Are you wondering how big a generator you need to run power tools? Well, you’ve come to the right place! Whether you’re a DIY enthusiast or a professional contractor, having a reliable power source for your tools is essential. In this article, we’ll break down everything you need to know about choosing the right generator to keep those power tools running smoothly.

Picture this: you’re in the middle of a home renovation project, and suddenly, the power goes out. Frustrating, right? That’s where a generator comes in handy. It’s like having your own portable power station, ensuring that you can continue working even when the electricity is down. But how do you determine the size of the generator you need?

Choosing the right generator size depends on several factors, such as the power requirements of your tools and the total wattage they consume. But don’t worry, we’ll guide you through the process and help you find the perfect generator to keep your power tools humming. So let’s dive in and discover how big a generator you need to run power tools efficiently!

Running power tools with a generator requires choosing the right size to ensure efficient operation. To determine how big of a generator you need, follow these steps:

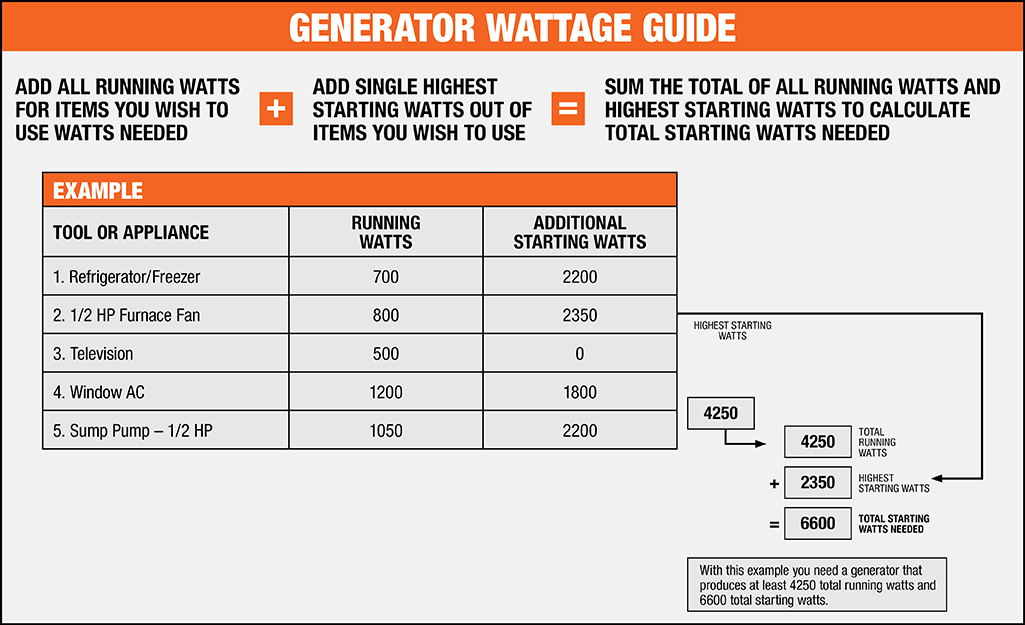

- Calculate the total wattage of all the power tools you plan to use simultaneously.

- Consider the starting wattage of each tool, which is usually higher than its running wattage.

- Add up the starting wattage of all tools to get the total starting wattage.

- Choose a generator with a continuous power output above the total starting wattage.

- Consider the generator’s fuel type and runtime as well.

By following these steps, you’ll be able to determine the right size of generator for running power tools.

How Big of a Generator Do You Need to Run Power Tools?

Power tools are essential for various projects, whether you’re a professional contractor or a DIY enthusiast. However, powering these tools can be a challenge, especially when you’re working in a remote location without access to grid electricity. That’s where generators come in. But how big of a generator do you need to run power tools efficiently? In this article, we’ll dive into the factors that determine generator size, the different power requirements of common power tools, and provide you with practical tips to help you choose the right generator for your needs.

Understanding Power Requirements

Before you can determine the size of the generator needed for power tools, it’s crucial to understand power requirements. The power rating of tools is typically expressed in watts or amps. Most power tools have a plate or label on them that indicates their power specifications. To calculate the total power required, you’ll need to add up the wattage or amperage of all the tools you plan to use simultaneously.

Additionally, it’s important to note that power tools have two types of power requirements: surge power and running power. Surge power refers to the extra power needed when a tool is initially turned on or during a sudden increase in workload. Running power, on the other hand, is the steady power consumption when the tool is in use. Both surge and running power should be considered when determining the size of the generator.

Once you have an estimate of the total power required for your tools, you can move on to selecting the appropriate generator size based on its power output capacity.

Factors to Consider When Choosing Generator Size

When selecting the size of a generator to run power tools, several factors come into play:

- Power Output: Generators are rated in terms of their power output capacity, typically expressed in watts. It’s important to choose a generator that can handle the total power requirements of your tools. An ideal generator should have a power output rating slightly higher than the combined running power of all your tools, considering surge power as well.

- Type of Tools: Different power tools have varying power requirements. While some tools, like drills and sanders, have relatively low power requirements, others, such as circular saws or air compressors, may require more power to operate. Make sure to check the power specifications of each tool and factor them into your generator selection.

- Start-Up Methods: Some power tools have soft start or variable speed features that reduce the initial surge power requirement. If your tools have these features, you may be able to opt for a slightly smaller generator.

- Future Expansion: Consider any potential future expansions or additions to your power tool collection. If you plan to acquire more tools in the future, it’s wise to choose a generator with some extra capacity to accommodate those additions.

Key Takeaways: How big a generator to run power tools?

- A generator’s size is determined by the power requirements of the power tools you plan to use.

- Calculate the wattage of each tool and add them together to determine the generator size needed.

- Consider starting wattage, as some power tools require more power during startup.

- Aim for a generator with a higher wattage capacity than the total power tool wattage to ensure smooth operation.

- Always check the generator’s user manual or consult a professional for accurate generator sizing.

Frequently Asked Questions

Have questions about determining the right generator size for powering your tools? Look no further! We’ve got you covered with the answers to the most common inquiries.

1. How do I determine the right generator size for running power tools?

When deciding on the size of a generator for your power tools, it’s crucial to consider their power requirements. Each power tool will have a wattage rating, and you need to sum up the wattage of all the tools you plan to run simultaneously. It’s vital to choose a generator that can handle the total wattage and have some extra overhead for future power needs. To calculate the required size accurately, you can consult the tool manuals or check the wattage information on the tool’s nameplate.

Additionally, factors like the start-up surge or peak power demand of certain tools, the inefficiencies of power conversion, and the type of generator (inverter or conventional) can affect the size requirements. Remember, it’s always better to go for a generator with a slightly higher capacity than to risk overloading a smaller one.

2. Can I use a small generator to power heavy-duty power tools?

While it may be tempting to use a smaller generator to power heavy-duty tools, it’s not always the best idea. Heavy-duty or high-powered tools often have high wattage requirements, especially during start-up when their motors require extra power. A small generator may not be able to handle the initial surge, causing it to trip or stall.

To ensure smooth and uninterrupted power supply for heavy-duty tools, it’s recommended to use a generator that has a higher wattage capacity than the tool’s requirements. This allows the generator to handle the start-up surges and provide a consistent power output throughout the operation. Before connecting any high-powered tools to a generator, always check the tool’s wattage rating and choose a generator that can comfortably handle the load.

3. Can I run multiple power tools simultaneously with a single generator?

Yes, you can run multiple power tools simultaneously with a single generator, but it’s essential to consider the total wattage requirements of all the tools. As each tool has its own power demands, sum up the wattage of all the tools you wish to operate at the same time. Make sure the generator you choose has a wattage capacity equal to or higher than the total wattage of all the tools combined, including any start-up surges.

Keep in mind that running multiple power tools at once can lead to a higher overall load on the generator and may decrease fuel efficiency. It’s a good idea to prioritize which tools you need to run concurrently and ensure the generator has the capacity to meet those requirements.

4. Can I use a generator with an inverter for running power tools?

Yes, you can use a generator with an inverter for running power tools. Inverter generators provide a stable, high-quality power output, making them suitable for sensitive electronics and power tools alike. They deliver clean power that is comparable to the electricity found in regular household outlets. Inverter generators are also typically quieter, more fuel-efficient, and produce fewer emissions compared to conventional generators.

When selecting an inverter generator for powering your tools, consider the total wattage requirements of the tools and choose a generator with a wattage capacity that can comfortably handle the load. Additionally, check the generator’s features, such as outlets and ports, to ensure compatibility with your specific power tool requirements.

5. What other factors should I consider when choosing a generator for power tools?

Aside from the generator size, there are a few other factors worth considering when choosing a generator for power tools. First, think about the fuel type you prefer, whether it’s gasoline, propane, or diesel. Gasoline is the most common and widely available, but propane and diesel may have advantages such as longer shelf life or better fuel efficiency.

It’s also important to think about the runtime you need. If you anticipate using your power tools for extended periods without access to refueling, consider generators with larger fuel tanks or higher fuel efficiency. Portability, noise level, and the availability of additional features like electric start or remote control are other aspects to keep in mind based on your specific needs and preferences.

Summary

Trying to figure out what size generator you need for power tools? Here’s a quick summary:

First, add up the wattage of all the tools you plan to use at the same time. Make sure to also consider the starting wattage, as some tools require more power when they first turn on.

Next, find a generator that has a rated wattage higher than the total wattage of your tools. This will ensure that it can handle the load and won’t get overloaded.

Remember, it’s always better to have a generator with more power than you need, so you’re prepared for any situation. Now you’re ready to choose the right generator for your power tools!