Have you been wondering how big a table saw table should be? Well, you’re in the right place! Choosing the right size for your table saw table is crucial for a smooth and efficient woodworking experience. In this article, we’ll dive into the factors to consider and help you find the perfect table size for your needs.

Whether you’re a beginner or a seasoned woodworker, finding the ideal table saw table size can make a world of difference. Imagine having enough space to handle larger projects without any hassle. A well-sized table can provide stability, versatility, and ease of use, allowing you to work on various woodworking tasks with precision.

The size of your table saw table should be determined by your workspace, the size of your projects, and your personal preferences. Let’s explore how these factors play a role in determining the ideal dimensions for your table saw table. So, let’s get started and find your perfect fit!

When determining the size of a table saw table, there are a few factors to consider. First, think about the size of the projects you’ll be working on. A larger table provides more stability and working space for bigger materials. Next, consider your workspace. Measure the available area to ensure the table fits comfortably. Additionally, think about portability. Smaller tables are easier to move around. Finally, think about your budget. Larger tables tend to be more expensive. Consider these factors to determine the ideal size for your table saw table.

How Big Should a Table Saw Table Be?

1. The Importance of Size

When it comes to choosing the size of a table saw table, there are several factors to consider. The size of the table directly impacts the usability and versatility of the tool. A larger table provides more surface area to support larger workpieces, allowing for accurate cuts and increased stability. On the other hand, a smaller table may be more suitable for compact workshops or for those who work on smaller projects. Ultimately, the size of the table should be determined based on the specific needs and constraints of the user.

Factors to Consider:

Firstly, assess the available space in your workshop. Measure the dimensions of the area where you plan to place the table saw. Consider not only the length and width but also the height, taking into account the user’s height for comfortable operation. Secondly, think about the types of projects you typically work on. If you primarily work with larger materials or need to make long rip cuts, a larger table will be beneficial. However, if you mainly work with smaller materials or have limited space, a smaller table may be more suitable.

Lastly, consider your budget. Larger tables often come with a higher price tag, so it’s important to find the right balance between size and affordability. After evaluating these factors, you can determine the ideal size for your table saw table.

Tips for Choosing the Right Size:

1. Measure your available workshop space accurately to ensure a proper fit.

2. Consider the types of projects you typically work on and the size of the materials involved.

3. Take into account your budget and find the right balance between size and affordability.

2. Standard Sizes

Table saw tables come in a range of standard sizes, each with its own advantages and applications. The most common sizes are 27 inches, 36 inches, and 52 inches in width. These sizes refer to the distance from the front edge of the table to the rear edge, or fence. The length of the table can vary depending on the specific model and brand.

The 27-inch table is typically found on portable or benchtop table saws. This size is suitable for small workshops or for those who need a compact, portable option. The 36-inch size is considered a good middle ground for most users. It provides ample surface area for cuts while still being manageable in terms of space. The 52-inch table is ideal for professional woodworkers or those handling large, heavy pieces of lumber.

Pros and Cons of Standard Sizes:

1. 27-inch table:

– Pros: Portable, compact, suitable for small spaces.

– Cons: Not ideal for larger materials or long rip cuts.

2. 36-inch table:

– Pros: Versatile, suitable for most applications, manageable in terms of space.

– Cons: May not provide enough surface area for very large materials.

3. 52-inch table:

– Pros: Excellent for large projects and heavy materials, provides ample support.

– Cons: Requires more workshop space, can be more expensive.

3. Customizable Options

While standard sizes offer a good starting point, some individuals may have specific needs that require a customized table saw table. Many manufacturers offer the option to customize the size of the table to suit the user’s requirements. This can be useful for those who have unique workshop layouts or work on specialized projects.

Customizable options allow woodworkers to have a table that perfectly fits their needs, providing optimal support and stability. When opting for customization, it’s important to communicate your requirements to the manufacturer or dealer to ensure that the table meets your specifications.

Benefits of Customization:

1. Tailored to individual needs and workshop constraints.

2. Provides optimal support and stability for specific projects.

3. Allows for better utilization of available space.

Additional Information on Table Saw Tables

4. Safety Considerations

Safety is paramount when using any power tool, and table saws are no exception. When determining the size of a table saw table, it’s essential to consider how it affects safety precautions. A larger table can offer more stability, reducing the risk of kickbacks and preventing workpieces from falling off the table. Additionally, a larger table provides more room for the user to maneuver and maintain control while making cuts.

5. Portable Table Saw Tables

For those who work in different locations or have limited workshop space, portable table saw tables can be a practical option. These tables are designed to be lightweight and easily carried from one job site to another. Portable table saw tables usually have smaller dimensions, making them more compact and convenient for transportation. However, it’s important to ensure that the table is sturdy enough to provide stability during operation, even when it is portable.

6. Comparing Table Saw Table Sizes

To help you better understand the different sizes available, here is a comparison table:

| Table Size (Width) | Recommended Project Type | Space Required |

|---|---|---|

| 27 inches | Small and medium-sized projects | Compact |

| 36 inches | General woodworking projects | Medium-sized |

| 52 inches | Large projects, heavy materials | Significant space required |

7. Maintenance and Care

Regardless of the size of your table saw table, proper maintenance is crucial for optimal performance and longevity. Keep the table clean and free of dust and debris, as these can affect the accuracy of your cuts. Regularly check for any signs of wear or damage on the table surface and fence, and make any necessary repairs or replacements. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation. Following proper maintenance practices will help extend the lifespan of your table saw table.

In conclusion, the size of a table saw table should be determined based on factors such as available space, the types of projects you work on, and your budget. Standard sizes like 27 inches, 36 inches, and 52 inches offer different advantages and applications. However, customization options are available for those who have specific needs. Remember to prioritize safety, consider portability if necessary, and maintain your table saw table regularly to ensure optimal performance.

Key Takeaways: How Big Should a Table Saw Table Be?

- A table saw table should ideally be large enough to accommodate the size of the materials you will be working with.

- Consider the space available in your workshop when determining the dimensions of your table saw table.

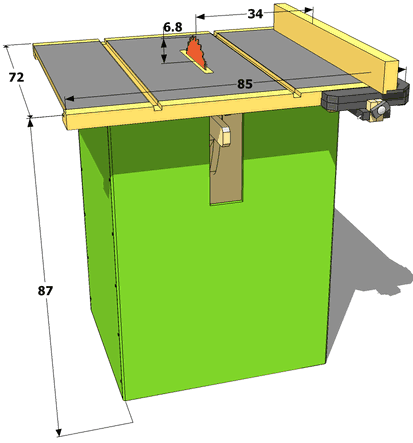

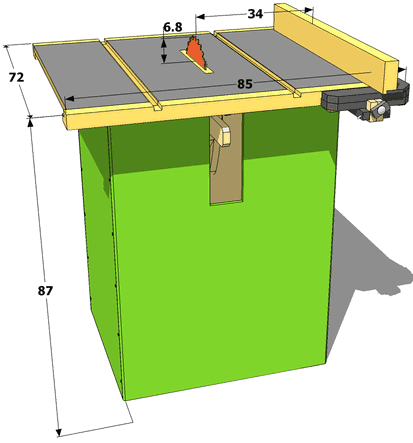

- A standard table saw table size is around 27 to 36 inches wide and 20 to 30 inches deep.

- A larger table can provide more support for larger materials, but it may also take up more space in your workshop.

- Remember to also consider the height of the table saw table for comfortable working conditions.

Frequently Asked Questions

In the world of woodworking, table saws are an essential tool. One of the key considerations when setting up a table saw is determining the appropriate size for the table itself. Here are some common questions about table saw table sizes:

1. What factors should I consider when deciding on the size of my table saw table?

When determining the size of your table saw table, there are a few important factors to consider. Firstly, think about the types of woodworking projects you typically undertake. If you work with large sheets of plywood or wide boards, you may require a larger table. Additionally, think about the space you have available in your workshop. You want to make sure your table saw table fits comfortably in the allotted area without hindering your movement. Lastly, consider your own comfort and safety. Make sure the table size allows you to work comfortably and with adequate support for the materials you are cutting.

2. Are there standard sizes for table saw tables?

While there are no universally set standard sizes for table saw tables, there are some common dimensions that many woodworkers follow. A typical table saw table measures around 27 inches in width and 44 inches in length. However, these dimensions can vary depending on the manufacturer and the specific model of the table saw. It’s important to check the specifications provided by the manufacturer to ensure the table size will meet your needs.

3. Is a larger table always better?

While a larger table may be advantageous for certain woodworking projects, it’s not always necessary or practical. A larger table requires more space in your workshop and can be more challenging to move around. Additionally, a larger table may not provide significant benefits for smaller projects or workpieces. It’s important to find a balance and choose a table size that suits the majority of your woodworking needs without overwhelming your workspace.

4. Can I modify the size of my table saw table?

Modifying the size of a table saw table can be a complex task and may void the warranty of the table saw. It’s generally recommended to choose a table size that meets your requirements from the start. However, if you have the necessary woodworking skills and experience, it may be possible to make modifications to the table. Be sure to carefully consider the potential impact on the stability and functionality of the table saw before making any modifications.

5. Are there any alternatives to a large table saw table?

If you have limited space in your workshop or don’t require a large table saw table for your projects, there are alternatives available. One option is to use table extensions or stands that can be attached to your existing table saw to provide additional support when working with larger materials. Another alternative is to use a compact or portable table saw that is designed for smaller, more mobile workspaces. These options allow you to work efficiently while adapting to the constraints of your workshop.

Summary:

So, to sum it up, when it comes to choosing the size of a table saw table, there are a few things to consider. First, think about the size of the projects you’ll be working on. If you need to cut large pieces of wood, then a larger table will be more suitable. Next, think about your workspace and how much room you have. You don’t want a table that’s too big for your space. Finally, consider your budget. A larger table may cost more, so make sure it fits within your price range.

In conclusion, finding the right size table saw table for you depends on your project needs, workspace, and budget. Take these factors into consideration, and happy woodworking!