Hey there, curious minds! Have you ever wondered how lathe chucks are mounted? Well, wonder no more because in this article, we’re going to dive into the fascinating world of lathe chuck mounting. So, if you’re ready to explore the ins and outs of this process, let’s get started!

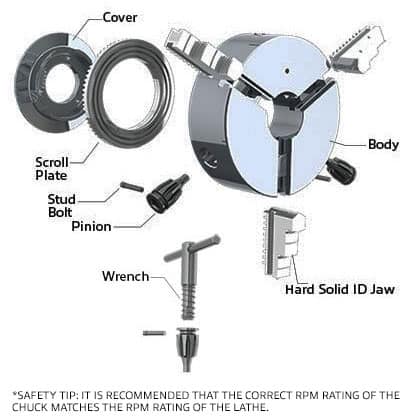

Now, you might be thinking, “What exactly is a lathe chuck?” Great question! A lathe chuck is a device used to hold and secure a workpiece on a lathe machine. It allows the machinist to rotate and shape the workpiece with precision and control. But how does this chuck actually get mounted onto the lathe? Stick around, and we’ll reveal the secrets!

Mounting a lathe chuck involves a few simple steps. First, you need to align the chuck with the spindle of the lathe. Then, you tighten the chuck onto the spindle using specialized mounting screws. This ensures a secure connection and allows the chuck to rotate with the lathe. Easy peasy, right? Stick around to discover more about the fascinating world of lathe chuck mounting!

Mounting lathe chucks requires a few simple steps:

- Prepare the lathe spindle by cleaning it thoroughly.

- Align the mounting holes on the back of the chuck with the holes on the spindle.

- Insert the mounting bolts into the holes and tighten them securely.

- Check the chuck for proper alignment and balance.

- Test the chuck’s rotation before proceeding with your lathe work.

How Are Lathe Chucks Mounted?

In the world of machining, lathe chucks are a vital tool used to securely hold and rotate workpieces during cutting and shaping processes. But have you ever wondered how these chucks are mounted onto the lathe? In this article, we will delve into the details of mounting lathe chucks and explore the various methods and considerations involved.

The Standard Mounting Method: Direct Mounting

One of the most common ways to mount a lathe chuck is through direct mounting. In this method, the chuck is attached directly to the spindle nose of the lathe. The spindle nose is a cylindrical protrusion located at the front of the lathe’s headstock. It typically has a threaded hole or a flange with bolt holes that allow for secure attachment of the chuck.

To mount a chuck using the direct mounting method, you need to match the chuck’s mounting configuration with the spindle nose on your lathe. This usually involves aligning the bolt holes or the threaded mounting recess on the chuck with the corresponding features on the spindle nose. Once aligned, the chuck is secured in place using bolts or screws, ensuring a tight and rigid connection. Direct mounting provides excellent stability and precision, making it suitable for a wide range of machining operations.

It’s important to note that different lathe brands and models might have specific mounting configurations, so always refer to the manufacturer’s instructions and specifications for proper mounting procedures.

Backplate Mounting: An Alternative for Versatility

While direct mounting is the standard method, some lathes and chucks offer an alternative mounting option called backplate mounting. Instead of attaching the chuck directly to the spindle nose, backplate mounting involves attaching the chuck to a separate backplate, which is then mounted onto the spindle nose.

The backplate is a flat circular plate with a hole in the center that matches the spindle nose’s configuration. It also has bolt holes that align with the chuck’s mounting holes or recess. To mount the chuck using the backplate method, you simply attach the chuck to the backplate using bolts or screws, ensuring a secure connection. The backplate is then mounted onto the spindle nose, allowing for quick interchangeability of chucks.

Backplate mounting provides versatility, as you can use different chucks with the same lathe by simply swapping out the backplates. This method is particularly beneficial for machinists working on various projects that require different chuck sizes or types.

Collet Mounting: Ideal for Precision Work

In addition to direct and backplate mounting, another mounting method that provides exceptional precision is collet mounting. Collets are specialized workholding devices that grip the workpiece from the inside, ensuring optimal concentricity. Collet mounting involves using a collet chuck, which is mounted directly onto the lathe’s spindle nose or attached to a backplate.

To mount a collet chuck, you need to align the chuck’s mounting holes or recess with the corresponding features on the spindle nose or backplate, similar to the direct and backplate mounting methods. Once aligned, the chuck is securely fastened in place, allowing for the insertion and tightening of the collets. Collet mounting is known for its excellent gripping power and minimal runout, making it ideal for precision machining tasks.

It’s worth mentioning that collet mounting requires specific collets that match the chuck’s design and the workpiece’s dimensions. Machinists often opt for collet mounting when working on intricate and delicate components that demand utmost precision.

Mounting Considerations for Safety and Efficiency

When it comes to mounting lathe chucks, it’s crucial to prioritize safety and efficiency. Here are some key considerations to keep in mind:

- Ensure proper alignment: Accurate alignment between the chuck and the spindle or backplate is essential for reliable and consistent performance. Take extra care to align the bolt holes or mounting recess precisely.

- Tighten securely: Always use the recommended torque specifications and tightening sequence when fastening the chuck to the lathe. This ensures a secure connection and reduces the risk of the chuck coming loose during operation.

- Inspect for damage: Before mounting a chuck, thoroughly inspect it for any signs of damage or wear. Ensure that all components, such as jaws and scrolls, are in proper working condition to prevent accidents or compromises in machining quality.

- Consider workpiece requirements: Different workpieces may require specific chuck types or jaw configurations. Assess the size, shape, and material of the workpiece to determine the most suitable chuck and mounting method for the job.

- Follow manufacturer’s guidelines: Always refer to the lathe and chuck manufacturer’s guidelines and instructions for mounting procedures, torque specifications, and any specific considerations or restrictions.

Conclusion

Mounting lathe chucks is a critical aspect of machining that directly impacts the safety, precision, and efficiency of the process. Whether you choose the standard direct mounting method, the versatile backplate mounting option, or the precision-focused collet mounting, it’s crucial to follow proper procedures, ensure accurate alignment, and prioritize safety at all times. By understanding the different mounting methods and considerations, you can elevate your machining capabilities and achieve superior results.

Key Takeaways: How Are Lathe Chucks Mounted?

1. Lathe chucks are mounted on the lathe spindle using a threaded connection.

2. The chuck is screwed onto the spindle, ensuring a tight and secure fit.

3. A chuck key is used to tighten or loosen the chuck on the spindle.

4. There are different types of lathe chucks, such as 3-jaw and 4-jaw chucks, each with its own mounting method.

5. It is important to properly align and center the workpiece in the chuck to achieve accurate results.

Frequently Asked Questions

Welcome to our FAQ section on mounting lathe chucks. Here, we have compiled a list of common questions and their answers to help you understand the process. Whether you are a beginner or an experienced lathe user, we hope you find this information helpful.

Q: What is a lathe chuck?

A: A lathe chuck is a device used to hold and secure the workpiece on a lathe machine. It is mounted onto the lathe’s spindle and serves as a gripping mechanism to secure the material being turned.

There are various types of lathe chucks, including three-jaw chucks, four-jaw chucks, and collet chucks. Each type has its own advantages and is suitable for different applications.

Q: How do you mount a lathe chuck?

A: Mounting a lathe chuck involves a few simple steps. First, ensure that the lathe spindle and chuck are clean and free of debris. Then, align the chuck’s mounting holes with the corresponding holes on the spindle.

Insert the mounting bolts through the holes and tighten them securely using a wrench or spanner. Make sure to tighten the bolts evenly and in a star pattern to distribute the pressure evenly across the chuck’s surface. Finally, check the chuck for any wobbling or misalignment before proceeding with your lathe operations.

Q: Do all lathe chucks have the same mounting mechanism?

A: No, not all lathe chucks have the same mounting mechanism. The type of mounting system depends on the chuck design and the lathe machine’s specifications. Some chucks have a direct mount, where they attach directly to the spindle, while others require an adapter plate.

It’s important to check the chuck’s specifications and the lathe’s requirements to ensure compatibility before attempting to mount the chuck. Using the wrong mounting mechanism can lead to unstable operations and potential safety hazards.

Q: What are the common mistakes to avoid when mounting a lathe chuck?

A: One common mistake is failing to clean the mounting surfaces properly. Any debris or dirt between the chuck and the spindle can cause misalignment or an uneven grip, affecting the turning operations.

Another mistake is overtightening the mounting bolts. While it’s crucial to tighten the bolts securely, excessive force can damage the chuck or the spindle. It’s best to follow the manufacturer’s recommended torque specifications for the specific chuck and lathe model.

Q: Can I mount different sizes of lathe chucks on the same lathe?

A: Yes, it is possible to mount different sizes of lathe chucks on the same lathe, as long as the lathe’s spindle and chuck mounting mechanism are compatible. However, it’s important to consider the lathe’s weight capacity and the chuck’s dimensions to ensure safe and efficient operations.

When changing to a different-sized chuck, you may need to adjust the lathe’s speed settings and take additional precautions to maintain stability during the turning process. Always refer to the lathe and chuck manufacturer’s guidelines for proper mounting and operation instructions.

Summary

Mounting a lathe chuck is important for secure and precise machining. There are two common methods: threaded mounting and camlock mounting. Threaded mounting uses screws to attach the chuck to the lathe spindle, while camlock mounting involves aligning notches and rotating the chuck into place. It’s crucial to follow safety guidelines and ensure the chuck is properly centered for effective turning operations.