Do you want to know how dangerous a lathe can be? Well, let me tell you, it’s important to handle this powerful machine with caution. Don’t worry, though! I’m here to give you some insights and help you understand the potential risks involved.

Now, you might be wondering, “What exactly is a lathe?” Great question! A lathe is a tool used to shape and turn materials like wood, metal, or plastic. It spins the workpiece while cutting, drilling, or sanding it. Sounds cool, right? But it’s also crucial to know the safety measures associated with operating a lathe.

In this article, we’ll delve into the potential hazards that come with using a lathe and explore some safety precautions you should take. So, buckle up and get ready to learn about the dangers and how to keep yourself safe! Let’s dive in!

When operating a lathe, it’s important to understand its potential dangers. Lathe machines can be hazardous if not used properly. To stay safe, follow these essential guidelines:

- Always wear protective gear, including safety glasses and gloves.

- Ensure the lathe is properly secured and stable before use.

- Keep your hands away from moving parts and use tools with long handles when necessary.

- Avoid loose clothing or jewelry that can get caught in the machine.

- Regularly inspect and maintain the lathe to prevent accidents.

By following these precautions, you can use a lathe safely and minimize the risk of injury.

How Dangerous is a Lathe?

Introduction: Lathes are powerful machines used in woodworking and metalworking to shape and cut materials. While they are incredibly useful tools, it’s important to understand the potential dangers they pose. In this article, we will explore the risks associated with lathes, safety measures to minimize those risks, and tips for using a lathe safely. Whether you are a professional or an enthusiast, this guide will provide you with valuable insights into the potential dangers of operating a lathe.

The Importance of Lathe Safety

Introduction: Before diving into the specifics of lathe dangers, it is crucial to understand the importance of lathe safety. Working with a lathe can expose individuals to various hazards that can cause serious injury or even death. It is vital for operators to be aware of these risks and take appropriate precautions to ensure their safety. In this section, we will discuss why lathe safety should be a top priority for anyone working with this machine.

The Potential Hazards of a Lathe

Paragraph 1: Lathes pose several potential hazards that operators need to be aware of. One of the main dangers is the rotating chuck or workpiece. The high-speed rotation of the chuck can cause materials to break apart or become airborne, leading to serious injuries. In addition, operators need to be cautious of getting their hands or clothing caught in the chuck or other moving parts, which can result in amputation or severe lacerations.

Paragraph 2: Another significant risk is associated with the cutting tools used in lathes. These tools are sharp and can cause deep cuts or punctures if not handled properly. Additionally, the chips and flying debris generated during the cutting process can pose a threat to the operator’s eyes, face, and other exposed body parts.

Paragraph 3: Apart from the mechanical hazards, lathes can also present electrical and fire hazards. Faulty wiring or improper grounding can lead to electrical shock or short-circuits, while the use of flammable materials or incorrect handling of lubricants can result in fires or explosions.

Safety Measures to Minimize Risks

Paragraph 1: To ensure the safe operation of a lathe, it is essential to implement a range of safety measures. Firstly, operators should be well-trained on how to use the machine properly, including understanding the controls, adjusting the speed, and securing the workpiece firmly. This training should also cover emergency procedures and first aid knowledge to handle any accidents that may occur.

Paragraph 2: Personal protective equipment (PPE) plays a critical role in lathe safety. Operators should always wear safety goggles, gloves, and ear protection to minimize the risk of injury. In case of long hair, it should be tied back, and loose clothing or jewelry should be avoided to prevent entanglement.

Paragraph 3: Regular maintenance and inspection of the lathe are essential to ensure it is in good working condition. This includes checking for loose or damaged parts, proper lubrication, and electrical safety. Any issues should be promptly addressed and resolved by trained professionals.

Tips for Using a Lathe Safely

Paragraph 1: In addition to the necessary safety measures, there are some practical tips that can further enhance lathe safety. Always start with a thorough assessment of the workpiece and select the appropriate tools and cutting speeds. This ensures a stable and controlled operation.

Paragraph 2: It is crucial to maintain a clear workspace around the lathe, free of any clutter or unnecessary items. This allows for better visibility and reduces the risk of accidents. The operator should also position themselves in a way that minimizes the exposure of their body to the rotating chuck and cutting tools.

Paragraph 3: Lastly, practicing good housekeeping and cleanliness is important for lathe safety. Regularly cleaning the lathe and removing any debris or excess lubricants not only helps maintain the machine’s performance but also reduces the risk of slips, trips, and falls in the work area.

Additional Safety Considerations

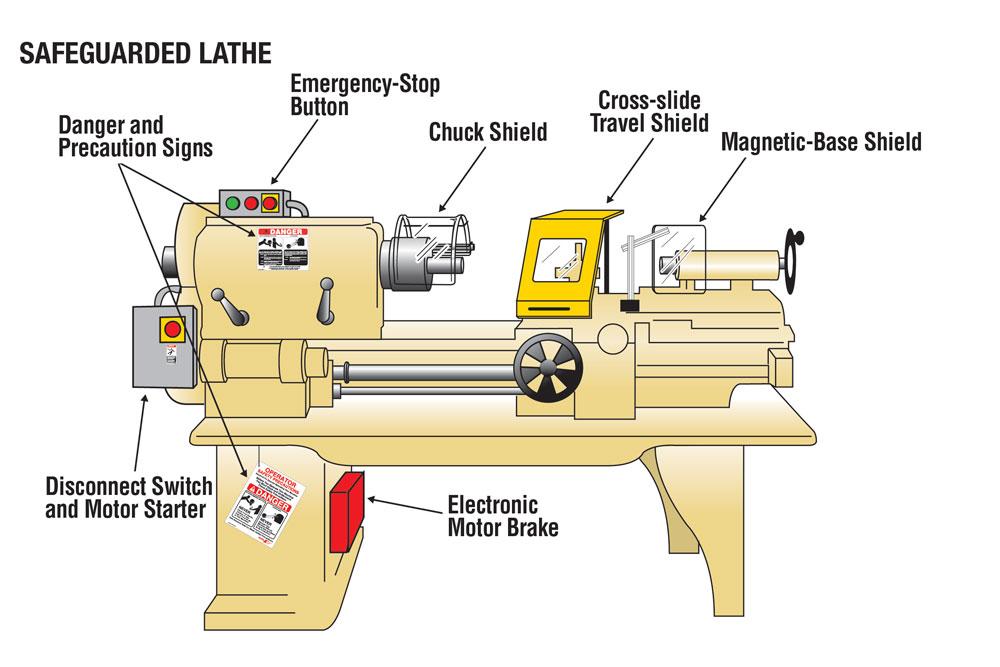

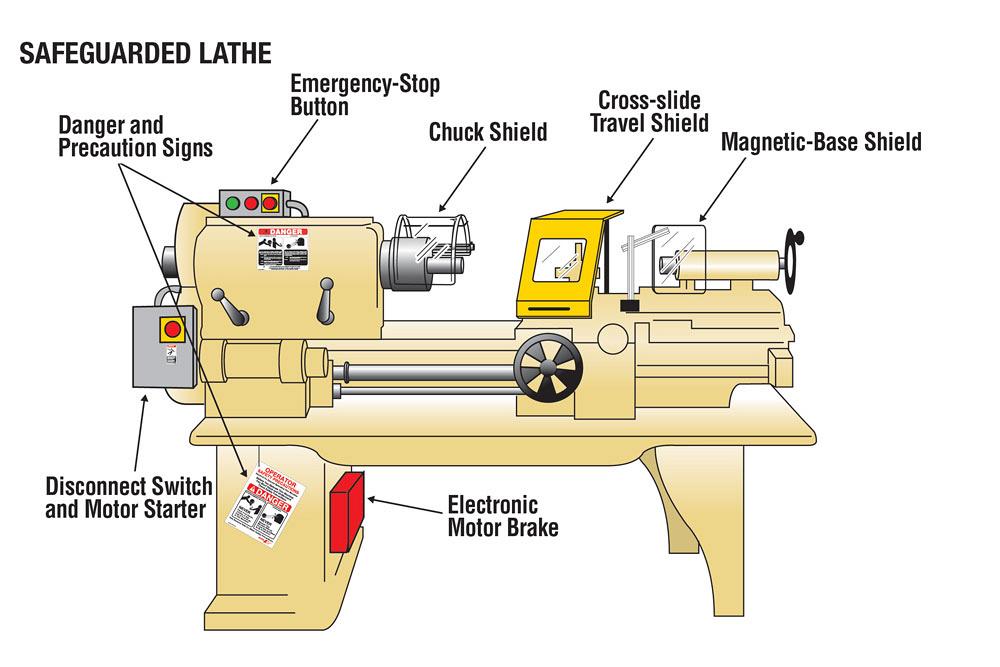

Introduction: While we have covered the main dangers and safety measures associated with lathes, there are some additional factors to consider to ensure a safe working environment. In this section, we will discuss the importance of proper ventilation, proper lighting, and the need for emergency stop devices when working with a lathe.

Safe Lathe Operation for Beginners

Introduction: If you are new to using a lathe, it is essential to learn the basics of safe operation before diving into more complex projects. In this section, we will provide beginners with valuable tips and advice on how to safely operate a lathe, helping them gain confidence and avoid potential accidents.

Safe Lathe Operation for Professionals

Introduction: Even experienced professionals can benefit from refreshing their knowledge of lathe safety. In this section, we will discuss advanced safety practices and techniques that professionals can implement to further enhance their lathe operation, ultimately ensuring a safe and productive work environment.

#Key Points:

In this article, we explored the potential hazards of operating a lathe, the importance of lathe safety, and various safety measures to minimize risks. We discussed the dangers associated with the rotating chuck and cutting tools, as well as electrical and fire hazards. To ensure safety, we emphasized the need for proper training, the use of personal protective equipment, regular maintenance, and good housekeeping. Additionally, we provided practical tips for safe lathe operation and highlighted the importance of proper ventilation, lighting, and emergency stop devices. Whether you are a beginner or a professional, prioritizing lathe safety is essential for a secure and productive working environment.

Key Takeaways: How Dangerous is a Lathe?

- Operating a lathe without proper training can be extremely dangerous.

- There is a risk of entanglement, if clothing or hair gets caught in the rotating parts.

- Inaccurate setups can cause tooling failure and lead to flying debris.

- Using improper cutting tools or techniques can result in kickbacks or tool breakage.

- Failure to use safety measures, such as wearing protective gear, can lead to serious injuries.

Frequently Asked Questions

Welcome to our FAQ section where we answer some commonly asked questions about the potential dangers associated with using a lathe. Whether you’re a beginner or an experienced user, it’s crucial to understand the risks involved to ensure your safety. Read on to learn more.

1. How can I stay safe when using a lathe?

Staying safe while using a lathe is essential to prevent accidents and injuries. Here are a few tips:

First, always wear safety goggles to protect your eyes from debris and flying objects. Next, practice proper body positioning and avoid wearing loose clothing or jewelry that could get caught in the machine. Keep your workspace clean and organized, ensuring all tools and materials are properly stored. Lastly, familiarize yourself with the lathe’s specific safety features and follow all manufacturer guidelines and recommendations.

2. What are the common hazards associated with using a lathe?

Using a lathe involves several potential hazards that users should be aware of. Some common hazards include:

First, there is a risk of getting entangled in the rotating parts of the machine, such as the chuck or the spindle. This can result in serious injuries, including amputations. Additionally, the high-speed rotation of the lathe can cause projectiles, such as wood chips or metal shavings, to be launched towards the operator. These projectiles can cause eye injuries or lacerations. The machine’s moving parts and sharp cutting tools can also pose a risk if not handled properly, leading to cuts, abrasions, or crushing injuries.

3. What safety precautions should I take before operating a lathe?

Prior to operating a lathe, there are several important safety precautions you should take:

First, make sure you receive proper training on how to use the lathe correctly and safely. Familiarize yourself with the machine’s controls, emergency shut-off procedures, and safety features. Always inspect the lathe and its components for any signs of damage or wear before each use. Keep your work area well-lit and free from any obstructions that may cause accidents. Finally, ensure that you have the appropriate personal protective equipment (PPE), such as safety goggles, gloves, and ear protection, as recommended by the lathe manufacturer.

4. Can a lathe catch fire while in use?

While it is possible for a lathe to catch fire, it is quite rare. However, it’s important to take certain precautions to minimize this risk:

First, ensure that the lathe is properly maintained and regularly cleaned to prevent the accumulation of dust, chips, or other flammable materials. Keep a fire extinguisher nearby and make sure you know how to use it. Avoid using the lathe near flammable substances or in an environment with poor ventilation, as this can increase the risk of fire. Additionally, never leave the lathe unattended while it is running, and be cautious when working with materials that may generate sparks or heat.

5. Are there any specific safety guidelines for turning operations?

Yes, there are specific safety guidelines to follow when performing turning operations on a lathe:

First, always secure the workpiece properly using appropriate clamps or chucks. Avoid touching the rotating workpiece or the chuck while the lathe is in operation. Use the tool rest to support the cutting tool and keep your hands clear of the turning area. It’s also important to use the correct cutting tools for the specific type of turning you’re performing, as using the wrong tools can lead to accidents. Lastly, take small, gradual cuts instead of trying to remove a large amount of material at once, as this can put excessive strain on the lathe and increase the risk of accidents.

Lathe incident

Summary

Using a lathe can be dangerous, but following safety guidelines can prevent accidents. Make sure to wear proper protective equipment, like goggles and gloves. Always secure the workpiece firmly and keep your fingers away from the cutting tool. Never wear loose clothing that could get caught in the lathe. Remember to turn off the machine and wait for it to fully stop before making any adjustments. With caution and attention, potential hazards can be avoided while using a lathe.

In conclusion, a lathe can be dangerous, but with the right precautions, accidents can be prevented. By following safety guidelines, wearing protective equipment, securing the workpiece properly, and being cautious around the machine, you can safely use a lathe without putting yourself at risk. So, stay alert, be responsible, and enjoy using this useful tool!