Have you ever wondered how lathe back gears work? Well, get ready to dive into the fascinating world of lathes and discover the inner workings of these incredible machines. Whether you’re a curious hobbyist or an aspiring engineer, understanding how back gears function is crucial to unlocking the full potential of a lathe. So, let’s embark on this exciting journey together and demystify the magic behind lathe back gears!

Imagine you have a lathe, a remarkable tool that allows you to shape and transform raw materials into intricate and precise objects. But have you ever wondered how the lathe can rotate at different speeds? This is where back gears come into play. By tinkering with these gears, you can manipulate the speed and torque of a lathe, giving you more control over the cutting process.

So, how exactly do lathe back gears work? Well, in simple terms, back gears create a lower speed range by increasing the number of gears involved in the gear train. By adding more gears, the rotational force coming from the motor is distributed over a larger area, resulting in a reduction in speed. This reduction in speed enables you to work with larger workpieces or shape harder materials, all while maintaining precision and accuracy.

Now that we have a basic understanding of how lathe back gears work, it’s time to explore the intricate mechanics behind these marvelous machines. From understanding the gear ratios to visualizing the gear train, we’ll embark on an exciting adventure that will unlock the secrets of lathe back gears. So, grab your curiosity and let’s embark on this thrilling journey together!

Lathe back gears are an essential part of a lathe machine, providing different speed ratios for various machining operations. By engaging these gears, you can achieve different rotational speeds for different tasks, such as threading or heavy cutting. The back gears work by connecting the spindle to the motor, allowing power to be transmitted at a reduced speed. This enables the machine to handle heavier workpieces and perform more precise operations. Understanding how back gears work is crucial for optimizing lathe performance.

How Do Lathe Back Gears Work?

Lathe back gears are an essential component of a lathe machine that allows for different speeds and torque settings. In this article, we will explore the inner workings of lathe back gears, their function, and how they contribute to the overall performance of a lathe machine.

Understanding Lathe Back Gears

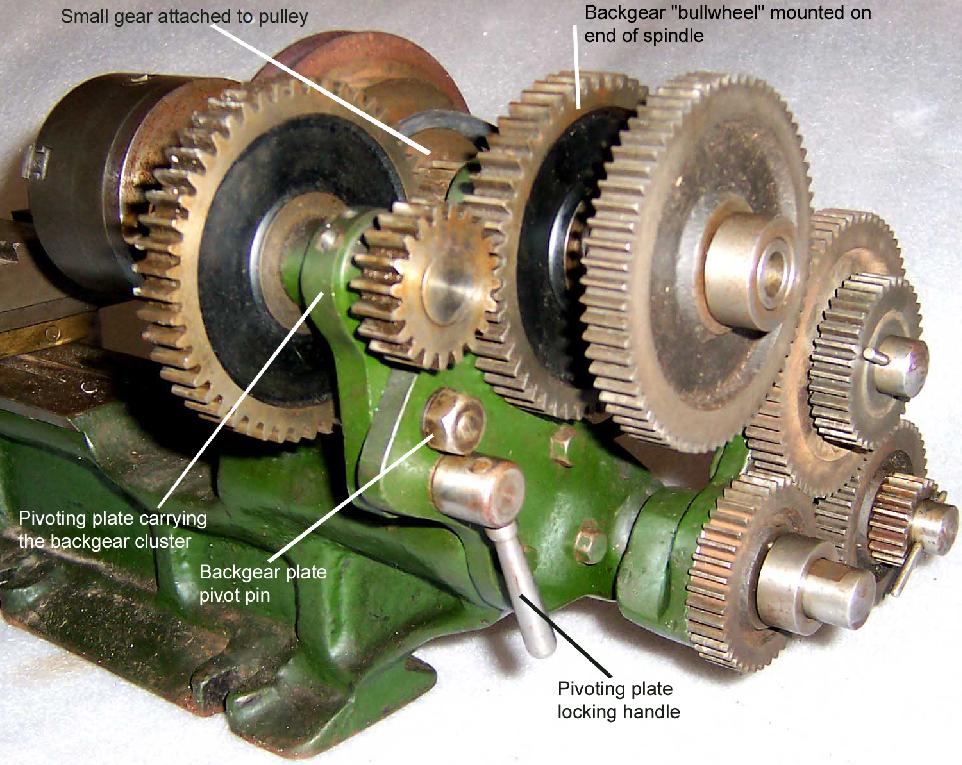

Before diving into the working of lathe back gears, it is important to understand their basic structure and purpose. Lathe back gears consist of two gears, typically connected by an idler gear, that interact with the spindle of a lathe machine. These gears provide additional speed options, allowing the user to work at a slower pace and generate more torque when needed. By engaging different combinations of gears, the lathe operator can customize the speed and power output of the machine.

Gear Engagement Mechanism

The gear engagement mechanism in a lathe machine plays a crucial role in the functioning of back gears. When the lathe operator wants to change the speed or torque, they manipulate the gear levers and handles on the lathe’s gearbox. These levers control the position of the gears in the gear train. By moving the levers and selecting different gear combinations, the operator can engage or disengage the back gears, thus altering the machine’s speed and torque output.

How Back Gears Affect Lathe Speed

When the back gears are not engaged, the lathe machine operates in direct drive mode. This means that the spindle is connected directly to the motor, allowing for high-speed operations. However, when the back gears are engaged, a reduction in speed occurs due to the different gear ratios involved. This reduction in speed allows for more controlled and precise machining, especially when working on larger or tougher materials that require lower speeds to avoid damaging the workpiece or tooling.

By engaging the back gears, the lathe operator can achieve slower rotational speeds that are better suited for threading, knurling, facing, and other operations that require high precision. This flexibility in speed adjustment is one of the key advantages of lathe back gears, as it allows for versatility in machining various materials and achieving different finishes.

In addition to reducing speed, the engagement of back gears also increases the torque output of the lathe machine. This means that the machine can handle more resistance and cut through tougher materials with ease. The enhanced torque provided by the back gears ensures that the lathe can tackle challenging turning tasks while maintaining stability and precision.

The Role of Idler Gear

In the gear train of the lathe back gears, an idler gear is often used to connect the two main gears. The presence of the idler gear helps to eliminate any gear clash or interference that may occur when changing the gear combinations. The idler gear acts as a bridge, ensuring that the gears are smoothly engaged and disengaged without causing any damage or disruption to the overall gear train.

The idler gear is positioned between the two main gears and typically rotates freely on a shaft. As the lathe operator selects the desired gear combination, the idler gear smoothly transfers power from one gear to the other, maintaining a consistent speed and torque throughout the engagement process. This ensures that there are no abrupt changes in the rotational speed that could potentially affect the quality of the workpiece being machined.

Furthermore, the idler gear also helps to distribute the wear and tear evenly across the entire gear train, thereby prolonging the lifespan of the gears and reducing the chances of premature failure or breakdown.

Maintaining and Troubleshooting Lathe Back Gears

As with any mechanical component, proper maintenance of lathe back gears is crucial for long-term performance and reliability. Regular lubrication of the gears and periodic checks for wear or damage should be part of the lathe maintenance routine.

Lubrication

Lathe back gears can operate at high speeds and generate significant friction and heat. Therefore, it is important to use the right lubricating oil or grease to ensure smooth operation and minimize wear. Consult the lathe machine’s manual or manufacturer for specific lubrication requirements and frequencies. Regular inspection and cleaning of the gears are also recommended to remove any debris or contaminants that may affect the gear performance.

Wear and Damage Checks

Over time, the gears in a lathe machine may wear out or sustain damage due to heavy usage or improper handling. It is essential to inspect the gears periodically for signs of wear, such as chipped teeth, excessive noise, or irregular operation. If any damage is detected, the gears should be promptly replaced or repaired by a qualified technician to prevent further complications and ensure safe operation of the lathe machine.

Troubleshooting Common Issues

Occasionally, lathe back gears may encounter issues that affect their performance or cause the machine to malfunction. Some common problems include gear slippage, improper engagement, or difficulties in changing gear combinations. In such cases, troubleshooting steps should be taken to identify the root cause and resolve the issue. Consulting the lathe machine’s manual or seeking professional assistance may be necessary to address complex problems or ensure proper repairs.

Conclusion

Lathe back gears play a vital role in optimizing the speed and torque output of a lathe machine. By engaging different gear combinations, operators can achieve the desired rotational speeds for various machining operations, ensuring precision and versatility. Regular maintenance and careful troubleshooting are necessary to keep the gears in top condition and prevent any potential issues that could disrupt the lathe machine’s performance. Understanding how lathe back gears work allows for improved control and efficiency in metalworking processes.

Key Takeaways: How Do Lathe Back Gears Work?

1. Back gears in a lathe are a set of gears that control the speed of the spindle.

2. These gears are connected to a lever or handle that allows the operator to engage or disengage them.

3. Back gears provide additional power and torque when working with heavy or tough materials.

4. By engaging the back gears, the lathe’s spindle speed is reduced, allowing for slower and more precise cutting.

5. Disengaging the back gears increases the spindle speed, making the lathe more efficient for lighter work.

Frequently Asked Questions

Curious about how lathe back gears work? Look no further! We’ve got the answers you’ve been seeking.

1. What is the purpose of back gears in a lathe?

Back gears in a lathe serve the essential purpose of providing different speed options for the spindle. By engaging the back gears, you can achieve slower speeds, allowing for precision work on larger or more delicate materials. This is particularly useful for threading or turning operations that require a slower rotational speed.

Back gears reverse the gearing ratio, resulting in reduced speed. This allows the lathe to operate at lower speeds than what the motor alone can provide. By using the back gears, you can achieve better control and accuracy for intricate machining tasks.

2. How do back gears work in a lathe?

Back gears consist of multiple gears and an intermediate gear that connects the spindle to the motor. When the back gears are engaged, power from the motor is transmitted to the intermediate gear. This gear, in turn, drives other gears to slow down the rotational speed of the spindle. The precise gear combination will depend on the specific lathe model.

Back gears work by providing a mechanical advantage, allowing the lathe to operate at lower speeds with increased torque. This reduction in speed is achieved by introducing more gears into the power transmission system, altering the gear ratio and resulting in a slower rotational speed.

3. How do you engage the back gears on a lathe?

The process of engaging the back gears on a lathe differs between models, but it typically involves the following steps:

1. Ensure the lathe is powered off and at a complete stop.

2. Locate the back gear lever or handle, usually located on the back of the lathe headstock.

3. Pull or push the lever/handle to engage the back gears, making sure it locks into position.

4. Turn on the lathe and set the desired speed using the appropriate controls.

Always consult your lathe’s user manual for specific instructions and safety guidelines to correctly engage the back gears.

4. Can I use back gears all the time when operating a lathe?

While back gears provide significant benefits, they are not meant to be used at all times. Back gears are primarily designed for low-speed applications that require precision, making them ideal for threading and turning larger or delicate materials. For general machining operations, you can operate the lathe without engaging the back gears.

Using back gears continuously can put unnecessary strain on the gears and other components, potentially causing premature wear and decreased performance. It’s always best to use the back gears when needed and revert to regular operation for most machining tasks.

5. Do all lathes have back gears?

No, not all lathes have back gears. The presence of back gears depends on the specific lathe model and its intended purpose. Smaller lathes designed for hobbyists or lighter-duty work may not include back gears, as they may not be necessary for the types of projects typically undertaken with those machines. Professional-grade lathes, specifically those used in heavy-duty industrial settings, are more likely to feature back gears for their enhanced versatility and ability to handle a broader range of materials and applications.

When considering the purchase of a lathe, it’s important to evaluate your specific requirements and choose a lathe model that meets those needs, whether it includes back gears or not.

What are Back Gears and How to Use them

Summary

Lathe back gears are important for controlling the speed and power of a lathe machine. They work by using different sized gears to change the ratio of the rotation speed, resulting in either faster or slower speeds. By engaging or disengaging these gears, the operator can adjust the cutting speed of the lathe, allowing for more precise and accurate work.

Understanding how lathe back gears work is crucial for anyone working with a lathe machine. These gears help control the machine’s speed and power, making it easier to work with different materials and achieve the desired results. So, whether you’re a hobbyist or a professional, knowing how to use and manipulate the back gears of a lathe is an essential skill to have.