Thinking about using a lathe for your DIY projects? Curious about how accurate it is? Well, you’ve come to the right place! In this article, we’ll delve into the fascinating world of lathes and explore just how precise they can be. Whether you’re a beginner or a seasoned hobbyist, understanding the accuracy of a lathe is essential for achieving those perfect cuts and smooth finishes. So, let’s get started and uncover the secrets behind the accuracy of lathes!

When it comes to woodworking or metalworking, precision is key. Imagine crafting a beautiful wooden bowl or creating intricate metal parts with absolute accuracy. That’s where the lathe comes in. But what exactly does “accuracy” mean in the context of a lathe? Simply put, it refers to the machine’s ability to produce consistent and precise results, ensuring that measurements and dimensions are on point. In other words, the accuracy of a lathe determines how closely it can replicate the desired shape or dimensions of the workpiece.

Now, you might be wondering, “How accurate can a lathe really be?” Well, the answer depends on various factors, such as the type and quality of the lathe, the skill of the operator, and the materials being worked on. While lathes can have impressive accuracy, it’s important to remember that perfection is rarely attainable in any craft or machine. However, with the right techniques, tools, and a well-maintained lathe, you can achieve remarkable precision in your projects.

So, whether you’re a hobbyist with a passion for woodworking or an aspiring machinist, understanding how accurate a lathe can be is crucial. In the following sections, we’ll explore the factors that influence lathe accuracy, tips to maximize precision, and common challenges you may encounter. So grab your safety goggles and let’s dive into the world of lathe accuracy!

When it comes to the accuracy of a lathe, several factors come into play. The precision of a lathe depends on its design, construction, and the skill of the operator. High-quality lathes are engineered to have tight tolerances, ensuring accurate results. Furthermore, regular maintenance and calibration are crucial for maintaining accuracy. It’s important to note that the accuracy of a lathe can vary depending on the specific model, so it’s recommended to refer to the manufacturer’s specifications for precise information.

How Accurate Is a Lathe? Exploring Precision in Machining

When it comes to machining, accuracy is of paramount importance. One of the most commonly used tools for precision machining is a lathe. But just how accurate is a lathe? In this article, we will delve into the world of lathes and uncover the factors that contribute to their accuracy. From the design and construction of the machine to the skill and technique of the operator, we will explore every aspect that affects the precision of a lathe.

The Design and Construction of Lathes

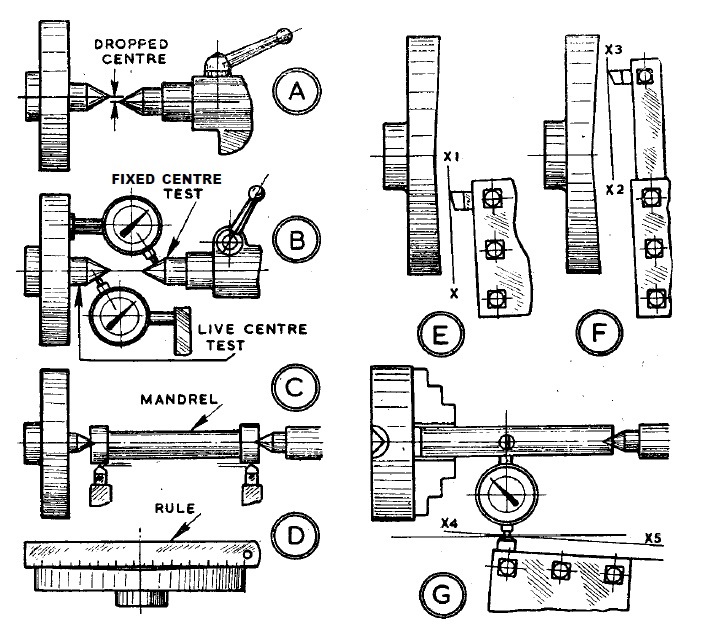

The accuracy of a lathe starts with its design and construction. A well-designed and meticulously built lathe will inherently have better accuracy compared to a machine with poor craftsmanship. The key components that play a crucial role in ensuring accuracy are the bed, headstock, tailstock, and carriage.

The bed, typically made of cast iron, provides a rigid and stable foundation for the lathe. It must be precisely machined to ensure that all parts align properly and minimize any deviation from the intended dimensions. The headstock, responsible for holding and driving the workpiece, must have tight tolerances to prevent any wobbling or deflection during operation. The tailstock, on the other hand, needs to align perfectly with the headstock to maintain concentricity.

Finally, the carriage, which moves along the bed and holds the cutting tool, must have minimal backlash and be able to move smoothly and accurately. The quality of these components, along with the overall design and construction of the lathe, directly impact its accuracy.

The Role of Operator Skill and Technique

While the design and construction of the lathe are critical, the skill and technique of the operator also play a significant role in achieving accuracy. The operator must have a thorough understanding of machining principles, tooling, and workpiece materials to make precise cuts. They need to know how to properly set up the lathe, adjust speeds and feeds, and select the appropriate cutting tools.

Furthermore, the operator must be able to read and interpret blueprints and use measuring instruments accurately. They should be skilled in taking precise measurements, whether using calipers, micrometers, or other specialized tools. The operator’s ability to make fine adjustments, maintain proper tool geometry, and perform meticulous workmanship greatly contributes to the accuracy of the lathe.

Experience and expertise are developed over time, and a skilled operator can enhance the accuracy of even the most basic lathe through their knowledge and technique.

The Importance of Regular Maintenance and Calibration

Another factor that affects the accuracy of a lathe is the regular maintenance and calibration of its components. Over time, wear and tear can occur, leading to degraded performance and reduced accuracy. It is crucial to perform routine maintenance tasks such as lubrication, cleaning, and inspection to ensure that the lathe operates at its best.

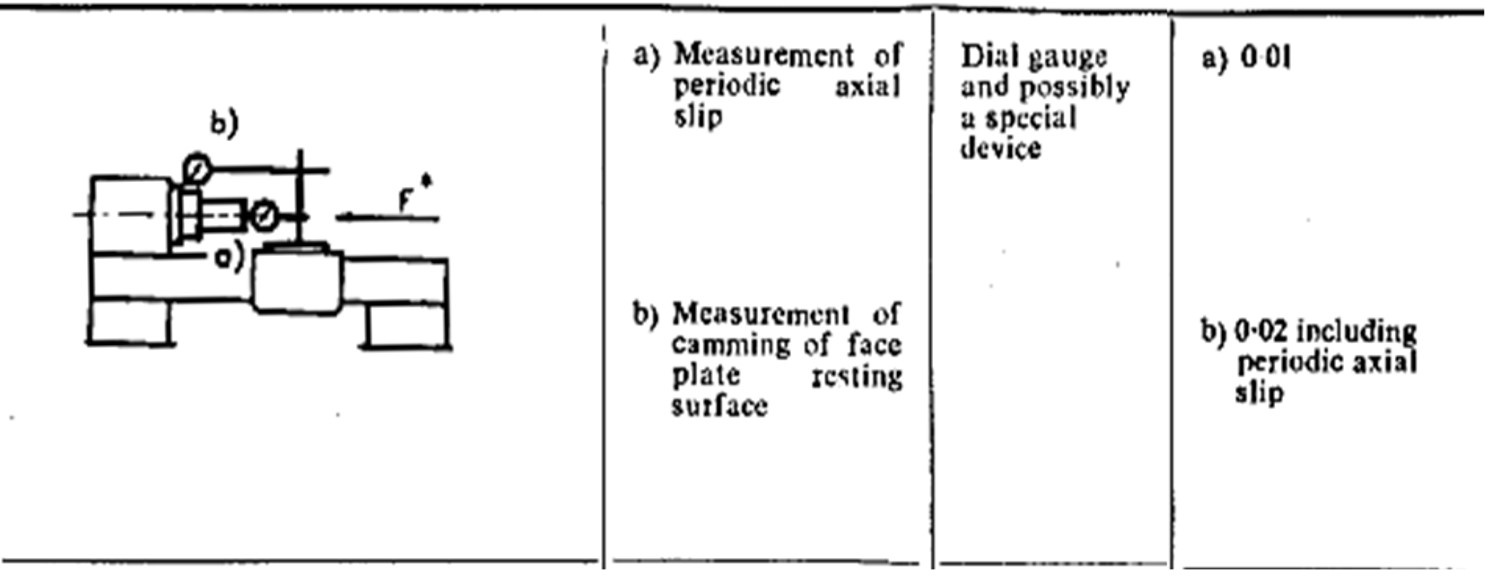

Additionally, calibration is essential to maintain accuracy. This involves checking and adjusting various elements of the lathe, including the alignment of the bed, headstock, and tailstock, as well as the perpendicularity of the ways and the accuracy of the carriage movement. Calibrating measuring instruments, such as dial indicators and scales, is also necessary to ensure accurate measurements.

By incorporating regular maintenance and calibration practices, the accuracy of the lathe can be preserved and even improved over time, ensuring consistent precision in machining operations.

Benefits of Using an Accurate Lathe

The accuracy of a lathe has several significant benefits. First and foremost, it allows for the production of precise and dimensionally accurate workpieces. This is crucial in industries such as aerospace, automotive, and medical, where tight tolerances are required. An accurate lathe enables the creation of complex parts with intricate details and ensures that the final product functions as intended.

Moreover, an accurate lathe reduces the need for secondary operations and minimizes material waste. With precise machining, parts can be manufactured with minimal or no additional machining required, saving time and resources. Additionally, accurate machining leads to tighter fits and better functionality in assemblies, resulting in improved overall product quality.

Lastly, an accurate lathe enhances the reputation and credibility of a machining shop. Consistently producing high-quality and precise parts establishes trust among customers and sets the foundation for long-term relationships and future business opportunities.

Tips for Maximizing Lathe Accuracy

To ensure the maximum accuracy of a lathe, there are several tips and best practices that operators should follow:

- Regularly clean and lubricate the lathe to prevent buildup and maintain smooth operation.

- Inspect and replace worn-out or damaged components to ensure optimal performance.

- Calibrate measuring instruments regularly to guarantee accurate measurements.

- Use high-quality cutting tools that are suitable for the workpiece material.

- Practice proper tool and workpiece alignment to minimize deflection and maximize precision.

- Implement effective chip removal methods to avoid interference with the cutting process.

- Monitor and maintain appropriate cutting speeds and feeds to prevent excessive tool wear and tear.

The Future of Lathe Accuracy: Technological Advancements

As technology continues to advance, so does the accuracy of lathes. In recent years, computer numerical control (CNC) lathes have revolutionized the machining industry. These automated machines are capable of incredibly precise movements, allowing for high levels of accuracy and repeatability.

CNC lathes utilize computer programming to control every aspect of the machining process, eliminating the limitations and variability associated with manual operation. They offer features such as automatic tool changing, adaptive machining, and real-time monitoring, all of which contribute to enhanced accuracy.

Furthermore, advancements in metrology, the science of measurement, have led to more accurate and sophisticated measurement systems. Laser measurement technologies, precision probes, and optical systems have enabled operators to measure workpieces and machine components with unprecedented accuracy, ensuring the highest level of precision.

Conclusion

When it comes to machining, the accuracy of a lathe is crucial. It starts with the design and construction of the machine, as well as the skill and technique of the operator. Regular maintenance and calibration are essential to preserving and enhancing accuracy over time. The benefits of using an accurate lathe are vast, from producing precise workpieces to minimizing waste and improving overall product quality.

By following best practices and embracing technological advancements, operators can maximize the accuracy of lathes and meet the demands of increasingly complex and precise machining tasks. As technology continues to evolve, the future of lathe accuracy looks promising, opening up new possibilities and opportunities for precision machining.

How Accurate is Lathe?

- A lathe is a machine used to shape wood or metal with precision.

- The accuracy of a lathe depends on various factors, such as its design, build quality, and the skill of the operator.

- Modern lathes can achieve high levels of accuracy, often measured in thousandths of an inch or millimeter.

- However, the accuracy can be affected by factors like wear and tear, tooling, and alignment issues.

- To ensure accuracy, regular maintenance, calibration, and correct setup are essential.

Frequently Asked Questions

Welcome to our FAQs about the accuracy of lathes! Below, we have answered some common questions related to the topic. Discover important insights and gain a better understanding of the accuracy of lathes.

1. How does the accuracy of a lathe affect the quality of the work produced?

The accuracy of a lathe plays a vital role in determining the quality of the work produced. When a lathe is accurate, it ensures precise cuts, smooth finishes, and dimensional consistency. This is crucial, especially in industries such as manufacturing and machining, where precision is key. An accurate lathe minimizes errors, reduces waste, and helps achieve the desired specifications of the workpiece.

On the other hand, if a lathe’s accuracy is compromised, it can lead to imperfections in the workpiece. Inaccurate lathes can result in uneven surfaces, out-of-round parts, and incorrect dimensions. This not only affects the aesthetic appeal of the final product but can also compromise its functionality. Therefore, the accuracy of a lathe directly affects the overall quality of the work produced.

2. What factors determine the accuracy of a lathe?

Several factors contribute to the accuracy of a lathe. Firstly, the construction and alignment of the lathe’s components, such as the bed, headstock, and tailstock, play a significant role. If these components are not properly aligned, it can lead to deviations and inaccuracies in the work produced.

The precision and condition of the lathe’s guides, bearings, and lead screws also impact its accuracy. Any wear or damage in these components can affect the smooth movement and precise positioning of the cutting tool. Additionally, factors such as the rigidity of the lathe structure, the quality of the cutting tools, and the expertise of the operator can all influence the lathe’s overall accuracy.

3. Can a lathe be calibrated to improve its accuracy?

Yes, lathes can be calibrated to enhance their accuracy. Calibration involves adjusting various components and parameters of the lathe to ensure its measurements and movements align with known standards. This process typically involves checking and adjusting the alignment of the lathe’s components, calibrating the measuring instruments, and fine-tuning any necessary adjustments.

It is important to note that calibrating a lathe requires expertise and specialized tools. It is recommended to consult a professional or refer to the manufacturer’s guidelines for proper calibration procedures. Proper calibration can significantly improve the accuracy of a lathe, resulting in better quality work and increased precision.

4. Are there different levels of accuracy for lathes?

Yes, lathes are available in different levels of accuracy depending on their intended use and the industry they cater to. High-precision lathes are designed to achieve extremely tight tolerances and are commonly used in industries such as aerospace, automotive, and medical device manufacturing where precision is critical.

On the other hand, lathes used for general-purpose machining or hobbyist projects may have a lower level of accuracy. These lathes, while still capable of producing quality work, may not achieve the same level of precision as high-end, specialized lathes. It is important to select a lathe that aligns with the intended applications and desired level of accuracy to ensure optimal results.

5. Can the accuracy of a lathe deteriorate over time?

Yes, the accuracy of a lathe can deteriorate over time due to various factors. Wear and tear on the lathe’s components, such as the guides, bearings, and lead screws, can lead to increased play or backlash, resulting in reduced accuracy. Additionally, improper usage or inadequate maintenance practices can contribute to the decline in accuracy.

Regular maintenance, routine lubrication, and proper cleaning can help minimize the deterioration of a lathe’s accuracy. It is also essential to periodically check and adjust the lathe’s alignment and perform any necessary repairs or replacements to maintain its accuracy over time.

How to increase the accuracy of turning lathe (Eng sub)

# Summary

Lathes are pretty accurate machines that can make things with a lot of precision. They use cutting tools to shape materials like wood or metal. But, just like with anything else, there can be some errors when using a lathe. If the machine isn’t set up correctly or if the measurements aren’t precise, it can affect the accuracy. So, it’s important to be careful and double-check your work when using a lathe.

Also, lathes can sometimes have a bit of “play” or movement, which can affect the accuracy too. To reduce this, you can adjust the machine and make sure everything is tightened up properly. But overall, if you take your time, follow the instructions, and pay attention to detail, a lathe can be a really useful tool for making things accurately. It’s all about being patient and careful!