Have you ever wondered how lathes are made? Well, you’re in luck! In this article, we’ll delve into the fascinating process of creating these versatile machines that play a vital role in various industries. So, get ready to dive into the world of lathe production!

When it comes to making lathes, it’s a complex and intricate process that involves skilled craftsmanship and cutting-edge technology. From designing the components to assembling the final product, every step requires careful precision. So, let’s roll up our sleeves and uncover the secrets behind the manufacturing of lathes!

From the raw materials to the finished product, it’s a journey filled with innovation and attention to detail. We’ll explore the various manufacturing techniques involved, such as casting, machining, and assembly. By the end of this article, you’ll have a deeper understanding of the effort and expertise required to bring lathes to life. So, let’s get started and uncover the magic behind how lathes are made!

How Are Lathes Made? A Closer Look at the Manufacturing Process

Lathes are precision machines used in various industries to shape and cut materials with rotational symmetry. They are incredibly versatile tools that have been around for centuries, evolving to meet the demands of modern manufacturing. But have you ever wondered how lathes themselves are made? In this article, we will take a dive into the manufacturing process of lathes, exploring the intricate steps involved in bringing these machines to life.

1. Design and Engineering

The first step in making a lathe is the design and engineering phase. Experienced engineers work on creating the blueprint for the machine, taking into account its intended purpose, size, and functionality. They also consider advancements in technology and industry standards to ensure that the lathe is cutting-edge and meets customer expectations.

Once the design is complete, engineers use computer-aided design (CAD) software to create a digital model of the lathe. This allows them to analyze the design, make adjustments, and test its performance virtually. The CAD model serves as the foundation for the entire manufacturing process, guiding the production team in building the physical machine.

2. Material Selection and Preparation

After the design is finalized, the next step is selecting the materials that will be used to construct the lathe. Common materials include cast iron, steel, and aluminum, each with its own set of properties and advantages. The choice of material depends on factors such as the lathe’s intended use, desired durability, and cost considerations.

Once the materials are selected, they undergo a rigorous preparation process. This may involve cutting them into specific shapes and sizes, machining any necessary features, and performing heat treatments to enhance their mechanical properties. This meticulous preparation ensures that the materials are ready to be assembled into a high-quality lathe.

3. Machining and Assembly

Machining is a crucial step in the manufacturing process of lathes. Skilled operators use various machining techniques, such as milling, turning, and drilling, to shape the individual components of the lathe according to the design specifications. This involves removing excess material and creating intricate features with utmost precision.

Once the components are machined, they go through a thorough quality control process to ensure they meet the required standards. Any necessary adjustments or refinements are made before the components move on to the assembly stage. At this stage, highly skilled technicians meticulously piece together the various components, following strict assembly instructions and using specialized tools and equipment.

The assembly process includes securing the components with fasteners, aligning precision surfaces and bearings, and ensuring proper lubrication. This critical step ensures that the lathe functions smoothly and accurately. After assembly, the lathe undergoes a comprehensive testing phase to confirm its performance, accuracy, and safety.

4. Finishing and Quality Control

The penultimate step in the manufacturing process is finishing the lathe. This involves carefully cleaning the machine to remove any debris or contaminants and applying protective coatings to enhance its durability and aesthetics. The lathe is then subjected to thorough quality control inspections to verify that it meets all specifications and adheres to strict industry standards.

During the quality control process, technicians use various measuring instruments, such as calipers, micrometers, and gauges, to ensure that the lathe’s dimensions and tolerances are within the required limits. They also check for any potential defects or abnormalities that may affect the lathe’s performance. If any issues are detected, they are addressed and resolved before the lathe is ready for shipment or installation.

5. Packaging and Delivery

The final step in the manufacturing process is packaging and delivery. The lathe is carefully packaged to protect it during transportation, using materials that provide adequate cushioning, support, and stability. Proper packaging is essential to prevent any damage or malfunctions that may occur during transit.

Once packaged, the lathe is shipped to its intended destination. This may involve coordinating logistics, such as arranging for transportation, addressing any import/export requirements, and ensuring timely delivery. The manufacturer may also provide installation services or guidance to ensure that the lathe is properly set up and ready for use.

In conclusion, the process of manufacturing lathes involves a meticulous combination of design, engineering, material selection and preparation, machining and assembly, finishing, quality control, and packaging. Each step is essential in creating a high-quality, functional, and reliable lathe. Understanding how lathes are made not only showcases the craftsmanship and attention to detail involved but also enhances our appreciation for these remarkable machines. Whether it’s shaping metal, wood, or other materials, lathes play a crucial role in countless industries, enabling precision and efficiency in manufacturing processes.

Key Takeaways: How Are Lathes Made?

- Lathes are machines used for shaping and cutting materials like wood or metal.

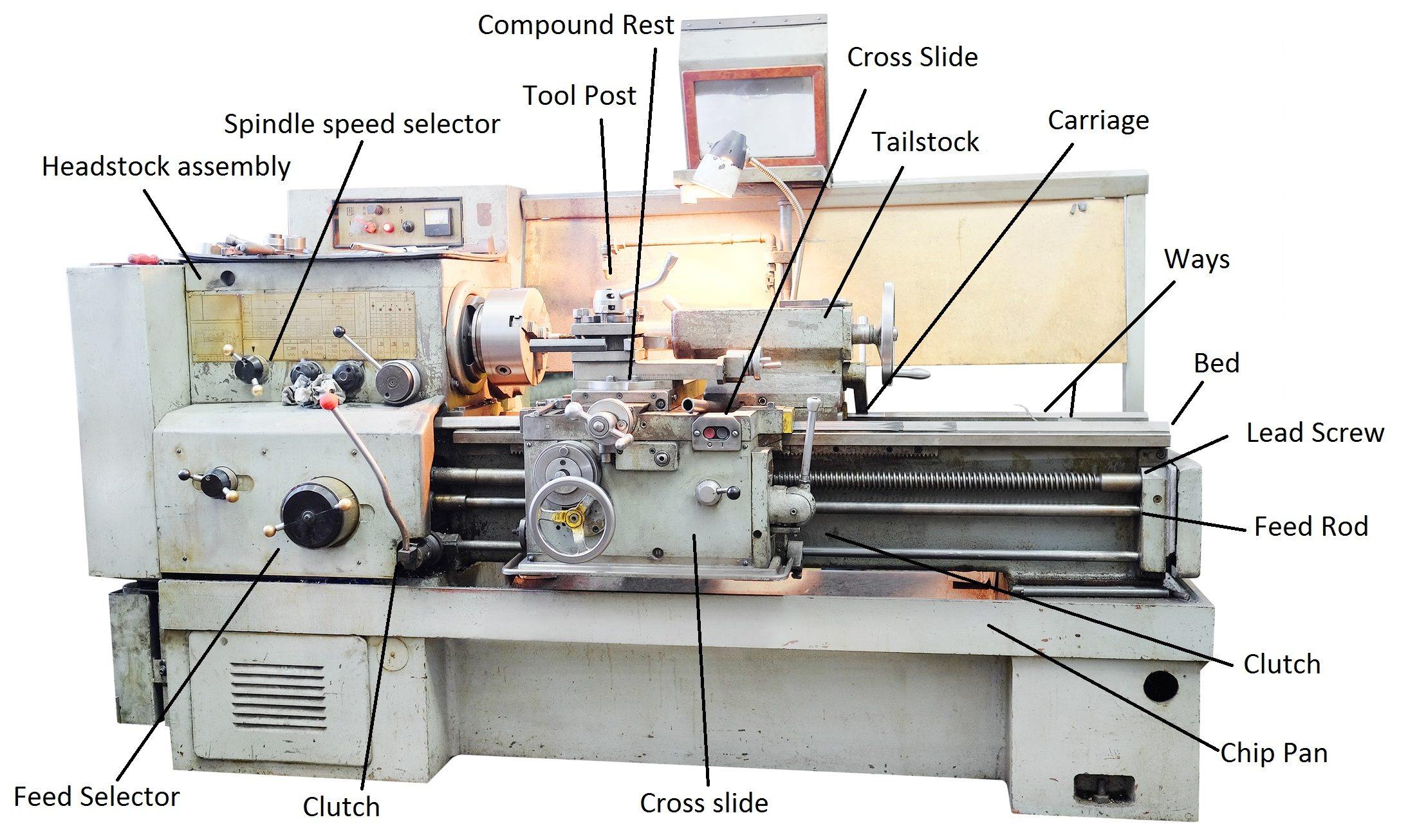

- Lathes are made by combining various components, including a bed, headstock, tailstock, and carriage.

- The bed is the foundation of the lathe and provides stability and support.

- The headstock holds the spindle, which rotates the workpiece.

- The tailstock is used for supporting long workpieces and can be adjusted for different lengths.

Frequently Asked Questions

Welcome to our frequently asked questions section where we’ll explore how lathes are made. Find answers to some common questions about the manufacturing process behind these essential machines.

1. What materials are used to make lathes?

The main materials used in the construction of lathes are cast iron and steel. Cast iron is favored for its durability and ability to absorb vibrations, which ensures stability during operation. Steel, on the other hand, is used for critical components such as gears and shafts due to its strength and wear-resistant properties.

Additionally, lathes may incorporate other materials such as bronze, brass, and aluminum for specific parts like the tailstock, chuck, and tool rest. The selection of materials depends on the functionality and performance requirements of the particular lathe being built.

2. How are lathes manufactured?

The manufacturing process of lathes involves several key steps. It starts with the design phase, where engineers create detailed plans and specifications for the lathe. Next, the chosen materials are prepared by cutting, shaping, and machining them into the required components.

These components are then assembled, aligning and securing them according to the design specifications. Precision is crucial during assembly to ensure accuracy and smooth operation. Once the lathe is fully assembled, it undergoes rigorous testing to verify its performance and functionality. Only after passing these tests, the lathe is ready for distribution and use.

3. Are lathes made by hand or using machines?

The manufacturing of lathes involves a combination of manual labor and the use of machines. Skilled technicians and engineers work together to craft and assemble the various components of a lathe. These professionals utilize their expertise and precision to ensure the highest quality during the manufacturing process.

However, modern manufacturing techniques also incorporate the use of advanced machinery, such as computer numerical control (CNC) machines. These computer-controlled machines can accurately shape and cut components with great speed and precision, enhancing the efficiency of the manufacturing process.

4. How long does it take to build a lathe?

The time required to build a lathe can vary depending on various factors such as the size and complexity of the lathe, the manufacturing techniques employed, and the resources available. In general, the process can take anywhere from a few weeks to several months.

Designing and prototyping can take a significant amount of time, and the production stage requires careful attention to detail. Additionally, testing and quality control procedures are necessary to ensure the lathe meets the required standards. Hence, building a lathe is a meticulous process that requires patience and precision at every step.

5. Where are lathes manufactured?

Lathes are manufactured in many countries around the world. Some of the leading producers of lathes include the United States, Germany, Japan, China, and Taiwan. These countries have a long history of expertise and innovation in the manufacturing industry.

It’s worth noting that there are various manufacturers and brands operating globally, each with its own manufacturing facilities. The choice of where to manufacture lathes can depend on factors like cost, access to skilled labor, and technological advancements in the specific region.

Summary

Lathes are made using a precise and complex process. They start with raw materials like iron and steel. These materials are shaped and formed into the various parts of the lathe. Then, these parts are carefully assembled and tested to ensure they work correctly. Lastly, the lathe is painted and packaged for sale.

It takes many skilled workers and specialized machinery to make a lathe. Each step is important to create a high-quality and functional machine. Now you know a little bit more about how lathes are made!