Hey there! Looking to learn how to identify a lathe machine? Well, you’ve come to the right place! In this article, we’ll break down the key features and characteristics that will help you spot a lathe machine in no time.

So, what exactly is a lathe machine? It’s a versatile tool used to shape and manipulate materials like wood or metal. From creating intricate designs to crafting functional components, the lathe machine is a handy device that every aspiring DIY enthusiast or hobbyist should know about.

But how can you identify a lathe machine? Don’t worry, we’ve got you covered! In the next few paragraphs, we’ll explore the telltale signs, unique parts, and distinct functions that will help you recognize a lathe machine when you see one. Let’s dive in!

Now that we’ve piqued your interest, let’s get down to the nitty-gritty of identifying a lathe machine. Get ready to learn about the fascinating world of this incredible tool. So, without further ado, let’s jump right in!

Want to identify a lathe machine? Follow these steps:

- Check the construction: Look for a sturdy and rigid framework made of cast iron.

- Examine the bed: Ensure it’s long, flat, and smooth.

- Inspect the headstock and tailstock: They should be aligned and have proper spindle rotation.

- Check the cutting tools: Look for various tools like turning, facing, and threading tools.

- Verify the motor: A robust motor is essential for smooth operation.

How Can You Identify a Lathe Machine?

Lathe machines are essential tools in the world of machining and fabrication. They are used to shape and cut materials, such as metal, wood, and plastic, with precision and accuracy. Identifying a lathe machine can be a useful skill, whether you are a beginner in the field or someone who wants to expand their knowledge. In this article, we will guide you through the process of identifying a lathe machine and provide you with important details to look for. By the end of this article, you will have a clear understanding of how to spot a lathe machine and distinguish it from other similar tools.

The Different Types of Lathe Machines

There are several types of lathe machines, each designed for specific purposes. It is important to understand the different types to accurately identify a lathe machine. Here are three common types:

Bench Lathe

Bench lathes are compact and designed for light-duty tasks. They are typically mounted on a workbench or table and used for small-scale projects. Bench lathes are commonly used by hobbyists and DIY enthusiasts.

These machines are characterized by their small size, often measuring less than 3 feet in length. They are equipped with a motor, a spindle, and a chuck to hold the workpiece. Bench lathes are ideal for simple turning operations, such as creating cylindrical shapes or cutting threads.

If you come across a compact lathe machine that is suitable for small-scale tasks, it is likely a bench lathe.

Engine Lathe

Engine lathes are larger and more powerful than bench lathes. They are commonly found in industrial settings and are used for heavy-duty machining operations. Engine lathes can handle larger workpieces and are capable of a wide range of operations, such as turning, threading, and facing.

These machines are distinguishable by their size and robust construction. They typically feature a bed, saddle, carriage, headstock, tailstock, and a variety of tooling options. Engine lathes are versatile and can be used for both simple and complex machining tasks.

If you encounter a sizable lathe machine with multiple attachments and capabilities, it is likely an engine lathe.

CNC Lathe

CNC (Computer Numerical Control) lathes are advanced machines that are operated via computer programs. They are highly precise and efficient, making them suitable for complex and high-volume production. CNC lathes are commonly used in industries such as automotive, aerospace, and medical.

These machines are distinguishable by their control panel or interface, which allows operators to program and control various aspects of the machining process. CNC lathes can perform intricate operations, such as contouring, threading, and grooving, with extreme accuracy.

If you come across a lathe machine that has a computerized control interface and is capable of complex machining operations, it is likely a CNC lathe.

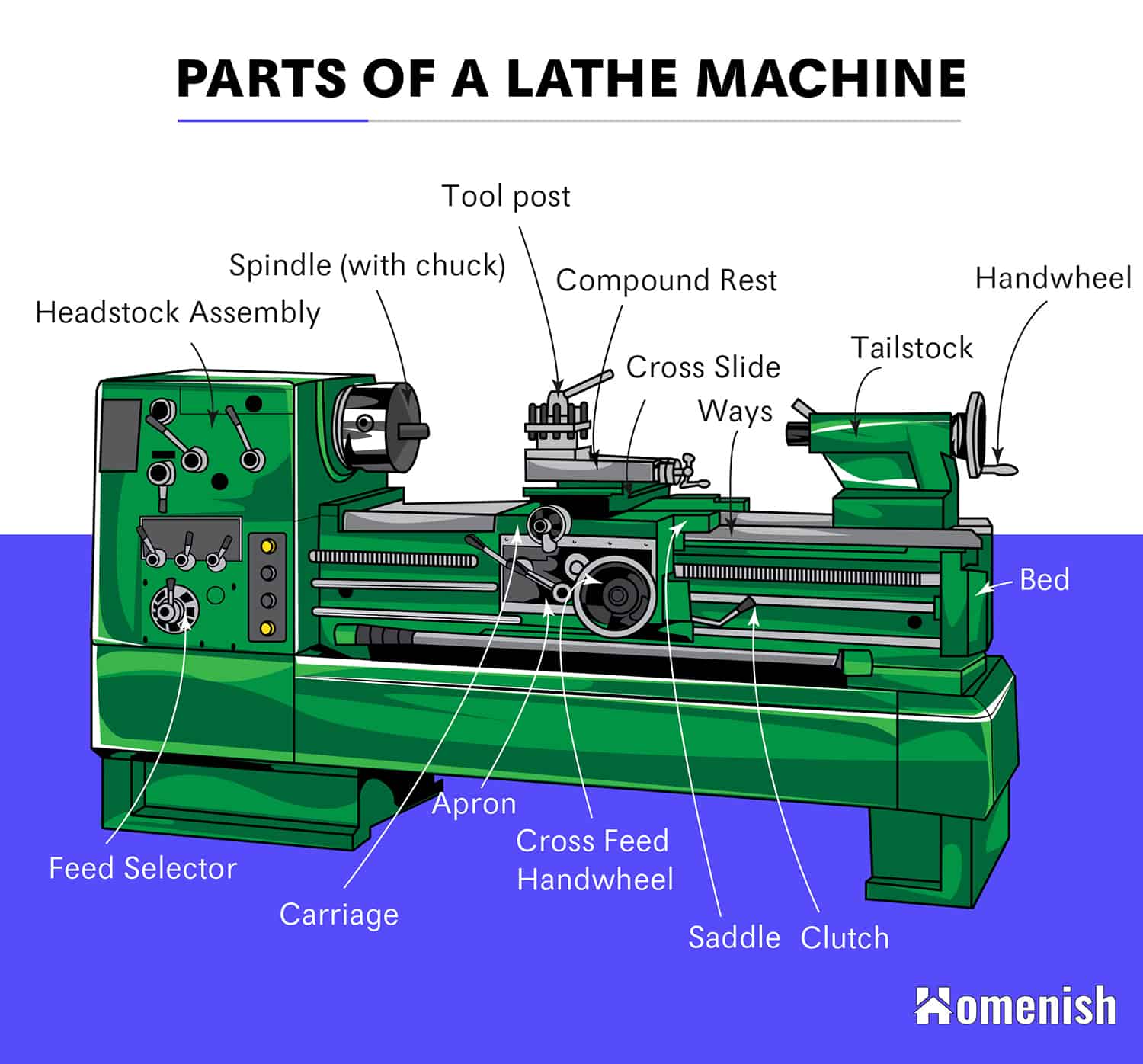

Identifying Features of a Lathe Machine

While the specific design and features may vary depending on the type and model of the lathe machine, there are certain common features that can help you identify a lathe machine:

1. Bed Length and Width

The bed is the horizontal base of the lathe machine where the workpiece is placed. It is usually made of cast iron and provides stability and support. The length and width of the bed can vary depending on the size and capacity of the machine. Measure the dimensions of the bed to get an idea of the machine’s size.

Depending on the type of lathe machine, the bed may have additional features like ways, which are precision-ground surfaces that guide the movement of the carriage.

2. Spindle and Chuck

The spindle is a rotating component of the lathe machine that holds the workpiece. It is connected to the motor and can rotate at different speeds. The chuck is the device attached to the spindle that secures the workpiece in place.

Inspect the spindle and chuck to identify their presence and condition. Look for signs of wear or damage, as these components are crucial for the proper functioning of the lathe machine.

3. Carriage and Cross Slide

The carriage is the part of the lathe machine that moves the cutting tool along the length of the bed. It consists of several components, including the saddle, which provides support to the cutting tool, and the cross slide, which allows for lateral movement.

Observe the carriage and cross slide to ensure they are present and functioning correctly. Check for smooth movement and any signs of damage or misalignment.

4. Tailstock

The tailstock is located on the opposite end of the lathe machine from the headstock. It provides additional support to the workpiece during machining operations. The tailstock typically has a spindle that can be adjusted for different lengths.

Check for the presence and condition of the tailstock. Ensure that it is aligned with the headstock and moves smoothly along the bed.

5. Motor and Control Panel

Most lathe machines are powered by an electric motor. The motor provides the rotational force needed for various machining operations. Some lathe machines, such as CNC lathes, have a control panel or interface that allows for precise programming and operation.

Inspect the motor and control panel to ensure they are present and in working condition. Observe any additional features or controls that may be specific to the type of lathe machine.

6. Tooling Options

Lathe machines can be equipped with various tooling options, such as tool holders, tool posts, and cutting tools. These components are used to shape the workpiece and perform different machining operations. Familiarize yourself with the different tooling options and their positioning on the lathe machine.

Check for the presence and condition of the tooling options. Look for signs of wear or damage and make sure they are securely attached to the lathe machine.

7. Additional Features and Accessories

In addition to the main components mentioned above, lathe machines may have additional features and accessories. These can include coolant systems, chip trays, digital readouts, and specialized attachments for specific machining tasks.

Inspect the lathe machine for any additional features and accessories it may have. These can give you further clues about the type and capabilities of the machine.

Conclusion

Identifying a lathe machine can be a valuable skill for anyone involved in machining or fabrication. By understanding the different types of lathe machines and the key features to look for, you can easily distinguish a lathe machine from other similar tools. Remember to consider the size, components, and additional features of the machine to make an accurate identification. Whether you are a beginner or an experienced professional, knowing how to identify a lathe machine will enhance your understanding and appreciation of this essential tool in the world of manufacturing and fabrication.

Key Takeaways: How Can You Identify a Lathe Machine?

- A lathe machine is a tool used for shaping materials by rotating them on a spindle.

- Look for a long bed that supports the material being worked on.

- Check for a chuck or collet holding the material securely in place.

- Identify the cutting tools, such as a tool post and tool holders, used to shape the material.

- Observe the spindle and motor that provide the rotational power for the lathe machine.

Frequently Asked Questions

Are you curious about how to identify a lathe machine? Look no further! Below, we have answered some of the most common questions to help you differentiate a lathe machine from other equipment.

What are the key features of a lathe machine?

A lathe machine typically consists of a bed, headstock, tailstock, carriage, chuck, tool rest, and spindle. The bed provides a sturdy base for the machine, while the headstock houses the main spindle, which holds the workpiece. The tailstock supports the other end of the workpiece, providing stability during machining. The carriage, on the other hand, holds the cutting tools and can move along the bed to shape the workpiece. The chuck securely holds the workpiece in place, allowing rotation, while the tool rest offers support and positioning for the cutting tools. Lastly, the spindle is responsible for rotating the workpiece at various speeds.

By identifying these key components, you can easily recognize a lathe machine and distinguish it from other types of machinery.

What types of workpieces can be processed on a lathe machine?

A lathe machine is extremely versatile and can work with a wide range of cylindrical or round workpieces. This includes materials such as wood, metal, plastic, and composite materials. Whether you want to turn wooden bowls, create intricate metal parts, or produce precise cylindrical shapes, a lathe machine is the ideal tool for the job. Its ability to rotate the workpiece while the cutting tool shapes it allows for accurate and symmetrical results.

So, if you come across a machine that can handle cylindrical workpieces and perform turning operations, there’s a good chance it’s a lathe machine.

How can you identify a lathe machine based on its cutting operations?

A key characteristic of a lathe machine is its ability to perform turning operations. Turning involves rotating the workpiece while a cutting tool removes material to create a cylindrical shape. This can include operations such as facing, boring, drilling, and threading. If you observe a machine that primarily focuses on these cutting operations and rotates the workpiece, it is likely a lathe machine.

Additionally, lathe machines can also perform other operations like tapering, chamfering, and knurling, providing further capabilities for shaping and refining workpieces.

What are some common applications of lathe machines?

Lathe machines have a wide range of applications across various industries. They are commonly used in woodworking to create furniture parts, decorative items, and utensils. In metalworking, lathe machines are essential for producing components such as shafts, valves, and bearings. They are also utilized in the automotive industry for manufacturing engine parts and other precision components. Additionally, lathe machines are often found in educational institutions for teaching and learning purposes, allowing students to gain hands-on experience in machining.

So, if you encounter a machine being used in any of these industries or applications, there’s a good chance it is a lathe machine.

What are the different sizes and types of lathe machines?

Lathe machines come in various sizes and types to accommodate different workpiece sizes and machining requirements. The size of a lathe machine is defined by its swing capacity, which refers to the maximum diameter of workpiece it can accommodate. Common sizes range from small benchtop lathes with a few inches of swing capacity to large industrial lathes with several feet of swing capacity.

In terms of types, there are engine lathes, turret lathes, CNC lathes, and more. Engine lathes are manually operated, while turret lathes have a turret tooling system for faster and more efficient tool changes. CNC lathes are computer-controlled and offer increased precision and automation. Each type has its own advantages and is suitable for different applications.

Therefore, by considering the size and type of a machine, you can identify whether it is a lathe machine or not.

Summary

So, to quickly recap what we’ve learned about identifying a lathe machine. First, look for a cylindrical bed that holds the workpiece. Next, find the spinning chuck or faceplate that grips the workpiece. Then, locate the tool post where the cutting tools are attached. Remember to check for a tailstock too, which can support long workpieces. Finally, keep an eye out for the power controls and the different speed settings.

Now that you know what to look for, you’ll be able to spot a lathe machine with ease. Just remember to look for the bed, the chuck, the tool post, the tailstock, and the power controls. Happy spotting!