If you’re curious about the accuracy of a centre lathe, you’ve come to the right place! Wondering how precise these machines are when it comes to machining and shaping materials? Let’s dive in and explore the world of centre lathes together!

When it comes to working with cylindrical pieces, a centre lathe is a go-to tool for many craftsmen and engineers. But how accurate is it? In this article, we’ll uncover the secrets behind the precision of centre lathes and shed light on the factors that influence their accuracy.

So, are you ready to discover the ins and outs of centre lathe accuracy? Let’s get started and learn all about the fascinating world of machining and precision engineering!

How Accurate is a Centre Lathe? An Exploration of Precision Engineering

Centre lathes are widely used machines in the field of precision engineering. They are known for their versatility and ability to create intricate and precise parts. However, many individuals wonder just how accurate these machines truly are. In this article, we will delve into the world of centre lathes, exploring their accuracy, factors that can affect precision, and the benefits they offer in various industries.

The Mechanics Behind Centre Lathes

Before diving into the accuracy of centre lathes, it’s important to understand their mechanics. A centre lathe, also known as an engine lathe or metal lathe, is a machine tool that rotates cylindrical workpieces on a central axis while cutting tools remove material to create the desired shape. These machines consist of various components, including the bed, headstock, tailstock, carriage, and tool post.

The accuracy of a centre lathe depends on multiple factors, such as the tolerances of its individual components, the level of maintenance, and the skill of the operator. In general, a well-maintained and properly set up centre lathe can achieve high levels of accuracy. However, it’s important to note that absolute precision can be influenced by external factors, such as ambient temperature and humidity, as well as the quality and consistency of the materials being machined.

In order to achieve optimal accuracy, centre lathes are equipped with features such as adjustable ways and gears, precise feed mechanisms, and tight fitting components. These elements, when properly calibrated and maintained, contribute to the overall precision of the machine.

The Role of Tolerance in Centre Lathe Accuracy

Tolerance is a crucial aspect of precision engineering, and it plays a significant role in determining the accuracy of centre lathes. Tolerance refers to the acceptable deviation from a specified dimension or specification. In the context of a centre lathe, it represents the degree of accuracy it can achieve during the machining process.

The accuracy of a centre lathe is typically specified using tolerances expressed in thousandths of an inch or in microns. For example, a lathe with a tolerance of ±0.001 inches means that it can produce parts that deviate from the desired dimensions by no more than 0.001 inches. The lower the tolerance, the more precise the lathe is considered to be.

It’s important to note that achieving tolerances in the sub-micron range requires specialized and often expensive equipment, including high-precision measuring tools and ultra-precise lathes. These types of lathes are typically used in industries such as aerospace, medical device manufacturing, and electronics, where precision is of utmost importance.

Factors Affecting Centre Lathe Precision

While centre lathes are designed to achieve high levels of accuracy, several factors can affect their precision. These factors include:

- Machine condition: A well-maintained and calibrated lathe will perform with greater accuracy compared to one that has not been properly maintained.

- Tool wear: As cutting tools wear down over time, they may introduce deviations in the machined parts. Regular tool inspections and replacements are necessary to maintain precision.

- Workpiece stability: Unstable workpieces can cause vibrations, resulting in inaccuracies. Proper setup and clamping techniques are crucial to ensure workpiece stability.

- Operator skill: The expertise and experience of the operator greatly influence the accuracy of a centre lathe. Skilled operators can adjust cutting parameters, select appropriate tools, and make necessary adjustments to achieve desired tolerances.

- Material characteristics: Different materials have varying properties that can impact machining accuracy. Factors such as hardness, brittleness, and thermal conductivity can affect the precision of the lathe’s operation.

The Benefits of Centre Lathes in Precision Engineering

Despite the potential factors that can affect their accuracy, centre lathes offer numerous benefits in the field of precision engineering. Some of the key advantages include:

- Versatility: Centre lathes can be used for a wide range of applications, from threading and turning to facing and tapering. Their adaptability makes them invaluable in industries where diverse machining tasks are required.

- Customization: Centre lathes allow for precise customization of parts, enabling manufacturers to meet specific design requirements and tolerances.

- Cost-effectiveness: Compared to more specialized precision machining equipment, centre lathes are relatively affordable. This makes them accessible to small-scale manufacturers and workshops.

- Ease of use: With proper training and experience, operating a centre lathe can be relatively straightforward. Their intuitive nature and user-friendly interfaces make them suitable for a wide range of operators.

- Longevity: Centre lathes are known for their durability and longevity when maintained properly. This ensures a reliable and consistent performance over an extended period of time.

Closing Thoughts

In conclusion, centre lathes are highly accurate machines that have their precision governed by multiple factors, including tolerances, machine condition, tool wear, workpiece stability, operator skill, and material characteristics. While they may not be able to reach the microscopic tolerances required for certain specialized applications, centre lathes offer a balance of precision, versatility, and cost-effectiveness that make them indispensable in various industries.

Whether it be in manufacturing components for the aerospace industry or crafting intricate parts for medical devices, centre lathes continue to play a crucial role in precision engineering. So, the next time you come across a centre lathe at work, appreciate its ability to create precise and intricate machined parts that are vital to our modern world.

Key Takeaways: How Accurate is a Centre Lathe?

- A centre lathe is a machine tool used for machining cylindrical workpieces with high precision.

- The accuracy of a centre lathe depends on various factors such as the quality of the machine, operator skill, and maintenance.

- The tolerance level of a centre lathe can range from a few micrometers to a few hundred micrometers.

- To ensure accuracy, regular calibration and alignment of the lathe are essential.

- Inaccuracies in a centre lathe can be minimized through proper setup, tool selection, and cutting techniques.

Frequently Asked Questions

Welcome to our frequently asked questions section on the accuracy of a centre lathe. Here, we’ll address some common queries regarding the precision and reliability of this machining tool. Read on to learn more!

1. What factors affect the accuracy of a centre lathe?

The accuracy of a centre lathe is influenced by various factors. Firstly, the quality and condition of the lathe itself play a significant role. A well-maintained machine with precise components will offer greater accuracy. Additionally, the skill and experience of the operator also impact the results achieved.

Furthermore, the cutting tool used, the workpiece material, and the machining conditions, including speed, feed rate, and depth of cut, can affect the accuracy of the final product. It’s important to consider and optimize these factors to achieve the desired level of accuracy.

2. How is the accuracy of a centre lathe measured?

The accuracy of a centre lathe is typically measured using tolerances. Tolerances define the allowable deviation from the desired dimensions or specifications. For example, a part may have a tolerance of ±0.01mm, which means it can deviate up to 0.01mm from the intended dimensions without being considered inaccurate.

To measure the accuracy of a centre lathe, precision measuring instruments such as calipers, micrometers, and gauges are used. These tools allow operators to compare the dimensions of the machined part with the specified tolerances, ensuring the final product meets the required accuracy standards.

3. How accurate can a centre lathe be?

The accuracy of a centre lathe can vary depending on several factors. Generally, modern centre lathes can achieve accuracies within a few thousandths of an inch (0.025mm). However, it’s important to note that the achievable accuracy also depends on the skill and experience of the operator, as well as the condition and quality of the lathe.

In some cases, industrial applications may require even higher levels of accuracy. In such situations, specialized lathes equipped with advanced features, such as CNC (Computer Numerical Control) capabilities, can be employed to achieve tighter tolerances and greater precision.

4. Can a centre lathe maintain its accuracy over time?

A centre lathe’s accuracy can be maintained over time with proper maintenance and regular calibration. Regular inspections, lubrication, and cleaning of the machine’s components are essential to ensure its accuracy remains consistent. Additionally, periodic calibration using precision measuring tools can detect any deviations and allow for necessary adjustments.

However, it’s important to note that with extended use and wear, some components of the lathe may require replacement or refurbishment to maintain the desired level of accuracy. By following recommended maintenance practices and addressing any signs of wear promptly, a centre lathe can maintain its accuracy for many years.

5. Are there any limitations to the accuracy of a centre lathe?

While centre lathes are capable of achieving high levels of accuracy, there are inherent limitations to consider. One such limitation is the size and weight of the workpiece. Large and heavy workpieces may introduce greater challenges in maintaining tight tolerances due to factors such as deflection or vibration.

Additionally, the capabilities of the cutting tools used can impact the achievable accuracy. Tool wear, tool material limitations, and the complexity of the required machined features can affect the accuracy of the final product. In such cases, alternative machining methods or specialized tools may be necessary to achieve the desired level of precision.

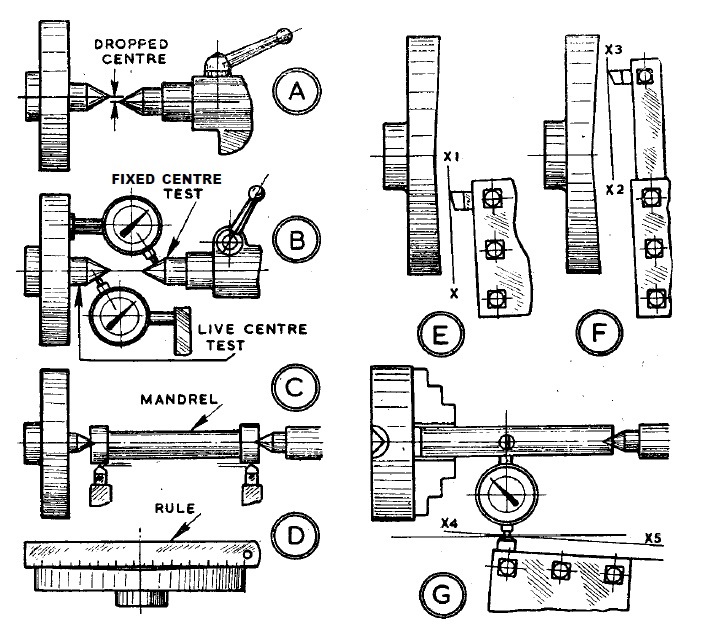

How To Align Your Lathe

Summary

When it comes to the accuracy of a centre lathe, there are a few key factors to consider. First, the skill and experience of the operator play a significant role in achieving precise results. Second, the condition and maintenance of the lathe itself can impact its accuracy. Finally, the type of work being done on the lathe can also affect its accuracy.

It’s important to remember that a centre lathe is a tool, and like any tool, it requires proper care and skill to achieve accurate results. By understanding these factors and taking the necessary steps to ensure accuracy, one can make the most of a centre lathe for various machining tasks.