Have you ever wondered how chisels are made? Well, you’re in for a treat! In this article, we’ll dive into the fascinating world of chisel manufacturing. From raw materials to the finished product, we’ll uncover the secrets behind crafting these essential tools. So, let’s roll up our sleeves and explore the intriguing process of how chisels are made.

When it comes to making chisels, it’s all about finding the perfect blend of strength and precision. Companies carefully select high-quality steel for the chisel’s blade, ensuring it can withstand the toughest tasks. But that’s not all—a chisel’s handle is just as important. Craftsmen often choose hardwoods like maple or beech for durability and ease of use.

Once the materials are gathered, the manufacturing process begins. Skilled artisans heat and shape the steel to create the chisel’s blade, carefully honing the cutting edge to perfection. The handle is carefully shaped and attached, creating a well-balanced and reliable tool. It’s a labor of love and dedication, resulting in chisels that can tackle any woodworking project with precision and finesse.

So, if you’ve ever wondered about the magic behind the chisels you use, now you know! From selecting top-quality materials to the artistry of craftsmanship, every step in the production process contributes to creating the perfect chisel. With these incredible tools in hand, you’ll be ready to bring your woodworking projects to life!

Curious about the creation of chisels? Let’s unveil this captivating process! Firstly, high-quality steel is carefully selected. Then, the chosen steel is heated and shaped into the desired chisel form, using a combination of forging and grinding techniques. Next, the chisel head is hardened through intense heating and rapid cooling processes. Finally, the handle is attached and finished, ensuring comfort and durability. Marvel at the craftsmanship that goes into making these versatile tools!

How Are Chisels Made?

Chisels are essential tools used in woodworking, metalworking, and other industries. They have a sharp-edged blade attached to a handle, allowing for precise cutting and shaping of materials. But have you ever wondered how chisels are made? In this article, we will explore the step-by-step process of chisel manufacturing, from raw materials to the finished product. Whether you’re a DIY enthusiast or simply curious about the craftsmanship behind these versatile tools, join us on this fascinating journey into the world of chisel production.

1. Raw Materials and Design

The first step in making chisels is selecting the right materials. The blade of a chisel is usually made of high-carbon steel or tool steel for durability and sharpness. The handle can be made from various materials such as wood, plastic, or composite materials, depending on the desired aesthetics and functionality of the chisel.

Once the materials are chosen, the design process begins. The shape and size of the blade, as well as the overall length and shape of the handle, are carefully considered. Designers create detailed plans or use computer-aided design (CAD) software to ensure precision and accuracy in the final product.

After the design is finalized, the raw materials are prepared for manufacturing. The steel is heated and shaped through forging or casting processes, and the handle materials are cut, shaped, and smoothed.

2. Blade Production

The production of the blade starts with shaping the steel into the desired chisel blade form. Forging is commonly used, where the steel is heated until it becomes malleable and then hammered into shape using specialized tools. This process aligns the steel’s grain structure, resulting in increased strength and durability.

Once the blade is shaped, it undergoes a heat treatment process called tempering. This involves heating the blade to a specific temperature and then rapidly cooling it to enhance its hardness. Tempering also reduces the brittleness of the steel, making it less prone to chipping or breaking during use.

After tempering, the blade is ground and honed to achieve a sharp cutting edge. This is done using grinding wheels or belt sanders, gradually removing material until the desired edge geometry and sharpness are obtained. Finally, the blade is polished to ensure a smooth surface finish, preventing unnecessary friction when cutting through materials.

3. Handle Production

While the blades are being produced, the handles are made simultaneously. If wood is chosen as the handle material, it is typically sourced from high-quality hardwoods like beech or ash. The wood is cut into appropriate lengths and then shaped using lathes or carving machines. The handles are carefully contoured and sanded to provide a comfortable grip.

For handles made from plastic or composite materials, a different manufacturing process is followed. These materials are melted or molded into the desired handle shape using injection molding or other techniques. The handles may also be ergonomically designed to provide better grip and control during use.

Once the handles are shaped and finished, they are attached to the blades. This is done using adhesives, bolts, or other fastening methods, ensuring a secure and stable connection between the blade and the handle.

4. Quality Control and Packaging

Before chisels are ready to be shipped, they undergo rigorous quality control checks. This includes inspecting the blade for any defects, checking the handle for proper attachment, and ensuring that the chisel meets the desired specifications and standards.

Once the chisels pass the quality control tests, they are cleaned, polished, and packaged. The packaging may vary depending on the manufacturer and intended market. Some chisels are sold individually, while others may come in sets or kits. The packaging is designed to protect the chisels during transportation and storage and may include additional accessories like sharpening stones or blade guards.

5. Distribution and Maintenance

After manufacturing and packaging, the chisels are distributed to retailers or directly to customers. They can be found in hardware stores, woodworking shops, and online marketplaces. It’s important to choose a reputable brand or supplier to ensure the quality and longevity of the chisels.

To prolong the lifespan of chisels, proper maintenance is essential. Regular sharpening and honing of the blades, cleaning after use, and storing in a dry and safe place will help maintain the chisels’ sharpness and prevent damage to the blade and handle.

In summary, the process of making chisels involves the careful selection of materials, precise design and manufacturing techniques, and rigorous quality control. From raw materials to the finished product, each step is crucial in creating chisels that are reliable, durable, and capable of delivering the precision and performance required by craftsmen and DIY enthusiasts alike.

Key Takeaways: How Are Chisels Made?

- Chisels are made by forging high-quality steel into the desired shape.

- The steel is heated to a high temperature and then carefully shaped using a hammer or press.

- After shaping, the chisel is quenched in water or oil to rapidly cool and harden the steel.

- The hardened chisel is then tempered to reduce its brittleness and improve its toughness.

- Finally, the chisel is ground and sharpened to achieve the desired cutting edge.

Frequently Asked Questions

Curious about how chisels are made? We’ve got you covered. Read on for answers to common questions about the manufacturing process.

1. What materials are used to make chisels?

Chisels are typically made from high-carbon steel or tool steel, which is known for its durability and ability to hold a sharp edge. These materials are chosen for their strength and resistance to wear and tear, ensuring that the chisel will last for a long time.

The handles of chisels are often made from wood or composite materials. Wood handles provide a traditional look and a comfortable grip, while composite handles offer extra durability and resistance to impact.

2. How are chisels shaped?

The shaping of chisels involves a combination of forging and grinding. First, the steel blank is heated to a high temperature and then hammered into shape using specialized tools. This process determines the overall shape and size of the chisel.

After forging, the rough chisel is carefully ground to create the cutting edge and refine the shape. This step involves removing excess material and achieving the desired bevel angle for the cutting edge. The process may be repeated multiple times to ensure precision and sharpness.

3. What is the heat treatment process for chisels?

Heat treatment is a critical step in making chisels. The chisels are heated to a specific temperature and then rapidly cooled to increase hardness and durability. This process, known as quenching, helps to optimize the physical properties of the chisel and improves its ability to withstand heavy use.

Following quenching, a tempering process is performed. This involves reheating the chisel to a lower temperature to reduce brittleness and relieve internal stress. The tempering process helps to enhance the toughness of the chisel while maintaining an appropriate level of hardness.

4. How are chisel handles attached?

The method used to attach chisel handles varies depending on the type and design of the chisel. For wood-handled chisels, the tang (a metal projection on the blade) is inserted into a pre-drilled hole in the handle. The tang is then secured in place through friction or by using an adhesive, such as epoxy.

On the other hand, many modern chisels feature handles with a socket design. The blade’s tang fits into the hollow socket in the handle, providing a secure and sturdy connection. Adhesive or other securing mechanisms may also be used to reinforce the attachment.

5. Are there any specialized manufacturing techniques for chisels?

Yes, there are several specialized techniques employed in chisel manufacturing. One such technique is known as lamination, where a layer of high-carbon steel is sandwiched between layers of softer steel. This creates a chisel with a durable cutting edge and a more flexible body. Laminated chisels are renowned for their balance of strength and resilience.

Another technique is known as cryogenic treatment, where the chisels are frozen at extremely low temperatures to further enhance their hardness and durability. This process helps to refine the steel’s internal structure and improve the overall performance of the chisel.

How to make Chisels {www downloadshiva com}

Summary

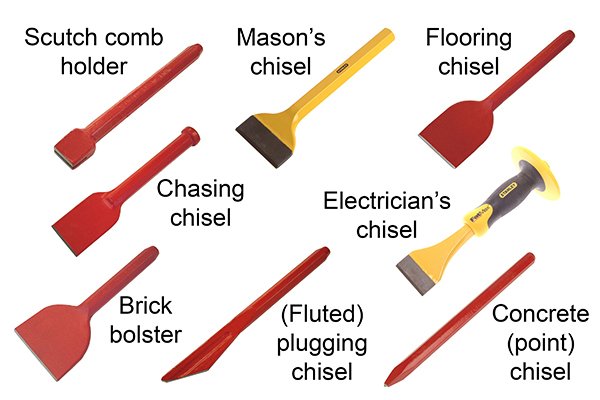

Chisels are made by shaping metal into a flat blade and attaching it to a handle. The metal is heated, hammered, and ground down until it becomes sharp. Different types of chisels are used for different purposes, like carving wood or cutting stone. It’s important to use chisels carefully and to wear protective gear to avoid accidents.

In conclusion, chisels are versatile tools that have been used for centuries. Understanding how they are made and how to use them safely can help you unleash your creativity and complete various projects with precision. So go ahead, grab a chisel, and create something amazing!