Have you ever wondered how the size of a lathe is determined? Well, you’re in luck! In this article, we’ll dive into the fascinating world of lathe sizing to uncover the key factors that go into determining the size of this versatile machine. So, whether you’re a curious hobbyist or an aspiring machinist, join us as we unravel the mystery of lathe size together!

When it comes to lathe size, there are several crucial elements to consider. From the distance between the lathe’s centers to the maximum swing over the bed, each aspect plays a vital role in determining the machine’s size and capabilities. So, get ready to explore the fascinating world of lathes and discover how these essential factors contribute to their overall size.

Now, you might be wondering why lathe size matters at all. Well, the size of a lathe directly affects the size and complexity of the workpieces it can handle. By understanding how lathe size is determined, you’ll gain valuable insights into matching the machine to your specific project requirements and achieving optimal results. So, let’s roll up our sleeves and dive right into the exciting details of how lathe size is determined!

How Are Lathe Sizes Determined?: A Comprehensive Guide

Understanding the Basics of Lathe Sizes

Understanding the Basics of Lathe Sizes

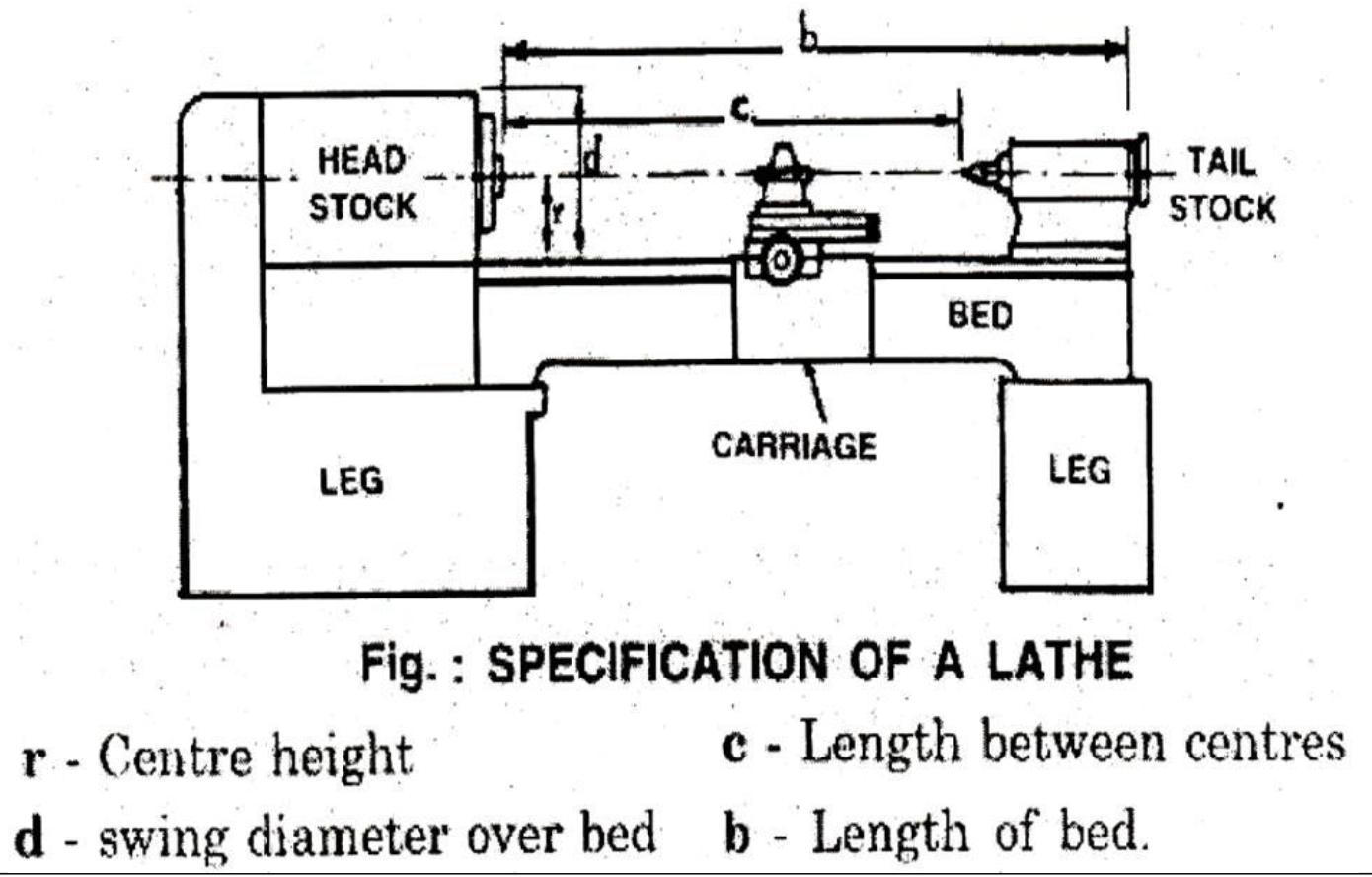

When it comes to lathes, size matters. The size of a lathe refers to its capacity and determines the range of work it can handle. The primary factors that determine the size of a lathe are the swing-over-bed and the distance between centers. The swing-over-bed is the maximum diameter of material that can be turned on the lathe, while the distance between centers refers to the maximum length of material that can be turned. These measurements are crucial in determining the size of a lathe and its suitability for specific projects.

In addition to the swing-over-bed and distance between centers, other considerations such as the spindle bore size and motor power play a role in determining the capacity of a lathe. The spindle bore size indicates the maximum diameter of material that can be passed through the spindle, allowing for larger workpieces. The motor power determines the lathe’s ability to handle heavy-duty tasks and larger workpieces. By considering these factors, you can determine the right lathe size for your needs.

It’s important to note that lathe sizes can vary significantly. Mini lathes typically have a small swing-over-bed and distance between centers, making them ideal for small-scale projects. On the other hand, industrial-sized lathes have a much larger capacity and are designed for heavy-duty turning. Understanding your specific requirements and the nature of your projects will help you choose the right lathe size for optimal performance.

Factors to Consider in Choosing the Right Lathe Size

Choosing the right lathe size can be a daunting task, given the various factors involved. To make an informed decision, consider the following:

- Project Size: Assess the typical size of the projects you will be working on. Determine the maximum diameter and length of the workpieces you need the lathe to handle.

- Available Space: Consider the space you have in your workshop. Measure the dimensions to ensure the lathe will fit comfortably without hindering other equipment or impeding your workflow.

- Budget: Determine your budget for the lathe. Larger lathes with more capabilities tend to be pricier. Consider your financial limitations while balancing the features and capacity you require.

- Intended Use: Evaluate the intended use of the lathe. Are you a hobbyist, a professional woodturner, or a metalworker? Each field may require different lathe sizes and features.

- Future Growth: Consider your future plans and whether you anticipate working on larger projects. It may be beneficial to invest in a lathe with a larger capacity to accommodate potential growth.

By carefully considering these factors, you can narrow down your options and choose a lathe size that suits your specific needs and preferences.

Types of Lathes and Their Ideal Sizes

Lathes come in various types, each with its own ideal size range based on their specific applications. Let’s explore some of the common types of lathes and the suitable lathe sizes for each:

1. Mini Lathes:

Mini lathes are compact and designed for small-scale projects and hobbyists. They typically have a swing-over-bed ranging from 8 to 12 inches and a distance between centers of around 16 to 24 inches. These lathes are perfect for pen turning, small spindle work, and intricate wood or metal crafting.

2. Midi Lathes:

Midi lathes are a step up from mini lathes, offering slightly larger capacity while remaining suitable for hobbyists and beginners. They typically have a swing-over-bed ranging from 12 to 14 inches and a distance between centers of around 30 to 36 inches. Midi lathes can handle larger bowls, furniture parts, and other medium-sized turnings.

3. Full-Sized Lathes:

Full-sized lathes are industrial-grade machines suitable for professional woodturners and metalworkers. They have a swing-over-bed ranging from 14 to 24 inches and a distance between centers of 36 inches or more. These lathes can handle large diameter workpieces, heavy-duty turning, and substantial projects such as furniture legs, stair spindles, and large bowls.

4. CNC Lathes:

CNC lathes are computer-controlled lathes that offer precision and automation. Their size can vary greatly depending on the specific application and industry they are designed for. CNC lathes are used in industries such as automotive, aerospace, and manufacturing, where high accuracy and repeatability are critical.

These are just a few examples of the different lathe types and their ideal size ranges. It’s essential to match the lathe size with the intended applications to ensure efficiency, quality, and safety in your turning projects.

Maximizing Efficiency and Safety with the Right Lathe Size

Choosing the right lathe size is crucial for maximizing efficiency and ensuring safety in your turning projects. Here are some tips to help you make the most of your lathe:

- Understand Your Project Requirements: Before starting any project, thoroughly assess the size and scope of your workpiece to determine if your lathe is suitable. If not, consider outsourcing the project or investing in a lathe with the appropriate capacity.

- Practice Safe Operation: Follow all safety guidelines and use the necessary safety equipment when operating the lathe. This includes wearing appropriate eyewear, securing your workpiece properly, and using tools with caution.

- Optimize Tool Selection: Use the correct tools for your project and ensure they are in good condition. Using the wrong tools or dull blades can lead to accidents and subpar results.

- Regular Maintenance: Keep your lathe well-maintained by cleaning it regularly and performing routine maintenance tasks. This will prolong its lifespan and ensure optimal performance.

- Grow Your Skills: Continuously work on improving your turning skills through practice, experimentation, and learning from experienced turners. This will result in better quality projects and the ability to tackle more complex designs and materials.

With the right lathe size and adherence to safety protocols, you can enjoy efficient and rewarding turning experiences while producing exceptional results.

Choosing the Right Lathe Size for Your Needs: Factors to Consider

When it comes to selecting the right lathe size, there are several important factors to consider. By taking these factors into account, you can ensure that you choose a lathe that meets your needs and allows you to complete your projects effectively and efficiently.

Key Considerations in Choosing a Lathe Size

There are several key considerations that you should keep in mind when choosing a lathe size. These include:

The Importance of Swing-Over-Bed and Distance Between Centers

The swing-over-bed and distance between centers are two vital measurements that determine the workpiece size a lathe can handle. The swing-over-bed refers to the maximum diameter of a workpiece that can be mounted on the lathe, while the distance between centers determines the maximum length of a workpiece that can be accommodated.

Understanding Spindle Bore Size

Another critical factor in determining lathe size is the spindle bore size. The spindle bore is the opening in the headstock through which the workpiece is fed. The size of the spindle bore dictates the maximum diameter of material that can be worked on using the lathe. Larger spindle bores offer greater flexibility and allow for the turning of larger and more complex workpieces.

Motor Power and the Capability of the Lathe

The motor power of a lathe directly impacts its performance and capability. A more powerful motor allows for better control over the workpiece, especially when handling larger or denser materials. Motor power also affects the lathe’s ability to cut smoothly and accurately, resulting in better overall results.

The Size of the Workspace

When choosing a lathe size, it’s essential to consider the available space in your workshop. Ensure that the lathe you select fits comfortably without impeding your movement or interfering with other equipment. Measure the area to determine the ideal size of the lathe for your workspace.

How the Lathe Will Be Used

The specific applications and usage of the lathe will also influence the size you choose. Are you a hobbyist working on small-scale projects, or do you require a lathe for industrial purposes? Understanding your intended use will help you determine the capacity and features you need.

Budget Constraints and Cost

Your budget is, of course, a critical consideration when choosing a lathe size. Larger lathes with more capabilities and higher power tend to be more expensive. Consider your financial limitations while balancing your need for certain features and the size of the projects you’ll be working on.

Future Needs and Growth

Finally, consider your future needs and potential growth in the field. If you anticipate taking on larger projects or expanding your turning capabilities, it may be wise to choose a lathe with a larger swing-over-bed and distance between centers to accommodate future requirements.

Conclusion

Choosing the right lathe size is crucial for successful turning projects. By considering factors such as swing-over-bed, distance between centers, spindle bore size, motor power, available space, intended use, budget, and future growth, you can make an informed decision. Remember to prioritize safety and proper maintenance to ensure the longevity and optimal performance of your lathe. With the right lathe size, you’ll be well-equipped to tackle a wide range of turning projects with confidence and precision.

How are lathe size determined?

- Lathe size is determined by the maximum swing over the bed, which is the largest diameter of the material that can be turned.

- The length between centers is another factor in determining lathe size.

- Bed length and spindle bore size also contribute to the overall size of the lathe.

- Weight and power capacity are important considerations for larger lathes.

- Lathe size is typically chosen based on the types and sizes of projects the lathe will be used for.

Frequently Asked Questions

In the world of machining, lathes play a crucial role. Determining the size of a lathe is an important aspect when considering its applications and capabilities. Below are some common questions about how lathe size is determined.

Q: What factors are considered when determining the size of a lathe?

When determining the size of a lathe, several factors are taken into consideration. The primary factors include the maximum swing capacity, which is the largest diameter that can be rotated over the bed, and the distance between centers, which is the maximum length of material that can be turned between the headstock and tailstock. Additionally, the power of the lathe’s motor, bed length, and spindle bore size are also considered.

In summary, the physical dimensions, such as swing capacity and distance between centers, as well as the power and other specifications, are all taken into account when determining the size of a lathe.

Q: How does swing over bed affect the size of a lathe?

The “swing over bed” refers to the maximum diameter of the workpiece that can be rotated over the bed of the lathe. It is an important factor when determining the size of a lathe because it dictates the size of the piece that can be machined. A larger swing over bed allows for the machining of larger projects, while a smaller swing over bed limits the size of work that can be done. For example, a lathe with a swing over bed of 12 inches can work on pieces with a diameter of up to 12 inches.

Therefore, when choosing a lathe size, it is important to consider the desired diameter of the workpiece to ensure it falls within the swing capacity of the lathe.

Q: What is the importance of the distance between centers in determining lathe size?

The distance between centers refers to the maximum length of material that can be turned between the headstock and tailstock of a lathe. It determines the size of the workpiece that can be accommodated in terms of its length. A longer distance allows for the turning of longer pieces, while a shorter distance limits the length of work that can be done. For example, a lathe with a distance between centers of 36 inches can handle workpieces up to 36 inches long.

When determining the lathe size, it is important to consider the desired length of the workpiece and ensure it falls within the distance between centers of the lathe.

Q: Does the power of the lathe’s motor affect its size?

Yes, the power of the lathe’s motor is an important consideration when determining its size. The power of a lathe’s motor is typically measured in horsepower (HP) and determines the cutting capability of the machine. A higher horsepower allows for more aggressive cutting, enabling the lathe to handle larger and tougher materials. On the other hand, a lower horsepower limits the size and type of materials that can be machined effectively.

Therefore, when determining the size of a lathe, it is crucial to consider the power of the motor based on the intended applications and the materials that will be worked on.

Q: What role does the spindle bore size play in determining the size of a lathe?

The spindle bore size is another important factor when determining the size of a lathe. It refers to the diameter of the hole through the lathe’s spindle, which allows the passage of materials such as long stock or bar stock. The spindle bore size determines the maximum diameter of material that can be passed through the spindle and turned on the lathe.

For projects that involve working with larger stock or materials, it is essential to choose a lathe with a spindle bore size that can accommodate the desired diameter.

Summary

Choosing the right size of a lathe is important for woodworking projects. A small lathe is great for small projects like pens or bowls, while a big lathe is needed for larger projects like furniture legs. Consider the size of the piece you want to turn when determining the right lathe size.

Additionally, the swing capacity of the lathe is crucial. This refers to the maximum diameter of wood that can be turned on the lathe. Make sure the lathe’s swing capacity is big enough to accommodate your desired project size. Remember, choosing the right lathe size will ensure you have the best tool for your woodworking needs.