When it comes to machining and creating precision parts, one tool that stands out is the lathe. You might be wondering, “How accurately can a lathe work?” Well, let me tell you, a lathe is a real game-changer in the world of manufacturing and craftsmanship.

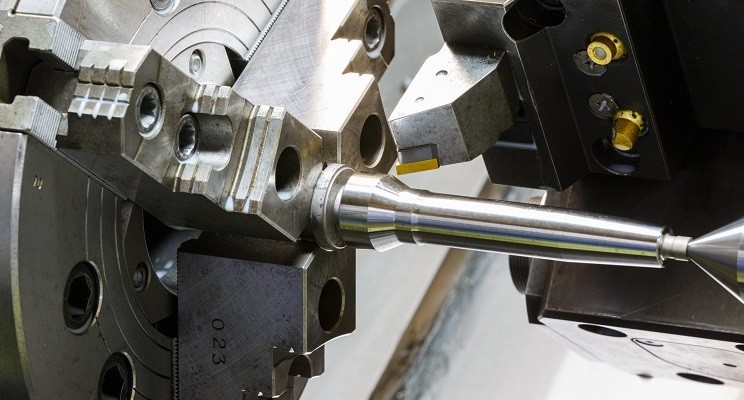

Picture this: a cylindrical piece of metal in the hands of a lathe, rotating and spinning at high speeds, while a skilled operator guides a cutting tool to shape and form the material with incredible precision. The result? Well, that’s what we’re here to explore.

So, buckle up and get ready for a fascinating journey into the world of lathes, as we dive deep into how these remarkable machines can achieve such remarkable accuracy. Get ready to have your mind blown!

How Accurately Can a Lathe Work?

Lathe machines are powerful tools extensively used in various industries for shaping, cutting, and drilling materials such as wood, metal, and plastics. Precision is the key when it comes to lathe work, as even the slightest error can affect the quality and functionality of the final product. In this article, we will explore the factors that contribute to the accuracy of a lathe and how it can ultimately impact the outcome of the work.

The Importance of Tool Geometry

When it comes to the accuracy of a lathe, the geometry of the cutting tool plays a crucial role. The cutting tool must be properly aligned and sharpened to ensure precise and clean cuts. The angle and shape of the cutting edge, known as the tool geometry, determine how well the lathe can work. A small deviation from the ideal geometry can result in imperfections on the workpiece. Factors such as tool wear, material hardness, and cutting speed also influence the accuracy of the lathe. To achieve the highest level of accuracy, it is essential to regularly inspect and maintain the cutting tools, keeping them sharp and properly aligned.

The Role of Machine Rigidity

Another important factor that determines the accuracy of a lathe is the rigidity of the machine itself. A lathe with high rigidity can resist vibrations, deflection, and other external forces that can negatively impact the precision of the work. Sturdy construction, quality materials, and proper alignment of the machine components contribute to its rigidity. Investing in a lathe with good rigidity can significantly improve the accuracy of the work. Additionally, reducing vibrations by using proper cutting techniques, choosing the right cutting speed, and securing the workpiece firmly can further enhance the precision of the lathe.

The Influence of Cutting Parameters

The choice of cutting parameters, such as the cutting speed, feed rate, and depth of cut, also affects the accuracy of a lathe. Finding the optimal combination of these parameters for a specific material and operation is crucial to achieve precise results. Adjusting the cutting speed too high or low, using an incorrect feed rate, or taking too deep cuts can lead to deviations and dimensional inaccuracies. It is essential to carefully analyze the material properties and the desired outcome to determine the appropriate cutting parameters that will ensure accurate lathe work.

Maximizing Accuracy Through Setup and Calibration

Proper setup and calibration of the lathe are essential steps in maximizing accuracy. Ensuring the lathe is leveled, aligned, and calibrated correctly contributes to achieving precise results. Regular maintenance and calibration checks should be performed to identify and address any potential issues that may arise. Additionally, utilizing advanced measurement tools such as dial indicators, micrometers, and laser systems can assist in verifying the accuracy of the lathe. By paying attention to the setup and calibration process, operators can optimize the performance of the lathe and achieve the highest level of accuracy.

Benefits of Accurate Lathe Work

Accurate lathe work offers several benefits that make it an indispensable tool in various industries. Precision machining ensures the compatibility and interchangeability of parts, allowing for seamless assembly and improved functionality. Accurate lathe work also results in smooth surfaces, reducing the need for additional finishing processes. This saves time, labor, and resources, making lathe work a cost-effective solution. Furthermore, precise lathe work contributes to the overall quality and reliability of the final product, enhancing customer satisfaction and reputation.

Conclusion: Striving for Perfection

When it comes to lathe work, accuracy is of the utmost importance. Factors such as tool geometry, machine rigidity, cutting parameters, and setup all play a role in determining the precision of the work. By paying careful attention to these factors, operators can maximize the accuracy of the lathe and achieve impeccable results. Accurate lathe work offers numerous benefits, from improved functionality and assembly compatibility to cost and time savings. Striving for perfection in lathe work is key to delivering high-quality products and maintaining a competitive edge in today’s industries.

Key Takeaways: How Accurately Can a Lathe Work?

- A lathe can work with high accuracy, creating precise shapes and measurements.

- Modern lathes have advanced features like digital controls and automatic tool changers, enhancing their accuracy.

- The accuracy of a lathe depends on factors such as the quality of the machine, cutting tools, and operator skills.

- Tolerances in lathe work can range from a few thousandths of an inch to micrometers, allowing for intricate machining.

- Regular maintenance and calibration are crucial in maintaining the accuracy of a lathe over time.

Frequently Asked Questions

A lathe is a versatile tool used in woodworking and metalworking to shape and cut materials into precise shapes. Below, we have answered some common questions related to the accuracy of a lathe’s work.

1. What factors affect the accuracy of a lathe’s work?

The accuracy of a lathe’s work is influenced by several factors. Firstly, the quality of the lathe itself plays a significant role. Higher-quality lathes tend to have better precision and are built with tighter tolerances. Secondly, the skill and experience of the operator are crucial. A trained operator with a good understanding of the lathe’s functions and techniques can achieve greater accuracy. Lastly, the choice and condition of the cutting tools used in the lathe can greatly impact the precision of the work.

Additionally, external factors such as vibrations and stability can affect accuracy. A stable work surface and proper machine setup help minimize unwanted movement, ensuring more precise results. It’s important to consider these factors to achieve the highest possible accuracy when working with a lathe.

2. How precise can a lathe’s work be?

A lathe has the potential to produce highly accurate results. However, the achievable precision depends on the specific lathe and the operator’s skill level. Professional-grade lathes are designed for maximum precision and can achieve tolerances within thousandths of an inch or even finer measurements. These lathes are commonly used in precision manufacturing and engineering applications where tight tolerances are essential.

On the other hand, hobbyist-grade lathes may not offer the same level of precision as professional models, but they can still produce satisfactory results for less demanding projects. With the right techniques and attention to detail, even a hobbyist lathe can achieve decent accuracy. Ultimately, the precision of a lathe’s work is a reflection of both the machine’s capabilities and the proficiency of the operator.

3. Can a lathe consistently replicate shapes and dimensions?

Yes, a lathe is designed to replicate shapes and dimensions consistently. By using the appropriate measurements and techniques, an operator can produce multiple identical pieces with ease. Lathes often come with guiding mechanisms such as indexes and templates, which aid in achieving consistent shapes and dimensions.

When working on a lathe, the operator can set the depth of cut, feed rate, and other factors to ensure consistent results. Additionally, precision measuring tools, such as calipers and micrometers, are used to periodically check the dimensions and make necessary adjustments. With careful setup and attention to detail, a lathe can consistently replicate shapes and dimensions.

4. Is it possible to improve the accuracy of a lathe?

Absolutely! There are several ways to improve the accuracy of a lathe’s work. Firstly, investing in a higher-quality lathe with better precision capabilities will naturally lead to more accurate results. Additionally, regularly maintaining and calibrating the lathe is essential. Lubricating moving parts, checking alignment, and replacing worn-out components can significantly improve accuracy.

Furthermore, continuous learning and practice can enhance an operator’s skill level, leading to greater precision. Studying proper techniques, attending workshops, and experimenting with different tools and materials can all contribute to improved accuracy. Taking the time to fine-tune settings and performing test cuts can also help optimize the lathe’s performance. By incorporating these practices, one can gradually enhance the accuracy of a lathe’s work.

5. Can a lathe achieve the same level of accuracy for different materials?

The accuracy of a lathe’s work can vary depending on the material being worked on. Some materials, such as metals, have inherently higher accuracy requirements due to their hardness and the need for precise shaping. Lathes designed specifically for metalworking are often more robust and equipped with features that cater to the demands of working with metal.

However, with proper techniques and adjustments, lathes can achieve good accuracy across various materials. It’s important to consider the specific properties of the material being worked on, such as its hardness, density, and behavior when machined. Additionally, different cutting tools and speeds may be required for optimal results with different materials. By understanding the characteristics of each material and making the necessary adjustments, a lathe can produce accurate and precise results across a range of materials.

How to Achieve Accurate Depth of Cut on a Manual Lathe

Summary

A lathe is a machine that can accurately shape and cut materials like wood or metal. It operates by rotating the material against a cutting tool to create the desired shape. However, the accuracy of a lathe’s work depends on various factors.

Firstly, the quality and precision of the lathe itself play a significant role in determining the accuracy of its work. A well-maintained and calibrated lathe will produce more precise results. Secondly, the skill and experience of the operator also come into play. A skilled operator can make precise adjustments and use the lathe in a way that maximizes accuracy. Finally, the choice of cutting tools, speed, and feed rates can affect the accuracy of the lathe’s work. By considering all these factors, we can ensure that a lathe produces accurate and precise results.