Do you know how big of an air compressor you need to run power tools? Well, let’s dive into this topic and find out! Whether you’re a professional or a DIY enthusiast, choosing the right air compressor can make all the difference in getting your power tools to perform at their best. So, let’s break it down and discover what size air compressor you need for those tools of yours.

Now, you might be wondering, “Why does the size of the air compressor matter?” It’s a great question! The size of the air compressor determines how much air it can deliver to power your tools. Different power tools have different air requirements, so it’s essential to match the compressor’s capacity to ensure optimal performance.

So, how do you determine the right size? Well, it depends on factors like the types of tools you’ll be using, their air consumption rate, and how many tools will be running simultaneously. Don’t worry; we’ll guide you through this process step by step and help you find the perfect air compressor suited for your power tools. Let’s get started!

If you’re wondering about the right size of an air compressor to power your tools, follow these steps:

- Determine the required air volume (CFM) for your most demanding tool.

- Check the CFM rating of the air compressor you’re considering.

- Make sure the compressor’s CFM rating exceeds your tool’s requirement.

- Consider additional CFM if you plan to use multiple tools simultaneously.

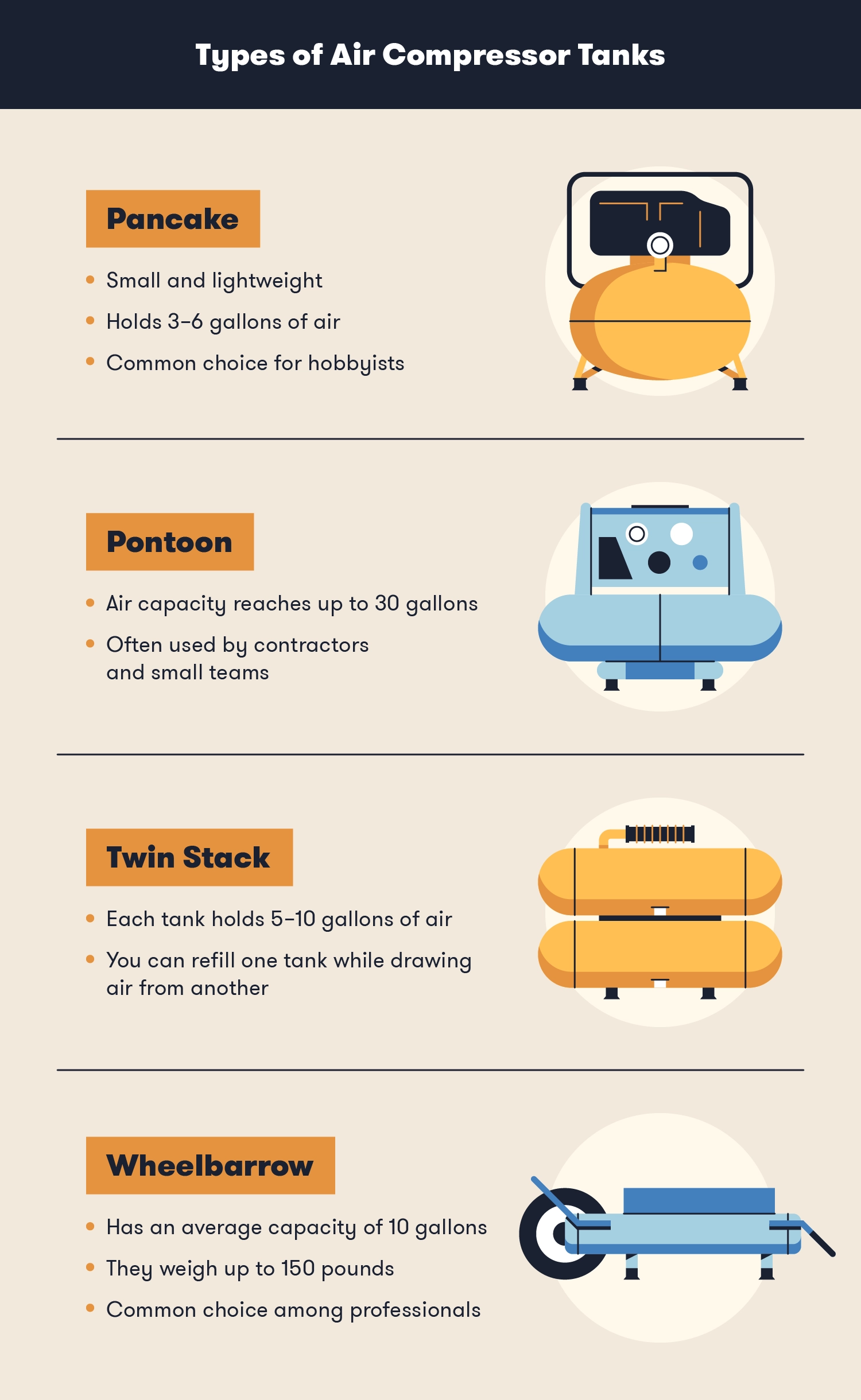

- Factor in the compressor’s tank size for continuous tool operation.

By following these steps, you’ll find the perfect air compressor size for your power tools.

How Big of an Air Compressor Do I Need to Run Power Tools?

Choosing the right air compressor for your power tools is essential to ensure they operate efficiently and effectively. In this article, we will explore the factors to consider when determining the size of an air compressor needed for running power tools. From understanding the requirements of your tools to evaluating the compressor’s specifications, we will provide you with valuable insights to help you make an informed decision.

Understanding Tool Requirements

When determining the size of an air compressor needed for running power tools, it’s crucial to understand the requirements of your tools. Different tools have varying levels of air consumption, which is measured in cubic feet per minute (CFM). To assess the CFM requirement, consult the documentation or product specifications that came with your power tools. By identifying the highest CFM rating among your tools, you can establish a baseline for selecting an air compressor with sufficient capacity.

Additionally, consider the air pressure requirement of your power tools. Most tools operate at a standard pressure of 90 PSI (pounds per square inch). However, certain tools, such as sanders or paint sprayers, may require higher pressures. Understanding the specific requirements of your tools will help you choose an air compressor that can meet their demands.

It’s important to note that if you plan on using multiple tools simultaneously, you will need an air compressor with a higher CFM rating to accommodate the combined air consumption. Add up the CFM requirements of all the tools you anticipate using simultaneously to determine the minimum CFM rating your air compressor should have.

Evaluating Compressor Specifications

Once you have determined the CFM and pressure requirements of your power tools, it’s time to evaluate the specifications of air compressors. Two key factors to consider are the compressor’s CFM rating and tank size.

The CFM rating indicates the volume of air that the compressor can deliver. It’s important to choose an air compressor with a CFM rating that is equal to or higher than the highest CFM requirement of your tools. This ensures that the compressor can supply a sufficient amount of air to keep your tools running smoothly without interruptions.

In addition to CFM rating, the tank size plays a role in the overall performance of the air compressor. The tank acts as a reserve for storing compressed air, allowing you to use tools that require short bursts of high airflow. A larger tank can provide a steady supply of compressed air, reducing the frequency of the compressor turning on and off. This can be beneficial for tools that require a continuous or sustained airflow, such as spray guns or sanders.

However, if you only use power tools that require short bursts of air, such as nail guns or staple guns, a larger tank may not be necessary. In such cases, a smaller tank combined with a higher CFM rating may be more suitable, as it will provide a quick recovery time and consistent pressure.

Benefits of Choosing the Right Size

Choosing the right size of an air compressor for your power tools offers several benefits. Firstly, it ensures that your tools operate at their optimal performance levels, enhancing productivity and efficiency. By providing an adequate supply of compressed air, the right-sized compressor minimizes the risk of stalling or reduced power when using the tools.

Additionally, using the appropriate size of air compressor helps prolong the lifespan of your power tools. Insufficient airflow can cause tools to overheat, leading to premature wear and potential damage. By supplying the necessary volume of air, the compressor reduces strain on the tools and promotes their longevity.

Moreover, selecting the right air compressor size can also contribute to energy efficiency. An oversized compressor that exceeds the required CFM rating can consume unnecessary energy, leading to higher operating costs. On the other hand, an undersized compressor may struggle to meet the demands of the tools, leading to increased energy consumption as it continuously runs at maximum capacity. By choosing the right-sized compressor, you can optimize energy usage and reduce costs.

Tips for Optimal Performance

Now that you understand how to determine the size of an air compressor needed for running power tools, here are a few additional tips to ensure optimal performance:

Regular Maintenance

To keep your air compressor running smoothly, perform regular maintenance tasks such as cleaning or replacing air filters, checking for leaks, and ensuring proper lubrication. Regular maintenance helps prevent issues and extends the lifespan of your compressor.

Invest in Quality Accessories

When using an air compressor, investing in high-quality accessories, such as hoses, fittings, and connectors, can improve performance and prevent air leaks. These accessories play a crucial role in maintaining consistent and reliable airflow to your power tools.

Properly Size Your Air Hose

Using an appropriately sized air hose can minimize pressure drop and enhance performance. Consider the length of the hose and its inside diameter to ensure an optimal flow of compressed air to your tools.

By following these tips and understanding the requirements of your power tools, you can choose the right size of an air compressor and achieve optimal performance with your tools. Always consult the manufacturer’s guidelines for specific recommendations regarding your power tools and air compressor.

Key Takeaways: How Big of an Air Compressor Do I Need to Run Power Tools?

- An air compressor’s size is determined by its horsepower (HP) and cubic feet per minute (CFM) rating.

- For most household power tools, a compressor with 2-6 HP and at least 4-6 CFM is sufficient.

- Heavy-duty tools like impact wrenches or sanders may require a compressor with 6-10 HP and 8-12 CFM.

- Consider the duty cycle, which indicates how long the compressor can run continuously without overheating.

- Remember to factor in additional tools or air consumption requirements when selecting the compressor size.

Frequently Asked Questions

Are you wondering about the size of an air compressor needed for power tools? Read on to find answers to some frequently asked questions on this topic.

1. What factors should I consider when determining the size of an air compressor for power tools?

When choosing an air compressor for power tools, several factors come into play:

First, consider the tools you’ll be using. Different power tools require different air volumes and pressures. Refer to the manufacturer’s specifications to determine the necessary airflow (measured in CFM) and pressure (measured in PSI) for each tool.

Next, think about the frequency and duration of tool use. If you’re using power tools for extended periods or continuously, you’ll need an air compressor with a larger capacity to maintain consistent pressure and airflow. On the flip side, if you’re using tools intermittently, a smaller compressor may suffice.

2. Can I use a small air compressor for power tools?

Using a small air compressor for power tools is possible, but it depends on the tool and its requirements. Small air compressors typically have lower CFM ratings, making them suitable for tools with lower air consumption, such as brad nailers or smaller pneumatic wrenches.

For more demanding tools like impact wrenches or grinders, a larger air compressor with a higher CFM rating is recommended. These tools require a continuous and sufficient airflow to operate effectively, which may exceed the capabilities of a smaller compressor.

3. What happens if I use an air compressor with insufficient airflow for my power tools?

If you use an air compressor with insufficient airflow (CFM) for your power tools, you may encounter performance issues. The tool may operate at a reduced power, resulting in slower operation, reduced torque, or weakened performance.

Insufficient airflow can also cause the compressor to cycle frequently, leading to overheating and potential damage to the compressor motor. In some cases, it may even cause the air compressor to stall or fail to provide enough pressure to operate the power tool properly.

4. Can I use an air compressor with higher CFM than required for power tools?

Using an air compressor with a higher CFM (airflow) rating than required by power tools is generally not an issue. The excess airflow won’t harm the tools but can provide a buffer for occasional increased air consumption.

The advantage of using a higher CFM air compressor is that it will have more reserve capacity, allowing the compressor to maintain steady pressure even when using multiple tools or operating a tool that occasionally demands more air.

5. Do I need to consider the tank size when choosing an air compressor for power tools?

Yes, tank size should also be considered when selecting an air compressor for power tools. A larger tank provides a greater reserve of compressed air, ensuring a steady supply when tools require short bursts of air. This can help prevent pressure drops and maintain consistent tool performance.

However, if you primarily use tools that require continuous or high-volume airflow, the tank size becomes less critical. In such cases, the compressor’s CFM rating becomes the primary consideration, as it determines the compressor’s ability to supply the necessary airflow to the tools.

What Size Air Compressor Do You Really Need? (Updated 2023)

Summary

If you’re wondering how big of an air compressor you need for power tools, here’s what you should know. Different tools have different air requirements, so it’s important to check the recommended air consumption for each tool. Make sure your compressor can deliver enough airflow to meet these requirements. To calculate the required CFM (cubic feet per minute), add up the CFM of all the tools you plan to use simultaneously. Choose a compressor with a higher CFM rating than your total calculated CFM. And don’t forget to consider the PSI (pounds per square inch) needed for your tools as well. Finally, if you’re unsure, it’s always best to consult the tool manufacturer or an expert.

The size of an air compressor depends on the tools you plan to use and their air requirements. Make sure to check the recommended air consumption for each tool and calculate the total CFM needed. Choose a compressor with a higher CFM rating than your calculated total CFM. Don’t forget to consider the required PSI as well. If you’re still unsure, ask the tool manufacturer or an expert for guidance. Happy tooling!