Have you ever wondered how the size of a lathe is determined? Well, you’re in luck! In this article, we’ll dive into the fascinating world of lathe sizing, uncovering the secrets behind this essential tool in machining. So, whether you’re a curious hobbyist or aspiring machinist, let’s unravel the mystery together, shall we?

When it comes to determining the size of a lathe, several factors come into play. From the swing capacity to the distance between centers, each measurement plays a crucial role in defining the lathe’s size. So, get ready to embark on a measurement adventure and uncover the key components that influence a lathe’s dimensions.

But wait, there’s more! We’ll also discuss the importance of selecting the right lathe size for your projects. Understanding how to match the lathe’s capabilities with your machining needs can make a world of difference in achieving precision and efficiency. So, get ready to uncover the secrets of lathe sizing and unlock a whole new level of machining mastery! Let’s dive in!

How are lathe sizes determined?

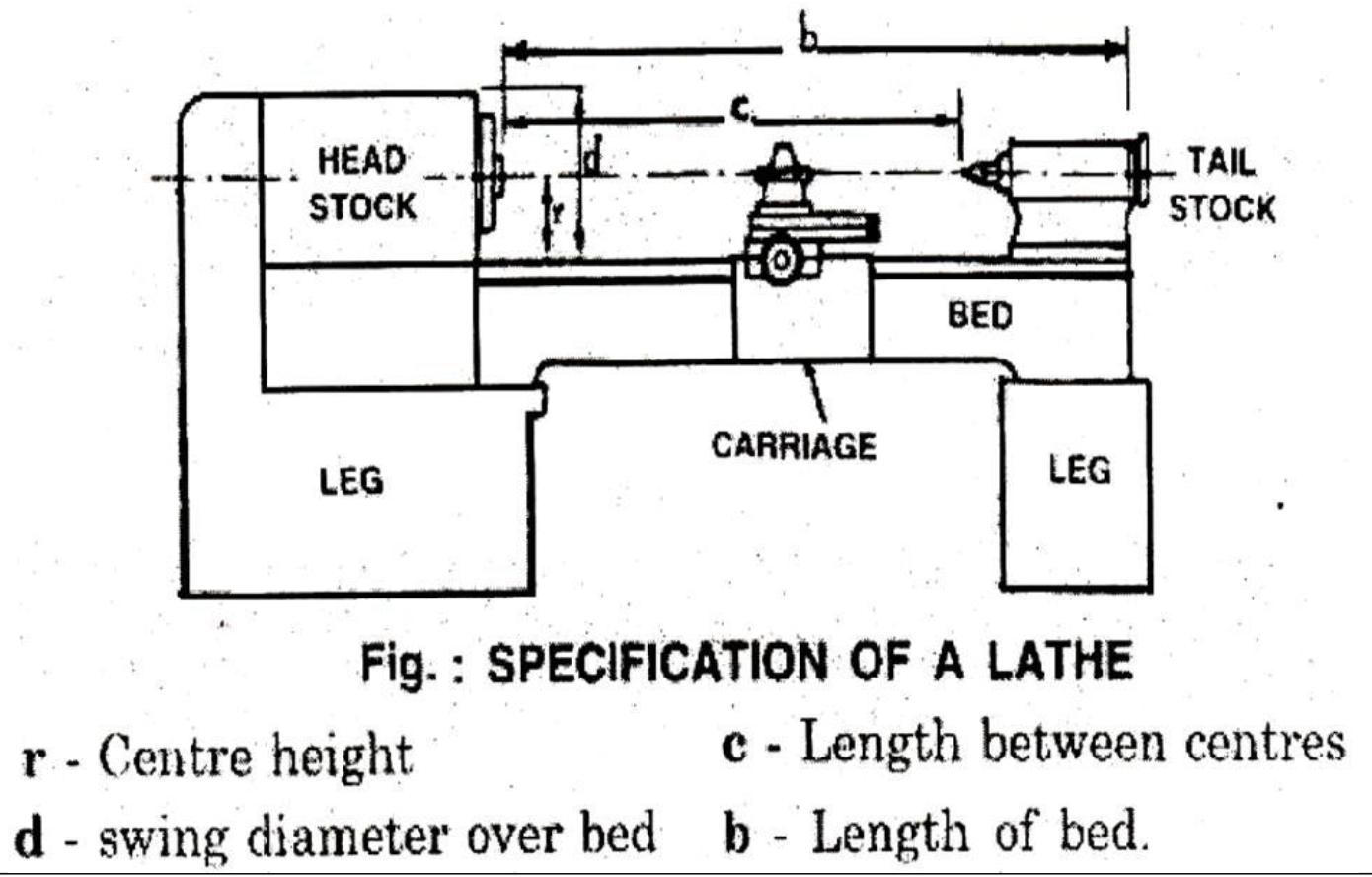

Lathe sizes, also known as lathe swing, refer to the maximum diameter of the workpiece that can be accommodated on a lathe. The size of a lathe is a critical factor to consider when choosing the right lathe for a specific application. It determines the types and sizes of projects that can be undertaken, and influences the overall functionality and versatility of the lathe. The determination of lathe size involves various factors, including the lathe’s physical dimensions, bed length, and the distance between the spindle and the lathe bed. In this article, we will dive into the details of how lathe sizes are determined, providing you with a comprehensive understanding of this important aspect of lathe selection.

Factors Influencing Lathe Size Determination

When it comes to determining the size of a lathe, several key factors come into play. These factors include:

- Physical dimensions of the lathe: This includes the height, width, and length of the lathe. Larger physical dimensions generally correspond to larger lathe sizes.

- Bed length: The bed length refers to the distance between the lathe’s headstock (spindle) and tailstock. It determines the maximum length of the workpiece that can be turned on the lathe.

- Swing over bed: This refers to the maximum diameter of the workpiece that can be turned on the lathe without interference from the bed.

- Swing over cross slide: This measurement indicates the maximum diameter of the workpiece that can be turned with the tool mounted on the cross slide.

- Distance between spindle and lathe bed: This measurement determines the maximum length of the workpiece that can be turned on the lathe without interference from the headstock or tailstock.

By considering these factors, lathe manufacturers and users can determine the appropriate size of the lathe for their specific needs.

Physical Dimensions and Lathe Size Determination

The physical dimensions of a lathe play a significant role in determining its size. Larger lathes generally have larger capacities and can handle larger workpieces. The height, width, and length of the lathe contribute to its overall size and weight. Additionally, the physical dimensions affect the stability and rigidity of the lathe, which in turn impact its performance and accuracy. When selecting a lathe, it is important to consider the available space in your workshop and ensure that the lathe’s size fits comfortably within that space.

It’s also worth noting that larger lathes often come with additional features and accessories, such as multiple spindle speeds and automatic tool changers, which provide enhanced functionality and versatility. However, these features also come with a higher price tag.

In summary, the physical dimensions of a lathe directly contribute to its size and should be considered in conjunction with other factors when determining the appropriate lathe size for a specific application.

Bed Length and Lathe Size Determination

The bed length of a lathe is a crucial factor in determining its size and the maximum length of workpieces that can be turned. The bed length refers to the distance between the lathe’s headstock (spindle) and tailstock. The longer the bed, the larger the workpiece that can be turned.

When selecting a lathe, it is important to consider the types of projects you plan to undertake. If you work with longer workpieces, such as table legs or baseball bats, a lathe with a longer bed length would be more suitable. However, if you primarily work with smaller items like pens or small bowls, a shorter bed length may suffice.

It’s worth noting that longer bed lengths come with some trade-offs. Longer beds tend to increase the overall size and weight of the lathe, making it less portable. Additionally, longer beds may introduce additional flex and decrease the rigidity of the lathe, potentially impacting its precision. Therefore, it is essential to strike a balance between the desired bed length and other considerations, such as available space and budget.

Swing Over Bed, Swing Over Cross Slide, and Lathe Size Determination

The measurements known as “swing over bed” and “swing over cross slide” are critical in determining the size of a lathe. The swing over bed refers to the maximum diameter of a workpiece that can be turned on the lathe without interference from the bed. On the other hand, the swing over cross slide indicates the maximum diameter of a workpiece that can be turned with the tool mounted on the cross slide.

These measurements are crucial because they determine the size limitations of the lathe in terms of the diameter of the workpiece. If you work with larger workpieces, you will need a lathe with a larger swing over bed and swing over cross slide. Conversely, if your projects involve smaller workpieces, a lathe with a smaller swing over bed and swing over cross slide may be sufficient.

The swing capacity of a lathe is typically specified by the manufacturer and can be used as a guide when selecting the appropriate lathe size for your needs. Keep in mind that the swing capacity should accommodate the largest workpiece you plan to turn, with some room for maneuvering.

Distance Between Spindle and Lathe Bed

The distance between the spindle and the lathe bed is another crucial factor in determining lathe size. This measurement refers to the maximum length of the workpiece that can be turned on the lathe without interference from the headstock or tailstock. A larger distance between the spindle and lathe bed allows for longer workpieces to be turned without restrictions.

It’s important to consider the types of projects you will be working on and determine the necessary distance between the spindle and lathe bed. If you primarily work with shorter workpieces, a smaller distance may be sufficient. However, if you plan to turn longer items, such as table legs or bedposts, a lathe with a larger distance between the spindle and lathe bed would be more appropriate.

Keep in mind that longer distances between the spindle and lathe bed can impact the overall size and weight of the lathe. Additionally, they may introduce additional flex, potentially affecting the lathe’s precision and stability. Therefore, it is crucial to find a balance between the necessary distance and other factors, such as available space and budget.

Additional Factors to Consider When Determining Lathe Size

In addition to the factors mentioned above, there are other considerations that can influence the determination of lathe size. These factors include:

- Workpiece weight and balance: If you frequently work with heavy or unbalanced workpieces, you may need a larger lathe to accommodate the weight and maintain stability.

- Desired spindle speed: Larger lathes often offer a wider range of spindle speeds, allowing for more versatility in terms of the types of projects that can be undertaken.

- Budget: The size of the lathe can have a significant impact on its price. Larger lathes with more features tend to be more expensive.

- Available space: Consider the dimensions of your workshop and ensure there is enough space to accommodate the chosen lathe.

- Weight and portability: If you need to frequently move or transport the lathe, a smaller and more lightweight option may be preferable.

By taking these additional factors into account, you can make a well-informed decision when determining the appropriate size of a lathe for your needs.

Conclusion

Choosing the right lathe size is crucial for ensuring optimal performance and functionality in your woodworking or metalworking projects. Factors such as physical dimensions, bed length, swing capacity, and the distance between the spindle and lathe bed all play a role in determining the size of a lathe. Additionally, considerations like workpiece weight, desired spindle speed, budget, available space, and portability are important factors to keep in mind. By carefully evaluating these factors and making an informed decision, you can select a lathe that meets your specific requirements and allows you to achieve your desired woodworking or metalworking goals.

#Key Takeaways: How are lathe sizes determined?

How are lathe sizes determined?

- A lathe’s size is determined by its swing capacity, which is the maximum diameter of the workpiece that can fit in the lathe.

- The length of a lathe is determined by its distance between centers, which is the maximum length of the workpiece that can be turned.

- Lathe sizes are usually specified as “swing over bed” and “between centers” measurements.

- The swing over bed measurement is the distance from the lathe’s bed to the highest point the workpiece can be turned.

- The between centers measurement is the distance between the two centers of the lathe, which aligns and supports the workpiece.

Frequently Asked Questions

When it comes to determining the size of a lathe, there are a few key factors to consider. If you’re curious about how lathe size is determined, read on to find the answers to some common questions.

1. What factors should I consider when determining the size of a lathe?

When determining the size of a lathe, consider the maximum diameter and length of the workpiece you plan to turn. The swing capacity of a lathe refers to the maximum diameter it can accommodate over the bed. The distance between centers, on the other hand, determines the length of the workpiece that can be turned. By considering these factors, you can choose a lathe that suits the size of the projects you’ll be working on.

Additionally, it’s important to consider the available space in your workshop. Make sure the lathe you choose fits comfortably in your workspace, allowing for easy maneuverability and access.

2. Is bigger always better when it comes to lathe size?

Not necessarily. The size of the lathe you choose should match the scale of the projects you’ll be working on. While larger lathes may offer increased capacity for larger workpieces, they also take up more space and tend to be more expensive. If you primarily work on smaller projects, a smaller lathe may be more practical and cost-effective.

Think about the types of projects you’ll be tackling and consider your available space and budget. It’s important to strike a balance between the size of the lathe and your specific needs.

3. Can I upgrade the size of my lathe in the future?

In many cases, it is possible to upgrade the size of your lathe in the future. Lathe manufacturers often offer accessories and attachments that can extend the capacity of the lathe. Additionally, you can sometimes purchase bed extensions that increase the distance between centers.

However, it’s important to check with the specific lathe manufacturer to determine if such upgrades are available for your model. Some lathes may have limitations when it comes to size upgrades, so it’s best to plan ahead and carefully research your options before making a purchase.

4. How do I know if a lathe is powerful enough for my projects?

When assessing if a lathe is powerful enough for your projects, consider its horsepower rating. A higher horsepower rating indicates that the lathe has more power and can handle heavier workpieces or more demanding turning tasks.

However, it’s important to note that power is not the only factor in determining a lathe’s suitability for your needs. Other factors, such as rigidity, torque, and the quality of the materials, also play a role in determining a lathe’s overall performance. It’s worth exploring all these aspects and seeking recommendations from experienced turners to ensure you choose a lathe that meets your project requirements.

5. Are there any safety considerations when determining lathe size?

Safety should always be a top priority when working with lathes, regardless of their size. However, larger lathes may require additional safety precautions due to their increased size and power.

When working with a larger lathe, make sure you have adequate space around the machine for safe operation. Use appropriate safety gear, such as goggles and a face shield, to protect yourself from debris and flying wood. Additionally, familiarize yourself with the lathe’s specific safety features and follow all recommended operating procedures to minimize the risk of accidents or injuries.

Summary

Choosing the right size for a lathe is important for your woodworking projects. You need to consider the length and diameter of the materials you will be working with. Smaller lathes are great for small projects like pens, while larger lathes are better for bigger items like table legs. Smaller projects need shorter distances between the centers, while larger projects require more space. The size also affects the power and speed of the lathe, so make sure to choose one that matches your needs.

When determining the size of a lathe, you also need to consider your workspace. Measure the available area to ensure there is enough room for the lathe, including the space needed for maneuvering. Take into account the weight and stability of the lathe as well. Remember, it’s better to have a lathe that is slightly bigger than you need rather than one that is too small, as you can always adjust your projects accordingly. Consider your needs and space carefully when choosing the size of your lathe.