Have you ever wondered just how accurate a bandsaw really is? Well, you’re in luck because today we’re going to dive into the world of bandsaws and explore their precision. So, buckle up and get ready to discover the ins and outs of this versatile tool!

When it comes to woodworking, precision can make all the difference between a masterpiece and a mess. That’s why understanding the accuracy of your tools is crucial. And when it comes to bandsaws, accuracy plays a significant role in achieving those clean, precise cuts you desire. But how accurate are they really? Let’s find out!

Whether you’re a seasoned woodworker or just starting out, knowing the accuracy of a bandsaw can help you choose the right tool for your projects and achieve the results you want. So, let’s take a closer look at the factors that affect bandsaw accuracy and uncover the secrets behind this mighty cutting machine.

How Accurate is a Bandsaw? Discover the Precision of this Powerful Tool

When it comes to accuracy, a bandsaw is renowned for its precise cutting capabilities. Here are some factors that contribute to its accuracy:

- High-quality blades with fine teeth for clean cuts

- Sturdy construction for stability

- Precision tracking systems for consistent blade alignment

- Adjustable guides to control the cut

- Variable speed control for versatility

With these features, a bandsaw ensures accurate cuts for woodworking projects, making it an essential tool for precision work.

How Accurate Is a Bandsaw?

A bandsaw is a versatile tool commonly used in woodworking and metalworking. It consists of a continuous band of toothed metal stretched over two or more wheels, allowing for precision cutting of materials. One common question that arises when considering the use of a bandsaw is how accurate it is. In this article, we will explore the factors that contribute to the accuracy of a bandsaw and provide insight into its capabilities.

The Anatomy of a Bandsaw

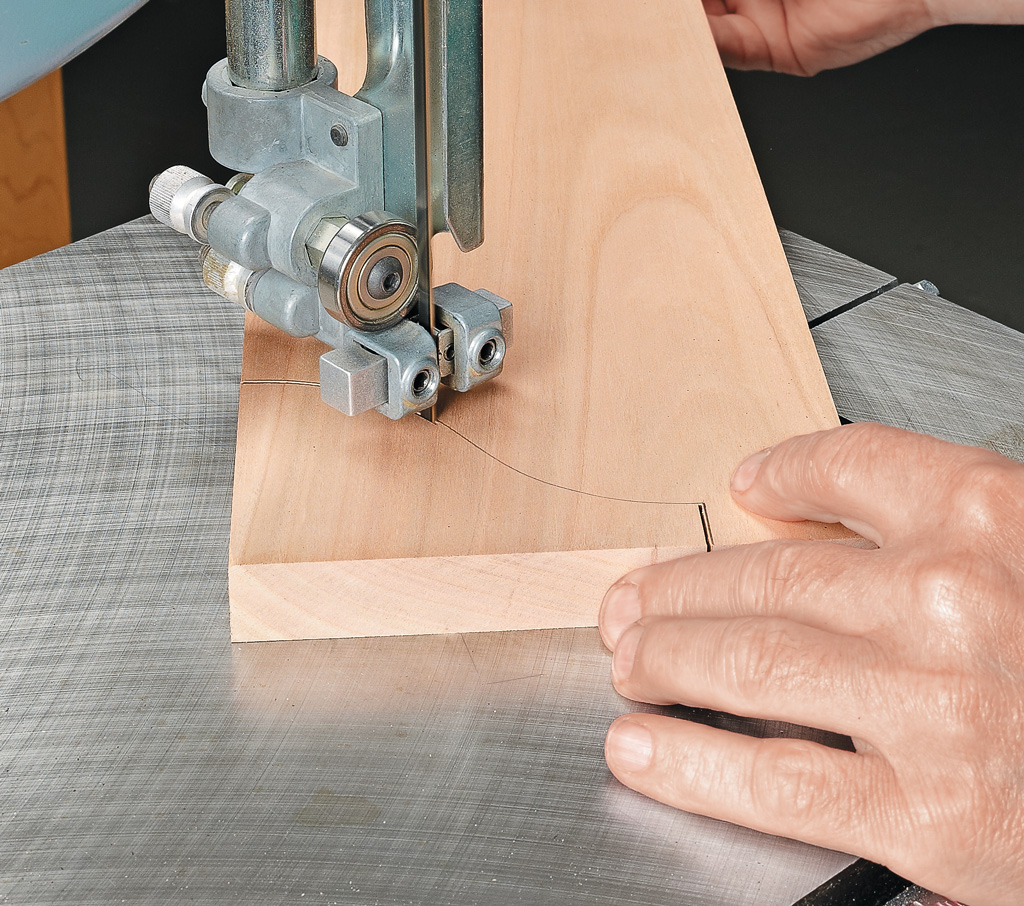

Before delving into the accuracy of a bandsaw, it is important to understand its basic components. A typical bandsaw consists of a table, a blade, guides, and wheels. The table provides a sturdy surface to support the material being cut, while the blade, usually made of steel, is responsible for the actual cutting. The guides help keep the blade aligned and prevent it from drifting during the cutting process. Finally, the wheels, connected to a motor, rotate the blade at high speeds, enabling efficient cutting.

Now that we have a basic understanding of a bandsaw’s components, let’s explore the factors that contribute to its accuracy.

The Blade

The choice of blade plays a crucial role in the accuracy of a bandsaw. Blades come in various sizes, tooth configurations, and materials, and each is suited to specific cutting tasks. For fine, precise cuts, a blade with a high tooth count and a narrow width is preferable. A wider blade with fewer teeth, on the other hand, is more suitable for resawing or cutting thicker materials. Additionally, the quality and sharpness of the blade are essential for accurate cuts. A dull or damaged blade will result in imprecise cuts and may cause the material to bind or kickback.

The tension of the blade is another critical factor. An improperly tensioned blade will lead to inaccurate cuts and may cause the blade to flex or wander during use. It is essential to follow the manufacturer’s guidelines for proper blade tension and regularly check and adjust it as needed.

Besides the blade itself, the condition of the bandsaw’s guides and wheels also impact its accuracy. Worn or damaged guides can cause the blade to deviate from its intended path, resulting in imprecise cuts. Similarly, wheels that are not properly aligned or have worn-out tires can affect the movement of the blade, leading to inaccuracies. Regular maintenance and inspection of these components are necessary to ensure the bandsaw’s accuracy.

Table and Fence

The flatness and stability of the bandsaw’s table are vital for accurate cuts. A warped or uneven table can cause the material being cut to rock or shift, resulting in imprecise cuts. It is crucial to regularly check the table’s flatness and make any necessary adjustments or repairs. Additionally, a solid, well-aligned fence is essential for guiding the material during cuts. The fence must be parallel to the blade and firmly secured in place to prevent movement, which can lead to inaccuracies.

Lastly, the power and control of the bandsaw’s motor also affect its accuracy. A powerful motor with variable speed control allows for precise adjustments based on the material being cut. The ability to fine-tune the speed can prevent burning or chattering and result in cleaner, more accurate cuts.

Getting the Most Accurate Cuts with a Bandsaw

Now that we have explored the factors that contribute to the accuracy of a bandsaw, let’s discuss some tips to ensure the most precise cuts:

Blade Selection and Maintenance

Choose the appropriate blade for the task at hand. For fine, detailed cuts, opt for a blade with a high tooth count and narrow width. Regularly inspect and sharpen the blade to maintain its cutting performance and accuracy.

Proper Blade Tension

Ensure the blade is correctly tensioned according to the manufacturer’s guidelines. Improper tension can lead to wandering cuts and imprecise results. Regularly check and adjust the tension as needed.

Check and Maintain Guides and Wheels

Inspect the guides and wheels for wear or damage regularly. Replace any worn or damaged components to ensure smooth and accurate cuts. Lubricate the guides to minimize friction and maximize their effectiveness.

Flat and Stable Table

Regularly check the flatness of the table and make any necessary adjustments or repairs. Ensure the table is stable and secure to prevent material movement during cuts. Align and secure the fence parallel to the blade to aid in accurate guiding of the material.

Motor Power and Control

Choose a bandsaw with a powerful motor and variable speed control for optimal cutting performance. Adjust the speed based on the material being cut to prevent burning or chattering and achieve accurate results.

By following these tips and considering the factors that contribute to a bandsaw’s accuracy, you can maximize the precision and quality of your cuts, resulting in exceptional woodworking or metalworking projects.

Common Questions About Bandsaw Accuracy

Q: Can a bandsaw provide as accurate cuts as other tools?

A: While a bandsaw offers a high level of accuracy, especially for curved cuts and intricate designs, it may not match the precision of other tools such as a table saw or a miter saw for certain tasks. Bandsaws excel in their ability to cut complex shapes and curves, but they may not be as accurate for repetitive, straight cuts.

Q: Is it necessary to use a bandsaw fence for accurate cuts?

A: While a bandsaw fence can aid in achieving accurate cuts, its use depends on the specific task. For straight cuts or resawing, a fence can provide additional guidance and stability. However, for intricate or curved cuts, relying solely on the bandsaw’s blade and without a fence can offer greater flexibility and maneuverability.

Q: Can I achieve accurate resawing with a bandsaw?

A: Yes, a bandsaw is well-suited for resawing tasks. With the proper blade and setup, a bandsaw can cut thin slices from the edge of a board, resulting in accurate and consistent thicknesses. It is important to use a wide blade with fewer teeth for resawing to prevent the blade from clogging and ensure efficient cutting.

Conclusion

A bandsaw is a versatile tool that can provide accurate and precise cuts when properly set up and maintained. Factors such as blade selection and maintenance, table and fence condition, and motor power and control all contribute to the bandsaw’s overall accuracy. By following the tips provided and considering these factors, you can ensure the best results from your bandsaw and achieve exceptional woodworking and metalworking projects.

Key Takeaways: How Accurate Is a Bandsaw?

- A bandsaw is generally considered to be a highly accurate tool for cutting wood and other materials.

- However, the accuracy of a bandsaw largely depends on various factors, such as blade quality, tension, and alignment.

- Regular maintenance and proper setup are crucial for achieving accurate cuts with a bandsaw.

- Bandsaw blade drift is a common issue that can affect accuracy, but it can be mitigated by adjusting the fence or using specialized techniques.

- Ultimately, with proper setup and technique, a bandsaw can provide precise and repeatable cuts for woodworking projects.

Frequently Asked Questions

Looking to learn more about the accuracy of a bandsaw? Check out these frequently asked questions and get all the answers you need!

How does the accuracy of a bandsaw compare to other woodworking tools?

The accuracy of a bandsaw is highly regarded among woodworking enthusiasts. While it may not provide the same level of precision as a table saw or a CNC machine, it is still considered a reliable tool for many tasks. Bandsaws are particularly good at making curved cuts and intricate designs due to their narrow blades and versatile functionality. However, when it comes to making perfectly straight cuts, other tools like a table saw might be more accurate. It’s important to choose the right tool for the specific job you’re tackling.

That being said, with practice and the right setup, a bandsaw can produce accurate results. By adjusting the blade tension, tracking, and blade guides properly, you can minimize any potential inaccuracies that might arise. Additionally, using a high-quality blade specifically designed for precision work can further enhance the accuracy of your cuts.

Is blade selection important for achieving accurate cuts on a bandsaw?

Absolutely! Blade selection plays a crucial role in achieving accurate cuts on a bandsaw. Different blades have different tooth configurations, widths, and materials, which can greatly impact the accuracy of your cuts. For example, a blade with a finer tooth count will provide smoother cuts on delicate materials, while a blade with coarser teeth might work better for rougher cuts. Choosing the correct blade for the task at hand is essential for achieving accurate results.

Furthermore, the condition of the blade is equally important. Dull or damaged blades can lead to imprecise cuts. Regularly inspecting and maintaining your blades will not only ensure their accuracy but also extend their lifespan. Remember to keep your blades clean, sharp, and properly tensioned to maximize their accuracy and performance.

Are there any techniques or tips for improving the accuracy of a bandsaw?

Yes, there are several techniques and tips that can help improve the accuracy of your bandsaw cuts. First and foremost, ensure that your bandsaw is properly set up. Check the blade tension, tracking, and alignment to minimize any potential inaccuracies. Investing in a good-quality fence or guide system can also greatly enhance the precision of your cuts.

Another important technique is taking your time and using a slow feed rate when making cuts. Rushing through the process can result in less accurate cuts. Additionally, using a resawing technique, which involves cutting larger wood pieces into thinner boards, can improve the accuracy of cuts by reducing the chance of blade deviations.

Can a bandsaw be used for intricate and detailed work?

Absolutely! Bandsaws are renowned for their ability to handle intricate and detailed work. The narrow blades of a bandsaw allow for tight curves and intricate designs that might be difficult to achieve with other woodworking tools. This makes bandsaws a popular choice for tasks like scrollwork, fretwork, and decorative cuts.

When working on intricate projects, it’s important to choose blades with smaller tooth counts and narrow widths. These blades provide better maneuverability and precision. Additionally, practicing proper blade control and using appropriate jigs and guides can further enhance the accuracy of your cuts when working on detailed projects.

How does the price range of a bandsaw affect its accuracy?

The price range of a bandsaw can have an impact on its accuracy, but it’s not the sole determining factor. While higher-end bandsaws often come with more precise components and advanced features, it’s still possible to achieve accurate cuts with mid-range or even entry-level bandsaws.

Ultimately, the accuracy of a bandsaw depends on various factors such as blade selection, setup, maintenance, and technique. Even a lower-priced bandsaw can produce accurate results if these factors are taken into consideration. However, investing in a higher-quality bandsaw can provide added stability, smoother operation, and more advanced features, which can contribute to improved accuracy and ease of use.

Summary

So, how accurate is a bandsaw? Well, while bandsaws are great for cutting curves and rip cuts, their accuracy can vary. It depends on factors like the quality of the blade, tension adjustments, and the skill of the operator. While bandsaws can produce fairly accurate cuts, they may not be as precise as some other tools.

If you’re looking for precise cuts, a bandsaw might not be your best bet. It’s more suited for rough cutting and shaping. Remember, practice and the right techniques can improve your accuracy with a bandsaw. So, go ahead and give it a try, but keep in mind its limitations.