Have you ever wondered how deep a circular saw can cut? Well, get ready to dive into the world of woodworking with us! Whether you’re a DIY enthusiast or just curious about power tools, understanding the cutting capacity of a circular saw is essential. So, let’s get started and find out how deep this mighty tool can go!

When it comes to the depth of a circular saw cut, there are a few factors that come into play. The type of saw blade, the power of the motor, and the material you’re cutting all contribute to how deep the saw can go. So, get your safety goggles on, because we’re about to take a closer look at these factors and unravel the mysteries of circular saw cutting depths!

But wait, before we dive in, it’s important to note that safety should always be your top priority when working with power tools. Make sure to follow proper safety measures and guidelines to avoid accidents. Alright, now that we’ve got that covered, let’s explore the amazing cutting capabilities of a circular saw!

A circular saw can cut through various materials, but the depth of the cut depends on several factors. The blade diameter, blade type, and the saw’s motor power all play a role. Generally, a standard circular saw can cut up to 2 inches deep. However, with the right blade and adjustments, some models can cut deeper. It’s important to always refer to the manufacturer’s guidelines for your specific saw to ensure safe and accurate cuts.

How Deep Can a Circular Saw Cut? Understanding the Limits

As DIY enthusiasts or professionals in construction, it is essential to understand the capabilities of your tools. One common question that arises is, “How deep can a circular saw cut?” Knowing the answer to this question is crucial for various projects and can help prevent accidents or damage. In this article, we will explore the factors that determine the depth of a circular saw cut, safety considerations, and tips to maximize the tool’s capabilities.

About Circular Saws: A Versatile Cutting Tool

Circular saws are widely used in the construction industry for their versatility and efficiency in making straight cuts in various materials such as wood, metal, and plastic. This handheld power tool features a toothed disc or blade that rotates at high speeds, enabling quick and precise cuts. The depth of the cut depends on the diameter of the blade and the adjustability of the saw. Most circular saws allow for adjustable cutting depths, making them suitable for different applications.

When it comes to the depth of a circular saw cut, it is important to consider the maximum cutting depth of your specific model. The typical range for circular saws is between 2 to 4 inches, with some higher-end models cutting up to 6 inches. However, it’s essential to consult the manufacturer’s instructions and specifications to determine the exact cutting depth of your circular saw.

Moreover, the material being cut also plays a role in the depth achievable by a circular saw. Softer materials like wood can be cut deeper than harder materials like metal. It’s crucial to choose the appropriate blade for the material you will be working with to ensure clean and efficient cuts.

The Factors Affecting Depth of Cut

Several factors influence the maximum cutting depth of a circular saw:

- Blade Diameter: The size of the blade is a primary factor in determining the depth of cut. Larger blades typically have greater cutting depths, but they may also require a more powerful motor and a larger saw body. Common blade sizes for circular saws range from 6 to 10 inches, with larger diameters providing deeper cuts.

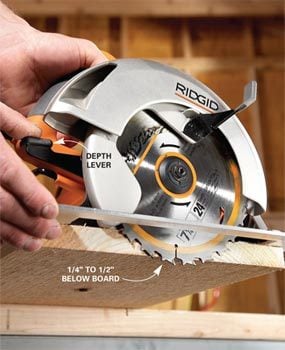

- Adjustability: Most circular saws feature a depth adjustment mechanism that allows users to set the desired cutting depth. This adjustment may be in the form of a lever or knob located near the base plate of the saw. By adjusting this setting, you can control how deep the saw will cut into the material.

- Motor Power: The power of the motor affects the saw’s ability to cut through materials. Higher-powered circular saws can handle greater cutting depths more easily. It’s important to choose a circular saw with an appropriate motor power for the materials you will be working with.

- Material Type: The type of material being cut also determines the achievable depth. Softer materials like wood allow for deeper cuts compared to harder materials like metal or masonry. It’s crucial to choose the appropriate blade and adjust the cutting depth accordingly.

- Accuracy and Precision: While the cutting depth determines how deep the saw can cut, accuracy and precision also play a vital role. Proper alignment, blade sharpness, and a steady hand are essential for achieving clean and accurate cuts at the desired depth.

Safety Considerations and Tips

Working with a circular saw requires caution and adherence to safety guidelines to prevent accidents and injuries. Here are some safety considerations and tips for using a circular saw:

- Wear Safety Gear: Always wear appropriate safety gear, including safety goggles, ear protection, and gloves, to protect yourself from flying debris and loud noise.

- Use a Stable Work Surface: Ensure that your workpiece is firmly secured on a stable surface, such as a workbench or sawhorses, to prevent it from moving while cutting.

- Follow Manufacturer’s Instructions: Read and understand the manufacturer’s instructions and guidelines for operating your specific circular saw model. This will ensure safe and correct usage.

- Inspect and Maintain the Saw: Regularly inspect your circular saw for any damage or loose parts. Keep the blade sharp and clean. If the blade becomes dull or damaged, replace it before using the saw.

- Avoid Overreaching: Maintain a stable stance and avoid overreaching when cutting. This will help you maintain control and reduce the risk of accidents.

- Work in a Well-lit Area: Ensure that your work area is well-lit to clearly see the cutting line and any potential hazards.

- Make Trial Cuts: If you’re working with unfamiliar materials or using a new blade, consider making trial cuts to ensure you have the correct cutting depth and to familiarize yourself with the material’s behavior.

Avoiding Common Circular Saw Mistakes for Accurate Cuts

Now that we understand the factors affecting the depth of a circular saw cut and the safety considerations, let’s explore some common mistakes to avoid for accurate and precise cuts.

Choosing the Wrong Blade

The blade you choose for your circular saw plays a significant role in achieving clean and accurate cuts. Using the wrong blade for the material you are cutting can result in splintering, rough edges, or even damage to the blade.

Each type of material requires a specific blade with the appropriate number of teeth and tooth configuration. For example, a blade with more teeth is suitable for cutting through plywood or other materials that require a finer finish, while a blade with fewer teeth is better for faster cuts in thicker materials.

Before starting a project, ensure you have the right blade for the job. Refer to the blade manufacturer’s guidelines or consult with an expert if you are unsure.

Poor Blade Alignment

Accurate cutting with a circular saw requires proper alignment of the blade. Misalignment can result in crooked or uneven cuts. To ensure the blade is aligned correctly:

- Check that the blade is parallel to the base plate of the saw.

- Adjust the cutting depth to the desired level.

- Before starting the cut, make sure the base plate is resting flat on the material.

- Hold the saw securely with both hands, and guide it along the cutting line smoothly and steadily.

Inadequate Support for the Material

When cutting larger or heavier materials, inadequate support can cause inaccurate cuts or even accidents. Ensure that the material is adequately supported on a stable surface, such as sawhorses or a workbench. Securing the material with clamps or other means can help prevent movement during the cut and increase overall stability.

Additionally, using a guide or a straight edge can help maintain a straight cutting line and enhance the accuracy of your cuts.

Choosing the Right Circular Saw for Your Needs

Now that you understand the depth capabilities, safety considerations, and common mistakes to avoid, it’s essential to choose the right circular saw for your specific needs.

Battery-Powered vs. Corded Circular Saws

Circular saws are available in both battery-powered (cordless) and corded versions. Each type has its advantages and considerations:

- Battery-Powered: These saws offer portability and the freedom to move around without restrictions imposed by power cords. They are suitable for projects where accessing electrical outlets may be challenging or when working in remote locations. However, battery-powered circular saws may have slightly less power compared to corded models, which can affect cutting performance, especially when working with denser materials or making deep cuts.

- Corded: Corded circular saws provide consistent power throughout the cutting process and are generally more powerful than their battery-powered counterparts. They are suitable for heavy-duty tasks, prolonged use, and applications that require deep cuts. However, the limited range determined by the power cord may restrict mobility.

Consider your specific needs, the nature of your projects, and the availability of a power source when deciding between a battery-powered and a corded circular saw.

Blade Replacement and Compatibility

When choosing a circular saw, it’s important to consider the availability and compatibility of replacement blades. Different projects and materials may require specific blade types or sizes. Ensure that the saw you choose can accommodate a wide range of blade options to suit your evolving needs.

Additionally, opt for circular saws with easily replaceable blades. Some models feature tool-free blade changes, allowing for quick and hassle-free blade swaps.

Ergonomics and Safety Features

The ergonomics of a circular saw impact user comfort and control during operation. Look for features such as rubberized grips, lightweight design, and optimized weight distribution to reduce fatigue and enhance maneuverability.

Safety features are also important. Some circular saws come with blade guards that retract automatically during operation but cover the blade when the saw is not in use. This helps reduce the risk of accidents and injuries.

By considering these factors when choosing a circular saw, you can ensure that you select a tool that will meet your needs and provide you with optimal performance and safety.

Maximizing the Depth of a Circular Saw Cut

While the maximum cutting depth of a circular saw is determined by various factors, there are ways to maximize its capabilities for specific projects or materials. Here are some tips:

Choose the Right Blade

Using the appropriate blade for the material you are cutting can significantly impact the cutting depth. Ensure that you have a blade designed for the specific material, whether it’s wood, metal, or plastic. Different blade configurations and tooth counts are available to cater to various cutting needs and achieve optimal results.

Adjust the Cutting Depth Properly

Take advantage of the adjustable cutting depth feature of your circular saw. Assess the material’s thickness and adjust the cutting depth accordingly. By setting the correct depth, you can ensure effective and efficient cuts while reducing the risk of overcuts or undercuts.

Work in Stages

If you need to cut through a material that exceeds the maximum cutting depth of your circular saw, consider working in stages. Make multiple shallow passes, gradually increasing the cutting depth with each pass. This approach allows you to achieve a deeper cut while maintaining control and accuracy.

In Summary

Understanding the depth capabilities of a circular saw is crucial for achieving accurate and efficient cuts. Factors such as blade diameter, adjustability, motor power, and material type all contribute to the maximum cutting depth. By following safety guidelines, avoiding common mistakes, and choosing the right circular saw for your needs, you can unlock the full potential of this versatile tool. Remember to prioritize safety, make proper adjustments, and use the appropriate blade to maximize the depth of a circular saw cut.

Key Takeaways: How Deep Does a Circular Saw Cut?

When using a circular saw, it’s essential to know how deep it can cut. Here are the key takeaways:

- A circular saw is capable of cutting to a depth of around 2 inches.

- Make sure to adjust the cutting depth of the circular saw to match the thickness of the material you’re cutting.

- Always use the appropriate blade size for your circular saw to ensure accurate and safe cuts.

- Be cautious of potential kickback when cutting with a circular saw, as it can be dangerous.

- Consider using a guide or straight edge to help you maintain a straight and accurate cut.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we answer common inquiries about the depth of a circular saw cut. If you’re curious about how deep a circular saw can cut, you’ve come to the right place! Read on for answers to some commonly asked questions.

1. How does the depth of a circular saw cut affect my project?

The depth of a circular saw cut plays a crucial role in determining the outcome of your project. Whether you’re working on wood, metal, or other materials, the depth directly affects the functionality and visual appeal of your work. Using the correct depth ensures structural integrity, prevents material splintering, and allows for precise cuts. It’s important to adjust the depth of your circular saw based on the thickness of the material you’re cutting.

With a shallow cut, you risk not penetrating the entire material, resulting in an incomplete cut. Conversely, if the depth is too deep, you may damage the underlying surface, ruining your project. Finding the right balance is key to achieving clean, accurate cuts that meet your project’s requirements.

2. How can I determine the appropriate depth for my circular saw cut?

When determining the depth for your circular saw cut, start by measuring the material you’re working with. Consider the thickness of the material, taking into account any additional layers or coatings. You’ll want to set your circular saw’s blade depth just below the thickness of the material to ensure a clean cut, avoiding any potential damage to the underlying surface.

It’s also advisable to make a test cut on scrap material before cutting your actual workpiece. This allows you to fine-tune the depth settings and make any necessary adjustments. Remember, it’s always better to start with a shallower depth and gradually increase it if needed. By taking these precautions, you’ll achieve precise cuts with minimal mistakes or material waste.

3. Can a circular saw cut through different materials at the same depth?

The ability of a circular saw to cut through different materials at the same depth depends on the hardness and density of those materials. While a circular saw is versatile and can handle various materials, different blades and techniques may be required to achieve the desired results.

For example, a circular saw equipped with a standard wood-cutting blade will cut through wood easily at a specific depth. However, cutting through metal or masonry will typically require a specialized blade designed for those materials. It’s important to use the appropriate blade and technique to ensure a safe and efficient cut, regardless of the material you’re working with.

4. Are there any safety precautions I should take when adjusting the depth of my circular saw?

Yes, there are several safety precautions you should follow when adjusting the depth of your circular saw. Firstly, always ensure that the saw is unplugged or its battery is disconnected before making any adjustments. This prevents accidental starts and protects you from potential injuries.

Secondly, use the depth adjustment mechanism provided by the circular saw manufacturer. Follow the user manual instructions carefully to avoid any mistakes. Additionally, wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and ear protection, to safeguard yourself against debris and noise while using the saw. Lastly, double-check the depth setting before starting any cutting operation to ensure it’s accurate and appropriate for the material you’re working with.

5. Can I cut deeper than the maximum cutting depth recommended for my circular saw?

We strongly advise against cutting deeper than the maximum cutting depth recommended for your circular saw. Exceeding the manufacturer’s specified cutting depth can lead to significant safety risks, including kickback, motor strain, and increased chance of accidents. It may also void any warranty or guarantees provided by the manufacturer.

Always adhere to the recommended cutting depth and consult the user manual for specific guidelines related to your circular saw model. If you find that your project requires a deeper cut, consider using alternative methods or tools better suited for the task. Prioritizing safety and adhering to manufacturer guidelines will ensure a successful and accident-free cutting experience.

Adjusting circular saw depth.

Summary

So, now you know how deep a circular saw can cut! Circular saws are powerful tools that can cut through different materials like wood, metal, and plastic. The depth of the cut depends on the size of the saw blade and the adjustment of the cutting depth. It’s important to always follow safety guidelines and wear protective gear when using a circular saw. And remember, if you’re not sure about using one, it’s always best to ask an adult for help! Stay safe and happy sawing!

That’s it! Now you understand how circular saws work and how deep they can cut. Always be careful and ask for help if you’re not sure. Happy sawing!