieces that cannot be securely held by the tailstock alone. While it provides some stability, it may not be as reliable as the tailstock.

Tailstock Vs. Faceplate: Versatility

In terms of versatility, the faceplate takes the lead. It allows for the attachment of various woodworking accessories such as chucks, collets, and other fixtures. These attachments enable the secure holding of irregularly shaped workpieces and the execution of complex turning operations. The faceplate also offers greater flexibility in terms of positioning and adjustments. However, the tailstock can also hold attachments and perform specific operations like drilling.

Tips for Operating the Tailstock

To optimize the performance of the tailstock on a lathe, here are some helpful tips:

- Ensure that the tailstock is securely locked in place before starting any turning operations.

- Regularly clean and lubricate the components of the tailstock to maintain smooth movement.

- Use the appropriate attachments, such as live centers or drill chucks, based on the specific task at hand.

- Always check the alignment of the tailstock with the headstock to ensure accuracy.

- Adjust the tailstock’s position and quill depth based on the length of the workpiece for optimal support.

Versatility of the Tailstock

Aside from providing stability and support, the tailstock offers a range of capabilities that enhance its versatility. Here are three key ways in which the tailstock can be used:

Drilling Operations

One of the primary functions of the tailstock is to facilitate drilling operations on the lathe. By attaching a drill chuck or other drilling accessories to the tailstock spindle, woodworkers can drill accurate holes in their workpieces. The tailstock provides the necessary support and stability for precise drilling without deflection. This capability is particularly useful when creating wooden bowls, vases, or spindle work that requires holes for assembly or decoration.

Turning Tapers

The tailstock is also crucial when turning tapers on a lathe. A taper is a gradual reduction in diameter along the length of a workpiece. By adjusting the tailstock’s position and angle, woodworkers can create tapers with precision and consistency. This is commonly used in furniture making, where tapered legs or spindles add elegance and visual interest to the pieces.

Supporting Long Workpieces

As mentioned earlier, one of the primary functions of the tailstock is to support long workpieces during turning operations. This is especially beneficial when working on projects such as table legs, chair spindles, or staircase balusters. The tailstock ensures that the workpiece remains stable and centered, allowing for accurate shaping and turning. Without the tailstock, these longer pieces would be prone to deflection or excessive vibration, compromising the quality of the final product.

In conclusion, the tailstock is a vital component of a lathe that provides stability, support, and versatility. Its ability to facilitate drilling operations, turn tapers, and support long workpieces makes it an indispensable tool for woodworkers. By understanding how the tailstock functions and utilizing its various features, craftsmen and hobbyists can achieve precise and high-quality results in their lathe projects. So, next time you ask, “Does the tailstock spin on a lathe?” remember that while it doesn’t spin, it serves a crucial purpose in your woodworking endeavors.

Key Takeaways: Does the Tailstock Spin on a Lathe?

- The tailstock on a lathe does not spin independently.

- It serves as a support for the workpiece and provides stability during machining.

- The tailstock can be locked into position to prevent movement.

- It houses the live center or dead center, which helps in holding and rotating the workpiece.

- The tailstock can be adjusted to accommodate different sizes of workpieces.

Frequently Asked Questions

Welcome to our FAQ section where we answer commonly asked questions about the tailstock on a lathe. Read on to find out more about this essential component of a lathe and its functionality.

1. How does the tailstock on a lathe work?

The tailstock on a lathe is a fixed component that provides support to the workpiece being machined. It is situated on the opposite end of the headstock. The tailstock typically consists of a spindle, a quill, and a taper for holding various tooling.

In operation, the tailstock is used to prevent the workpiece from moving while being machined. The quill can be extended or retracted to adjust the position of the tailstock in relation to the workpiece. This allows for precise machining and accurate drilling or turning operations.

2. Can the tailstock be rotated on a lathe?

No, the tailstock on a lathe does not spin or rotate like the headstock. It is primarily designed to provide support and stability to the workpiece. The rotational motion in machining is driven solely by the headstock.

However, the tailstock can be moved along the bed of the lathe to accommodate different lengths of workpieces. This allows for versatility in machining operations, enabling the lathe to handle a wide range of workpiece sizes and shapes.

3. What is the purpose of a live center in the tailstock?

A live center is a type of centerpoint that is placed in the tailstock to support the workpiece. It has bearings that allow it to rotate along with the workpiece as it is being machined. The live center helps to reduce friction and heat generated during the machining process.

This rotating motion of the live center assists in creating a smooth, even surface on the workpiece. It enables precision turning and reduces the chances of the workpiece getting damaged or distorted. The use of a live center also assists in achieving symmetrical and accurately centered workpieces.

4. Can the tailstock be removed from a lathe?

Yes, the tailstock on a lathe can usually be removed for certain machining operations. This feature allows for the machining of longer workpieces that may extend beyond the bed of the lathe. By removing the tailstock, the workpiece can be supported on its entirety without any obstruction.

However, it is important to note that removing the tailstock may limit the machining capabilities of the lathe, particularly for operations that require the support and stability provided by the tailstock. It is essential to carefully consider the requirements of the specific machining task before removing the tailstock.

5. How do you align the tailstock on a lathe?

Aligning the tailstock on a lathe is a crucial step to ensure precise machining. To align the tailstock, you can use various methods, such as using a dial test indicator or a precision alignment tool. The goal is to ensure that the tailstock is perfectly parallel and aligned with the lathe’s bed.

By correctly aligning the tailstock, you can achieve accurate machining results without any misalignment or deflection. This is particularly important for operations such as drilling or turning where precision is crucial. Regularly checking and adjusting the alignment of the tailstock is recommended to maintain the accuracy of the lathe.

How I Stop Drills from Spinning in the Tailstock

Summary

So, to sum it up, the tailstock on a lathe does not spin. Its main purpose is to support the other end of the workpiece, providing stability and accuracy.

In a lathe, the tailstock remains stationary while the headstock, which holds the spinning spindle, does all the rotating. This allows for precise and controlled shaping and cutting of the material being worked on. Remember, the tailstock is there to help keep everything in place and ensure smooth and efficient machining.