Are you curious about how bandsaws are measured? Well, you’ve come to the right place! In this article, we’ll dive into the fascinating world of bandsaws and explore the different ways they are measured. So, buckle up and get ready for an exciting journey through the world of woodworking tools!

Now, you might be wondering why it’s important to understand how bandsaws are measured. Well, knowing the measurements will help you choose the right bandsaw for your specific needs. Whether you’re a professional woodworker or just starting out, having the right equipment is essential for a successful project. So, let’s get started and unravel the mystery behind bandsaw measurements!

When it comes to measuring bandsaws, there are a few key factors to consider. Blade length, throat capacity, and cutting height are some of the primary measurements that determine the size and capabilities of a bandsaw. By understanding these measurements, you’ll be able to find a bandsaw that suits your needs perfectly. So, let’s explore each measurement in detail and uncover the secrets of bandsaw sizing!

How Are Bandsaws Measured?

When it comes to choosing the right bandsaw for your needs, understanding how bandsaws are measured is crucial. From the blade length to the throat depth and horsepower, various measurements and specifications play a significant role in determining the right bandsaw for your specific requirements. In this article, we will dive into the details of how bandsaws are measured, providing you with the knowledge to make an informed decision when selecting a bandsaw for your woodworking or metalworking projects.

Blade Length: The Starting Point

The blade length is one of the primary measurements for a bandsaw, as it dictates the size and type of cuts you can make. The blade length refers to the total circumference of the blade, measured from the tip of one tooth to the tip of the tooth on the opposite side. It is typically measured in inches, and the length affects the overall cutting capacity of the bandsaw.

To ensure you choose the correct blade length for your bandsaw, you need to consider the manufacturer’s recommendations. The blade length can vary based on the specific make and model of the bandsaw. You may find this measurement in the bandsaw’s user manual or on the manufacturer’s website. It’s essential to select a blade length that is compatible with your bandsaw’s blade guides and tensioning system to ensure optimal performance and safety.

Throat Depth: Determining Cutting Capacity

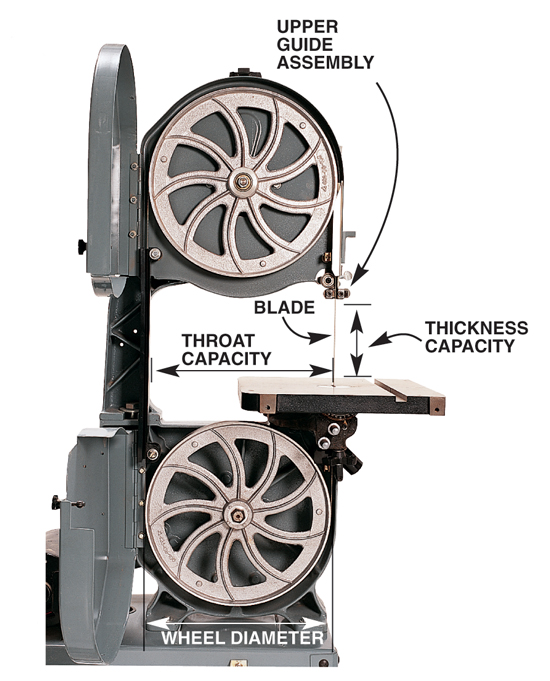

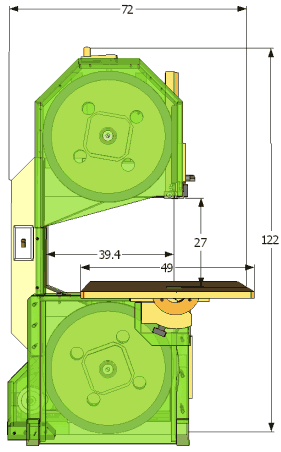

The throat depth of a bandsaw refers to the distance between the blade and the frame of the machine. It determines the maximum width of the material that can be cut on the bandsaw. In other words, the throat depth indicates the size of the workpiece that can fit through the bandsaw’s cutting area.

When measuring the throat depth, you need to measure from the blade to the inside edge of the frame. This measurement is usually expressed in inches. It’s important to note that the throat depth does not necessarily correlate with the maximum cutting height of the bandsaw. The cutting height is determined by the distance from the table to the upper blade guides, which may be greater than the throat depth.

When choosing a bandsaw based on throat depth, consider the size of the workpieces you typically work with. If you frequently handle larger materials, you will need a bandsaw with a larger throat depth to accommodate those dimensions.

Horsepower: Powering Through the Cuts

The horsepower (HP) rating of a bandsaw is an indication of the power and cutting capacity of the machine. It determines how efficiently the bandsaw can cut through various materials. The higher the horsepower, the more powerful the bandsaw and the more demanding cutting tasks it can handle.

When it comes to choosing the right horsepower for your bandsaw, consider the type of materials you work with and the intensity and frequency of your cutting tasks. For lighter cutting tasks on softwoods and thin metals, a bandsaw with lower horsepower may be sufficient. However, if you frequently work with dense hardwoods or thick metals, you will need a bandsaw with higher horsepower to ensure smooth and efficient cutting.

Additional Considerations for Bandsaw Measurements

Beyond blade length, throat depth, and horsepower, there are a few other measurements and specifications worth considering when selecting a bandsaw:

- Cutting Speed: The speed at which the bandsaw blade moves can impact the quality and efficiency of the cuts. Higher cutting speeds are generally recommended for cutting metal, while slower speeds are better suited for cutting wood.

- Tensioning Mechanism: Bandsaws typically have a tensioning mechanism that allows you to adjust the tightness of the blade. The tensioning mechanism should be easy to operate and provide sufficient blade tension for accurate cuts.

- Table Size: The size of the bandsaw’s table affects the stability and support it provides for the workpiece. A larger table can accommodate larger materials and provide more stability during cutting.

- Guides and Bearings: The quality of the guides and bearings in a bandsaw can impact the accuracy and smoothness of the cuts. Look for bandsaws with high-quality guides and bearings for optimal performance.

Choosing the Right Bandsaw for Your Needs

Now that you have a thorough understanding of how bandsaws are measured, you can confidently choose the right bandsaw for your specific needs. Consider factors such as blade length, throat depth, horsepower, cutting speed, tensioning mechanism, table size, and the quality of guides and bearings to find a bandsaw that will deliver outstanding performance and reliability for your woodworking or metalworking projects. Remember to always refer to the manufacturer’s recommendations and specifications when making your decision.

Key Takeaways: How Are Bandsaws Measured?

- Bandsaws are measured by their throat capacity, which is the distance between the blade and the vertical frame of the bandsaw.

- The depth of cut refers to how thick a piece of material the bandsaw can cut through in a single pass.

- The wheel diameter is another factor that determines the size of a bandsaw. Bigger wheels provide more cutting power.

- The blade width is an important measurement as it determines the tightness of curves the bandsaw can cut.

- Bandsaw size can also be determined by the length of the blade, which affects the capacity for cutting larger materials.

Frequently Asked Questions

Welcome to our FAQ section on how bandsaws are measured. Here, we will answer some common questions about the measurements and specifications of bandsaws. Whether you’re a woodworking enthusiast or a professional carpenter, understanding how bandsaws are measured can help you make better-informed decisions when purchasing or using these versatile tools. Read on to find the answers to your questions!

1. What are the key measurements used to describe a bandsaw?

When describing a bandsaw, there are a few key measurements to consider. The first is the throat capacity or the distance from the blade to the vertical frame section of the bandsaw. This measurement determines the maximum width of a workpiece that the bandsaw can comfortably handle. Another important measurement is the height capacity, which refers to the distance from the table to the upper blade guides. This measurement determines the maximum thickness of a workpiece that the bandsaw can cut. Additionally, the blade length, expressed in inches, is an essential measurement that indicates the size of the blade needed for the bandsaw.

These measurements are crucial when choosing a bandsaw that is suitable for your specific woodworking needs. By understanding these measurements, you can ensure that the bandsaw you select will be capable of handling the size and type of projects you have in mind.

2. How is the blade width of a bandsaw measured?

The blade width of a bandsaw is typically measured from the back of the blade to the tip of the teeth. It is important to note that the blade width can vary for different bandsaw models and manufacturers. The width of the blade determines the minimum radius that the bandsaw can cut and affects the overall accuracy of the cuts. A narrower blade is better suited for intricate curved cuts, while a wider blade is more suitable for straight cuts and resawing.

When selecting a bandsaw, consider the type of cuts you will be making and choose a blade width that matches your intended applications. It’s also worth noting that some bandsaws offer the option to change the blade width, allowing for greater versatility in your cutting tasks.

3. What is the significance of the horsepower rating on a bandsaw?

The horsepower (HP) rating on a bandsaw refers to the power of the motor that drives the blade. A higher horsepower rating indicates that the bandsaw has more cutting power and can handle tougher materials or thicker cuts. However, it’s important to note that the horsepower alone does not determine the overall performance of the bandsaw. Other factors such as blade tension, blade quality, and blade speed also play a significant role in achieving clean and precise cuts.

When considering the horsepower rating of a bandsaw, it’s important to match it to the type of material and cutting requirements you anticipate. If you primarily work with softer woods or smaller projects, a lower horsepower bandsaw may be sufficient. However, if you frequently work with denser woods or large-scale projects, a bandsaw with higher horsepower may be more suitable.

4. How does the table size affect the usability of a bandsaw?

The table size of a bandsaw refers to the dimensions of the flat surface where the workpiece rests during cutting. A larger table provides more support and stability, especially when handling large or heavy workpieces. It allows for better control and minimizes the risk of the workpiece tipping or wobbling during cutting.

The table size also determines the maximum width and length of workpieces that can be accommodated on the bandsaw. A larger table offers more flexibility for handling larger projects or making angled cuts. However, it’s important to strike a balance between a table size that suits your needs and the available space in your workshop.

5. What is the purpose of the blade guides on a bandsaw?

The blade guides on a bandsaw serve to support and stabilize the blade during cutting. They help to reduce blade deflection and improve cutting accuracy. Most bandsaws have both upper and lower blade guides. The upper blade guides are adjustable and can be set closer to the workpiece for better guidance and control. The lower blade guides are fixed and provide additional support to prevent the blade from twisting or wandering off track.

Properly adjusted blade guides are essential for achieving precise cuts and extending the lifespan of the blade. They help to minimize friction and heat buildup, which can result in premature blade wear. Regular maintenance, including cleaning and lubricating the blade guides, is important to ensure optimal performance and accurate cuts.

Summary

So, bandsaws are measured in three main ways: throat size, resaw capacity, and wheel diameter. Throat size tells you the distance between the blade and the frame. Resaw capacity refers to the maximum height the bandsaw can cut. Wheel diameter is the size of the wheels that the blade rides on.

When choosing a bandsaw, you need to consider your specific needs and the type of work you’ll be doing. A larger throat size and resaw capacity are better for cutting larger pieces of wood, while a smaller bandsaw may suffice for smaller projects. Additionally, a bigger wheel diameter allows for a smoother cut. By understanding these measurements, you’ll be able to find the right bandsaw for your woodworking needs.