So you’re thinking about using a generator to power your tools, huh? Well, let me tell you, choosing the right size generator can make all the difference. If it’s too small, you’ll be left frustrated with power outages. But if it’s too big, well, you might end up with a generator that’s just too much for your needs. Don’t worry, though! I’m here to help you figure out just how big of a generator you need to run your power tools efficiently.

Now, I know what you’re thinking. Why does the size of the generator matter? Well, my friend, it all comes down to the wattage requirements of your power tools. Different tools have different power needs, and you want to make sure that your generator can handle them all. After all, you don’t want your saw or drill to sputter out in the middle of a project, do you? Nope, I didn’t think so.

But fret not, for determining the size of the generator isn’t rocket science. You just need to know the wattage of each power tool you plan to use simultaneously, add them up, and then find a generator that can handle that total power load. Simple, right? With a little bit of math and some basic information, you’ll be well on your way to finding the perfect-sized generator to keep your tools humming along smoothly. So let’s dive in and figure out just how big of a generator you need!

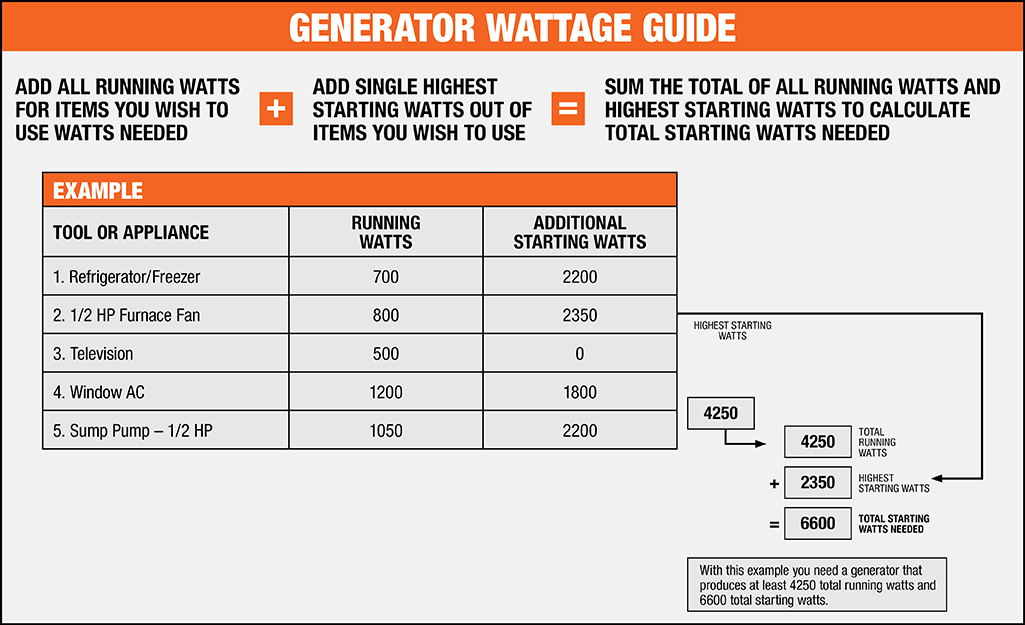

Wondering what size generator you need to power your tools? Follow these steps to find out:

- List all the power tools you plan to run simultaneously.

- Add up the starting watts of each tool.

- Identify the tool with the highest starting wattage.

- Calculate the total starting watts by adding the highest starting wattage to the sum of the running watts of all tools.

- Choose a generator that exceeds the total starting watts to ensure optimal performance.

Remember, it’s always better to have a generator with a slightly higher wattage than what you need.

How Big of a Generator Do You Need to Power Your Tools?

When it comes to powering your tools, having a generator is a must. But how do you know how big of a generator you need? Choosing the right generator size is crucial to ensure that your power tools run smoothly and efficiently. In this article, we will explore the factors that affect the size of generator you need for your tools. From wattage requirements to the type of tools you use, we’ll provide you with all the information you need to make an informed decision.

Understanding Wattage Requirements

One of the most important considerations when determining the size of generator you need for your power tools is understanding their wattage requirements. Each tool has a specific power rating, usually measured in watts or amps. To calculate the total wattage required, you need to add up the wattage of all the tools you plan to run simultaneously.

For example, if you have a circular saw that requires 1,200 watts, a drill with a power rating of 800 watts, and a sander that needs 600 watts, the total wattage required would be 2,600 watts. However, it’s important to note that power tools often have a higher power draw when starting up, so it’s recommended to factor in an additional 25% to 50% to account for this surge in power demand.

Once you have calculated the total wattage required, you can choose a generator that meets or exceeds this wattage output. It’s always better to opt for a slightly larger generator to ensure that you have enough power to handle any additional tools or fluctuations in power demand.

Considering the Type of Tools

Another factor to consider when determining the size of generator you need for your power tools is the type of tools you use. Different types of tools have varying power requirements. For example, smaller hand tools like drills and sanders typically have lower wattage requirements compared to larger power tools like table saws or air compressors.

If you primarily use smaller hand tools, a smaller generator with a lower wattage output may suffice. However, if you frequently use bigger power tools or have a combination of tools with varying power requirements, you may need a larger generator to handle the peak power demands.

It’s also important to consider any specific power requirements or recommendations provided by the tool manufacturer. Some tools may require a certain level of voltage or have specific recommendations for generator size to ensure optimal performance and safety.

Other Factors to Consider

In addition to wattage requirements and the type of tools you use, there are other factors that can impact the size of generator you need for your power tools. Here are a few important considerations:

Frequency of Use:

If you use your power tools frequently or for extended periods of time, you may need a larger generator to handle the continuous power demand. On the other hand, if you only use your tools occasionally, a smaller generator may be sufficient.

Power Quality:

If you require a consistent and clean power supply for sensitive tools or equipment, you may need a generator with additional features, such as inverter technology, to ensure stable power output.

Portability:

Consider the portability of the generator. If you frequently move from one job site to another, a smaller and more portable generator may be more suitable for your needs.

Noise Level:

If noise is a concern, you may want to choose a generator that is quieter in operation, especially if you are working in residential areas or noise-sensitive environments.

Future Expansion:

If you anticipate adding more tools to your collection in the future or plan to expand your workshop, it may be wise to invest in a larger generator to accommodate future power needs.

Choosing the Right Generator Size

Now that you have a better understanding of the factors affecting the size of generator you need, it’s time to choose the right generator for your power tools. Make a list of all the tools you plan to run simultaneously, noting their power ratings. Calculate the total wattage required, factoring in any surge power demands.

When choosing a generator, opt for one that meets or exceeds the total wattage requirement. Keep in mind the other factors we discussed, such as the type of tools you use, frequency of use, and any specific recommendations from the tool manufacturer. It’s always better to have a generator with a slightly higher wattage output to ensure you have enough power for your tools and any future needs.

Remember, the size of the generator directly impacts its portability, cost, and other features, so finding the right balance between power and practicality is key. By considering all these factors, you can confidently select the right generator size to power your tools and get the job done with efficiency and reliability.

The Benefits of Choosing the Right Generator Size

No matter the nature of your work, choosing the right generator size to power your tools offers several benefits:

Efficient Power Delivery

By selecting a generator that is appropriately sized for your tools, you can ensure efficient power delivery. This means your tools will run smoothly and perform optimally without any issues like power surges or voltage drops. The right generator size keeps your tools running at their best, enhancing productivity and preventing damage.

Longer Generator Lifespan

Using a generator that is properly sized for your power tools prevents overloading and strain on the generator. When a generator is too small to handle the power demands, it can lead to overheating and damage to the generator’s components. By choosing the right generator size, you can extend the lifespan of your generator and avoid costly repairs or replacements.

Cost-Effective Solution

Investing in a generator that meets your power requirements exactly may seem like a cost-effective option. However, this approach may leave you without any room for future expansion. By selecting a generator with slightly more wattage than you currently need, you can accommodate future power needs without having to invest in a new generator. This saves you money in the long run and allows for flexibility as your work or projects evolve.

Enhanced Versatility

Choosing a generator with a larger wattage output than strictly required for your current power tools provides enhanced versatility. You can connect additional tools or equipment without worrying about overloading the generator, providing you with more flexibility in your work. This versatility is especially valuable in environments where power needs can change and new tools may be added over time.

Improved User Experience

When your generator is the right size for your power tools, it leads to an overall improved user experience. You can work with confidence, knowing that your tools have the necessary power supply to perform at their best. This enhances efficiency, reduces downtime, and allows you to focus on the task at hand without any interruptions or frustrations.

Tips for Proper Generator Usage

Now that you have a better understanding of how to choose the right generator size for your power tools, here are a few additional tips for proper generator usage:

Keep the Generator Well-Maintained

Regular maintenance is essential to ensure that your generator runs smoothly and efficiently. Follow the manufacturer’s guidelines for maintenance and schedule regular check-ups and servicing. This includes replacing air filters, changing oil, and inspecting the generator for any signs of wear or damage.

Store Fuel Safely

If you need to store fuel for your generator, make sure you do so in a safe and well-ventilated area away from any potential ignition sources. Store fuel in approved containers and follow local regulations and safety guidelines for storage and disposal.

Use Proper Extension Cords

When connecting your power tools to the generator, use extension cords that are rated for outdoor use and can handle the wattage requirements of your tools. Long extension cords can cause a voltage drop, so it’s best to use shorter and thicker-gauge cords to minimize power loss.

By following these tips and guidelines, you can ensure safe and efficient operation of your generator and power your tools effectively for all your projects and work.

Key Takeaways: How Big of a Generator to Run Power Tools?

- Power tools have different wattage requirements; check the manufacturer’s guidelines for each tool.

- Add up the wattage of all the tools you plan to use simultaneously.

- Choose a generator with a higher wattage capacity than the total wattage of your power tools.

- Consider the starting watts of tools with electric motors, as they may require extra power during startup.

- It’s always safer to choose a slightly larger generator to avoid overload and give some margin for additional tools or appliances.

Frequently Asked Questions

Welcome to our FAQ section, where we answer common questions about choosing the right generator to power your tools. Whether you’re a professional or a DIY enthusiast, finding the right generator size is crucial for efficient and effective tool usage. Let’s dive into some frequently asked questions to guide you in determining how big of a generator you need for running power tools.

1. How can I determine the size of the generator I need for my power tools?

When determining generator size for your power tools, you should consider both the starting and running wattage of your tools. For each power tool, check its user manual or label to find the wattage information. Add the starting wattage of all your tools together to determine the minimum size generator you’ll need.

Keep in mind that some power tools, like air compressors, may require higher surge wattage during startup. If you’re unsure about the wattage, you can use an online wattage calculator or consult an electrician for professional guidance.

2. What is the starting wattage and running wattage of power tools?

The starting wattage refers to the temporary surge of power needed by a tool when you first turn it on. It’s higher than the running wattage, which is the power required to keep the tool running. Knowing both values is essential for selecting the right generator size.

For example, a circular saw may have a starting wattage of 1,200 watts and a running wattage of 800 watts. By considering these numbers for all your power tools, you can make an accurate estimation of the generator size needed.

3. What happens if I choose a generator that is too small for my power tools?

If you choose a generator that is too small for your power tools, it may struggle to provide enough power to run them. Inadequate power supply can lead to reduced performance, frequent tripping of the generator’s overload protection, and potential damage to both the generator and the tools.

To avoid these issues, it’s crucial to choose a generator with sufficient capacity to handle the starting wattage and running wattage of your power tools. This ensures smooth and uninterrupted power supply, maximizing the efficiency and lifespan of your generator and tools.

4. Can I use an inverter generator to power my power tools?

Absolutely! Inverter generators are an excellent choice for powering power tools. These generators are known for their clean and stable power output, making them safe to use with sensitive electronic equipment, including power tools.

Inverter generators provide a consistent and stable power supply, preventing voltage fluctuations that could damage your tools. They’re also more fuel-efficient, quieter, and generally more portable than conventional generators.

5. Are there any other factors to consider when choosing a generator for power tools?

Yes, in addition to the power requirements, there are a few other factors to consider when choosing a generator for power tools. These include fuel type (gasoline, propane, diesel), noise level, portability, runtime, and additional features like electric start or parallel connectivity for increased power output.

It’s important to evaluate these factors based on your specific needs and preferences. For example, if you value portability, a compact and lightweight generator may be ideal. Taking these factors into account will help you find the perfect generator that meets both your tool power requirements and personal preferences.

Summary

So, here’s what you need to know about choosing a generator for power tools:

First, figure out the wattage requirements of your tools by checking their manuals or labels. Then, add up the wattages to find the total load. Next, choose a generator that can handle at least 20% more than your total load. And finally, consider factors like the starting wattage and runtime to ensure smooth and efficient operation.

Remember, safety is a priority, so always read the manufacturer’s instructions and use the right generator for your power tool needs. Now you’re ready to power up and get to work!