Do you ever wonder just how accurate a lathe can be? Well, get ready to dive into the fascinating world of precision machining! When it comes to turning, shaping, and cutting materials, lathes play a crucial role in creating intricate and precise parts. But just how accurate can a lathe work? Let’s find out!

When you think about it, a lathe is like a magician’s tool, capable of transforming raw materials into carefully crafted masterpieces. But how does it achieve such precision? It all comes down to the incredible engineering behind this versatile machine. From the precise alignment of its components to the advanced control systems, a lathe is designed to achieve astonishing accuracy.

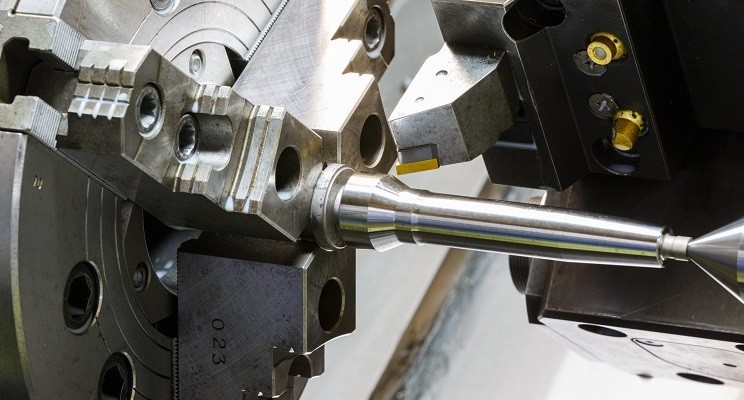

Imagine creating a perfectly round cylinder or a precisely threaded rod with utmost precision. A lathe’s high accuracy can be attributed to its ability to maintain tight tolerances, which means it can repeatedly produce parts that meet strict specifications. Thanks to technological advancements, lathes can now achieve accuracy in the range of a few thousandths of an inch, sometimes even less!

So, whether you’re a hobbyist or a professional machinist, understanding the accuracy of a lathe is key to accomplishing your machining goals. In this article, we’ll explore the factors that influence the accuracy of a lathe, the techniques used to enhance its precision, and the incredible applications where precise machining plays a vital role. Get ready to unlock the secrets of the lathe’s accuracy and discover the magic it brings to the world of manufacturing!

1. Leveling and aligning the lathe bed.

2. Calibrating the spindle and tailstock alignment.

3. Using quality cutting tools and correct tool geometry.

4. Applying proper cutting speeds and feeds.

5. Regularly checking and adjusting the lathe’s backlash and wear.

By following these steps, a lathe can achieve impressive accuracy for precise machining tasks.

How Accurate Can a Lathe Work? Exploring Precision in Turning Operations

When it comes to machining and fabrication processes, accuracy and precision are of utmost importance. A lathe, a versatile tool used in various industries, is renowned for its ability to shape and turn materials with high precision. In this article, we will delve into the world of lathes and explore the factors that contribute to their accuracy, uncovering just how accurate a lathe can work.

The Importance of Precision in Lathe Operations

Precision plays a pivotal role in lathe operations. Whether it’s creating intricate designs, manufacturing complex parts, or achieving tight tolerances, precision is the key to ensuring successful outcomes. In lathe work, precision refers to the ability to reproduce dimensions accurately and consistently. This level of accuracy is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can result in significant issues or failures.

Several factors contribute to the precision of lathe work. From the quality and design of the lathe itself to the skill and experience of the operator, each element plays a vital role in achieving the desired level of accuracy. Let’s take a closer look at some of the key factors that influence the accuracy of a lathe.

The Quality of the Lathe

A well-built, high-quality lathe lays the foundation for accurate work. The rigidity of the lathe’s structure, the precision of its components, and the overall stability all contribute to its ability to work with precision. Lathes made from high-quality materials such as cast iron or steel are less prone to vibrations, ensuring consistent and precise machining.

Additionally, modern lathes often feature advanced technologies such as CNC (Computer Numerical Control) systems. These systems allow for precise control over the movement of the cutting tools, resulting in highly accurate and repeatable cuts. CNC lathes can achieve extremely tight tolerances and produce complex geometries with ease.

The Skill and Experience of the Operator

While a high-quality lathe sets the stage for precision, the operator behind the machine is equally important. The skill and experience of the lathe operator can greatly influence the accuracy of the work produced. A skilled operator understands the intricacies of lathe operations, knows how to optimize cutting parameters, and can make adjustments on the fly to achieve precise results.

Furthermore, an experienced operator knows how to select and install the appropriate tools, determine the correct cutting speeds and feeds, and implement the necessary tooling strategies to minimize tool wear. Their expertise allows them to mitigate common challenges that could compromise the accuracy of the workpiece, such as tool deflection or chatter.

The Cutting Tools and Tooling Strategies

The cutting tools used in lathe operations have a significant impact on the accuracy of the work. Choosing the right tool geometry, material, and coating can greatly enhance precision. High-quality carbide inserts or solid carbide tools exhibit excellent wear resistance, reducing the chances of dimensional inaccuracies caused by tool wear.

Tooling strategies, such as selecting the appropriate tool path or employing specialized techniques like profiling or threading, also contribute to the final accuracy of the workpiece. The choice of tooling strategy depends on the desired outcome, material properties, and the complexity of the design.

Maintaining and Calibrating the Lathe

Regular maintenance and calibration of the lathe are imperative to ensure consistent accuracy. Over time, wear and tear can affect the performance and precision of the machine. Regular cleaning, lubrication, and replacement of worn-out components are necessary to keep the lathe in optimal working condition.

Furthermore, calibrating the lathe using precision measuring instruments helps validate and adjust its performance. By periodically checking and adjusting the lathe’s positioning, backlash, and other critical parameters, any deviations can be identified and corrected, ensuring continued accuracy in the machining process.

Key Takeaways: How Accurate Can a Lathe Work?

- A lathe can work with high accuracy, often measured in thousandths of an inch.

- The accuracy of a lathe depends on various factors such as machine precision and skill of the operator.

- Machinists use techniques like tool selection, proper setup, and careful monitoring to achieve accurate results.

- Advanced lathes equipped with numerical control systems can achieve even higher levels of precision.

Frequently Asked Questions

Welcome to our frequently asked questions section, where we explore the accuracy of lathes. If you’re curious about how precise a lathe can be, you’ve come to the right place. Don’t worry, we’ll break down the topic and provide simple explanations to help you understand.

1. How does a lathe achieve accuracy in its work?

A lathe achieves accuracy through various mechanisms and components. One important factor is the precision of the machine’s spindle, which holds and rotates the workpiece. High-quality spindles reduce vibrations and ensure smooth movement, leading to greater accuracy in the final product.

Additionally, the quality and precision of the lathe’s cutting tools play a crucial role. Sharp and properly aligned tools help create precise cuts and shapes with minimal errors. The overall rigidity of the lathe’s structure is also important, as it reduces any flex or movement that could affect accuracy.

2. What factors can affect the accuracy of a lathe’s work?

Several factors can impact the accuracy of a lathe’s work. First and foremost, the skill and experience of the operator can make a significant difference. Proper setup and alignment, along with the appropriate choice of cutting tools and speeds, are all dependent on the operator’s knowledge and proficiency.

The condition and maintenance of the lathe itself are also crucial. Any wear or damage to the machine’s components, such as the spindle, bed, or tailstock, can lead to inaccuracies. It’s essential to regularly inspect and maintain the lathe to ensure optimal accuracy during the machining process.

3. Can a lathe achieve micrometer-level accuracy?

Yes, lathes are capable of achieving micrometer-level accuracy when operated with precision and using the right techniques. However, achieving such high levels of accuracy requires advanced machinery, carefully selected cutting tools, and an experienced operator who understands the nuances of the lathe.

Lathes equipped with digital readouts (DROs) or computer numerical control (CNC) systems offer increased accuracy, as these technologies allow for precise control of cutting parameters. With proper setup, calibration, and meticulous attention to detail, a lathe can produce components with incredible precision.

4. How can I improve the accuracy of my lathe’s work?

Improving the accuracy of a lathe’s work requires attention to several aspects. Start by ensuring your lathe is properly calibrated and aligned. Check for any signs of wear and tear, and address any issues promptly. Regularly clean and lubricate the machine to maintain its optimal performance.

Investing in high-quality cutting tools and regularly sharpening them can significantly improve accuracy. Additionally, take the time to learn proper lathe techniques and experiment with different feed rates and cutting speeds to find the optimal settings for your specific project. Lastly, practice makes perfect, so keep honing your skills to enhance the accuracy of your lathe’s work.

5. What are the limitations to the accuracy of a lathe’s work?

While lathes can achieve impressive accuracy, there are limitations to consider. The type of material being machined can affect the achievable accuracy, as some materials may be more prone to deformation or warping during the machining process.

Moreover, the size and dimensions of the workpiece can impact accuracy. Large workpieces with extended lengths may experience slight deflection, affecting precision. It’s important to understand these limitations and account for them in your machining plans to ensure accurate results.

Summary

Lathe work is pretty accurate, but not perfect. Small errors can occur due to machine limitations or operator mistakes. However, by using proper techniques and tools, the accuracy of lathe work can be improved.

If you’re a beginner, don’t worry! With practice and patience, you can achieve greater precision. It’s important to understand the machine’s capabilities and limitations, and make adjustments accordingly. Don’t forget to double-check your measurements and take your time to achieve the best possible results. Keep learning and honing your lathe skills, and you’ll see improvements over time.