So you’re curious about band saws and how they’re measured? Well, you’ve come to the right place! Band saws are versatile power tools used for cutting various materials, including wood, metal, and plastic. But how exactly are these mighty machines measured? Let’s dive in and find out!

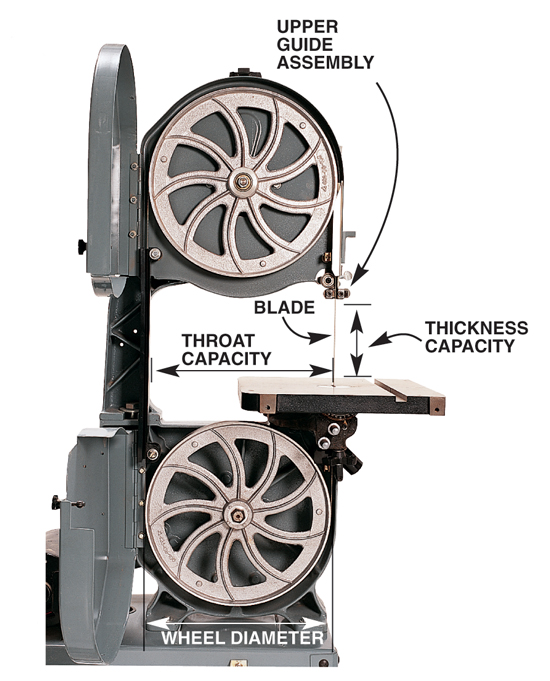

When it comes to band saws, there are a few key measurements that you need to know. First off, there’s the throat capacity, which refers to the distance between the saw blade and the vertical frame of the saw. This measurement determines the width of material that can be cut on the band saw.

Next up is the depth of cut, which tells you how thick of a material the band saw can handle. This measurement is essential as it determines the maximum thickness of the material you can cut through.

Last but not least, we have the blade length. This refers to the length of the band saw blade, which is essential for fitting the correct blade on your saw and ensuring smooth and accurate cuts.

Now that you know the basic measurements of band saws, you’re one step closer to becoming a band saw pro! So, let’s dig deeper and explore how these measurements affect your ability to tackle different projects with ease. Get ready to unleash your inner woodworker or metalworker!

How Are Band Saws Measured? A Comprehensive Guide

Band saws are versatile tools used by woodworkers and metalworkers alike. Whether you’re a professional or an enthusiast, understanding how band saws are measured is crucial for choosing the right tool for your needs. In this article, we will explore the various measurements that are used to define band saws, from the length of the blade to the size of the table. Let’s dive in and demystify the world of band saw measurements!

The Blade Length: An Essential Measurement for Band Saws

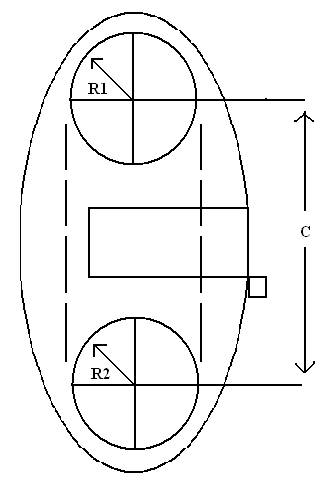

The blade length is one of the most critical measurements when it comes to band saws. It determines the size and capacity of the material you can cut. Band saw blades come in various lengths, typically measured in inches. To measure the blade length, you need to measure from the point where the blade enters the band saw’s housing to the point where it exits. This length represents the maximum size of material that can be cut on the band saw.

When selecting a band saw, it’s crucial to choose a blade length that suits your cutting needs. Longer blades allow for cutting larger materials, while shorter blades are ideal for intricate and detailed cuts on smaller materials. It’s important to note that different band saw models have different blade length ranges, so be sure to check the specifications of the specific model you are considering.

Additionally, when measuring and selecting a blade length, you should also consider the width of the blade. Band saw blades come in a variety of widths, ranging from narrow blades for detailed cuts to wider blades for larger, straight cuts.

The Throat Capacity: Determining the Width of your Cuts

Another crucial measurement to consider when choosing a band saw is the throat capacity. The throat capacity refers to the distance between the bandsaw’s blade and the vertical frame section. It represents the maximum width of the material that the band saw can cut. To measure the throat capacity, you need to measure the distance from the blade to the inside edge of the frame on the side of the cutting area.

When selecting a band saw based on the throat capacity, consider the width of the materials you plan to cut regularly. A larger throat capacity allows for wider cuts, making it suitable for cutting large wooden boards or metal sheets. However, keep in mind that a wider throat capacity may also require a more powerful motor to handle the extra load.

It’s important to note that the throat capacity may vary depending on the position of the blade guide. The blade guide can be adjusted to accommodate different material thicknesses, so make sure to consider this when determining the throat capacity requirement for your projects.

The Table Size: Providing Stability and Support

The table size is another crucial measurement to consider when choosing a band saw. It refers to the dimensions of the working surface that supports the material being cut. The table size plays a significant role in providing stability and support during the cutting process.

When measuring the table size, you need to consider both the length and the width of the table. The length determines the maximum length of material that can be supported, while the width determines the maximum width of the material that can be accommodated comfortably.

If you work with larger materials or require additional support for your projects, a larger table size will be beneficial. It provides a more stable surface for maneuvering and cutting larger pieces of wood or metal. However, keep in mind that a larger table size may also require more space in your workshop or work area.

Additional Factors to Consider when Measuring Band Saws

Now that we have covered the essential measurements for band saws, it’s important to consider other factors that may influence your purchasing decision. While these measurements are not typically used to measure band saws directly, they play a crucial role in determining the overall functionality and usability of the tool.

The Motor Power: Ensuring Efficient and Smooth Operation

The motor power is an essential factor to consider when choosing a band saw. It determines the cutting efficiency and performance of the tool. Motors for band saws are typically measured in horsepower (HP). The higher the horsepower, the more powerful the motor, allowing for smoother and more efficient cutting.

When selecting a band saw, consider the type of materials you will be cutting and the thickness of those materials. Thicker and denser materials may require a band saw with a more powerful motor to ensure smooth and accurate cuts. Additionally, if you anticipate heavy use of your band saw for extended periods, a more powerful motor will help prevent overheating and ensure durability.

It’s worth noting that the motor power is not the only factor that determines cutting performance. The quality and sharpness of the blade, as well as the tension and speed control, also contribute to the overall cutting experience.

The Blade Guides and Adjustments: Enhancing Precision and Control

The blade guides and adjustments are features that significantly impact the precision and control of your band saw. Blade guides help keep the blade aligned and reduce vibrations during the cutting process. They can be adjusted to accommodate different blade thicknesses and provide optimal support for accurate cuts.

When choosing a band saw, ensure that the blade guides are adjustable and easy to operate. Look for features such as micro-adjustments that allow for fine-tuning and precise cuts. Additionally, consider the accessibility and ease of adjusting the guides. This will contribute to the overall user experience and the quality of your cuts.

Furthermore, other adjustments such as the blade tension and speed control can also enhance the precision and control of your cuts. These adjustments allow you to optimize the band saw’s performance based on the specific material and cutting requirements. Having these features available and easily adjustable can make a significant difference in the quality of your work.

The Fence and Miter Gauge: Facilitating Accurate and Angled Cuts

The fence and miter gauge are accessories that facilitate accurate and angled cuts on a band saw. The fence is a guide that provides support and helps maintain a consistent distance between the blade and the material being cut. It is especially useful when cutting straight lines or when making repetitive cuts.

The miter gauge, on the other hand, allows for angled cuts. It can be adjusted to various angles, typically up to 45 degrees, to achieve bevel cuts or angle joints. The miter gauge is particularly useful for woodworking projects that require precise angled cuts.

When selecting a band saw, ensure that it comes with a reliable and adjustable fence and miter gauge. These accessories will greatly contribute to the versatility and accuracy of your cuts, allowing for more creative and intricate woodworking projects.

In Summary

Understanding how band saws are measured is essential for choosing the right tool for your woodworking or metalworking projects. From blade length to throat capacity and table size, these measurements provide valuable insights into the capabilities and limitations of a band saw. Additionally, factors such as motor power, blade guides and adjustments, as well as the fence and miter gauge, enhance the overall functionality and usability of the tool.

By considering these measurements and factors, you can make an informed decision when purchasing a band saw that suits your specific needs. Remember to consider your cutting requirements, workspace limitations, and budget to ensure that you choose a band saw that will meet your expectations and help you achieve precise and high-quality results in your woodworking or metalworking endeavors.

Key Takeaways: How Are Band Saws Measured?

- Band saws are measured based on their throat capacity, which is the distance between the blade and the vertical frame of the saw.

- The cutting height of a band saw refers to the maximum height of the material that can be cut using the saw.

- Blade length is an important measurement as it determines the size of the material that can be cut.

- The width of the band saw’s blade determines the turning radius and the type of cuts it can make.

- Tension is a measurement that refers to how tight the band saw’s blade is to ensure a smooth and accurate cut.

Note: This article has been written using the information available online. The key takeaways provided are based on our research and understanding.

Frequently Asked Questions

Welcome to our FAQ section on measuring band saws. Below, you’ll find answers to some commonly asked questions related to this topic.

1. What are the different measurements used for band saws?

Band saws are typically measured using three main criteria: blade length, throat capacity, and cutting depth. Blade length refers to the circumference of the blade and is measured in inches. Throat capacity measures the distance between the blade and the vertical frame of the saw. Lastly, cutting depth determines the maximum thickness a band saw can cut through.

When purchasing a band saw, it’s important to consider these measurements to ensure the saw meets your specific needs. It’s also crucial to keep in mind that different band saw models may have different measurement ranges, so it’s essential to check the specifications of the particular model you’re interested in.

2. How do I measure blade length for a band saw?

Measuring the blade length for a band saw is quite simple. Start by removing the old blade (if applicable). Then, unroll the blade and lay it flat on a surface. Next, measure the distance from the tip of the blade to the point where it enters the opposite side of the blade housing. This measurement will give you the blade length in inches.

It’s important to note that for accurate results, the blade should be completely straightened and free from any kinks or bends. Additionally, ensure that the blade is properly tensioned before measuring. A correctly tensioned blade will give you a more precise measurement.

3. What is throat capacity and how do I measure it?

Throat capacity refers to the distance between the band saw blade and the vertical frame of the saw. It determines the maximum width of a material that can be cut along the blade’s length. To measure throat capacity, position the blade in the center of the band saw table and measure the distance from the blade to the edge of the throat. This measurement will give you the throat capacity in inches.

It’s important to ensure that the band saw table is properly aligned when measuring throat capacity, as any misalignment can affect the accuracy of the measurement. Additionally, it’s worth noting that the throat capacity of a band saw is fixed and cannot be adjusted.

4. How is cutting depth measured for a band saw?

Measuring the cutting depth of a band saw is relatively straightforward. First, raise the blade guide assembly to its highest position. Then, position the material you would like to cut against the band saw’s table. Measure the distance between the table and the lowest point of the upper blade guide assembly. This measurement will give you the cutting depth in inches.

It’s essential to consider the cutting depth when working with thicker materials, as it determines the maximum thickness the band saw can handle. If you frequently work with materials of varying thickness, it’s advisable to choose a band saw with an adjustable cutting depth feature.

5. Are there any other important measurements to consider when buying a band saw?

While blade length, throat capacity, and cutting depth are the primary measurements to consider, there are a few other important factors to keep in mind. These include motor power, blade speed, and table size. Motor power and blade speed determine the band saw’s cutting performance, while table size affects the stability and support for larger workpieces.

Opting for a band saw with a powerful motor, adjustable blade speed, and a spacious table can enhance your overall woodworking experience and allow you to work with a wider range of materials effectively.

Bandsaw Sizing – What’s in a Name?

Summary

Band saws are measured by their throat capacity, which is the distance from the blade to the frame. The blade length is another important measurement, as it determines the size of material you can cut. Understanding these measurements will help you choose the right band saw for your needs.

When shopping for a band saw, pay attention to the throat capacity and blade length. The throat capacity tells you how wide a piece of wood you can cut, while the blade length determines the maximum height of the material. By considering these measurements, you can find a band saw that is suitable for your woodworking projects.