Have you ever wondered how a tapered part can be turned on a lathe? Well, you’re about to find out! Turning a tapered part on a lathe is a fascinating process that involves precision and skill. In this article, we will explore the step-by-step process of how to create a tapered part on a lathe. So, whether you’re a woodworking enthusiast or simply curious about the world of machining, get ready to dive into the world of lathe turning!

Imagine holding a wooden dowel and wanting to transform it into a beautifully tapered shape. How do you go about achieving that? The answer lies in the power and versatility of a lathe. A lathe is a machine used to rotate a workpiece while cutting, shaping, or sanding it with various tools. Turning a tapered part on a lathe involves carefully shaping the workpiece using specialized techniques.

To create a tapered part, the lathe operator adjusts the position of the cutting tool, known as the lathe’s tool rest, and determines the angle and depth of the cut. By gradually moving the tool rest closer to the rotating workpiece, the lathe operator can shape the part to achieve the desired taper. It’s a delicate process that requires precision, as even the slightest deviation can affect the final outcome.

So, if you’re ready to discover the secrets of turning a tapered part on a lathe, let’s dive deeper into the process. Grab your imagination and brace yourself for an exciting journey into the world of lathe turning!

1. Set up the lathe with the appropriate tools and materials.

2. Mark the start and end points of the taper on your workpiece.

3. Position your cutting tool and adjust the lathe’s settings.

4. Slowly feed the tool into the workpiece, removing material gradually.

5. Continuously measure and check the taper’s progress using calipers.

6. Make adjustments as needed until the desired taper is achieved.

7. Finish the part by smoothing any rough edges.

With these steps, turning a tapered part on a lathe is a manageable task.

How Can a Tapered Part be Turned on a Lathe?

Turning a tapered part on a lathe requires precision and careful planning. By following the right techniques and using the correct tools, it is possible to create a perfectly tapered part with smooth surfaces. Whether you are a professional machinist or a hobbyist, understanding how to turn a tapered part on a lathe is a valuable skill. In this article, we will explore the step-by-step process of turning a tapered part on a lathe, the tools and equipment needed, as well as some tips and tricks to achieve the best results.

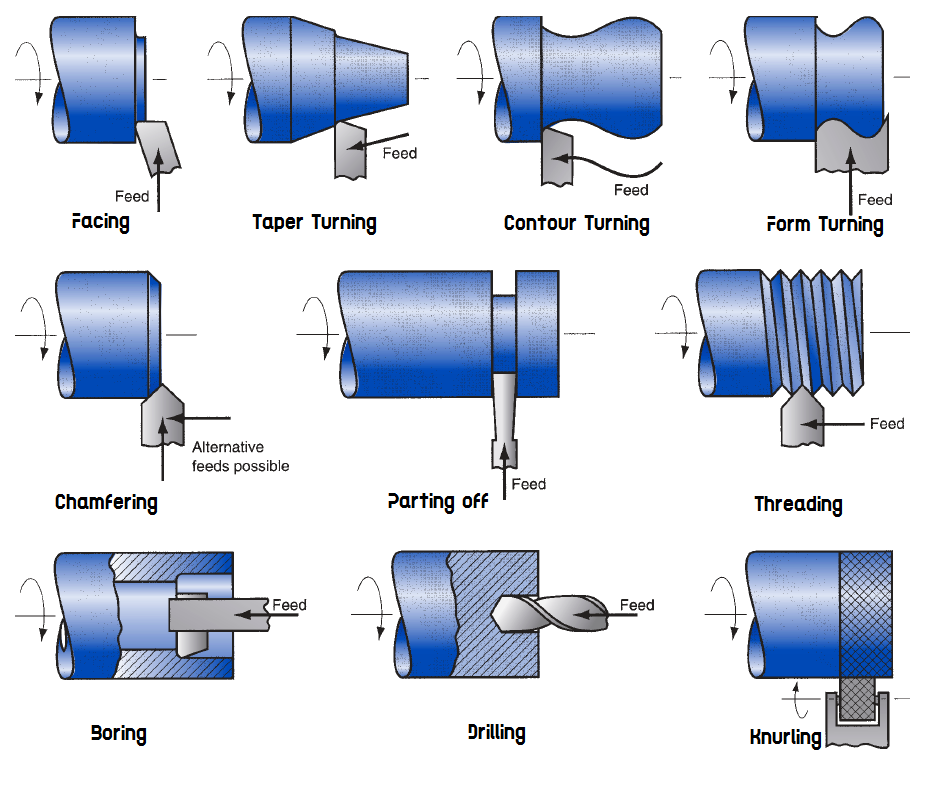

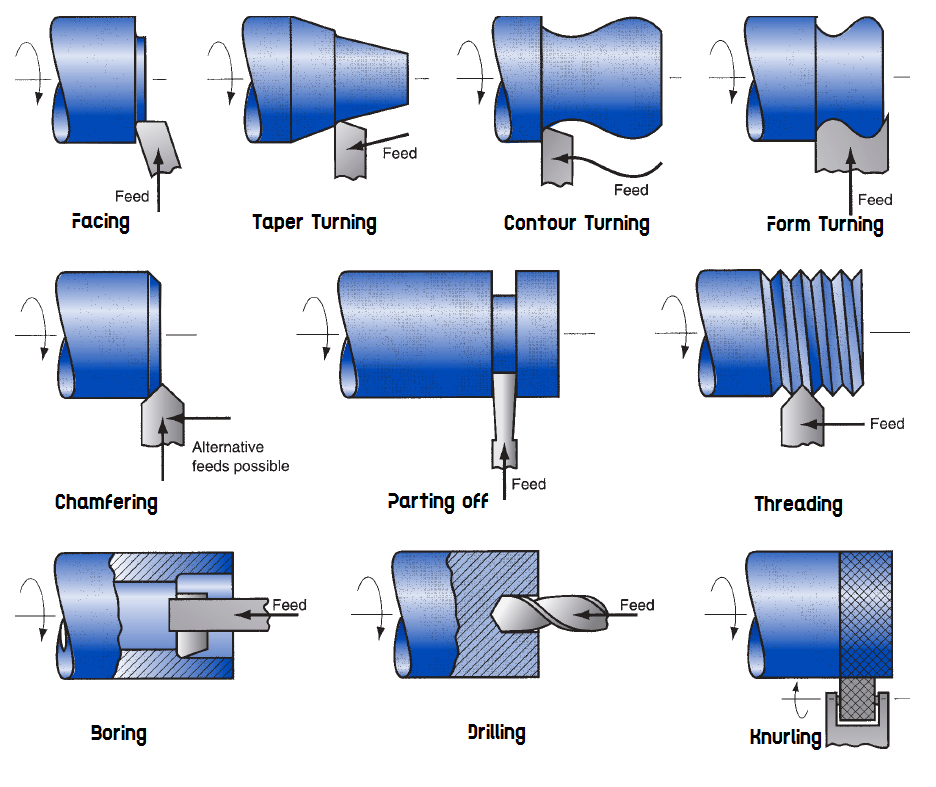

Understanding the Lathe

Before diving into the process of turning a tapered part, it is essential to have a basic understanding of the lathe and its components. A lathe is a machine tool used for various cutting and shaping operations on different materials, such as wood or metal. The primary components of a lathe include the bed, headstock, tailstock, tool rest, and spindle. The bed of the lathe provides a stable base for the machine and houses the components. The headstock contains the motor and the spindle, which holds the workpiece. The tailstock is used to support the other end of the workpiece, providing stability. The tool rest is adjustable and holds the cutting tools in place during turning operations. With this understanding, let’s move on to the step-by-step process of turning a tapered part.

Step 1: Selecting the Material

The first step in turning a tapered part is selecting the appropriate material. Consider the type of material you will be using and choose one that is suitable for the desired application. For example, if you are turning a wooden leg for a table, you may choose a hardwood such as oak or maple. If you are working with metal, select a material that is easily machinable, like aluminum or brass. Ensure that the material is properly sized and free from any defects or imperfections that could affect the turning process.

Next, prepare the material by cutting it to the desired length. It is recommended to leave some excess material at both ends to allow room for adjustments during the turning process. Square the ends of the material using a saw or a bandsaw, ensuring that they are perpendicular to the length of the piece. This will make it easier to mount the material securely in the lathe.

Step 2: Mounting the Material

Once you have prepared the material, the next step is to mount it securely in the lathe. Start by ensuring that the lathe is turned off and unplugged for safety. Place the material between the headstock and tailstock, aligning the centers of both with the ends of the material. Ensure that the material is held securely in place by tightening the tailstock. Use a live center on the headstock side to provide additional support and prevent any wobbling during turning.

After mounting the material, check its alignment and adjust if necessary. Verify that the material is centered and straight by turning the lathe by hand. Make any adjustments to ensure that the material is properly aligned before proceeding to the next step.

Step 3: Shaping the Taper

Now that the material is securely mounted, it is time to shape the taper. Start by turning on the lathe and adjusting the speed to an appropriate level based on the material and desired finish. Generally, a slower speed is preferred for larger workpieces or when using harder materials, while a faster speed may be suitable for smaller workpieces or softer materials.

Use a roughing gouge or a skew chisel to gradually remove material from the wider end of the part. Move the cutting tool from left to right, keeping a steady and even pressure. Take light cuts to avoid any tear-out or splintering. Continue shaping the taper by moving the cutting tool towards the narrower end, gradually reducing the diameter to achieve the desired taper angle. Use calipers or a taper gauge to measure and monitor the taper as you progress.

Once the taper is shaped, carefully sand the surface of the part to remove any tool marks or imperfections. Start with a low-grit sandpaper and work your way up to finer grits for a smooth finish. Use a combination of hand sanding and sanding pads to reach all areas of the taper. After sanding, apply a finish or sealant of your choice to protect the wood or enhance the appearance of the metal.

Key Takeaways: How Can a Tapered Part be Turned on a Lathe?

- 1. A lathe is a machine tool used to shape materials by rotating them against a cutting tool.

- 2. To turn a tapered part on a lathe, you need to set the correct angle on the lathe’s compound rest.

- 3. The tailstock of the lathe is used to support the workpiece while it is being turned.

- 4. To create a taper, the cutting tool is gradually moved along the length of the workpiece.

- 5. It is important to measure the taper using precision instruments to ensure accuracy.

Frequently Asked Questions

Here are some common questions about turning a tapered part on a lathe:

1. How do you create a tapered shape on a lathe?

To create a tapered shape on a lathe, you can use a technique called turning between centers. First, mount the workpiece between two centers on the lathe. Then, using a carbide or high-speed steel cutting tool, gradually remove material from one end of the workpiece while maintaining a consistent rotation. By adjusting the lathe’s tool rest and gradually moving it closer to the workpiece, you can achieve a tapered shape.

Alternatively, you can use a taper attachment, which is a device that can be attached to the lathe. This allows you to feed the cutting tool along a predetermined angle, resulting in a tapered shape.

2. What is the purpose of a taper attachment on a lathe?

A taper attachment is a device that can be added to a lathe to facilitate the turning of tapered parts. It consists of a guide bar that can be adjusted to the desired angle of taper. By attaching the taper attachment to the lathe’s carriage and using it in conjunction with the lathe’s cross-slide, you can accurately and easily create tapered shapes. The taper attachment allows for precise control over the depth of cut and angle of taper, resulting in consistent and accurate tapered parts.

Using a taper attachment can save time and effort compared to manually adjusting the lathe’s tool rest and moving it gradually closer to the workpiece. It also reduces the chances of errors or inconsistencies due to operator variations.

3. How do you calculate the taper for a specific part?

To calculate the taper for a specific part, you need to determine the difference in diameter between the two ends of the tapered shape and the length of the taper. The taper is usually expressed as a ratio of the difference in diameter to the length. For example, a 1:10 taper means that the diameter decreases by 1 unit for every 10 units of length.

You can use a taper calculation formula, such as the trigonometric tangent function, to determine the specific angle of taper. However, using a taper attachment with a pre-set angle eliminates the need for manual calculations and ensures consistent results.

4. Can a lathe cut both internal and external tapers?

Yes, a lathe can cut both internal and external tapers. For external tapers, you would mount the workpiece between centers or in a chuck and use a cutting tool to gradually remove material, creating the desired tapered shape. For internal tapers, you would use a boring bar or a specially designed taper attachment to remove material from the inside of the workpiece, creating the taper.

It’s important to choose the correct cutting tool or attachment and follow proper operating procedures to ensure safe and accurate cutting of both internal and external tapers.

5. Are there any limitations to turning tapered parts on a lathe?

While lathes are versatile machines for shaping various parts, there can be limitations when it comes to turning tapered parts. The size and length of the workpiece may pose restrictions, as larger or longer parts may require more powerful or specialized lathes. Additionally, the taper angle may have limitations depending on the lathe’s capabilities or available taper attachments.

It’s also important to consider the material being used, as some materials may be more prone to vibration or deflection during the turning process. This can affect the accuracy and quality of the tapered shape. Proper tool selection, cutting speeds, and feeds can help mitigate these limitations and achieve satisfactory results.

Tapers on Hobby Lathes – How to make them and why!

Summary

So, to sum it all up, turning a tapered part on a lathe is a process where you use a special tool called a taper attachment. This tool helps you gradually change the diameter of the part as it spins on the lathe. By adjusting the angle and position of the attachment, you can create a smooth and even taper.

It’s important to remember that turning tapered parts requires precision and patience. You need to carefully measure and make calculations to ensure the desired taper is achieved. And with practice, anyone can master this technique and create beautifully tapered parts on a lathe.