Have you ever wondered how boring machines work? You’re in luck! In this article, we’ll explore the fascinating world of boring machines and uncover the secrets behind their operation.

So, what exactly is a boring machine? Well, it’s a powerful tool used to dig tunnels, drill holes, and create cylindrical cavities in the Earth’s surface. But how does it do all that? Let’s find out!

Get ready to embark on a thrilling journey into the inner workings of these incredible machines. By the end of this article, you’ll have a clear understanding of how boring machines accomplish their impressive feats. Let’s dive in!

Boring machines are powerful tools used in construction and manufacturing. They work by rotating a cutting tool, such as a drill bit or a boring head, to create holes or tunnels in various materials. The process involves several steps:

- Choose the appropriate cutting tool for the desired hole size and material.

- Secure the workpiece in place using clamps or fixtures.

- Set the cutting speed and feed rate on the machine.

- Start the machine and guide the cutting tool into the workpiece.

- Monitor the drilling progress and adjust the settings as needed.

With these steps, boring machines make it easy to create precise and accurate holes for a wide range of applications.

How Do Boring Machines Work?

When it comes to construction and excavation, boring machines play a crucial role in creating tunnels, pipelines, and other underground structures. These powerful machines are designed to bore through various types of materials, including soil, rock, and concrete. Understanding how boring machines work can give us a deeper appreciation for their capabilities and the importance of their role in construction projects. In this article, we will explore the inner workings of these impressive machines and shed light on their fascinating functionality.

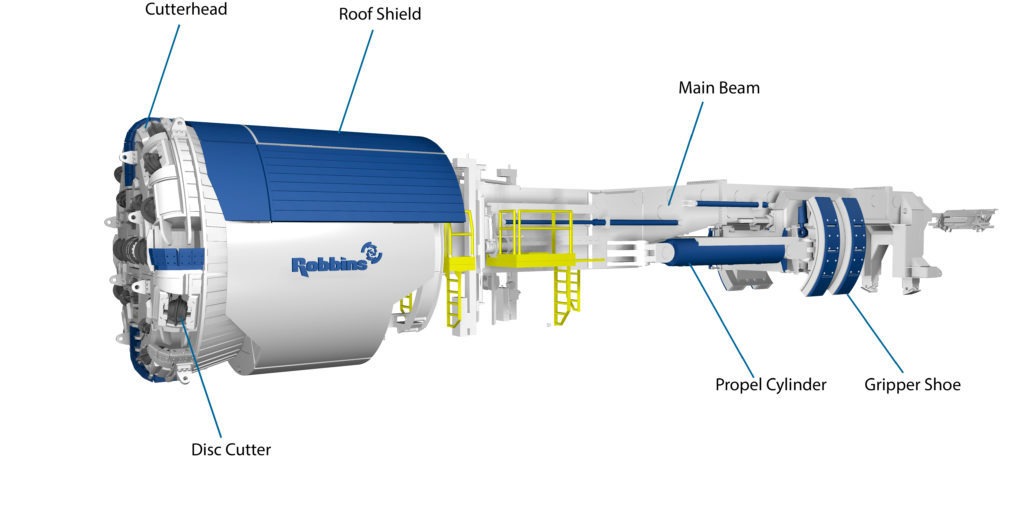

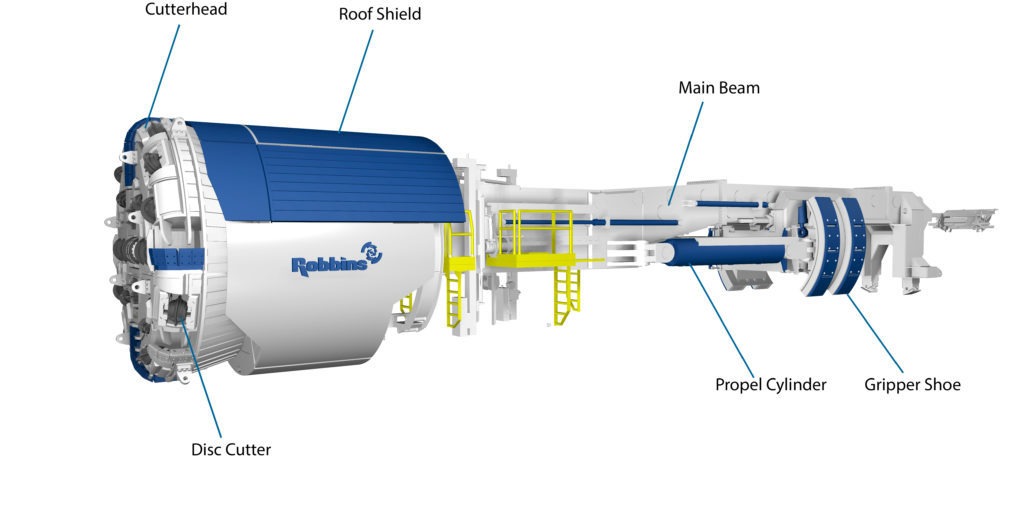

The Anatomy of a Boring Machine

Before delving into the details of how boring machines work, let’s first familiarize ourselves with their key components. Boring machines consist of several essential parts that work together harmoniously to achieve their intended purpose. Here are the main components of a typical boring machine:

The Cutting Head

The cutting head is arguably the most important part of a boring machine. It is responsible for excavating the material during the boring process. Equipped with cutting tools, such as disc cutters or roller cutters, the cutting head rotates and applies pressure to the material, gradually creating a tunnel or hole. The design and configuration of the cutting head may vary depending on the type of material being excavated.

Behind the cutting head, there is a system that provides support and stability to the machine. This includes components such as the thrust system, which applies force to push the machine forward, and the steering system, which enables the machine operator to control the direction of the excavation. The cutting head and the supporting systems work in tandem to ensure smooth and efficient boring operations.

The Boring Process: Step by Step

Now that we have a basic understanding of the components of a boring machine, let’s dive into the step-by-step process of how these machines work:

Step 1: Site Preparation

Prior to starting the boring process, the site needs to be prepared to ensure safe and efficient operations. This involves clearing the area of any obstacles or debris that may hinder the machine’s movement. Additionally, the machine needs to be positioned and aligned correctly to ensure accurate excavation.

Step 2: Entry Point Creation

Once the site is ready, the boring machine is positioned at the desired entry point, typically at the surface level. The cutting head is then activated, and the machine is gradually advanced into the material. As the cutting tools penetrate the material, they create a hole or tunnel, while the thrust system propels the machine forward.

Step 3: Soil Extraction

As the boring machine progresses, a system is in place to remove the excavated soil or debris from the tunnel. Various methods may be employed for soil extraction, such as conveyor belts or auger systems. These systems ensure that the tunnel remains clear and accessible for further excavation.

The boring process continues until the desired depth or length of the tunnel is reached. Once the excavation is complete, the boring machine is retracted from the tunnel, leaving behind a meticulously created passageway.

Benefits of Boring Machines

Boring machines offer several advantages compared to traditional excavation methods. Here are some of the key benefits:

1. Precision and Accuracy

Boring machines can create tunnels and holes with exceptional precision and accuracy. This is especially beneficial when working in densely populated areas or near existing structures, where minimal disruption is essential.

2. Increased Safety

By using boring machines, excavation can be carried out with enhanced safety measures. The machine’s enclosure protects workers from potential hazards, such as cave-ins or collapses, and reduces the risk of accidents.

3. Time Efficiency

Boring machines are designed to work efficiently and quickly, minimizing project timelines. Compared to manual excavation, which requires significant labor and time, boring machines can significantly expedite the process.

4. Versatility

Boring machines can adapt to various types of materials, making them adaptable for a wide range of projects. Whether it’s excavating soft soil or hard rock, these machines can handle the task with ease.

Conclusion

Boring machines are engineering marvels that have revolutionized the field of construction and excavation. By employing cutting-edge technology and ingenious design, these machines have made it possible to create tunnels and underground structures with precision, safety, and efficiency. Understanding their inner workings and benefits allows us to appreciate their importance in shaping the modern world of construction.

Key Takeaways: How Do Boring Machines Work?

- Boring machines are used to create holes or tunnels in hard materials.

- They work by rotating a cutting tool, known as a boring head, into the material.

- The cutting tool removes material, creating the hole or tunnel.

- Boring machines can be controlled manually or with computer programs.

- They are commonly used in construction, mining, and manufacturing industries.

Frequently Asked Questions

Are you curious about how boring machines work? Look no further! We’ve got the answers to your burning questions right here. Dive in to discover the inner workings of these powerful machines and satisfy your curiosity.

How do boring machines create holes?

Boring machines create holes by rotating a cutting tool known as a boring bar. The boring bar moves horizontally through the material, gradually removing material to create the hole. This cutting tool is designed with multiple cutting edges, which helps in achieving smooth and precise holes. The machine is usually equipped with a guide system to ensure accuracy and stability during the boring process.

Additionally, boring machines may use coolant or lubricant to facilitate the cutting process and prevent overheating. By applying a combination of rotation, feed rate, and cutting tool design, boring machines can effectively create holes of various sizes and depths with great accuracy.

What types of materials can boring machines work with?

Boring machines are highly versatile and can work with a wide range of materials. Whether it’s wood, metal, plastic, or composites, boring machines can handle them all. The cutting tools used in boring machines are selected based on the type of material and the desired outcome.

For example, when working with wood, cutting tools with sharp edges are used to achieve clean cuts. On the other hand, when dealing with metal, the cutting tools need to be specially designed to withstand the high temperatures and forces involved in the cutting process. Boring machines are designed to adapt to different materials, making them invaluable in various industries.

How do boring machines ensure precision?

Precision is a critical aspect of boring machines. To ensure accuracy, boring machines are equipped with advanced technology and features. They often incorporate digital control systems that allow operators to program specific dimensions, depths, and tolerances for the holes.

Furthermore, some boring machines are equipped with sensors and feedback mechanisms that continuously monitor the cutting process. This real-time data helps adjust the machine’s parameters, such as feed rate and cutting speed, to maintain the desired level of precision. Tight tolerances can be achieved by carefully calibrating the machine and using high-quality cutting tools.

What safety measures should be taken when using boring machines?

When working with boring machines, safety should always be a top priority. Operators should receive proper training and adhere to safety guidelines to prevent accidents. It is crucial to wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect against flying debris or sharp edges.

Additionally, boring machines should be used in a well-ventilated area, and proper machine guards should be in place to prevent access to moving parts. Regular maintenance and inspection of the machine are also essential to ensure its safe operation. By following these safety measures, operators can prevent injuries and create a secure working environment.

Can boring machines be automated?

Yes, boring machines can be automated to enhance efficiency and productivity. Automation in boring machines involves integrating robotic systems to handle various tasks, such as material handling, tool changing, and even part inspection.

With automated systems, boring machines can operate continuously, reducing downtime and optimizing production. The use of computer numerical control (CNC) technology allows for precise control over the machine’s movements and parameters. This level of automation streamlines the boring process, reduces human error, and increases overall productivity.

Summary

Boring machines are used to dig tunnels underground or create holes in the ground. They have a rotating cutting head that chips away at the soil or rock. The tunnel is supported by concrete segments that are placed behind the cutting head. Boring machines make underground construction safer and faster.

Using a boring machine involves several steps. First, a pilot hole is drilled, and then the machine is launched. The cutting head turns and removes the soil or rock, while the machine moves forward. The tunnel is created by continuously adding concrete segments, and the process is repeated until the tunnel is complete. Boring machines are an incredible technology that helps us build tunnels and underground structures efficiently.