If you’ve ever wondered how deep a circular saw can cut, you’ve come to the right place! Today, we’re diving into the world of circular saws and exploring just how deep they can go. So, let’s buckle up and get ready to uncover the secrets of the circular saw!

When it comes to woodworking or DIY projects, it’s essential to know the capabilities of your tools. And the circular saw is one of the most versatile and powerful tools in a handyman’s arsenal. But how far can it plunge into materials like wood, plywood, or even metal? Stay tuned as we dig deeper into the depths a circular saw can reach!

So, whether you’re a woodworking enthusiast or someone who loves getting their hands dirty with DIY projects, understanding the cutting capacity of a circular saw is fundamental. Get ready to discover the fascinating world of circular saws and how deep they can cut. Are you excited? Let’s roll!

A circular saw can cut through various materials with different depths. The cutting depth of a circular saw depends on its blade size and the power of the tool. Blades are available in different diameters, such as 7 1/4 inches or 10 inches, with cutting depths ranging from around 2 inches to 3 1/2 inches. Be sure to check the specifications of your specific circular saw to determine its maximum cutting depth.

How Deep Will a Circular Saw Cut?

When it comes to woodworking and construction projects, a circular saw is an essential tool that can make clean and precise cuts. However, understanding the depth that a circular saw can cut is crucial for safety and achieving the desired results. In this article, we will delve into the factors that determine the depth of a circular saw cut and provide useful tips to ensure accurate cuts in your projects.

Factors Affecting the Depth of a Circular Saw Cut

1. Blade Diameter

The blade diameter is one of the primary factors that determine how deep a circular saw can cut. Circular saws typically come with different blade sizes, ranging from around 6 inches to 10 inches in diameter. The larger the blade diameter, the deeper the cut it can make. A 7 ¼ inch blade, which is commonly used in many circular saws, can usually cut through materials up to 2 ½ inches thick.

It is important to note that the depth capacity of a circular saw also depends on the type of saw and its adjustability. Some saws allow you to adjust the blade depth for shallower cuts, while others have fixed depth settings.

2. Motor Power

The power of the motor in a circular saw also plays a role in determining the depth of the cut. A saw with a more powerful motor will have the strength to cut through thicker and denser materials. Circular saws come with varying motor powers, usually measured in amps. Higher amp ratings indicate more power and the ability to cut through tougher materials.

When working with dense or hardwood, it is essential to choose a circular saw with a motor power that suits your cutting needs. This will help prevent stalling or damaging the saw’s motor while ensuring clean and accurate cuts.

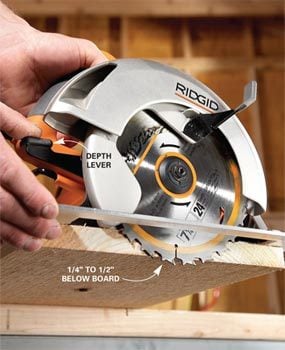

3. Cutting Depth Adjustments

Many modern circular saw models are equipped with cutting depth adjustment features. These allow you to set the desired depth of the cut, giving you greater control and precision in your woodworking or construction projects.

To adjust the cutting depth, most circular saws have a lever or knob that allows you to raise or lower the blade. By setting the desired depth before making a cut, you can ensure that the saw will only cut to the required depth, reducing the risk of overcuts or damaging the workpiece.

4. Material Type

The type of material you are cutting is another crucial factor in determining how deep a circular saw can cut. Softwood, such as pine or cedar, is generally easier to cut through and allows for deeper cuts. On the other hand, hardwood and dense materials like oak or metal may require more power and specialized blades to achieve the desired depth.

It is essential to match the blade type and saw power to the material you are working with to ensure efficient and accurate cuts. Using the wrong type of blade or inadequate power for a specific material can result in jagged cuts, splintering, or even damage to the saw.

5. Blade Quality

Lastly, the quality and sharpness of the circular saw blade can significantly impact the depth of the cut. Dull or low-quality blades may struggle to make deep cuts, leading to uneven or rough edges. Regularly maintaining and replacing your circular saw blades will ensure optimal performance and clean cuts.

Investing in high-quality blades designed for the specific material you are cutting will not only enhance the depth capacity of your circular saw but also improve the overall cutting experience and the longevity of your blades.

Tips for Achieving Accurate Cuts with a Circular Saw

1. Measure and Mark the Cut

Precision begins with accurate measurements and markings. Use a measuring tape or a ruler to mark the dimensions of your desired cut on the workpiece. This will serve as a guide for keeping the saw blade on track and ensuring a straight and even cut.

Consider using a straightedge or a guide when making long cuts to maintain consistent depth and prevent deviation from the intended line.

2. Choose the Right Blade

Selecting the appropriate blade for the type of material you are cutting is crucial for achieving clean and accurate cuts. Different materials may require specialized blades with varying tooth configurations and cutting capabilities.

Refer to the manufacturer’s recommendations for blade selection or consult with professionals at a local hardware store to ensure you choose the right blade for your specific project.

3. Support the Workpiece

Providing proper support for the workpiece is essential for both safety and accuracy. Use clamps or vice grips to secure the workpiece to a stable surface, ensuring it does not move or shift during the cutting process.

For larger pieces or materials prone to splintering, placing a sacrificial piece of scrap wood beneath the workpiece can help reduce tear-out and achieve cleaner cuts.

Common Circular Saw Cutting Depth FAQs

1. Can a circular saw cut through metal?

Circular saws can cut through metal, but it requires the use of specialized blades designed for metal cutting. These blades typically have carbide-tipped teeth or abrasive edges to handle the tougher nature of metal. Using a standard wood-cutting blade on metal can cause damage to the blade and potentially lead to accidents.

2. How deep of a cut can a 7 ¼ inch circular saw make?

A 7 ¼ inch circular saw can typically make cuts up to 2 ½ inches in depth. However, the exact depth may vary based on the specific saw model, blade type, and material being cut.

3. Can I adjust the cutting depth of a circular saw?

Most modern circular saws allow for cutting depth adjustments. This feature enables you to set the desired cutting depth, providing greater control and precision in your cuts. Refer to your saw’s manual for instructions on how to adjust the cutting depth.

4. How often should I replace the blade on my circular saw?

The frequency of blade replacement depends on several factors, including the frequency of use, the type of material being cut, and the overall condition of the blade. Dull or damaged blades should be replaced promptly to ensure clean and accurate cuts. Regular maintenance, such as cleaning and sharpening, can help prolong the life of your blades.

Remember to always follow the manufacturer’s guidelines and safety instructions when using a circular saw or replacing the blade.

In conclusion, understanding the factors that determine the depth of a circular saw cut is crucial for achieving accurate and clean cuts in your woodworking and construction projects. Consider the blade diameter, motor power, cutting depth adjustments, material type, and blade quality to ensure optimal performance. By following the tips provided and adhering to safety guidelines, you can confidently use a circular saw to make precise cuts and bring your projects to life.

Key Takeaways – How Deep Will Circular Saw Cut?

- A circular saw can typically cut up to 2.25 inches in depth when using a 7.25-inch blade.

- The depth of cut can vary depending on blade size and type of material being cut.

- It’s important to follow the manufacturer’s instructions and guidelines for your specific circular saw.

- Always wear appropriate safety gear, such as goggles and gloves, when operating a circular saw.

- If you need to cut deeper than the maximum capacity of your circular saw, you may need to make multiple passes.

Frequently Asked Questions

In this section, we will explore common questions related to the depth of a circular saw cut.

How deep can a circular saw cut?

A circular saw has the potential to cut to a depth of around 2.5 inches. However, this depth can vary based on the size and type of circular saw blade you are using. Additionally, the depth of the cut may also depend on the material being cut. It is important to adjust the cutting depth of your saw based on the requirements of your specific project.

Remember to always refer to the user manual of your circular saw for guidance on adjusting the depth of cut. Using a circular saw beyond its recommended depth may lead to safety hazards or damage to the tool.

Can a circular saw cut through thick materials?

Yes, a circular saw is designed to cut through a wide variety of materials, including thick ones. However, the maximum thickness that a circular saw can cut through will depend on its blade diameter. Generally, a circular saw with a larger blade will be able to cut through thicker materials. For thicker cuts, it is recommended to use a circular saw with a larger blade diameter and a higher horsepower rating.

If you are planning to cut through exceptionally thick materials, it may be necessary to make multiple passes, gradually increasing the depth of the cut. Always ensure that the saw blade is sharp and suitable for the material you are working with.

What safety precautions should I take when using a circular saw?

When using a circular saw, it is crucial to prioritize safety. Here are some essential precautions to follow:

First, always wear appropriate safety gear, including safety glasses, hearing protection, and gloves. Ensure that the work area is well-lit and cleared of any potential hazards. Additionally, firmly secure the material you are cutting and use clamps to prevent it from moving during the cutting process.

Make sure to keep your hands and body clear of the blade’s path by using push sticks or other suitable tools. Lastly, always disconnect the saw from the power source before making any adjustments or changing the blade.

What are some common circular saw blade sizes?

Circular saw blades come in various sizes, each serving different purposes. Common blade diameters range from 7 ¼ inches to 12 inches. The most commonly used size is the 7 ¼ inch blade, which can cut through a wide variety of materials, including wood and plywood.

Larger blades, such as the 10 or 12-inch ones, are typically used for heavy-duty tasks and can handle thicker materials. It is important to select the appropriate blade size based on the requirements of your project to ensure efficient and precise cutting.

Can a circular saw cut different materials?

Absolutely! Circular saws are versatile tools that can cut through a wide range of materials. They are commonly used to cut wood, plywood, particleboard, and other similar materials. However, with the right blade, a circular saw can also cut through plastic, metal, ceramic tiles, and even concrete.

It is crucial to use the appropriate blade type and quality for the specific material you are cutting to achieve the best results. Using the wrong blade may result in ineffective cutting or damage to the material and the saw.

Adjusting circular saw depth.

Summary

Circular saws can cut through different materials, but their cutting depth depends on a few factors. Firstly, the size of the blade matters – the larger the blade, the deeper the cut. Secondly, the saw’s maximum cutting depth is determined by the motor and the design of the saw. Lastly, it’s important to use the correct blade for the material being cut to ensure a clean and efficient cut.

When using a circular saw, it’s vital to prioritize safety by wearing protective gear and following safety guidelines. Remember to always measure and adjust the cutting depth properly before starting the saw. With the right technique and precautions, a circular saw can be a handy tool for various DIY projects.