Are you wondering how big to make a table saw sled? Well, you’ve come to the right place! Building a table saw sled is a great way to improve your woodworking skills and make precise cuts. But before you dive into the project, it’s important to determine the right size for your sled.

Finding the optimal size for a table saw sled can depend on various factors such as the size of your workpiece and the space you have available in your workshop. A larger sled can accommodate bigger pieces of wood, while a smaller sled may be more convenient if you have limited space.

In this article, we’ll explore different considerations to help you decide how big to make your table saw sled. So grab your tape measure and let’s get started on this woodworking adventure!

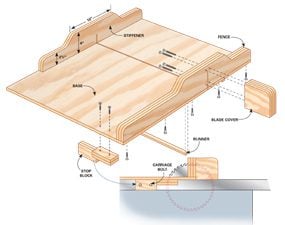

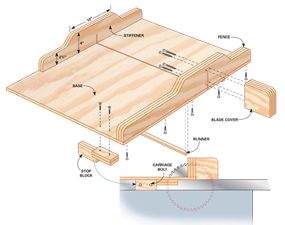

- Measure the width and depth of your table saw’s cutting surface.

- Add a few inches to the width to account for the sled’s runners.

- Determine the length of the sled based on your cutting needs.

- Create a base using a sturdy and flat material like plywood.

- Ensure the sled fits securely on the table saw for accurate cuts.

Follow these steps to create a table saw sled that suits your needs and enhances your woodworking projects.

How Big to Make a Table Saw Sled?

When it comes to using a table saw, safety is paramount. One tool that can greatly enhance safety and accuracy is a table saw sled. A table saw sled is a device that holds the workpiece securely and allows for precise, controlled cuts. But how big should your table saw sled be? In this article, we will explore the factors to consider when determining the size of your table saw sled, as well as provide some tips for building and using one effectively.

Factors to Consider when Determining Table Saw Sled Size

Before deciding on the size of your table saw sled, it is important to consider a few key factors. First and foremost, you need to determine the size of the materials you will be working with most frequently. If you typically work with smaller pieces of wood, a smaller sled may be more practical. However, if you frequently work with larger materials, a larger sled will provide more stability and support. Additionally, you need to consider the size of your table saw’s work surface. A sled that is too big for your table saw may not function properly and could pose a safety risk. On the other hand, a sled that is too small may not provide sufficient support for your workpiece.

Another factor to consider is the type of cuts you will be making. A longer sled is beneficial for making longer crosscuts, while a wider sled is helpful for making wider cuts, such as panels or shelves. Additionally, if you plan on using your table saw sled for angled cuts, you will need to factor in the size of the sled in relation to the angle at which you will be cutting. It is important to ensure that your sled is wide enough to support the workpiece at the required angle without compromising stability or accuracy.

Finally, it is important to consider your own comfort and ease of use when determining the size of your table saw sled. If you have a smaller workshop or limited space, a compact sled may be more practical. On the other hand, if you have ample space and prefer a larger working area, a larger sled may be more suitable. Ultimately, the size of your table saw sled should be determined by a combination of the factors discussed above, as well as your own personal preferences and requirements.

Tips for Building and Using a Table Saw Sled

Building a table saw sled doesn’t have to be a daunting task. With the right guidance and some basic woodworking skills, you can create a sled that meets your specific needs. Here are some tips to help you build and use a table saw sled effectively:

1. Choose the Right Materials

When constructing a table saw sled, it is important to choose materials that are sturdy and durable. Plywood or hardwood boards are popular choices for the sled base, as they provide stability and can withstand the forces exerted during cutting. Additionally, consider using materials that are dimensionally stable to minimize the risk of warping or twisting over time.

2. Ensure Accurate and Secure Alignment

One of the most critical aspects of building a table saw sled is ensuring accurate and secure alignment. Misaligned components can compromise the accuracy and safety of your sled. Take the time to carefully measure and mark your cuts and use clamps or screws to securely fasten the components in place. Double-check your alignment before making any cuts to ensure accuracy.

3. Incorporate Safety Features

Safety should always be a top priority when working with any power tool, including a table saw sled. Consider incorporating safety features into your sled, such as a blade guard or a hold-down device, to minimize the risk of accidents or injuries. Additionally, make sure to wear appropriate safety gear, such as safety glasses and hearing protection, whenever you are using your table saw sled.

4. Regularly Maintain and Inspect Your Sled

To ensure optimal performance and safety, it is important to regularly maintain and inspect your table saw sled. Check for any signs of wear or damage, such as loose components or splintered edges, and make any necessary repairs or replacements. Keep the sled clean and free of dust and debris to prevent interference with the movement or accuracy of your cuts. Regular maintenance will help prolong the lifespan of your sled and ensure consistent, high-quality results.

Choosing the Right Size for Your Table Saw Sled

Now that you understand the factors to consider when determining the size of your table saw sled and have some tips for building and using one effectively, it’s time to select the right size for your specific needs. Remember to prioritize safety, stability, and ease of use when making your decision. Take into account the size of materials you typically work with, the type of cuts you will be making, and the available space in your workshop. By taking these factors into consideration, you can ensure that your table saw sled is the perfect size for your woodworking projects.

Pros and Cons of Different Table Saw Sled Sizes

When deciding on the size of your table saw sled, it is important to consider the pros and cons of different sizes. Let’s take a look:

1. Small Table Saw Sled

Pros:

- Compact and easy to store in a small workshop

- Suitable for working with smaller materials

- Allows for more maneuverability and flexibility

Cons:

- May lack stability when working with larger materials

- Less support for longer crosscuts and wider cuts

2. Medium Table Saw Sled

Pros:

- Provides a balance between stability and maneuverability

- Suitable for a wide range of materials and cuts

- Adequate support for longer crosscuts and wider cuts

Cons:

- Requires more space for storage and operation

- Slightly less maneuverability compared to a small sled

3. Large Table Saw Sled

Pros:

- Offers maximum stability and support for larger materials

- Provides ample space for comfortable operation

- Ideal for making longer crosscuts and wider cuts

Cons:

- Requires more space for storage and operation

- May be less maneuverable in limited workspaces

- Can be heavier and more difficult to handle

Conclusion

When it comes to determining how big to make a table saw sled, there are several factors to consider. It’s important to assess the size of the materials you typically work with, the type of cuts you will be making, and the available space in your workshop. By carefully considering these factors, you can select the right size for your needs, ensuring safety, accuracy, and ease of use. With the right size sled, you can enhance your table saw capabilities and take your woodworking projects to the next level.

Key Takeaways: How Big to Make a Table Saw Sled?

- 1. Measure the size of your table saw’s surface to determine the maximum dimensions for your sled.

- 2. Consider the types of cuts you’ll be making to determine the length and width of the sled.

- 3. A standard size sled is usually around 24 inches long and 12 inches wide.

- 4. Ensure the sled is large enough to safely support your workpiece and allow for maneuverability.

- 5. Customize the size of your sled based on your specific needs and preferences.

Frequently Asked Questions

In this section, we will answer some common questions about the optimal size for a table saw sled.

1. What factors should I consider when determining the size of a table saw sled?

When deciding on the size of a table saw sled, there are a few factors to consider. Firstly, think about the projects you will be working on most frequently. The size of your sled should accommodate the dimensions of the materials you commonly use. Additionally, consider the available space in your workshop. A larger sled may require more room to maneuver.

Another crucial factor is the capacity of your table saw. Check the specifications of your saw to determine the maximum width and length it can handle. This will help you determine the appropriate size for your sled without overloading your table saw.

2. Should I make my table saw sled larger than the dimensions of my table saw?

It is generally recommended to make your table saw sled slightly larger than the dimensions of your table saw. This allows for better support and stability when working on larger materials. A sled that extends beyond the edges of your table saw also provides a larger surface area for positioning and controlling your workpieces.

However, it is important to strike a balance between size and practicality. If the sled becomes too large, it may become cumbersome to handle and limit your maneuverability. Aim for a sled that gives you a comfortable working area without sacrificing control over your workpieces.

3. Can I adjust the size of a table saw sled after it has been built?

In most cases, the size of a table saw sled can be adjusted after it has been built. If you find that your current sled is too large or too small for your needs, you can modify it accordingly. This may involve resizing the base and the fences to better suit your preferences.

Keep in mind that making adjustments to an existing sled might require some additional work and materials. It is important to plan ahead and consider potential modifications before building your sled to minimize future adjustments.

4. Is there a standard size for a table saw sled?

There is no one-size-fits-all answer to this question, as the size of a table saw sled can vary depending on personal preference and specific needs. However, a common guideline is to make the sled around 2-3 times the width of your table saw’s top. This provides ample space for workpieces and allows for comfortable control during cuts.

Ultimately, the size of your sled should be based on your specific requirements and the projects you typically undertake. Experiment with different sizes to find what works best for you.

5. Are there any safety considerations when determining the size of a table saw sled?

Safety is always a top priority when working with woodworking tools, and the size of your table saw sled is no exception. It is important to ensure that the sled does not obstruct any safety features on your table saw, such as the blade guard or the anti-kickback pawls.

Additionally, consider the stability of the sled. If it becomes too large or too heavy, it may compromise the stability of the workpiece or the sled itself. Choose a size that allows for secure and controlled cuts while maintaining optimal safety.

Summary

So, when it comes to making a table saw sled, there are a few key points to keep in mind. First, you need to determine the right size for your sled based on the size of your table saw. Measure carefully and make sure it fits well. Second, consider the purpose of your sled. Will you be using it for crosscuts, miter cuts, or both? This will help determine the size and shape of your sled. Lastly, always prioritize safety. Use sturdy materials, ensure your sled is properly aligned, and don’t forget to wear safety goggles and follow all safety precautions. With these tips in mind, you’ll be on your way to making an effective and safe table saw sled!