Are you wondering how big your table saw sled should be? Well, you’ve come to the right place! Table saw sleds are incredibly useful tools that can enhance your woodworking projects. But determining the perfect size for your sled can be a bit puzzling. Don’t worry though, we’ve got you covered!

When it comes to table saw sleds, size does matter. The dimensions of your sled will largely depend on the type of projects you undertake and the space available in your workshop. So, let’s dive in and explore the factors that can help you determine how big your table saw sled should be.

Finding the optimal size for your table saw sled is crucial for achieving accurate and safe cuts. In this guide, we’ll walk you through the process of determining the ideal dimensions, taking into account factors like project size, workshop space, and personal preference. So, let’s get started on building your perfect table saw sled!

How Big Should a Table Saw Sled Be?

A table saw sled is a valuable tool for woodworkers, providing stability and precision when making crosscuts or angled cuts. However, determining the right size for your table saw sled can be a bit of a challenge. The size of the sled depends on various factors such as the size of your table saw, the types of projects you work on, and your personal preferences. In this article, we will explore the considerations for determining the ideal size for a table saw sled and provide some helpful tips to guide you in the process.

1. Consider the Size of Your Table Saw

The first factor to consider when determining the size of your table saw sled is the size of your table saw itself. Measure the dimensions of your table saw’s surface area, specifically the width and length. The sled should be slightly smaller than the surface area of your table saw to ensure a proper fit and smooth operation. A good rule of thumb is to make the sled about 2 inches narrower and 6 to 8 inches shorter than the surface area of your table saw.

By making the sled slightly smaller than the table saw, you will have enough space to maneuver it without it being too cumbersome. Additionally, allowing some space between the sled and the edges of the table saw will prevent any interference with the blade guard or any other accessories that may be attached to the table saw.

2. Consider Your Project Needs

Another crucial consideration when determining the size of your table saw sled is your typical project needs. Think about the size of the materials you work with most often and the type of cuts that are required for your projects. If you primarily work with smaller materials, a smaller sled might be sufficient. However, if you frequently work with larger sheets of plywood or long boards, a larger sled may be necessary to provide the necessary support and stability.

Keep in mind that a larger sled will require more space in your workshop, so consider your available workspace as well. If space is limited, you may need to prioritize functionality over size and make a smaller sled that can still effectively handle your project needs.

3. Consider Your Personal Preferences

Your personal preferences as a woodworker play an important role in determining the size of your table saw sled. Some woodworkers may prefer a larger sled for added stability, while others may opt for a smaller sled for easier maneuverability. Take into account your comfort level and the ergonomic factors that contribute to a workflow that suits you best.

Additionally, consider any specific features or modifications you may want to incorporate into your table saw sled, such as built-in stops, clamps, or hold-downs. These additions may require additional space and considerations when determining the size of your sled.

4. Tips for Building Your Table Saw Sled

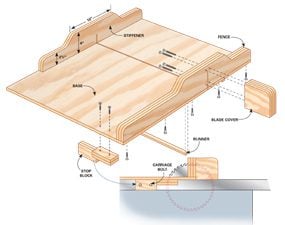

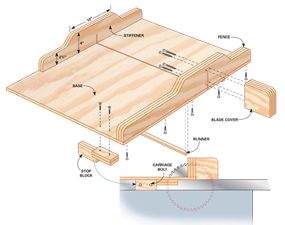

4.1 Choose the Right Materials

When building your table saw sled, it’s essential to choose the right materials for durability and stability. Opt for a sturdy and flat material for the base, such as high-quality plywood or medium-density fiberboard (MDF). Make sure the material is free from any warping or bending that could affect the accuracy of your cuts.

4.2 Ensure Smooth Sliding

Smooth sliding is crucial for the functionality of a table saw sled. To achieve this, consider applying a layer of low-friction material, such as high-density polyethylene (HDPE), to the bottom of the sled. This will reduce friction and allow for smoother movement along the table surface.

4.3 Incorporate Safety Features

Safety should always be a top priority when working with any woodworking tool, including a table saw sled. Consider adding safety features such as a blade guard, a non-slip surface, and ergonomic handles to enhance the safety and usability of your sled.

Key Measurements and Calculations for a Table Saw Sled

Now that we have discussed the considerations for determining the size of a table saw sled, let’s delve into some key measurements and calculations involved in building a table saw sled that suits your needs:

5. Width and Length

The width and length of the sled should be smaller than the surface area of your table saw, as mentioned earlier. Aim for a width that allows for comfortable handling and maneuverability, while still providing ample support for your workpieces. The length should accommodate the size of the materials you typically work with, ensuring stability and preventing any potential overhang.

6. Cutting Capacity

The cutting capacity refers to the maximum size of workpieces that the table saw sled can handle. It is determined by the length of the sled’s fence, which provides support and guidance during the cutting process. Measure the distance from the blade to the farthest edge of the fence to determine the cutting capacity of your sled.

7. Angle Cuts

If you frequently work with angled cuts, it’s important to consider the sled’s capacity for making these types of cuts. Measure the maximum length and width of workpieces that can be accommodated on the sled at different angles to ensure you have enough space and support for angled cuts.

Additional Considerations for Building an Effective Table Saw Sled

8. Using a Stop Block

Adding a stop block to your table saw sled can greatly improve its functionality and accuracy. A stop block allows you to make repetitive cuts with consistent precision. Measure the desired distance from the blade to the stop block and secure it to the sled to create a reference point for your cuts.

9. Adding T-Tracks

T-tracks are an excellent addition to a table saw sled as they provide versatile clamping options. These tracks allow you to secure workpieces with various clamps and accessories, enhancing the stability and safety of your cuts. Determine the appropriate location and size of the T-tracks based on your project needs and the size of your sled.

10. Maintenance and Adjustments

Regular maintenance and adjustments are vital to keeping your table saw sled in optimal condition. Periodically check for any signs of wear or damage and make any necessary repairs or replacements. Additionally, ensure that the sled is properly aligned with the blade by adjusting the fence and runners as needed.

In conclusion, the size of a table saw sled depends on factors such as the size of your table saw, your project needs, and personal preferences. By considering these factors and implementing the tips provided, you can build a table saw sled that enhances your woodworking experience, improves accuracy, and ensures safety. Remember to prioritize functionality, stability, and ease of use when determining the size of your table saw sled.

Key Takeaways: How Big Should a Table Saw Sled Be?

- A table saw sled should be designed to fit the specific dimensions of your table saw.

- It’s important to ensure that the sled is wide enough to support your workpieces securely.

- The length of the sled should be long enough to accommodate the size of your workpieces.

- Consider the available space in your workshop when determining the size of your table saw sled.

- Always test the sled with scrap pieces before using it with expensive or valuable materials.

Frequently Asked Questions

If you’re wondering about the size of your table saw sled, we have answers for you!

1. What factors should I consider when determining the size of my table saw sled?

When determining the size of your table saw sled, you’ll want to consider the size of your workpieces, the available space in your workshop, and your personal comfort and safety. It’s important to have a sled that can accommodate the size of the materials you’ll be working with regularly. If your sled is too small, it may not provide enough support for larger workpieces. Conversely, if your sled is too large, it may be cumbersome to maneuver.

Additionally, consider the available space in your workshop. A sled that is too big might not fit comfortably on your table saw or may take up excessive room in your workspace. Finally, don’t forget to think about your own comfort and safety. You’ll want a sled that allows you to work comfortably and efficiently, with a design that minimizes the risk of accidents.

2. What is the recommended size range for a table saw sled?

The recommended size range for a table saw sled is typically between 18 to 30 inches in width and around 24 to 36 inches in length. This range provides enough surface area to support various workpieces while still allowing for maneuverability and ease of use. However, depending on your specific needs and the size of your workpieces, you may choose to go slightly smaller or larger within this range.

Keep in mind that a larger sled will provide more stability and support for bigger workpieces, while a smaller sled is more suitable for smaller projects. It’s important to find the right balance that suits your particular woodworking needs and the space available in your workshop.

3. How can I determine the ideal size for my table saw sled?

To determine the ideal size for your table saw sled, start by assessing the typical size of the workpieces you’ll be working with. Measure the width and length of these materials to get an idea of the surface area required for support. Additionally, consider the available space you have around your table saw. Measure the dimensions of the area where you’ll be using the sled to ensure it will fit comfortably.

You can also take into account your own work habits and preferences. If you only work with smaller projects, a smaller sled may suffice. However, if you often work with larger materials, a larger sled will provide more stability. Ultimately, the ideal size of your table saw sled is a balance between the size of your workpieces, your available space, and your personal comfort.

4. Are there any drawbacks to having a larger table saw sled?

While a larger table saw sled can offer stability and support for larger workpieces, it’s essential to consider any potential drawbacks. One of the main drawbacks is the amount of space it occupies in your workshop. A larger sled may limit your workspace and make it more challenging to move around your workshop freely.

Another consideration is the weight of the sled. A larger sled may be heavier, which can make it more challenging to handle, especially for extended periods. It’s important to ensure that you can comfortably maneuver and control the sled to maintain both accuracy and safety.

5. Can I customize the size of my table saw sled if needed?

Yes, you can definitely customize the size of your table saw sled to suit your specific needs. If you find that the standard size range does not meet your requirements, you can modify the dimensions accordingly. This can be done by adjusting the length and width of the main sled platform to better accommodate your workpieces.

However, keep in mind that modifying the size may affect the stability and balance of the sled. It’s important to ensure that any modifications or adjustments you make still maintain the overall integrity and functionality of the sled. Taking accurate measurements and properly aligning the components during the customization process will help you achieve the desired size while still ensuring the sled functions effectively and safely.

your crosscut sled is way too big

Summary

So, what’s the ideal size for a table saw sled? Well, it really depends on your needs. If you’re working on small projects or have limited space, a smaller sled will do the job. But if you’re tackling larger projects and have the space for it, a bigger sled can be more versatile and provide better support. Ultimately, it’s all about finding the right balance for your specific needs.

Remember, safety is key when using a table saw sled. Always follow proper safety guidelines, use the necessary protective gear, and ensure that the sled is securely fastened to the table saw. With the right size sled and a focus on safety, you’ll be well-equipped to tackle your woodworking projects with ease and precision.