Have you ever wondered how bandsaw sizes are measured? It’s an interesting topic that can unlock the secrets of these powerful tools. Let’s dive in and discover the ins and outs of bandsaw sizing!

When it comes to bandsaws, size matters. But how exactly do we measure them? In this article, we’ll explore the different dimensions and specifications that determine the size of a bandsaw. So, if you’re curious to know more, keep on reading!

Whether you’re a woodworking enthusiast or just someone who appreciates the craftsmanship of a bandsaw, understanding how they are sized can enhance your knowledge and appreciation for these versatile machines. Let’s unravel the mystery together!

How Are Bandsaw Sizes Measured?

When it comes to bandsaws, understanding their size and how it is measured is crucial. Whether you are a woodworking enthusiast or a professional carpenter, knowing the ins and outs of bandsaw sizes will help you make informed decisions when purchasing or using a bandsaw. In this article, we will delve into the details of how bandsaw sizes are measured, providing you with the knowledge to make the most of this powerful tool.

1) Overall Width of the Bandsaw Blade

One of the key factors in measuring a bandsaw size is the overall width of the bandsaw blade. This measurement refers to the distance between the two sides of the blade when it is fully extended. Typically, this measurement is given in inches, ranging from narrower blades of 1/8 inch all the way up to wider blades of 1 inch or more. The width of the blade is an important consideration as it determines the maximum thickness of the material that can be cut with the bandsaw.

Additionally, the width of the blade affects the precision and accuracy of the cuts made by the bandsaw. Thicker blades provide stability and strength, ideal for cutting denser materials, while thinner blades are better suited for intricate cuts and curves. It’s essential to choose a bandsaw with the right blade width to suit your cutting needs.

Furthermore, bandsaws often come with different blade widths as a standard feature or offer the option to use wider or narrower blades based on your specific requirements. This versatility allows you to adapt the bandsaw for different projects, making it a valuable tool for woodworking professionals and hobbyists alike.

2) Throat Capacity of the Bandsaw

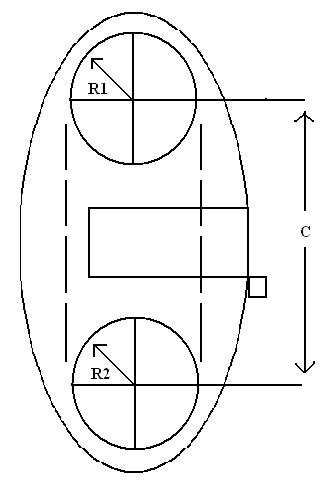

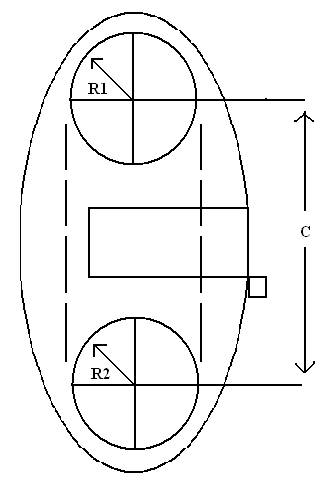

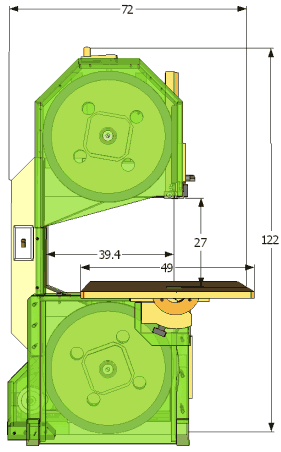

Another crucial aspect of measuring a bandsaw size is the throat capacity. The throat capacity refers to the distance between the vertical frame of the bandsaw and the blade. It determines the maximum width of the material that can be cut on the bandsaw. This measurement is usually stated as the distance between the cutting blade and the inside edge of the frame.

The throat capacity is an essential consideration when choosing a bandsaw, as it determines the size of the workpiece that can be accommodated. Smaller bandsaws usually have a throat capacity of around 12 inches, while larger industrial-grade bandsaws can have throat capacities of 36 inches or more. Your choice of bandsaw should align with the size of the projects you typically work on.

It’s worth noting that the throat capacity can also affect the maneuverability and ease of use of the bandsaw. Bandsaws with larger throat capacities may require more space, making them unsuitable for cramped workshops. Conversely, smaller throat capacities provide greater control and maneuverability for intricate cuts, making them a popular choice for detailed woodworking tasks.

3) Cutting Height of the Bandsaw

In addition to the throat capacity, the cutting height is another important dimension when it comes to measuring a bandsaw size. The cutting height refers to the distance between the cutting table (or work surface) and the upper blade guides. It determines the maximum thickness of the material that can be cut vertically on the bandsaw.

Like throat capacity, the cutting height is typically measured in inches. Entry-level bandsaws might have a cutting height of 6 inches, while industrial-grade models can offer cutting heights of up to 20 inches or more. Choosing the right cutting height is crucial to ensure that the bandsaw can handle the size and thickness of the materials you work with.

It’s important to understand that the cutting height also affects the stability and accuracy of the cuts made with the bandsaw. Higher cutting heights allow for greater clearance and flexibility when working with thicker materials, while lower cutting heights provide better control and precision for thinner materials. Consider the types of projects you frequently undertake to determine the appropriate cutting height for your bandsaw.

Additional Considerations for Bandsaw Sizes

With a solid understanding of how bandsaw sizes are measured, let’s explore a few more considerations to keep in mind when choosing a bandsaw:

1) Motor Power

The motor power is an essential factor to consider when selecting a bandsaw. The motor power determines the cutting capacity and performance of the bandsaw. Higher motor power allows for more efficient cutting of thicker and denser materials. It’s important to choose a bandsaw with a motor power that matches the demands of your woodworking projects.

2) Table Size and Tilt

The size and tilt of the cutting table play a crucial role in the versatility and functionality of the bandsaw. A larger table provides more support for larger workpieces, while a tilting table allows for bevel cuts and angled cuts. Consider the types of cuts you frequently make and the size of the materials you work with to ensure that the bandsaw’s table size and tilt can accommodate your needs.

3) Throat Plate and Blade Guides

The quality and design of the throat plate and blade guides greatly impact the performance and precision of the bandsaw. A well-designed throat plate reduces friction and allows for smooth cuts, while high-quality blade guides provide stability and control during operation. Pay attention to these components when selecting a bandsaw to ensure the best cutting experience.

Now that you have a comprehensive understanding of how bandsaw sizes are measured and the considerations to keep in mind when choosing a bandsaw, you are well-equipped to make informed decisions and select the right bandsaw for your woodworking needs. Remember to consider the overall width of the blade, throat capacity, cutting height, motor power, table size and tilt, and the quality of the throat plate and blade guides. Investing in a well-suited bandsaw will enhance your woodworking experience and allow you to create precise and professional results.

Key Takeaways: How Are Bandsaw Sizes Measured?

- Bandsaw sizes are measured by the diameter of the wheel, which determines the cutting capacity of the machine.

- The most common bandsaw sizes are 14″, 17″, and 18″, which are suitable for most woodworking tasks.

- Smaller bandsaws, like the 10″ size, are more portable and convenient for lighter jobs.

- Blade length is another important factor in bandsaw sizing, as longer blades allow for wider cuts.

- Bandsaw sizes are typically advertised as the distance between the blade and the throat, indicating the maximum width of a board that can be cut.

Frequently Asked Questions

When it comes to measuring bandsaw sizes, many people have questions. Here are some frequently asked questions to help you understand how bandsaw sizes are measured.

1. How do you measure the throat size of a bandsaw?

The throat size of a bandsaw refers to the distance between the blade and the vertical frame of the saw. To measure the throat size, simply measure the distance between the blade and the back of the bandsaw’s vertical arm. This measurement is important because it determines the width of the material that can be cut by the bandsaw.

For example, if the bandsaw has a 14-inch throat size, it means that material up to 14 inches wide can be cut with the saw. Keep in mind that the throat size of a bandsaw is usually the maximum width that it can cut, so it’s important to choose a bandsaw with a throat size that suits your cutting needs.

2. What does the resaw capacity of a bandsaw mean?

The resaw capacity of a bandsaw refers to the height of the material that can be cut vertically. This measurement is important when you need to cut thick pieces of wood or other materials vertically. To measure the resaw capacity of a bandsaw, measure the distance from the table to the highest point the blade can reach.

For example, if a bandsaw has a resaw capacity of 12 inches, it means that it can cut materials up to 12 inches in height. This measurement is particularly useful for woodworking projects that involve cutting thicker boards or creating veneers from larger pieces of wood.

3. How is the blade length of a bandsaw determined?

The blade length of a bandsaw is determined by measuring the circumference of the wheels to which the blade is attached. To measure the blade length, wrap a measuring tape around the wheels while ensuring it follows the path of the blade. Make sure to measure the working area of the wheels where the blade actually spans.

Once you have the measurement, convert it to inches and round it to the nearest inch. For example, if the measurement is 145 inches, the blade length would be 145 inches. It’s important to note that bandsaw manufacturers usually provide recommended blade lengths for their specific models, so it’s a good idea to check those recommendations before purchasing blades.

4. What is the importance of the horsepower rating in a bandsaw?

The horsepower rating of a bandsaw is an indication of its power and cutting capabilities. Higher horsepower means the bandsaw can handle tougher materials and make more precise cuts. However, the required horsepower depends on the type of cutting you plan to do.

If you mostly work with softer woods and thinner materials, a bandsaw with a lower horsepower rating will suffice. On the other hand, if you plan to cut hard or dense materials, a higher horsepower rating will be necessary. It’s important to choose a bandsaw with the appropriate horsepower rating for your specific cutting needs to ensure optimal performance.

5. Are there standard bandsaw sizes available in the market?

While there are common bandsaw sizes available in the market, there isn’t a strict standard for bandsaw sizes. Bandsaws come in various sizes and configurations to cater to different cutting needs and budgets. The size of a bandsaw can vary based on factors like throat size, resaw capacity, and blade length.

It’s important to choose a bandsaw that suits your specific cutting requirements. Consider the materials you plan to cut, the size of the projects you’ll be working on, and the available space in your workshop. By evaluating these factors, you can find a bandsaw size that will meet your needs and help you achieve precise and efficient cuts.

Summary

So, now you know how bandsaw sizes are measured! It’s actually pretty simple. The size is determined by the distance between the blade and the throat of the saw. The bigger the size, the wider the cut. Just remember that the size doesn’t always indicate the capacity or power of the bandsaw. That depends on other factors like motor strength and construction materials. So, if you’re looking to buy a bandsaw, make sure you consider both the size and the overall features of the saw to find the right one for your needs. Happy sawing!